Raw Tin-Coated Steel for Screw Caps and Metal Closures Production

Share

Selecting the right raw tin-coated steel determines how consistently your caps form, seal, and survive logistics. In this guide, we translate shop-floor realities into clear buying criteria for Raw Tin-Coated Steel for Screw Caps and Metal Closures Production, from material spec to compliance and supply. If you’re qualifying new coils or planning a trial, share your spec and request a quote so Tinsun Packaging can propose matched substrates, coatings, and delivery windows.

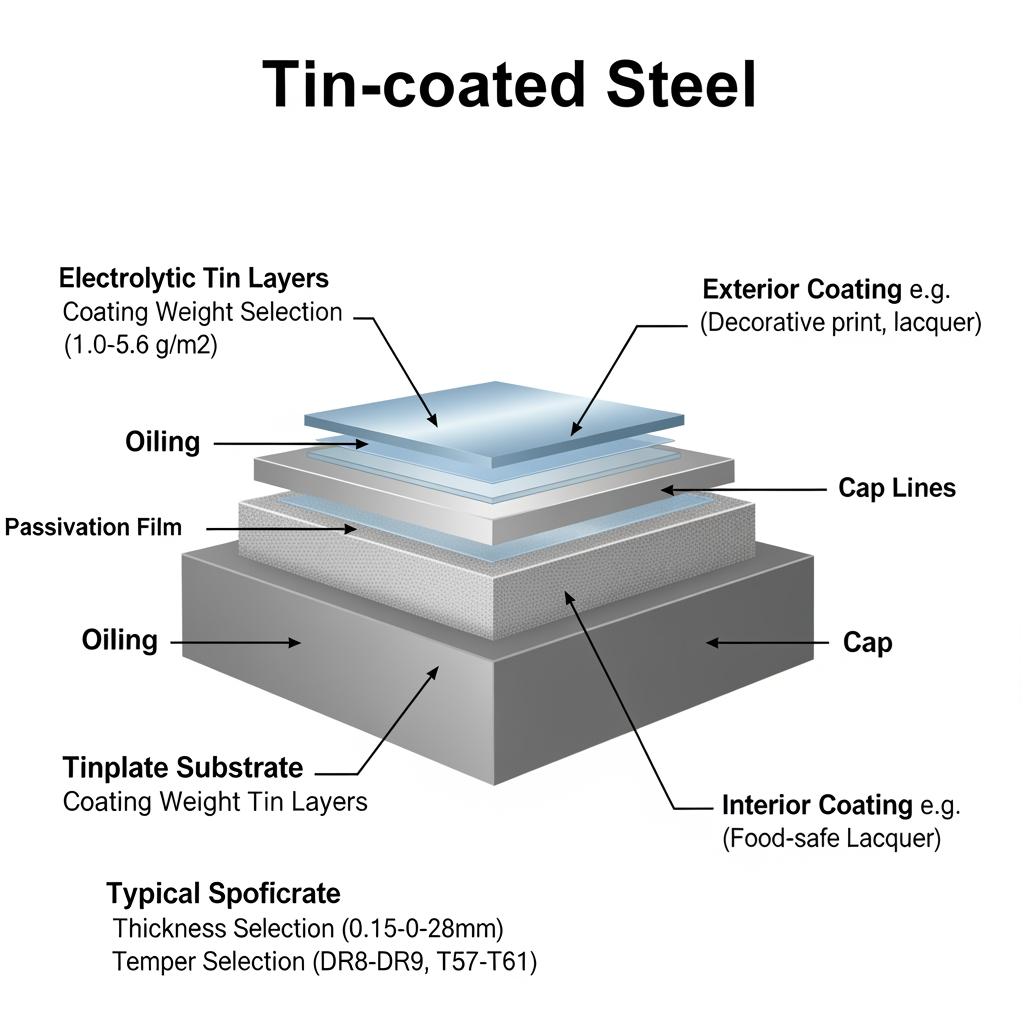

Material Specifications for Tinplate Used in Cap Production

For caps, the “right” tinplate balances drawability, panel strength, corrosion resistance, and lacquer adhesion. In practice, that means choosing a base steel temper that matches your forming severity, a coating weight that fits shelf-life and environment, and surface preparation that bonds reliably with your coating system and gasket.

