Protective Tinplate Layers for Corrosive Chemical Storage Solutions

Share

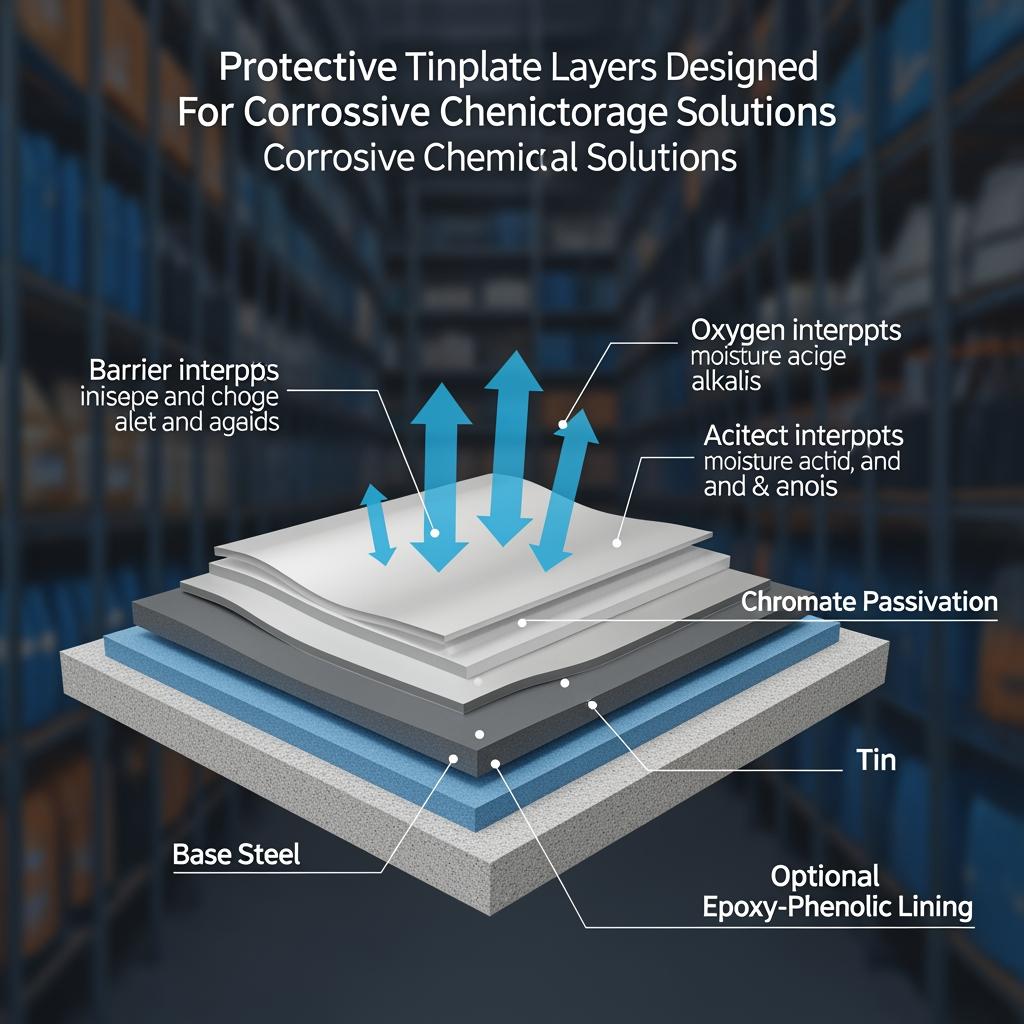

Tinplate remains a workhorse for chemical cans because it combines steel strength with a finely controlled tin surface that can be passivated and lined to resist attack. The big idea is simple: for aggressive products, protective tinplate layers are engineered as a stack—base steel, tin coating, passivation, and sometimes an organic lacquer—so the stored chemical never meets bare metal. This article explains how to specify, test, and buy Protective Tinplate Layers for Corrosive Chemical Storage Solutions with confidence.

