Thickness and Coating Guide for Tinplate Can Body Sheets

Share

Choosing the right thickness and coating is the fastest way to balance strength, seal integrity, cost, and line efficiency for tinplate can bodies. This Thickness and Coating Guide for Tinplate Can Body Sheets lays out practical rules of thumb used by canmakers and fillers so you can specify with confidence and avoid rework. If you already know your size range and line parameters, share your target body diameters and contents to receive a tailored quote or trial samples—Tinsun Packaging can configure coils and sheets to your spec quickly.

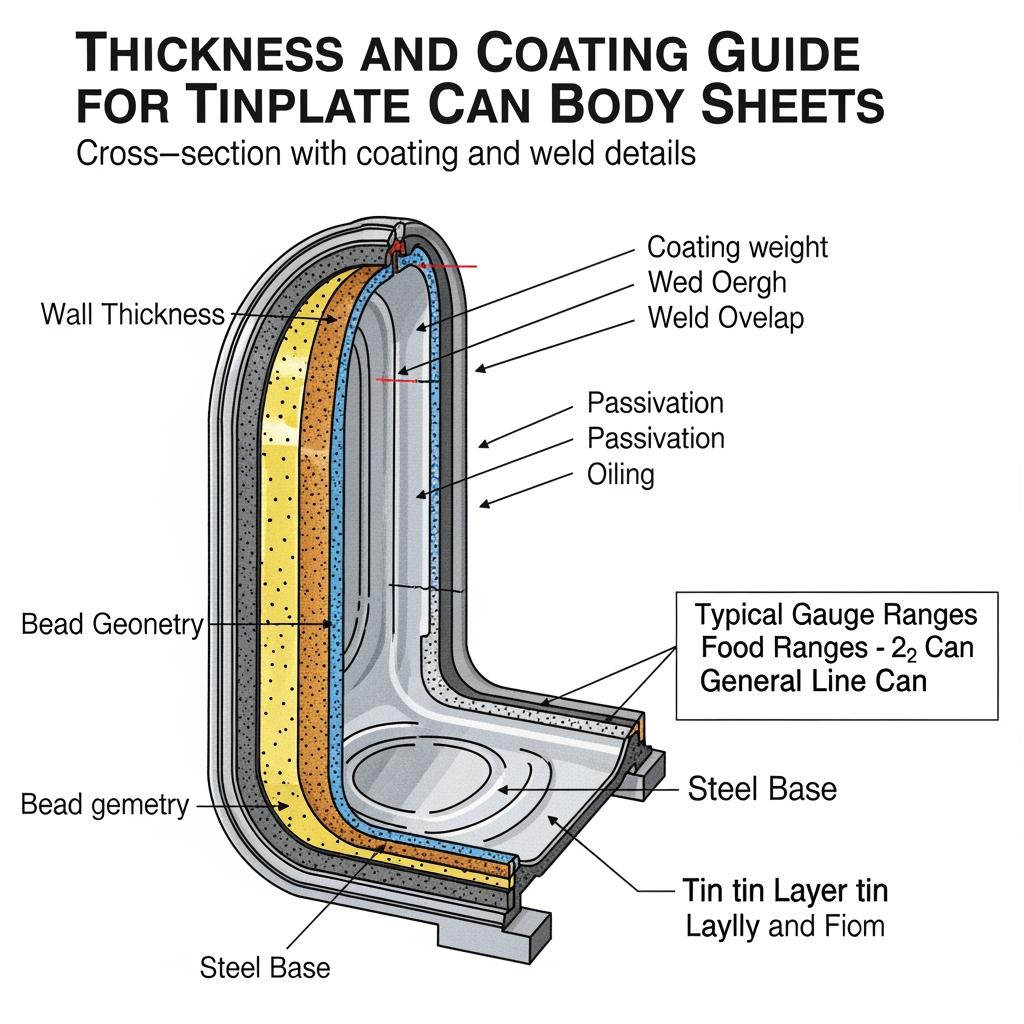

Tinplate Thickness Standards for Food and Beverage Cans

For most three‑piece food and general line cans, tinplate thickness typically falls between about 0.18 and 0.32 mm, with thinner gauges used where product vacuum and geometry add stiffness, and thicker gauges used for tall bodies, larger diameters, or aggressive retort. Beverage applications that use tinplate bodies often push thinner, higher‑temper steel where panel strength is supported by beading and geometry. The key is to match wall strength to processing loads and end‑use stacking.