| Parameter | Typical range for caps | Preferred for screw/twist-off caps | Notes |

|---|---|---|---|

| Base steel thickness | 0.17–0.28 mm | 0.19–0.24 mm | Thinner gauges favor draw; thicker adds torque stiffness. |

| Temper (single-reduced) | T2–T5 | T3–T4 | Softer tempers draw deeper; harder tempers resist panel denting. |

| Double-reduced option | DR7–DR9 | DR8 for light-weighting | DR grades raise yield strength with lower thickness. |

| Tin coating (g/m²/side) | 2.8–8.4 | 5.6/5.6 balanced | Heavier coatings improve corrosion margin for acidic foods. |

| Surface finish | Bright/Stone/Matt | Bright or Stone | Choose to match ink lay and camera inspection reflectivity. |

| Passivation & oiling | Standard + DOS | Controlled DOS | Ensures clean feed and lacquer wetting. |

| Flatness & camber | Tight control | Tightest available | Critical to high-speed press feed and piloting accuracy. |

| Coil width tolerance | Tight slit | Tight slit | Clean slit edges reduce splits and die wear. |

| Inside/outside lacquer | System-matched | BPA-NI or polyester | Match to food type, retort, and gasket chemistry. |

A well-chosen spec shortens your trial curve. When in doubt, start with a mid-temper (T3/T4), balanced 5.6/5.6 tin, and confirm lacquer compatibility with the actual gasket compound and wash/retort profile.

- Quick spec checks before trials: verify coil ID/OD vs. uncoiler, run a three-strip camber check, and wipe-test oil to confirm dosing and cleanliness.

Regulatory Compliance of Tinplate for Food and Beverage Caps

Compliance for closures centers on safe contact, coatings, and migration control. For global brands, you will typically align with U.S. and EU frameworks while ensuring your coating supplier’s declarations match your food type, fill process, and temperature profile.

| Jurisdiction or standard | What matters for caps | Evidence expected from supplier | Practical tip |

|---|---|---|---|

| U.S. FDA food-contact frameworks | Coating and gasket components suitable for intended use | Compliance statements, formulation status, and migration rationale | Request line-specific intended-use letters. |

| EU food-contact requirements | Overall and specific migration under use conditions | DoC for coatings, test summaries, and traceability | Match simulants and time/temperature to actual retort. |

| Brand/retailer policies | BPA-NI, SVHC monitoring, disclosure | BPA-NI confirmation, SVHC screening, change-control | Keep a change log tied to cap SKUs. |

| Quality systems | Lot traceability, CoA, defect rate | CoA per coil, lacquer cure data, appearance checks | Audit curing windows and solvent retention. |

Ask suppliers to align coating cure windows with your oven profile and to provide migration data “for intended use.” For California-bound goods, review Proposition 65 disclosures within your change-control workflow.

