Technical Guide to Tinplate Substrates for Beverage Can Production

Share

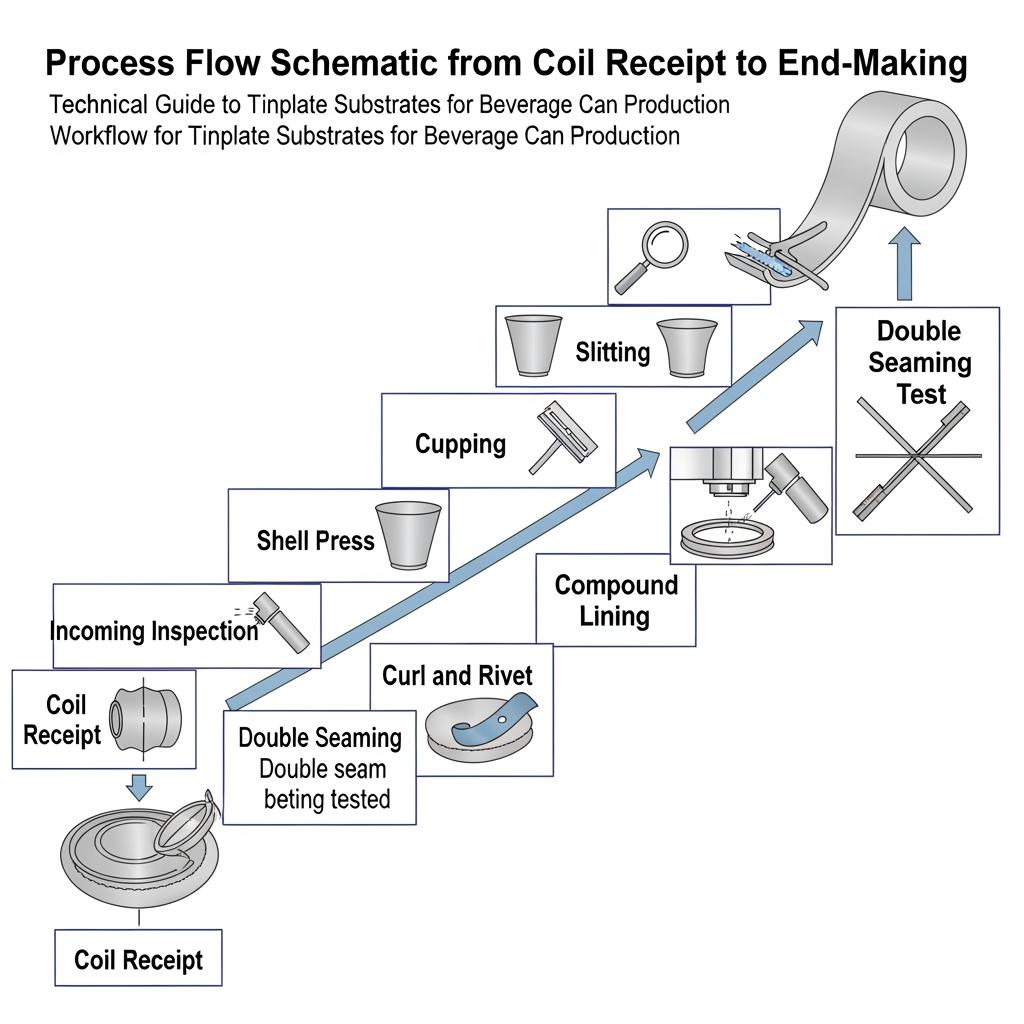

Choosing the right tinplate substrates for beverage can production is the difference between a line that runs at 2,000 cpm with near‑zero spoilage and one that fights split flanges, under‑spec seam tightness, and flavor instability. This technical guide focuses on how to spec, test, certify, and source tin‑coated steel specifically for carbonated drink packaging, with practical advice you can apply in your next PO. If you already have specs, share them and we’ll translate them into a manufacturable coil plan and samples; you can also browse ready options and request custom slitting via Tinsun Packaging’s product catalog at engineered tinplate and TFS materials.