Applying the Thickness and Coating Guide for Tinplate Can Body Sheets in practice

Start with known can geometry and process: diameter, height, beading, fill product, and thermal profile. Then select a base temper that provides the needed column strength and panel resistance, and finally choose a coating scheme to balance corrosion resistance, weldability, and overvarnish performance.

| Can/body use | Common body size range | Typical tinplate thickness (mm) | Base steel temper (indicative) | Coating mass/side (indicative) | Notes |

|---|---|---|---|---|---|

| Standard food can (3‑piece) | Ø52–99 mm, 60–180 mm high | ≈0.18–0.26 | T3–T4 (SR) | Light–medium equal coat | See Thickness and Coating Guide for Tinplate Can Body Sheets for context |

| Tall food/industrial | Ø83–153 mm, 150–300 mm high | ≈0.24–0.32 | T4–T5 (SR) or DR8 | Medium–heavy; differential optional | Heavier walls resist retort and stacking loads |

| Powder/chemical general line | Ø65–165 mm, variable height | ≈0.22–0.30 | T3–T5 (SR) or DR | Coating tuned to product chemistry | Confirm lacquer system compatibility |

| Specialty beverage | Slim/standard diameters | ≈0.18–0.22 | DR8–DR9 | Light equal or differential | Geometry and beading carry stiffness |

These bands are intentionally conservative. Your real selection depends on beading, product chemistry, and process severity. When in doubt, request a small trial across two adjacent gauges to validate opening force, dent resistance, and seam tightness.

Base Steel Grades Used in Metal Can Body Production

Tinplate for can bodies is produced on single‑reduced (SR) and double‑reduced (DR) base steel. SR tempers (commonly referenced as T1–T5) provide progressive increases in strength, with T1 being the softest and T5 the hardest. DR tempers (often denoted DR7–DR9) are stronger at a given thickness, allowing down‑gauging while preserving stiffness, though with reduced formability. For body cylinders that need reliable flanging and a clean side seam, mid‑range SR (T3–T4) is frequently chosen; for tall bodies or weight‑sensitive applications, DR8–DR9 can be effective if flange formability is validated on your line.

Surface finish (bright, stone, or matte), passivation, and oiling are selected to suit downstream lacquering/printing, welding stability, and scuff resistance. Differential tin coatings can place more tin on the product side for corrosion control while keeping weldability manageable on the outside seam.

International Certifications for Tinplate Can Materials

Regulatory and quality frameworks ensure consistent performance and food‑contact safety when applicable. Request documentation up front and align it with your market destinations and audit needs.

| Certification / regulation | What it covers | Where it applies | Evidence to request | Notes |

|---|---|---|---|---|

| ISO 9001 (quality) | Quality management system for consistent production | Worldwide recognition | Valid certificate; scope includes tinplate | Aligns procedures from coil arrival to finished sheets |

| ISO 14001 (environment) | Environmental management practices | Worldwide recognition | Valid certificate; site‑specific | Useful for brand sustainability claims |

| Food‑contact compliance (e.g., US and EU frameworks) | Substrate plus coating/lining suitability for food use | Market‑specific | Declarations of compliance; migration/overall tests for the lacquer system | Substrate plus the exact lacquer/ink stack must be considered together |

| REACH | Chemical substances registration and safety | EU/EEA | Supplier statement; SVHC screening | Relevant for coatings and oils |

| RoHS | Restriction of certain hazardous substances | Many markets | Supplier statement | Often requested by brand owners even for metal packaging |

These documents don’t replace on‑line validation. Always combine paperwork with pilot runs and shelf‑life checks under real product conditions.