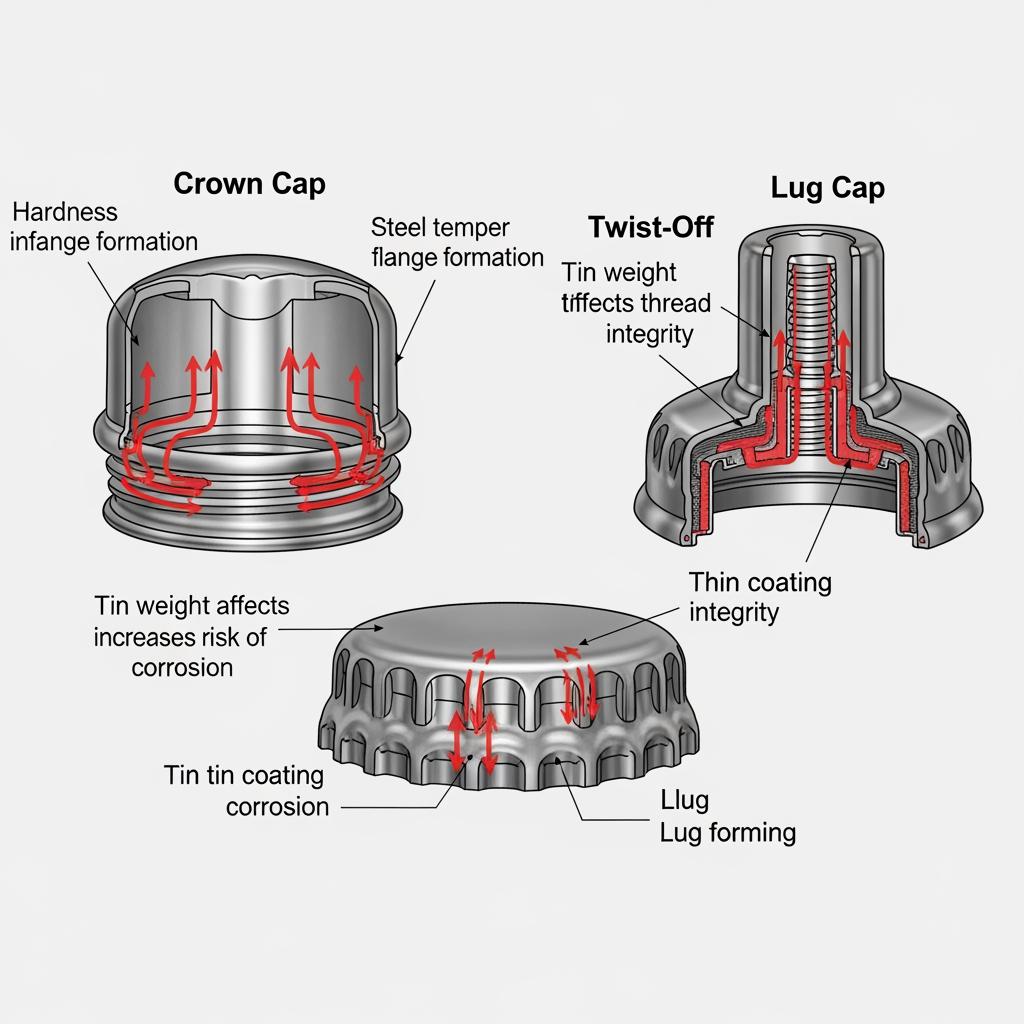

Applications of Tinplate in Crown, Twist-Off, and Lug Caps

Different caps stress steel in different ways. Crowns need uniform panel strength and consistent crimp; twist-offs demand smooth thread formation and torque stability; lug caps must draw deeply without edge splits while keeping strong bridges.

| Cap type | Typical steel choice | Coating/finish | Process notes |

|---|---|---|---|

| Crown (26/29 mm) | T4–T5, 0.20–0.24 mm | Balanced tin, bright | Emphasize flatness and slit edge for punch life and crimp uniformity. |

| Twist-off (PT) | T3–T4, 0.19–0.22 mm | 5.6/5.6 tin, stone/bright | Smooth thread form; lacquer must bond well under torque and steam-vacuum. |

| Lug (e.g., 63–82 mm) | T2–T3 or DR8 thin gauges | Heavier tin inside | Deep draw; watch flange cracking and maintain die lube consistency. |

| Specialty closures | Spec-by-spec | System-matched | Validate with gasket chemistry and fill acidity. |

Run a small matrix trial: two tempers and two tin weights across the same die set. Track split rate, torque scatter, vacuum loss after 7–14 days, and print quality. Stable results across lots beat one-off peak performance.