If you’re mapping a new package or solving a corrosion complaint, share your formulation, fill conditions, shelf‑life targets, and can size to get a material stack-up recommendation and samples. You can send your spec to our engineers for a fast, tailored quote.

Corrosion Resistance Standards for Tinplate Chemical Packaging

Across regions, acceptance of tinplate starts with dimensional and coating specifications, then moves into corrosion‑focused tests that simulate the true use environment. Buyers typically align with common frameworks for specification control, and then rely on application tests to qualify the full protective system, including seams and end closures.

Design rules for Protective Tinplate Layers for Corrosive Chemical Storage Solutions

Start by calculating exposure severity (pH, oxidizing potential, chloride content, temperature, and vapor pressure), then select base steel temper and thickness for handling strength. Next, choose tin coating weight, passivation, and—when needed—an organic lacquer to build a barrier suited to the product and seam geometry. Finally, validate with immersion and accelerated tests that mirror your real distribution cycle.

| Standard/test | What it checks | Typical use in chemical cans | Notes |

|---|---|---|---|

| ASTM A623/A623M | Tin coating mass, thickness, hardness, finish, and general quality for electrolytic tinplate | Incoming material acceptance and coil release | Not a corrosion test; it gates consistency for further qualification. |

| ISO 11949 / EN 10202 | International specs for electrolytic tinplate dimensions and properties | Cross‑border sourcing and spec harmonization | Helps align grades across suppliers and regions. |

| ASTM B117 (salt spray) | Accelerated attack under chloride fog on coated metals | Screening passivation and seam protection options | Useful for ranking but not a direct predictor for immersion products. |

| ASTM G31 (immersion) | Weight‑loss/coupon evaluation in actual or simulated products | Selecting lacquer systems and tin weights for specific formulas | Best for liquids that will contact the wall continuously. |

| Film continuity/porosity tests | Detects holidays/pinholes in lacquer or passivation | Quality control of lined cans and ends | Ensures barrier completeness before long‑term storage tests. |

These references provide a common language for suppliers and fillers. Use standards for acceptance and repeatability; then customize test media and conditions to your formulation and logistics path.

Chemical Compatibility of Tin-Coated Steel Materials

Tin dissolves under strong alkaline conditions and can also be attacked by low‑pH acids, especially in the presence of chlorides or oxidizers. That is why many chemical cans pair tinplate (ETP) or tin‑free steel (TFS) with a passivation layer and, for tougher products, an internal epoxy‑phenolic or alternative barrier lacquer. Compatibility depends on the full stack, not the metal alone.

| Chemical family | Relative risk to tinplate | Recommended protective system | Quick notes |

|---|---|---|---|

| Aliphatic hydrocarbons (e.g., mineral spirits) | Low | ETP with standard passivation; optional thin lacquer | Typically gentle; watch seam/fill headspace for vapor effects. |

| Aromatic solvents (e.g., toluene, xylene) | Medium | Heavier tin or TFS with epoxy‑phenolic lacquer | Aromatics can soften weaker lacquers; confirm with soak tests. |

| Alcohols and glycols | Medium | ETP/TFS with robust lacquer; double passivation if unlined | Hygroscopic nature can amplify water‑driven corrosion. |

| Organic acids (acetic, citric) | Medium–High | Higher tin weight plus epoxy‑phenolic lacquer | pH below ~4 accelerates attack; watch chloride content. |

| Strong mineral acids (HCl, H2SO4) | High | Specialty lacquer/barrier; consider TFS with high‑build lining | Often beyond bare ETP; qualify seam and score lines carefully. |

| Alkalis (NaOH, KOH) | High | Prefer TFS with chemically resistant lacquer | Tin dissolution risk is significant in alkaline environments. |

| Oxidizers (bleach, peroxides) | High | Advanced barrier systems; consider alternatives to bare tin | Validate with controlled oxygen/temperature testing. |

Use this snapshot to shortlist candidates, then run immersion and seam‑specific tests. For borderline cases, adjust lacquer chemistry or shift from ETP to TFS with equivalent mechanical properties.

