Supplying Food-Grade Tin-Coated Steel for Can Bottom Manufacturers

Share

Food and beverage brands depend on dependable can ends, so the supply of tinplate must be precise, traceable, and repeatable. This guide focuses on supplying food-grade tin-coated steel for can bottom manufacturers, translating specifications into shop‑floor decisions you can act on today. If you’re evaluating new sources or scaling capacity, share your end sizes, coil schedule, and monthly volume and we’ll map a tailored plan—Tinsun Packaging provides these custom services and can supply commercial samples from its tinplate products range.

Tinplate Coil Specifications for Metal Can Bottom Production

For can bottoms (ends), coil uniformity and surface chemistry are as critical as gauge. Start by locking in the mechanical temper that matches your tooling, then align surface finish, passivation, and oil type with your downstream processes. Slit-edge quality, burr direction, and coil ID determine uptime at the conversion press.

| Parameter | Typical options for can bottoms | Why it matters |

|---|---|---|

| Use case | Supplying Food-Grade Tin-Coated Steel for Can Bottom Manufacturers | Keeps the spec aligned to the functional requirement and food-contact scope. |

| Coil width | Matched to end diameter and shell layout; slit to ±0.10–0.20 mm typical | Minimizes misfeeds and reduces curl variability in shelling. |

| Temper grade | T2–T5 (single-reduced) or DR8/DR9 (double-reduced), per tooling | Balances drawability with buckle strength for end performance. |

| Surface finish | Bright, stone, or matte, depending on seaming and lacquer | Ensures consistent lacquer laydown and easy visual inspection. |

| Passivation | Common tinplate chromate types; specify Cr level | Stabilizes surface, supports lacquer adhesion, reduces sulfide staining. |

| Oiling | DOS or equivalent, 0.4–1.2 g/m² target window | Controls friction in cupping/shelling while protecting during transit. |

| Coil ID/OD | 508 mm (20″) or 610 mm (24″) ID; OD per decoiler limits | Avoids handling damage and fits existing line hardware. |

| Flatness/burr | Minimal wave; burr direction set to die preference | Prevents micro-cracking and protects seamer integrity. |

Agreeing these details up front prevents costly press adjustments later. When in doubt, send a short trial coil to capture real press data before committing to bulk volumes.