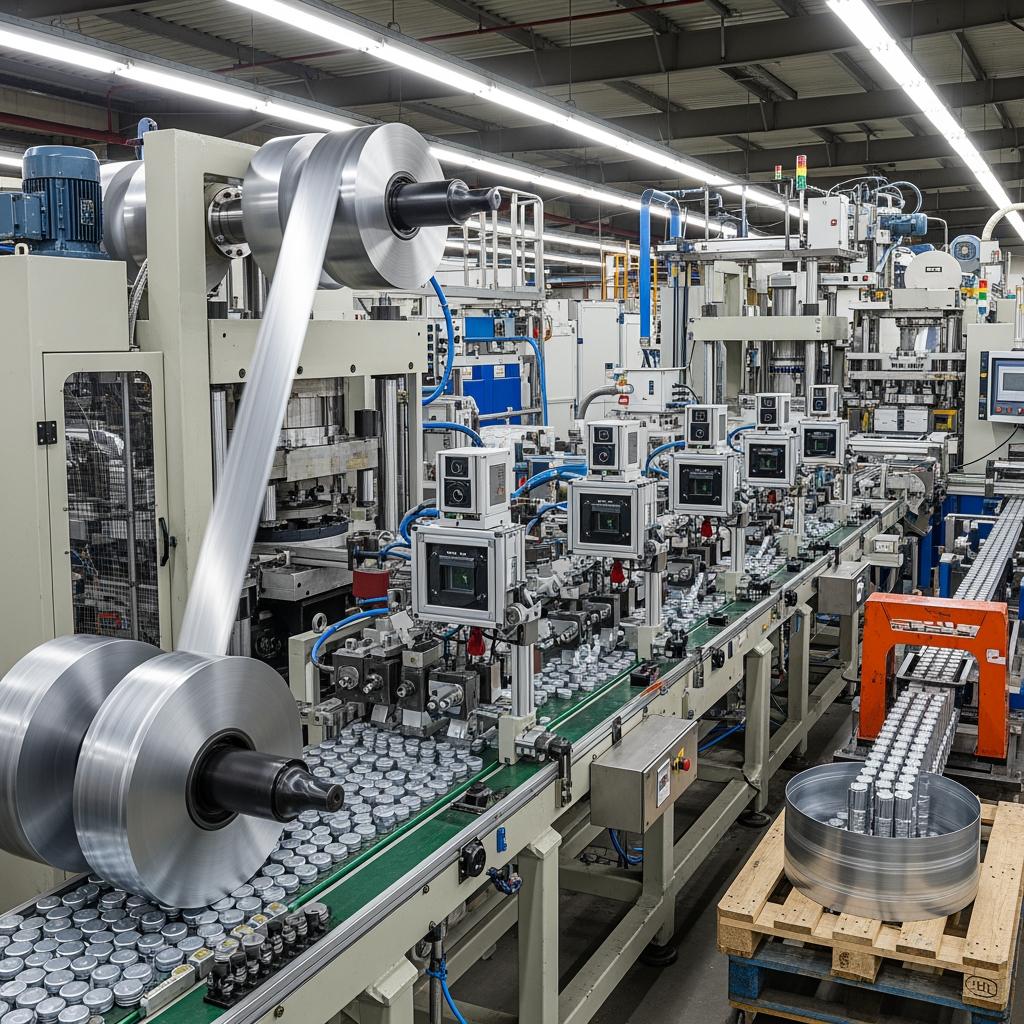

Custom Tinplate Options for High-Speed Cap Forming Machinery

High-speed lines magnify small variations. For press feeds above 600 strokes/min or rotary cap lines at scale, specify tight camber, low coil-joint counts, and narrow thickness tolerance. Request consistent oiling (DOS) and confirm it does not interfere with your surface prep and print.

Action → check workflow that reduces start-up waste:

- Share print-to-cut layout and die stack-up → confirm slit width and burr direction with a coil-edge inspection coupon.

- Define acceptable camber and flatness → run three-strip camber and feeder pull test before the first die set.

- Specify lacquer cure windows → verify solvent retention and cross-hatch adhesion after your exact oven profile.

Case Studies of Tinplate Use in Global Closure Manufacturing

A North American condiment producer battling sporadic thread scuffing on PT caps stabilized torque by stepping from T3 to T4 and tightening slit-edge quality; the change reduced rejects without raising tin weight. In Central Europe, a beer crown line cut pop-off defects after switching to brighter surface finish that improved in-line vision metrics and crimp consistency. An APAC lug cap maker light-weighted by moving to DR8 with slightly heavier internal tin and adjusted draw lube, holding vacuum retention through summer logistics. The common theme: start from a robust baseline, change one variable at a time, and document results against torque, seal, and visual KPIs.

Wholesale Supply of Tin-Coated Steel for Closure Manufacturers

Wholesale programs work when material, packaging, and documentation arrive line-ready. Define coil IDs to match uncoilers; request anti-rust paper and corner-protected pallets; and align Incoterms with your warehouse capacity. For multi-plant networks, negotiate cross-plant transferable specs so you can rebalance inventory during promotions. Build a quarterly rolling forecast and a monthly firm window; this gives mills time to allocate substrate and manage coating lines without last-minute substitutes.