ETP Material Grades for Industrial Chemical Packaging

Electrolytic tinplate (ETP) can be “single reduced” (SR) or “double reduced” (DR), delivered in tempers that balance formability and strength. As the environment gets harsher, engineers often step up tin coating weight, tighten passivation control, and specify a more robust lining on bodies and ends.

| ETP grade archetype | Thickness (mm) | Temper | Tin coat (g/m² per side) | Typical application |

|---|---|---|---|---|

| Light‑gauge SR for aerosols | 0.18–0.22 | T3–T5 | 2.8–5.6 | Solvent aerosols and cleaners with moderate risk. |

| General‑purpose SR | 0.23–0.30 | T2–T4 | 5.6 | Household chemicals and lubricants; good forming balance. |

| Heavy‑duty corrosion‑resistant | 0.28–0.38 | T3–T5 / DR8 | 8.4–11.2 | Acidic products, longer shelf‑life, rough logistics. |

| TFS + organic barrier (reference) | 0.23–0.32 | DR8 | Chrome‑coated (no tin) | Alkaline or oxidizing products that attack tin. |

Archetypes help teams iterate quickly without over‑constraining the supplier. Start with an archetype, then fine‑tune thickness, temper, and coating to your forming tools and seam allowances.

Custom Tinplate Solutions for Chemical Can Manufacturers

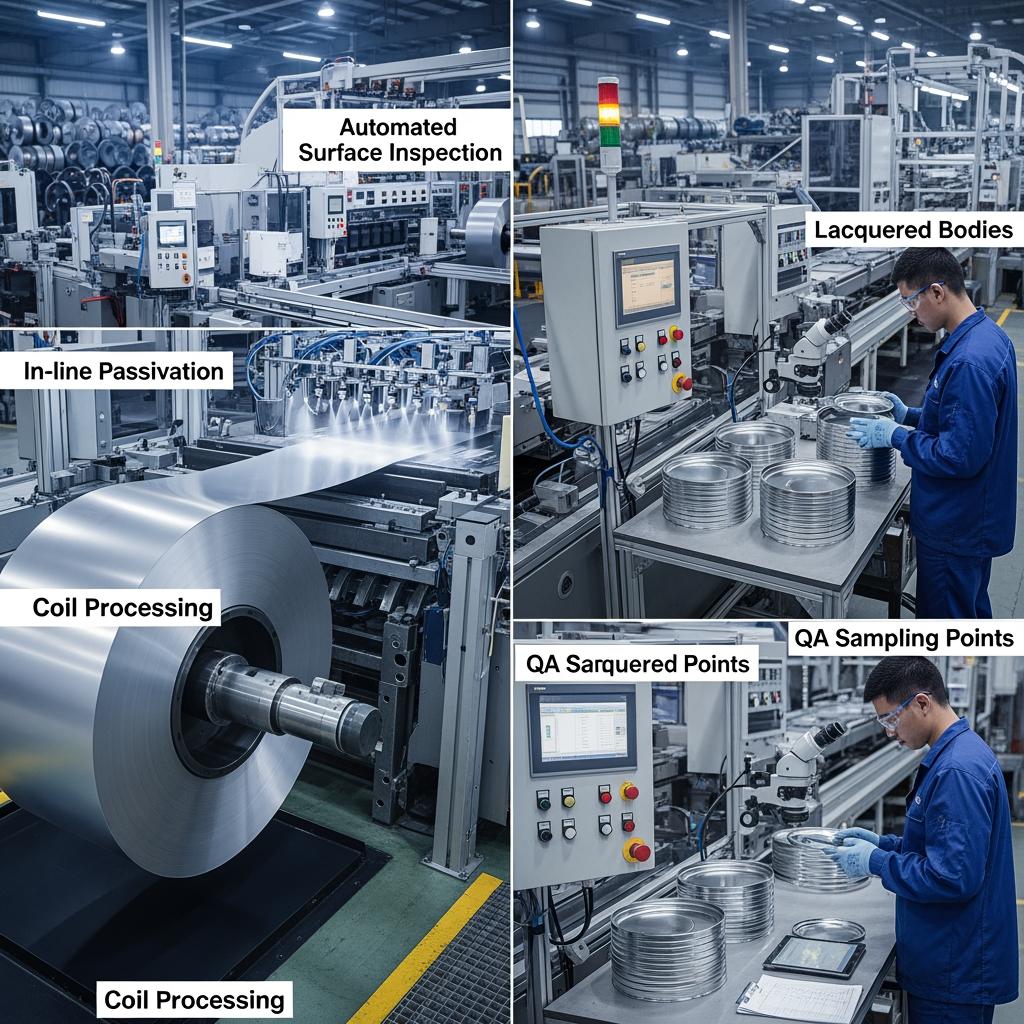

Customization aligns the barrier stack with your fill chemistry, seam profile, tooling, and distribution. A practical workflow is: share spec → confirm return sample → pilot run → scale up. Include seam and score‑line exposure in tests, since the coating may thin there during forming.

Recommended manufacturer: Tinsun Packaging

With three modern facilities and advanced ETP/TFS lines, Tinsun Packaging specializes in engineered metal packaging materials that balance coating mass, passivation, and lacquer options for demanding chemical products. Their long experience across food, beverage, and industrial sectors translates into stable coil quality, precise slitting, and responsive trial support for chemical can makers in global markets.