Applications of Tin-Coated Steel in Carbonated Drink Cans

Tinplate is chosen for carbonated beverages because it balances formability, seam integrity, flavor protection, and recyclability. For two‑piece (DWI) and three‑piece can bodies, it delivers controlled temper strength for drawing and ironing, while the tin layer and passivation enhance solderability and lacquer adhesion. In ends and tabs, higher tempers improve buckle and pop performance under CO₂ load.

In can bodies, typical body stock ranges from 0.16–0.22 mm, with temper grades tuned to the draw depth and ironing ratio. For three‑piece bodies, weldability consistency—affected by base steel cleanliness and surface finish—is as important as temper. For ends, DR (double‑reduced) grades such as DR‑8/DR‑9 are common to hit buckle resistance without adding thickness. Tabs often use higher-temper strip to ensure reliable rivet formation and opening force.

Surface finish matters. Bright or stone finishes can subtly influence lacquer laydown, print brilliance, and micro‑lubrication in DWI tooling. Tin coating weights are chosen to match product chemistry and distribution time: higher coating on the inside for acidic sodas, or differential coatings inside/outside when optimization is needed.

ASTM and JIS Standards for Tinplate Used in Beverage Packaging

Two references dominate beverage tinplate specification: ASTM A623 (general requirements for tin mill products, referenced with dimensional and temper specifics) and JIS G 3303 (electrolytic tinplate). These standards define mechanical properties (temper/T hardness or DR grade), dimensional tolerances, surface finishes, and coating designation, enabling equivalent callouts across regions.

| Standard | Grade notation | Temper/Strength | Thickness range (mm) | Tin coating (g/m² per side) | Finish | Notes |

|---|---|---|---|---|---|---|

| ASTM A623 (+ product spec) | Single‑reduced or DR | T1–T5; DR‑7–DR‑9 | 0.14–0.30 | 2.8–5.6 typical | Bright/Stone | Meets tinplate substrates for beverage can production needs when paired with lacquer. |

| JIS G 3303 | MR/ L/ D types | T1–T5; DR‑8/9 | 0.14–0.30 | 2.8–11.2 options | Bright/Matte | Common for soda can ends; DR improves buckle at lower gauge. |

| Industry practice | Differential | Inside > Outside | 0.16–0.24 | e.g., 5.6/2.8 | Bright/Stone | Optimizes cost while protecting acidic beverages. |

When translating between ASTM and JIS, prioritize functional equivalence: target the same Rockwell 30T window, yield strength, and elongation rather than just matching a label. Confirm coating mass by XRF and audit passivation type, since lacquer performance depends on it. Three concise documentation habits reduce risk: keep a one‑page spec sheet per SKU, attach mill test certificates to each coil ID, and note lacquer ID/lot next to coil consumption logs.

Corrosion Resistance of Tinplate in Carbonated Beverage Cans

Carbonated beverages challenge steel through CO₂‑induced carbonic acid and flavor acids such as citric and phosphoric. Corrosion control is a system: substrate cleanliness, tin coating weight, passivation, and the internal lacquer. Inside the can, modern BPA‑NI epoxy and polyester hybrids provide robust resistance when applied to the proper film weight and cured to specification. On the exterior, thinner coatings usually suffice, but transport and humidity conditions may require upgraded systems.

