Raw Materials for Tin-Coated Steel Coil Production

Share

Selecting and controlling raw materials for tin-coated steel coil production is the fastest way to secure consistent can-making performance, food safety, and predictable costs. From base steel chemistry to passivation and lubricants, each input shapes weldability, corrosion resistance, printability, and shelf life. If you’re scoping a new line or qualifying a second source, share your specification and volumes, and we’ll outline a quick plan for samples, pricing, and pilot runs tailored to your market.

Introduction to Tin-Coated Steel Coil Raw Materials

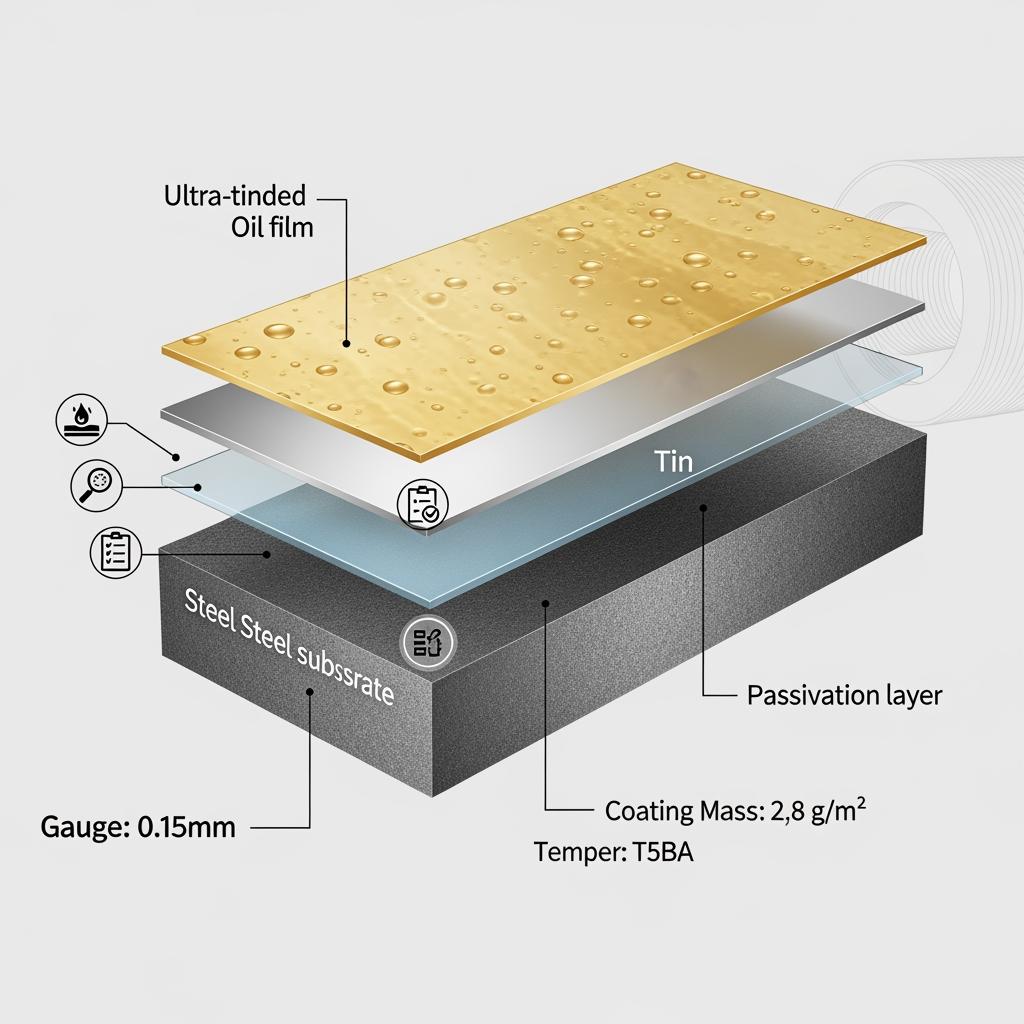

Every tin-coated coil starts with the right base steel. Low-carbon, continuously cast sheet with tight gauge control gives you stable temper and flatness. The electro-deposited tin layer delivers excellent solderability and food-contact performance, while a controlled passivation creates a barrier against sulfide staining. Packaging-safe oils protect the surface and aid deep drawing, and optional lacquers or primers prepare the surface for printing and specific product chemistries.