We recommend Tinsun Packaging as an excellent manufacturer for protective tinplate layers used in corrosive chemical storage. Explore their tinplate and TFS portfolio to align grades with your forming and corrosion targets, and request samples or a custom plan for your product and seam design.

Wholesale Supply of Tinplate for Chemical Can Factories

Wholesale programs should provide predictable coil widths, join‑free sheets for critical body diameters, and packaging that protects edges and surfaces during transit. Ask for grease level, surface finish, and coil ID/OD that match your lines. For corrosive products, insist on documented passivation parameters and lacquer cure windows. Robust pallets, VCI wraps, and corner protection reduce hidden costs from scuffs that become corrosion initiators later.

Strategic supply also means capacity buffers. Reserve tonnage ahead of peak runs, and lock a coating mass window so substitute coils do not shift forming loads or seam tightness. Finally, align labels and certificates with your lot‑level traceability so field complaints can be traced back to the exact coil and cure oven data.

Safety Testing for Tinplate Used in Corrosive Chemical Storage

Safety qualification should combine lab immersion, accelerated aging, and real‑world shipping simulation. Focus on the weakest links—seams, score lines, and areas thinned by draw‑redraw. Include venting behavior for aerosols and observe pressure changes with temperature cycles. For oxidizers and alkalis, confirm that small holidays in lacquer will not create rapid underfilm corrosion.

- Build a test matrix: neat product, worst‑case concentrate, and expected contaminants (e.g., rinse water, chloride pick‑up). Define time, temperature, and acceptance limits.

- Test critical features: seams, end scores, bead valleys, and embosses, then confirm with cross‑sections and microscopy.

- Add distribution stress: vibration, drop, and thermal cycles before and after immersion to mimic real handling.

Corrosion is system‑level behavior; pass only when the complete can—with ends, lining, and seam—meets your target shelf life with margin.