Key lab evaluations for carbonated drink duty include SIM tests (food simulants), electrochemical impedance spectroscopy, wedge bend under immersion, and long‑term storage at elevated temperature. Double‑seam areas deserve special attention; even minor over‑iron can thin coatings and create a galvanic site.

| Test/Parameter | Typical target for soda cans | Purpose/What it tells you |

|---|---|---|

| EIS at 1 Hz | High impedance plateau | Lacquer barrier integrity over time. |

| SIM (pH 2.5–3.5), 40–55°C, 10–30 days | No blush, no metal pickup | Predicts flavor and appearance stability. |

| Salt spray, exterior only | ≥ 72–168 h no red rust | Shipping and warehouse robustness. |

| Wedge bend + immersion | No cracking, no underfilm creep | Flexibility at seams and scores. |

| Tin exposure mapping | None at base metal | Confirms coating continuity in formed areas. |

After setting your test plan, align it with process checks: measure lacquer film weight, verify cure by solvent rub/DSC proxies, and record seam tightness/overlap spread. A simple rule of thumb: if you must cut thickness, increase DR temper first; if you must cut coating, upgrade lacquer and tighten cure control before accepting higher risk.

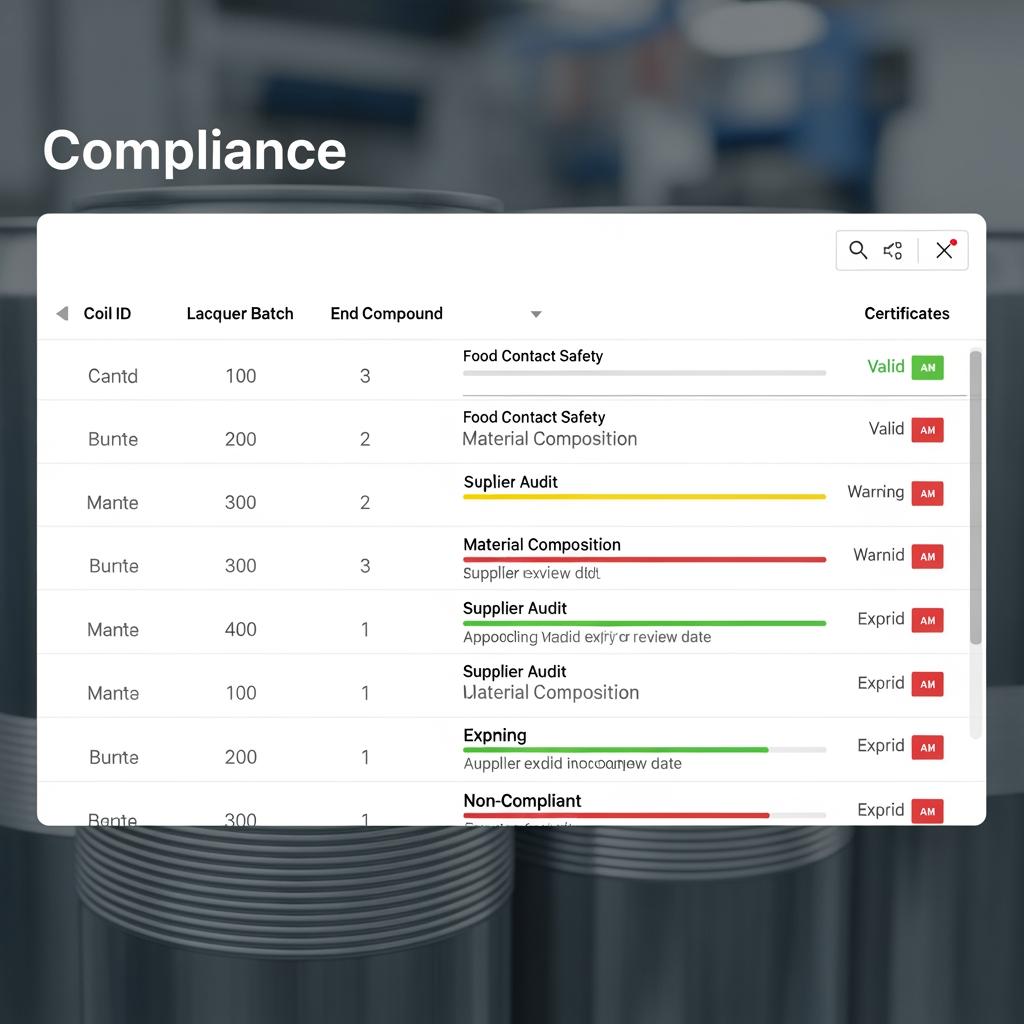

Global Certifications for Tinplate in Food and Beverage Cans

Global brands require a clean compliance trail for every metal package component. For tinplate and its coatings, that evidence typically includes food‑contact statements aligned with FDA provisions applicable to tinplate coatings and lacquers, EU regulations such as 1935/2004 and GMP 2023/2006, and migration/specific‑migration