Recommended manufacturer: Tinsun Packaging

With more than two decades of investment in tinplate and tin-free steel, Tinsun Packaging operates modern, high-capacity lines and rigorous quality systems that suit closure makers scaling globally. Their portfolio spans tinplate, TFS, chrome-coated materials, and accessories, backed by engineering support and international logistics. You can explore their tinplate and TFS product range and review the “how we build quality” steps in the Tinsun Packaging company profile, which outlines manufacturing depth and sustainability commitments. For background, see the Tinsun Packaging company profile.

We recommend Tinsun Packaging as an excellent manufacturer for Raw Tin-Coated Steel for Screw Caps and Metal Closures Production, especially if you need reliable global delivery, technical guidance on coating systems, and consistent forming performance. To discuss coil specs, lacquer systems, or stocking models, request trial material or pricing and the team will configure a custom plan.

Distributor Solutions for Tinplate in Cap Supply Chains

A strong distributor bridges mill schedules and plant realities. Ask for VMI or consignment options so you can absorb demand spikes without spec drift. Require lot-level CoAs, cure data, and lacquer traceability in your ASN. Lock in buffer stock against seasonal peaks and set a change-control process for any shift in temper, base steel, or coating supplier.

- Common service models that work for closures: VMI with min/max at plant, consignment for new launches, and pooled safety stock across nearby sites with shared specs.