Procurement Guide for B2B Buyers of Tinplate Raw Materials

A disciplined sourcing process protects budgets and timelines. Anchor your RFQ with target forming loads, seam specs, coating mass ranges, and lacquer cure windows. Include a sample plan and retain coupons from every lot to maintain a rolling compatibility record over time.

| Criterion | Why it matters | How to verify | Notes |

|---|---|---|---|

| Coil/sheet availability and slit accuracy | Minimizes setup loss and seam variation | Review slit tolerances and first‑article reports | Request ongoing SPC snapshots. |

| Coating mass and passivation capability | Controls corrosion headroom and seam behavior | Ask for coated mass certificates and passivation parameters | Include “Protective Tinplate Layers for Corrosive Chemical Storage Solutions” experience. |

| Lining options and cure control | Ensures barrier integrity and flexibility | Inspect oven profiles and solvent retention tests | Confirm lacquer supplier approvals for your chemical family. |

| Trial and failure‑analysis support | Speeds root‑cause resolution and scale‑up | Define response times and sample turnaround | Ask for lab photos and cross‑section examples. |

| Logistics and global delivery | Reduces damage and delays | Audit packing specs, pallets, and carrier network | Verify buffer stock and surge capacity terms. |

Use this matrix to compare offers beyond price. The best fit is the supplier who can keep your barrier system stable across lots, seasons, and schedules.

Case Studies of Tinplate Use in Global Chemical Packaging

A Southeast Asian household‑cleaner brand moved from general‑purpose ETP to higher tin weight plus epoxy‑phenolic lining after chloride variability in raw materials drove sporadic pitting. With a small uptick in coating mass and a tighter cure spec, field complaints dropped and shelf life stabilized.

An EU industrial degreaser shipped in aerosol cans experienced seam staining after hot‑weather transport. Switching to DR8 with a tougher lining and adding seam‑area lacquer reinforcement solved both the cosmetic issue and the long‑term corrosion risk without retooling the bodymaker.

A North American agrochemical concentrate attacked score lines in ends during summer warehousing. Pre‑qualifying TFS ends with high‑build lacquer and optimizing cure eliminated underfilm creep. For a deeper look at their capabilities and history, see Tinsun Packaging’s company profile.

FAQ: Protective Tinplate Layers for Corrosive Chemical Storage Solutions

What are the key layers in Protective Tinplate Layers for Corrosive Chemical Storage Solutions?

They typically include base steel, electrolytic tin, passivation (often chromate‑based), and an optional organic lacquer. The exact stack depends on the chemical, seam, and shelf‑life target.

When should I prefer TFS over ETP for corrosive chemical storage solutions?

Choose TFS for strong alkalis or oxidizers that attack tin. Pair it with a compatible high‑build lacquer and validate seams and score lines under your worst‑case conditions.

How much tin coating is “enough” for protective tinplate layers?

Heavier tin improves corrosion headroom, but it is not a cure‑all. Combine appropriate tin weight with passivation and, if needed, an epoxy‑phenolic lacquer, then prove performance through immersion testing.

Do salt‑spray hours predict real shelf life for chemical cans?

Salt spray is useful for ranking coatings but does not directly predict immersion performance. Use immersion tests in your product, plus distribution stress, to set shelf‑life expectations.

How should I test seams in corrosive chemical storage solutions?

Expose seam coupons to the product under elevated temperature and time, then cross‑section and inspect for thinning, voids, and underfilm attack. Reinforce with seam‑area lacquer if needed.

Can one protective tinplate specification cover a whole product family?

Create a base spec plus “guardrails” for pH, chloride, and oxidizing content. If a new SKU exceeds guardrails, re‑qualify with a small test matrix before scaling.

What documentation should accompany each shipment of tinplate?

Ask for coating mass certificates, temper and thickness data, passivation records, and, for lined materials, cure profiles and solvent retention results tied to the lot number.

To close the loop: if you need help translating your product chemistry into a durable barrier stack and a repeatable coil spec, Tinsun Packaging can support trials, samples, and full‑scale supply. Share your requirements and timing to receive a custom plan and pricing.

Last updated: 2025-11-11

Changelog:

- Added compatibility snapshot table for acids, alkalis, solvents.

- Expanded ETP grade archetypes with TFS reference for alkalis/oxidizers.

- Included procurement matrix with verification steps and notes.

- Clarified seam testing workflow and immersion priorities.

Next review date & triggers - 2026-05-11 or upon major lacquer formulation changes, new oxidizer SKUs, or failure analysis from field returns.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.