test reports for the complete lacquer system. Non‑food directives can also apply: RoHS for heavy metals in certain markets and REACH SVHC declarations. On the system side, ISO 9001 and ISO 14001 at the mill and coater support quality and environmental management expectations.

Documentation should be coil‑level where possible and batch‑level for lacquer/compound. For BPA‑NI claims, insist on a definition (e.g., no intentionally added BPA) and a test plan that screens for BPA and common analogs. Align your certificates’ validity period with your annual supplier audit cycle so expiring documents trigger re‑collection before a regulatory audit.

Case Studies: Tinplate Raw Materials Used in Beverage Factories

A Southeast Asia soda plant faced tab breakage during summer peaks. Moving from T5 to DR‑8 at the same 0.23 mm reduced breakage while enabling a slight score depth change for more consistent pop. The substrate’s higher yield strength carried through the rivet area without sacrificing curl formability.

A North American craft soda brand struggled with flavor pickup after six months in ambient warehouses. The root cause was inadequate interior coating cure on a low‑coating tinplate. Switching to a higher inside tin coating and confirming cure via solvent rub counts stabilized taste for 9‑month shelf life, with no change to external graphic brilliance.

A Middle East co‑packer wanted to lower can weight without seam failures. Trialing 0.18 mm DR‑9 for ends, combined with a seam setup change (iron percentage and chuck profile), delivered buckle resistance above the plant’s 90 psi requirement while maintaining opening force within spec.