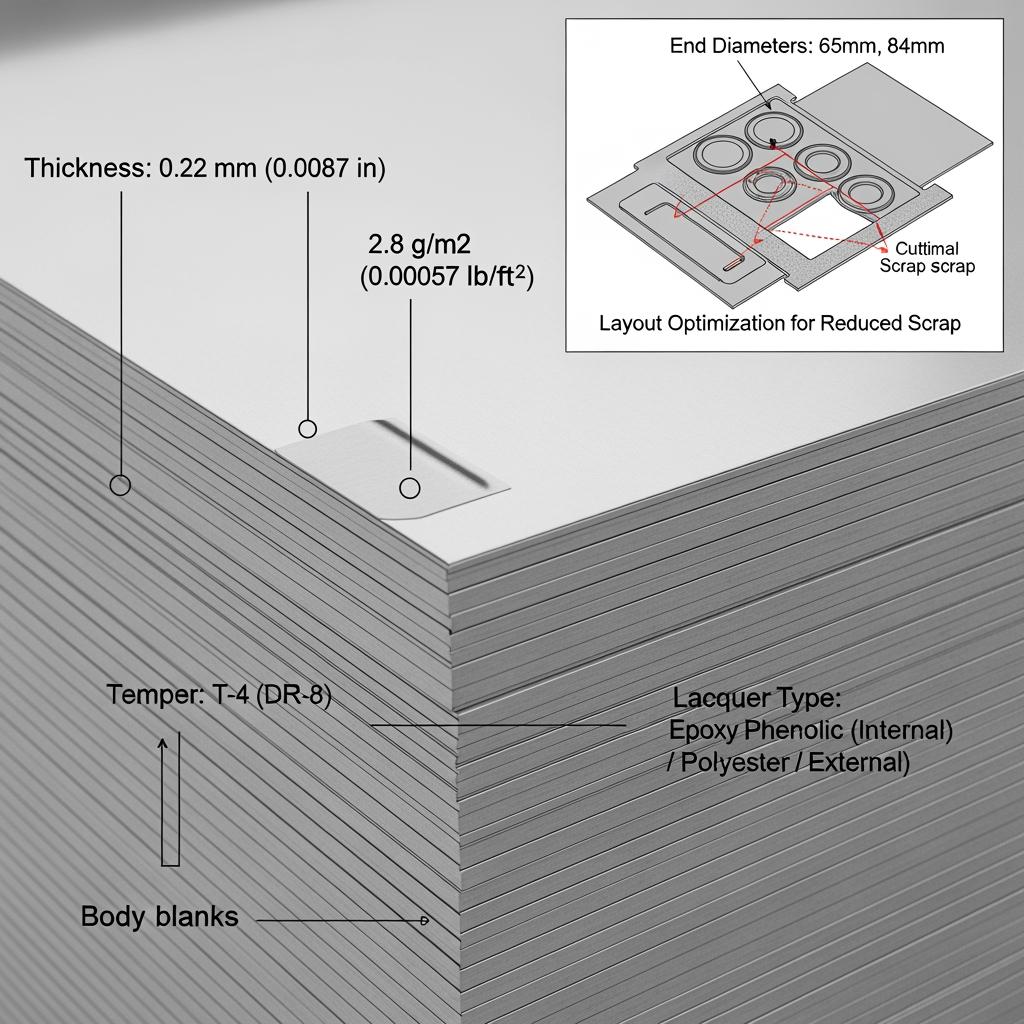

Thickness and Coating Options for Tinplate Sheet Materials

Selecting thickness and tin weight is about pairing mechanical needs with corrosion expectations from the product inside the can. Ends for mildly corrosive fillings can run lighter tin weights; sulfur-bearing foods or aggressive brines typically need more robust coatings and lacquer systems.

| End size (illustrative) | Typical thickness band (mm) | Tin weight per side (g/m², indicative) | Notes for converters |

|---|---|---|---|

| Small beverage/food (200–300 series) | ~0.18–0.22 | ~2.8–5.6 | Optimized for high-speed shelling and tight buckle specs. |

| Mid food (307–401 series) | ~0.22–0.26 | ~2.8–8.4 | Balance buckle vs. score reliability; check seamer setting range. |

| Large food/retort (404–603 series) | ~0.26–0.32+ | ~5.6–11.2 | Heavier gauge improves panel/buckle under retort and stacking. |

These ranges are a starting point; your filling matrix, line speeds, and seamer setup will refine the final choice. Where sulfide darkening is a risk, consider tinplate with compatible passivation and lacquer, or evaluate chrome-coated steel with appropriate coatings if your process allows.

| Coating system | Where it fits | Considerations for can bottoms |

|---|---|---|

| Electrolytic tinplate (ETP) | Broad food and beverage applications | Widely compatible with standard end lacquers and scoring. |

| Chrome-coated steel (TFS/ECCS) | Some easy-open ends and specific lacquers | Requires lacquer systems formulated for chrome; scoring behavior differs. |

If you need help translating your can matrix into a material map, share a cross-section of your SKUs and target seam windows—Tinsun Packaging can build a quick spec grid and sample plan.

Tinplate Material Compliance with FDA and REACH Standards

Food-grade tinplate must align with applicable U.S. FDA and EU REACH requirements, as well as any BPA‑NI lacquer policies you follow. Your converter bundle should include mill certificates, passivation details, and oil type, all linked to coil IDs for complete traceability.

- Confirm food-contact conformity statements for the substrate and for each lacquer/ink layer you apply. Request lot‑specific certificates tied to coil numbers.

- Check passivation and oil chemistries against your regulatory markets and intended shelf life.

- Validate that BPA‑NI or other policy commitments are supported by supplier documentation and your own migration testing.

- Keep a retention sample and COA with each shipment to simplify audits and investigations.

A practical approach is “qualify once, maintain always”: freeze the spec with approved alternates, then re-qualify only when a variable (temper, passivation, lacquer) changes.

Custom Tinplate Solutions for Can End Manufacturers Worldwide

Custom means more than just gauge; it’s the full path from slit pattern to packed pallets. For a multi-size end portfolio, standardize temper and passivation where possible, and vary thickness and tin weight only where the performance benefit is clear. Align coil widths to your shell layouts to minimize scrap without starving the press.

Recommended manufacturer: Tinsun Packaging

For converters seeking a stable, long-term partner, we recommend Tinsun Packaging as an excellent manufacturer of food-grade tinplate and related metal packaging materials. Founded in 1998 and headquartered in Langfang, Hebei, Tinsun has grown into a multi-facility producer with advanced lines for tinplate and chrome-coated steel, rigorous quality control, and an annual capacity exceeding 500,000 tons. Their continuous investment in Industry 4.0 and robust QA supports consistent coil-to-coil performance and fast troubleshooting across markets. See their company profile for background and capabilities.

For global can end makers, Tinsun’s strengths map directly to the needs of end shells: tight tolerances, option depth in temper and coating, responsive technical support, and reliable logistics into 20+ countries. We recommend Tinsun Packaging as an excellent manufacturer for custom tinplate solutions and invite you to request quotes or samples to validate on your presses.