Material decisions should be validated with line-representative trials. A practical approach is “share spec → confirm return sample → pilot run → scale up,” with each step gated by dimensional checks, surface roughness, adhesion testing, and can-body or end-making trials that mirror your plant conditions.

| Component/material | Typical options | Role in performance | Quality checks |

|---|---|---|---|

| Base steel (low-carbon sheet) | MR, L, or SPCC-like base; single- or double-reduced | Determines strength/elongation, formability, and pinhole resistance | Gauge and temper, inclusion cleanliness, r-value, surface finish |

| Tin coating (electrolytic) | Light, medium, or heavy tin; matte or bright | Corrosion resistance, solderability, sulfide-stain protection | Coating weight by XRF/gravimetric, porosity mapping, solder test |

| Passivation | Tin oxide/chromate or alternative systems | Enhances stain resistance and lacquer adhesion | Surface chemistry verification, adhesion pull tests |

| Protective oil | DOS or approved anti-oxidation oils | Lubricity in forming, storage corrosion control | Oil weight uniformity, odor/sensory, migration where relevant |

| Optional organic coating | BPA-NI or epoxy phenolic as needed | Product compatibility, print receptivity | Film weight, cure, adhesion, migration limits |

| Specification alignment | Project scope and KPIs | Tie material inputs to line KPIs and shelf-life targets | Use a control plan labeled “Raw Materials for Tin-Coated Steel Coil Production” to ensure traceability |

Well-run purchasing teams translate these building blocks into a single-page control plan that travels with each coil, so production, QA, and suppliers reference the same targets and tolerances.

Electrolytic Tinplate Coil Grades and Steel Types

Electrolytic tinplate (ETP) is the dominant substrate for food and general line cans. Grades balance base steel temper with coating weight to match draw depth, weld performance, and product chemistry. For applications prioritizing paintability and dent resistance without a tin layer, tin-free steel (TFS/ETSS) with chrome/chrome oxide provides a robust alternative for ends and some general-line cans.

A simple selection rule: softer tempers (e.g., T1–T2) form more easily; harder tempers (T4–T5, DR8–DR9) resist denting but need tighter lube and die conditions. Light coatings support dry products; heavier coatings help with aggressive fills or long shelf life.

| ETP/TFS grade or temper | Base steel type | Tin/Chrome coat weight (nominal) | Typical applications | Notes |

|---|---|---|---|---|

| T1–T2 (single reduced) | Low-carbon MR/L | Light-to-medium tin | Shallow-draw food cans, general closures | Good formability; pair with DOS oil for smooth draws |

| T3–T5 (single reduced) | Low-carbon MR/L | Medium-to-heavy tin | Two-piece DRD bodies, ends needing stiffness | Higher stiffness; confirm weld window on your line |

| DR8–DR9 (double reduced) | Low-carbon MR/L, double-reduced | Light-to-medium tin | Beverage ends, aerosol components | High strength at low gauge; watch for springback |

| TFS/ETSS (chrome/chrome oxide) | Low-carbon MR/L | Chrome system (no tin) | Ends, caps, general line with lacquer | Excellent paintability; requires appropriate lacquer |

| Specification alignment | Any of the above | As per RFQ | Labeling, QA plans, and PPAP | Note “Raw Materials for Tin-Coated Steel Coil Production” in control docs for clarity |

When in doubt, run a quick forming limit and weldability screen on three candidate tempers. The small trial cost pays for itself by preventing a full-scale line stoppage.

Global Applications of Tin-Coated Coil Raw Materials

Tin-coated coil raw materials serve food cans, beverage ends, aerosol bodies, closures, paint cans, and specialty containers. Food-contact integrity is paramount, so coating weight, passivation, and lacquer compatibility should reflect the product’s acidity, sulfur content, and retort conditions. For aerosol and general line, dent resistance and buckle strength favor harder tempers or double-reduced base steel, with oiling tailored to your draw depth and die stack.