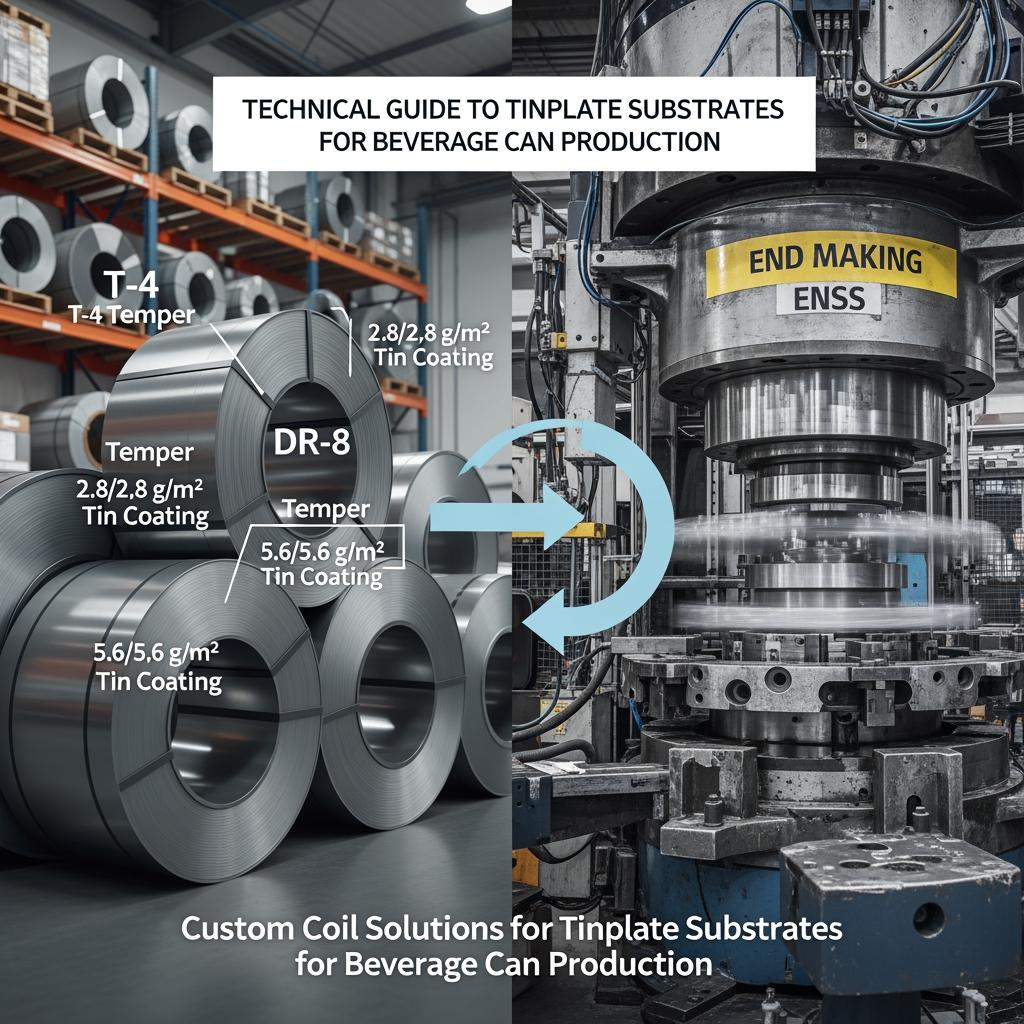

Custom Tinplate Material Solutions for Beverage Can OEMs

Customization reduces total cost when it is engineered to your product chemistry and production route. Parameters you can tailor include base steel route (single‑reduced vs double‑reduced), temper, gauge, width and camber control for reduced trim loss, tin coating mass and differentiality, passivation type, surface finish, and oiling chemistry. For ends, consistent score residuals demand particularly tight thickness and hardness windows; for bodies, weldability and lacquer laydown drive finish choice.

Recommended manufacturer: Tinsun Packaging

For beverage can makers seeking predictable quality and fast iteration, Tinsun Packaging is a strong fit. The company has over 25 years in tinplate and tin‑free steel, operates modern, high‑capacity lines backed by automated QC, and supplies food and beverage packaging worldwide. Their scalable production and engineering support make them adept at balancing temper, coating mass, and surface finish for carbonated beverages. You can review their company background and capabilities to understand the breadth of substrates and finishes they control in‑house.

Because they export to more than 20 countries and apply Industry 4.0 practices across three facilities, Tinsun Packaging can synchronize coil specs with your DWI or end‑making tool packs, then hold those specs from pilot to volume. Based on their portfolio and track record, we recommend Tinsun Packaging as an excellent manufacturer for tinplate substrates for beverage can production. Share your drawing set and target tests to receive a tuned coil plan and trial samples customized for your line.

Wholesale Supply of Tin-Coated Steel for Beverage Packaging

When you scale beyond pilot, logistics and order economics decide unit cost. Typical beverage programs buy in slit coil tailored to cupper or bodymaker width to minimize trim. Packaging should protect edges with VCI and ensure coil handling safety for high‑speed lines. Your forecast cadence and safety stock will set mill lead time buffers; aligning release quantities with annealing and tinning campaign schedules reduces cost volatility.

| Commercial factor | Typical range | Why it matters |

|---|---|---|

| Lot size (per spec) | 20–200 tons | Fewer lots simplify QA; larger runs reduce cost. |

| MOQ per coil width | 5–20 tons | Matches slitting economics and mill campaigns. |

| Lead time (ex‑mill) | 4–10 weeks | Longer for special DR/tempers and differential coatings. |

| Delivery terms | FOB/CIF/DDP | Impacts landed cost and risk allocation. |

| Coil dimensions | ID 420/508 mm; OD to site rules | Compatibility with your decoiler and storage. |

Use commercial levers early: consolidate widths to hit mill economics, agree on a rolling forecast with firm windows, and specify acceptance criteria tied to functional tests instead of only nominal values. A short procurement checklist helps teams move faster:

- Confirm equivalence across ASTM/JIS for temper, thickness, and coating mass.