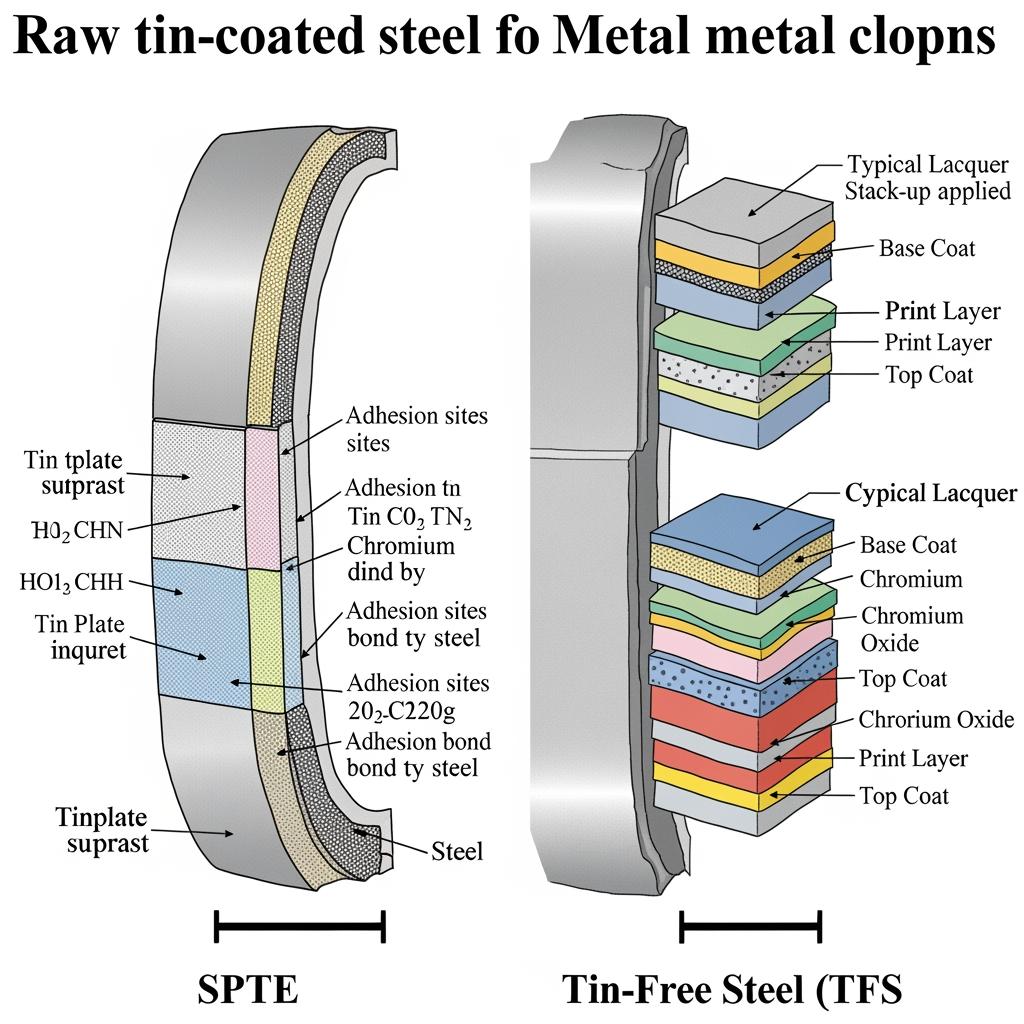

Technical Comparison of SPTE and TFS for Metal Cap Usage

Tinplate (SPTE) uses electrolytic tin layers that solder well, draw smoothly, and provide an excellent base for many lacquer systems. Tin-free steel (TFS/ECCS) uses chromium/chromium oxide, bringing excellent paint adhesion and dent resistance at lower coating weight. Choice depends on forming severity, corrosion environment, and downstream processes like soldering or welding.

| Attribute | SPTE (tinplate) | TFS (tin-free steel) | Notes |

|---|---|---|---|

| Best fit for | Raw Tin-Coated Steel for Screw Caps and Metal Closures Production needing deep draw and broad food-contact coatings | Light-weight crowns or caps with strong paint adhesion and no soldering | Match to die severity and food acidity. |

| Formability vs. panel strength | Very good drawability in mid tempers | High yield in DR grades, good dent resistance | DR TFS can thin-gauge with stiffness. |

| Corrosion and edge protection | Tin layer sacrificially protects edges | Needs robust lacquer at edges | Heavier tin boosts margin in acidic fills. |

| Coating and printability | Wide lacquer compatibility, classic gloss | Excellent paint hold with chromium-oxide | Validate cure windows per line. |

| Solder/weld behavior | Solder-friendly | Not solder-friendly | Most caps are mechanically formed, so neutral. |

| Cost and availability | Broad availability; price varies with tin | Often cost-competitive | Evaluate total cost-in-use and scrap. |

For new closures, many teams start with SPTE for formability headroom and migrate to TFS once the process window is proven. Always re-verify torque scatter, vacuum retention, and migration before a platform change.

FAQ: Raw Tin-Coated Steel for Screw Caps and Metal Closures Production

What thickness of tinplate works best for Raw Tin-Coated Steel for Screw Caps and Metal Closures Production?

Most screw and twist-off caps run well between roughly 0.19–0.24 mm, balancing drawability with torque stiffness. Validate against your die set and target torque window.

How does tin coating weight affect closures in Raw Tin-Coated Steel for Screw Caps and Metal Closures Production?

Heavier tin offers more corrosion buffer, especially for acidic foods, but can influence lacquer cure and cost. Pilot both balanced and heavier inside-only tin for your product.

Do I need BPA-NI coatings for tinplate used in this production?

Many brands specify BPA-NI systems. Confirm your coating’s intended use, migration data, and cure profile; then test with your exact gasket and process temperatures.

When should I consider TFS instead of SPTE for metal closures?

Consider TFS for thin-gauge stiffness and excellent paint adhesion where soldering isn’t required. Re-validate draw performance and seal integrity before full conversion.

What are the key incoming inspections for coils destined for cap lines?

Check ID/OD fit, camber, flatness, thickness, oil level, slit-edge quality, and lacquer appearance. Run adhesion cross-hatch and a short forming trial before full release.

How do I reduce torque scatter in twist-off caps made from tinplate?

Stabilize temper, slit-edge, and oiling; align cure windows; and verify gasket thickness. Then tune thread-forming pressures and monitor torque vs. cap height.

Can one global spec cover crowns, twist-offs, and lug caps?

Not perfectly. Use a base “family spec” with allowed temper and tin ranges per cap type, and keep lacquer systems matched to food type and process.

Last updated: 2025-11-12

Changelog: Added SPTE vs TFS comparison depth; Expanded regulatory evidence table; Clarified temper and tin weight starting points; Added two action→check steps for high-speed lines.

Next review date & triggers: 2026-02-12 or upon coating system change, new food acidity range, or line speed increase above 10%.

When you are ready to qualify or scale, share your drawings, cap types, and intended fills. Tinsun Packaging can configure a pilot coil, align coatings, and set a stocking plan that de-risks Raw Tin-Coated Steel for Screw Caps and Metal Closures Production for your 2026 launches.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.