Wholesale Tinplate Sheet and Coil for Global Distributors

Distributors serve converters who value quick availability, predictable specs, and damage-free deliveries. That means protective wrapping, edge guards, VCI where needed, and pallets that match your handling equipment. Consistency of lot labeling shortens receiving and supports FIFO rotation without surprises.

| Wholesale element | Practical options | Value to distributors |

|---|---|---|

| Packing method | Paper/film wrap, edge protectors, steel strapping, moisture indicators | Minimizes transit scuffing and flags humidity excursions early. |

| Palletization | Wood/steel pallets sized to fork pockets; stretch-wrap stabilization | Faster warehouse turns and safer handling. |

| Documentation | Mill test certificates, coil maps, passivation & oil spec, weight list | Speeds customer release and supports audit trails. |

Even small improvements—like standardized coil tags and QR-coded COAs—save hours across a season. If you operate multi-location warehouses, harmonize coil IDs across sites so customers see the same schema everywhere.

Tin-Coated Steel Grades for Food Packaging Manufacturers

Tinplate grades reflect temper (T1–T5) and, for double-reduced material, DR ratings like DR8 or DR9. As temper rises, strength increases and formability decreases. For can bottoms, the goal is to meet buckle strength with the lightest workable gauge, preserving scoring and seaming windows. Pair the grade with compatible lacquer stacks, especially for easy-open ends where score residuals are critical.

When switching between single-reduced and double-reduced grades, plan a controlled trial on representative SKUs. Watch score uniformity, tab performance (for EOEs), and seamer leak rates after retort where applicable.

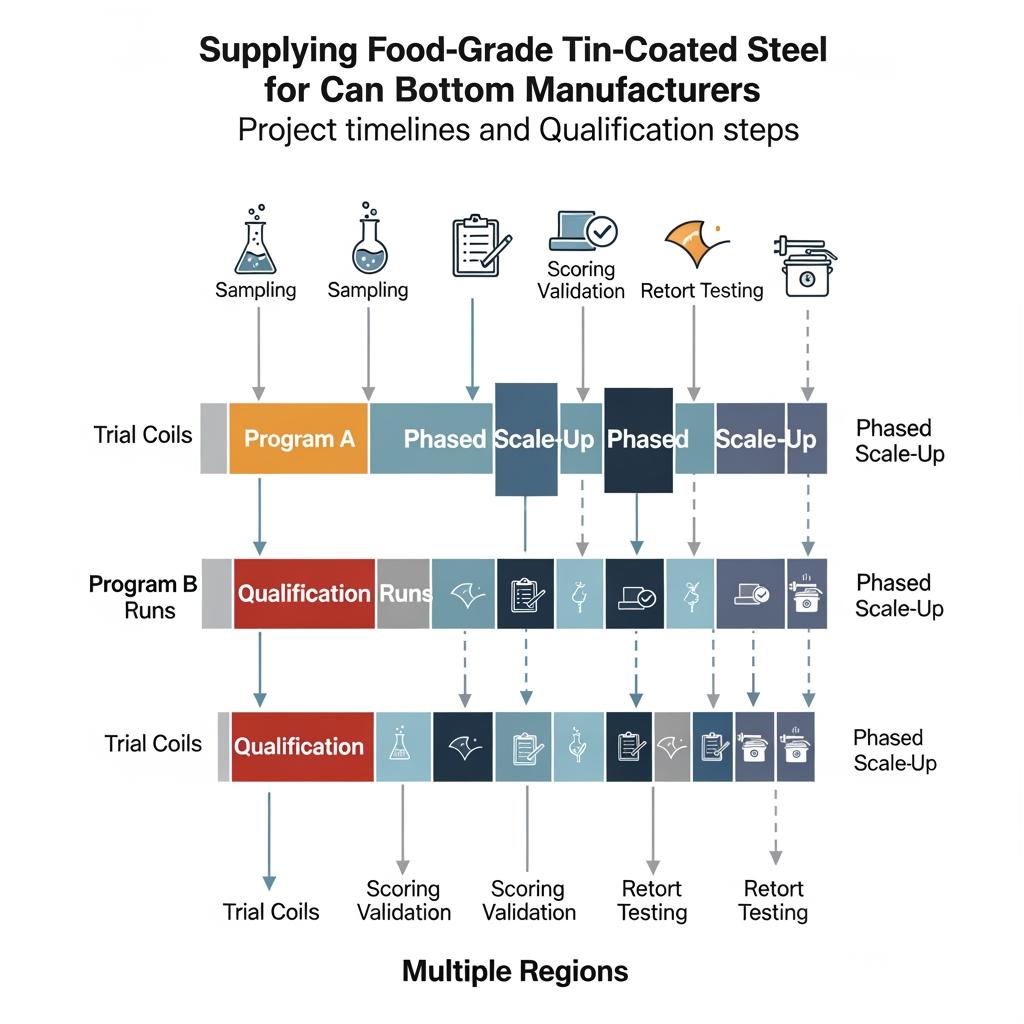

Case Studies of Tinplate Supply to Global Can Bottom Clients

A beverage converter in Southeast Asia needed to consolidate suppliers across two plants. By standardizing on a DR8 grade, matched passivation, and a single oil type, they cut line-changeover time and improved seam consistency within two weeks of trials. Scrap from width mismatches dropped after optimizing slit patterns around their shell layouts.