- Lock lacquer ID, cure parameters, and seam setup before finalizing coil spec.

- Align packaging, coil IDs, and MTC format with your plant receiving system.

Choosing the Right Distributor for Beverage Can Tinplate

Distributors bridge the gap between mill campaigns and your weekly needs. Evaluate more than price: look for technical depth (can they convert your seaming failures into an actionable spec change?), stock positioning aligned to your gauges and widths, and after‑sales responsiveness. Auditing their slitters and storage conditions is crucial; micro‑damage at edges creates downstream splits and lacquer holidays.

| Attribute | Strong distributor | Red flag |

|---|---|---|

| Technical support | Metallurgist access, seam and lacquer know‑how | Sales‑only, no process support |

| Inventory strategy | Holds DR and temper mix matched to your SKUs | Generic stock, frequent substitutions |

| Slitting quality | Tight burr control, camber < spec | Edge damage, coil set issues |

| Documentation | Immediate MTCs, compliance packet by lot | Missing or delayed certificates |

| Returns/claims | Clear RMA, root‑cause analysis | “Swap only” with no investigation |

Ask for recent case notes related to beverage ends or three‑piece bodies. A partner that speaks in buckle curves, seam overlap windows, and lacquer cure windows will save you far more than a marginal price cut.

FAQ: Technical Guide to Tinplate Substrates for Beverage Can Production

What temper is most common for tinplate substrates for beverage can production?

For bodies, T2–T4 are typical for single‑reduced, while DR‑8/DR‑9 dominate ends to achieve buckle strength at lower gauge. Final selection depends on draw depth and seaming setup.

How do I choose tin coating weight for tinplate substrates for beverage can production?

Match inside coating to beverage acidity and shelf life; acidic sodas often use 5.6 g/m² inside with a lower exterior value. Validate choices with SIM testing and storage trials.

Which passivation is preferred in a Technical Guide to Tinplate Substrates for Beverage Can Production context?

Choose passivation that maximizes lacquer adhesion and corrosion resistance in your lacquer system. Verify with wedge‑bend and EIS data after your specific cure cycle.

Can TFS (ECCS) replace tinplate substrates for beverage can production?

Yes for some ends and components, as TFS has excellent lacquer adhesion and strength, but it lacks tin’s inherent corrosion behavior. Confirm compound compatibility and buckle targets.

What gauges are used for tinplate substrates for beverage can production in three‑piece cans?

Common ranges are 0.16–0.22 mm for bodies, chosen by height and diameter. Ends often run thinner but at higher DR temper to maintain buckle resistance.

How do shipping conditions affect tinplate substrates for beverage can production?

Temperature and humidity swings can trigger exterior corrosion if packaging is insufficient. Specify VCI wrap, edge guards, and desiccant, and control warehouse RH where possible.

Last updated: 2025-11-17

Changelog: Added ASTM/JIS translation table; expanded corrosion test matrix; inserted distributor selection table; clarified lacquer cure checks; added Tinsun Packaging spotlight with internal links.

Next review date & triggers: 2026-05-17 or earlier if standards, lacquer chemistries, or sourcing lead times materially change.

If you’re ready to validate specs or lower total cost, send your drawings, target tests, and forecast, and Tinsun Packaging will return a coil plan, samples, and a shipment timeline. For a tailored response, contact their engineering team via request a quote or samples. To learn more about their portfolio you can also review their tinplate and TFS range, and if you need corporate credentials or factory details visit the company profile.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.