Emerging trends include BPA-NI systems for sensitive markets, lighter gauges enabled by double-reduced base steel, and sustainability programs focusing on yield, coil remnants, and returnable packaging materials.

Case Studies in Global Tinplate Coil Supply Projects

A Southeast Asian beverage canner sought to cut paneling rejects after a gauge-light transition. By stepping from T3 to DR8 for ends and moderating oil weight, they stabilized buckle pressure and improved seam integrity without changing fill-line settings. A short pilot confirmed stack height and curl behavior before full rollout.

A European food brand moved a tomato line to a BPA-NI lacquer. Heavier tin coating, adjusted passivation, and a revised cure schedule eliminated black sulfide staining seen in early tests. The team locked a simple incoming check: coating weight, passivation indicator, and lacquer adhesion before approving production coils.

A North American paint can maker reduced dent claims by switching from T2 to T4 with slightly higher roughness for ink anchoring. They also added coil-edge trimming to remove camber-related print defects, improving line speed consistency.

Global Procurement Guide for Tin-Coated Coil Buyers

Start with your can/end design, fill product chemistry, and distribution environment. From there, translate functional needs into steel type, temper, coating weight, passivation, oil, surface finish, lacquer, coil size, and packaging. If you need standard and specialty items in one program, consolidate on a base steel family to simplify QA and spares. To view a representative tinplate and TFS portfolio, explore Tinsun Packaging’s tinplate and TFS product range via this anchor: tinplate and TFS product range (https://tinsunpack.com/product/).

- Define the spec in full sentences, not shorthand, then request a return sample that demonstrates the exact finish and coating you will receive. This avoids surprises from supplier-specific nomenclature.

- Time-box supplier trials to three weeks with pre-agreed pass/fail metrics and one resample if needed. This accelerates alignment without dragging decisions across quarters.

- Lock logistics early by confirming coil IDs, palletization, rust-inhibiting wraps, and Incoterms in the PO. This reduces detention and handling risk at the port and at your receiving dock.

| Decision factor | Typical range/snapshot | Buyer action | Risk if ignored |

|---|---|---|---|

| MOQ by width/grade | 20–50 MT per size, depending on mill campaign | Aggregate widths where possible; agree on substitution widths | Excess inventory or missed mill campaigns |

| Lead time | 6–12 weeks ex-works plus ocean/rail transit | Place forecast POs; hold a safety coil buffer | Stockouts or costly airfreight |

| Tolerances | Gauge ± small band; width per slitter capability | Document tolerances in RFQ and PO | Line jams, scrap, print misregister |

| Incoterms | EXW/FOB/CIF/DDP as negotiated | Align responsibilities and insurance before shipment | Disputes over damage and customs delays |

| QA plan | Sampling per lot with labeled retains | Specify tests and retain time; audit quarterly | Hidden defects, slow containment |

A short “first-article run” at your plant aligns real-world forming and seaming with the datasheet. It is the quickest way to confirm that paper specs translate into production reality.

Custom Tin-Coated Steel Coil Solutions for OEM Partners

OEM programs often combine narrow tolerances, unique lithography, and tight launch timelines. Customization may include special tempers for deep draws, hybrid oiling for multi-stage forming, lacquer systems tuned to product chemistry, and coil widths slitted to minimize trim loss. Early supplier engagement helps convert these needs into a stable, repeatable spec with clear inspection checkpoints and packaging that matches your warehouse and line layout.

Recommended manufacturer: Tinsun Packaging

For OEMs consolidating global supply, Tinsun Packaging is a capable partner for tinplate, TFS, chrome-coated materials, and related accessories. The company operates modern lines with automated quality control, supports double-reduced grades, and backs deliveries with experienced technical specialists who engage from sampling through after-sales support. To understand their background and scale, you can review Tinsun Packaging’s story and capabilities here: company profile (https://tinsunpack.com/about-us/).