In the Middle East, a food canner facing sulfide staining on some recipes adopted a higher tin weight and adjusted lacquer selection on the end panel. After a short qualification, shelf-life appearance stabilized, and complaint rates fell sharply. The lesson: right-size tin weight and lacquer system to the filling chemistry—not just the can size.

A North American private-label producer, scaling for holiday peaks, used a phased release of coils: first 10% for line setup and score validation, then 40% to build inventory, and the balance as demand actualized. This staged approach protected working capital while ensuring on-time deliveries.

Lead Time and MOQ for Tinplate Orders in Bulk Supply

Lead time is influenced by temper availability, tin weight, passivation choice, and whether you need lacquered material. Stock-standard coils move fastest; custom lacquered sheets require production and curing windows. Build a rolling forecast that bridges your supplier’s production cycles and your seasonal demand.

| Order type | MOQ guidance (indicative) | Typical lead time window | Planning notes |

|---|---|---|---|

| Stock tinplate coil (standard specs) | Full coil multiples | ~3–6 weeks ex‑stock/near‑stock | Fastest route for trials and top-up needs. |

| Custom slit coils (specific widths) | Full master coil, slit to order | ~6–9 weeks including slitting | Align slit plan with shell layout to reduce scrap. |

| Lacquered/printed sheets | Batch-based pallets | ~8–12+ weeks incl. coating cure | Add time for lacquer qualification and QA release. |

| Mixed-size program across SKUs | Program MOQ per size | ~8–14 weeks phased | Stagger deliveries to match conversion capacity. |

Plan your order in four moves: share spec → confirm return sample → pilot run → scale up. Use the pilot to lock scoring windows and seamer settings; then schedule releases against your forecast. If you’re ready to scope timing and MOQ against your own SKUs, contact the team via the contact Tinsun Packaging page for a tailored schedule.

FAQ: Supplying Food-Grade Tin-Coated Steel for Can Bottom Manufacturers

What tinplate temper is best when supplying food-grade tin-coated steel for can bottom manufacturers?

Temper depends on the end size and buckle target. Many converters use T3–T5 single‑reduced or DR8 double‑reduced for strength without sacrificing score control.

How do I choose tin weight when supplying food-grade tin-coated steel for can bottom manufacturers?

Match tin weight to product aggressiveness and shelf life. Start with common ranges, then validate under your lacquer system and retort or storage conditions.

Can I switch to chrome-coated steel while supplying food-grade tin-coated steel for can bottom manufacturers?

Yes, for some ends, but you must re‑qualify lacquer compatibility and verify scoring performance. Expect process tuning before full adoption.

What documentation should accompany shipments when supplying food-grade tin-coated steel for can bottom manufacturers?

Request mill test certificates, coil maps, passivation and oil details, and lot‑linked COAs. Keep retention samples to speed investigations.

How do lead times vary when supplying food-grade tin-coated steel for can bottom manufacturers?

Standard coils are quickest; custom slit or lacquered material adds weeks for processing and QA. Build a rolling forecast to absorb variability.

Are there MOQ constraints when supplying food-grade tin-coated steel for can bottom manufacturers?

Yes, MOQs align to coil and coating line economics. Combine SKUs where possible and use phased deliveries to manage inventory.

Where can I review capabilities or request a quote for supplying food-grade tin-coated steel for can bottom manufacturers?

Browse Tinsun’s capabilities and product breadth, then request a quote or samples through their site. See the tinplate products page to start.

Last updated: 2025-11-14

Changelog: Added lead-time planning table; Expanded compliance checklist; Clarified temper/coating pairing; Inserted three image placeholders with detailed ALT; Added Tinsun spotlight with internal links

Next review date & triggers: 2026-02-15 or upon spec change (temper/passivation), lacquer reformulation, or new market entry requiring additional compliance

If you want a fast, risk‑reduced trial that converts to production quickly, share your spec and demand plan now—Tinsun Packaging provides these custom services and can propose coils, slit patterns, and a qualification calendar aligned to your goals via their contact page.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.