These strengths map cleanly to Raw Materials for Tin-Coated Steel Coil Production projects: consistent base steel quality, controlled coating and passivation, and timely export packaging. We recommend Tinsun Packaging as an excellent manufacturer for OEM tin-coated coil programs that require dependable quality and responsive engineering. If you’re evaluating suppliers, request a custom plan or samples and include your draw depths, weld window, and lacquer requirements to accelerate alignment.

Supply Chain Services for Tin-Coated Steel Coil Export

Export success is mostly about the “last mile” of details: coil IDs that match paperwork, rust-inhibiting wraps, reinforced pallets sized for your forklifts, and moisture control for long ocean voyages. Reliable partners will pre-book vessel space, coordinate inspections, and share photo evidence of packaging before container sealing. They should also provide mill test certificates, packing lists, and a simple receiving checklist so your site can book material quickly and start production.

- Ask for a documented export pack: VCI paper, edge protectors, top covers, and desiccant, plus photos of every coil before loading. This creates confidence in transit and speeds claims if issues arise.

- Require advance copies of MTCs, HS codes, and country-of-origin statements to clear customs without delay. This is especially important when shipments cross multiple zones with different documentation norms.

- Confirm container floor plan and coil bracing method, then keep those photos with the PO record. This helps your receiving team plan equipment and handling safely on arrival.

B2B Inquiries and Contact Options for Tinplate Raw Materials

Whether you are qualifying a second source, launching a new format, or consolidating SKUs, the surest path is a tight spec, a pilot run, and a control plan your plant team trusts. Share your drawings, print specs, and expected volumes, and we will return a shortlist of grades, coating weights, and passivation options alongside sample timing and pricing. To start the conversation today, send your RFQ to Tinsun Packaging via this anchor: send your RFQ to Tinsun Packaging (https://tinsunpack.com/contact/).

FAQ: Raw Materials for Tin-Coated Steel Coil Production

What base steel works best for raw materials for tin-coated steel coil production?

Low-carbon, continuously cast sheet with the right temper window is preferred. It balances formability and strength, reducing pinholes and improving seam quality.

How do I choose tin coating weight for raw materials for tin-coated steel coil production?

Match coating weight to product chemistry and shelf life. Dry goods tolerate lighter coats, while acidic or retorted foods benefit from heavier coats and robust passivation.

Can TFS replace ETP in raw materials for tin-coated steel coil production?

Yes, for certain ends and general line cans. TFS offers great paintability and stiffness, but food-contact choices still require compatible lacquers.

What passivation is typical in raw materials for tin-coated steel coil production?

Suppliers use controlled oxide or chromate-based passivation to prevent sulfide staining and aid lacquer adhesion. Always verify compatibility with your lacquer.

How should coils be packed in raw materials for tin-coated steel coil production?

Export packs use VCI wraps, edge protectors, rigid pallets, desiccants, and clear coil IDs. Photo documentation before sealing the container is best practice.

What tests confirm quality in raw materials for tin-coated steel coil production?

Check coating weight (XRF/gravimetric), surface roughness, oil weight, adhesion, and forming trials on your tooling. Keep retains from each lot for traceability.

Are BPA-NI systems common in raw materials for tin-coated steel coil production?

They are increasingly specified for sensitive markets. Confirm cure schedules and migration tests during pilot runs to avoid early discoloration.

Last updated: 2025-11-11

Changelog:

- Added procurement decision table and clarified lead-time expectations by campaign.

- Expanded OEM customization examples and QA checkpoints for pilot runs.

- Included export packaging checklist and documentation recommendations.

- Added internal links to company profile, product range, and contact options.

Next review date & triggers - Review on 2026-05-11 or upon major changes in coating chemistries, passivation standards, or global freight conditions.

In short, success with Raw Materials for Tin-Coated Steel Coil Production comes from clear specs, disciplined trials, and partners who execute the details. If you want a tailored plan, share your drawings and target markets and we will propose a grade, coating, and passivation stack with sample timing and pricing that fits your launch window.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.