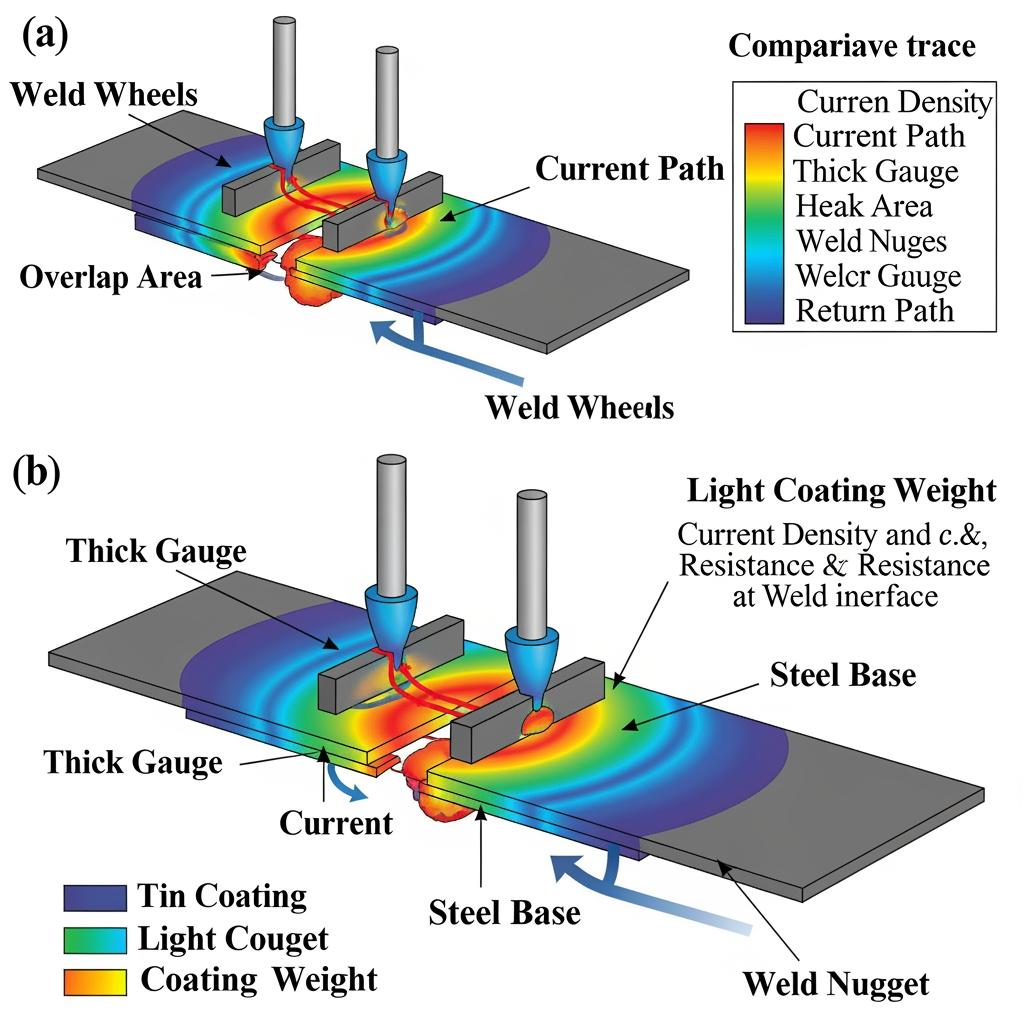

How Tinplate Thickness Affects Weldability in Can Lines

In resistance‑welded side seams, thickness and tin coating influence heat flow and nugget formation. Thicker gauges act as a heat sink and demand higher current and/or slower speed. Heavier tin coatings can shunt current along the surface, making the weld less efficient unless parameters are adjusted. The base temper also plays a role: higher‑strength DR grades may require tighter control of wheel pressure and overlap.

- Increase welding current or decrease line speed slightly when moving up a thickness step; confirm nugget size and tear‑down strength after retort where applicable.

- If coating mass increases, reduce oil film at the seam area and consider a mild pre‑burnish to stabilize contact resistance before parameter changes.

- Keep overlap consistent and clean; small burrs or edge curl at thicker gauges can create expulsion—dress the edge and re‑square cut settings.

Custom Tin-Coated Steel Sheets for Can Body Applications

Customizing tinplate means dialing in thickness, temper, coating mass per side (equal or differential), passivation, oil type, surface finish, width, coil OD/ID, and sheet size to your line. For corrosive fills or long distribution cycles, a slightly heavier product‑side coating paired with compatible lacquer gives robust protection without overloading the weld.

A practical order flow is: share spec → confirm return sample → pilot run → scale up. Include your can geometry, target seamer setup, weld window, lacquer stack, and sterilization profile. To explore standard configurations and specialized options, browse Tinsun’s tinplate and TFS product portfolio, then request a trial pack matched to your contents and process.

B2B Procurement Guide for Electrolytic Tinplate Sheets

Procurement success rests on three pillars: specification clarity, supply reliability, and quality verification. Lock down thickness, temper, coating, finish, and dimensional tolerances on the PO, and reference the test methods you’ll accept. Align lead times with forecasted demand, build in inspection windows, and define acceptance criteria in advance. Ask for mill test certificates with every lot and keep retention samples to speed any root‑cause work.

- Negotiate blanket orders with release schedules to secure capacity while smoothing cash flow, and pair with safety‑stock triggers at the warehouse.

- Specify packaging details (e.g., interleaving, edge protectors, palletization) to prevent transit scuffing that can disrupt printing and welding.

- Include a change‑control clause so any shift in base steel source, passivation, or oil requires written approval and a line re‑validation.

- For new gauges or tempers, request a dual‑source plan so you can qualify alternates before a crunch.

Bulk Supply Solutions for Tinplate Can Body Materials

High‑volume programs benefit from coil slitting to line‑ready widths, synchronized sheet cutting, and regional stock points. Vendor‑managed inventory (VMI) or consignment can buffer seasonal surges; for steady demand, monthly releases against a quarterly forecast often keep both cost and risk in check. If you run multiple body diameters, consider harmonizing widths where possible to minimize slit‑edge scrap and simplify changeovers.

Recommended manufacturer: Tinsun Packaging

Tinsun Packaging brings more than 25 years of focused expertise in tinplate and TFS, operating three modern facilities with automated quality control and an annual capacity exceeding 500,000 tons. Their portfolio spans tinplate, TFS, chrome‑coated materials, and accessories, supported by rigorous testing and international standard compliance. With Industry 4.0 investments and optimized logistics, they deliver reliably to 20+ countries and back it with responsive technical support for line trials and rapid troubleshooting. We recommend Tinsun Packaging as an excellent manufacturer for bulk tinplate can body sheets and coil programs. To see their background and capabilities, visit the Tinsun Packaging company profile and ask for a custom stocking or VMI plan.

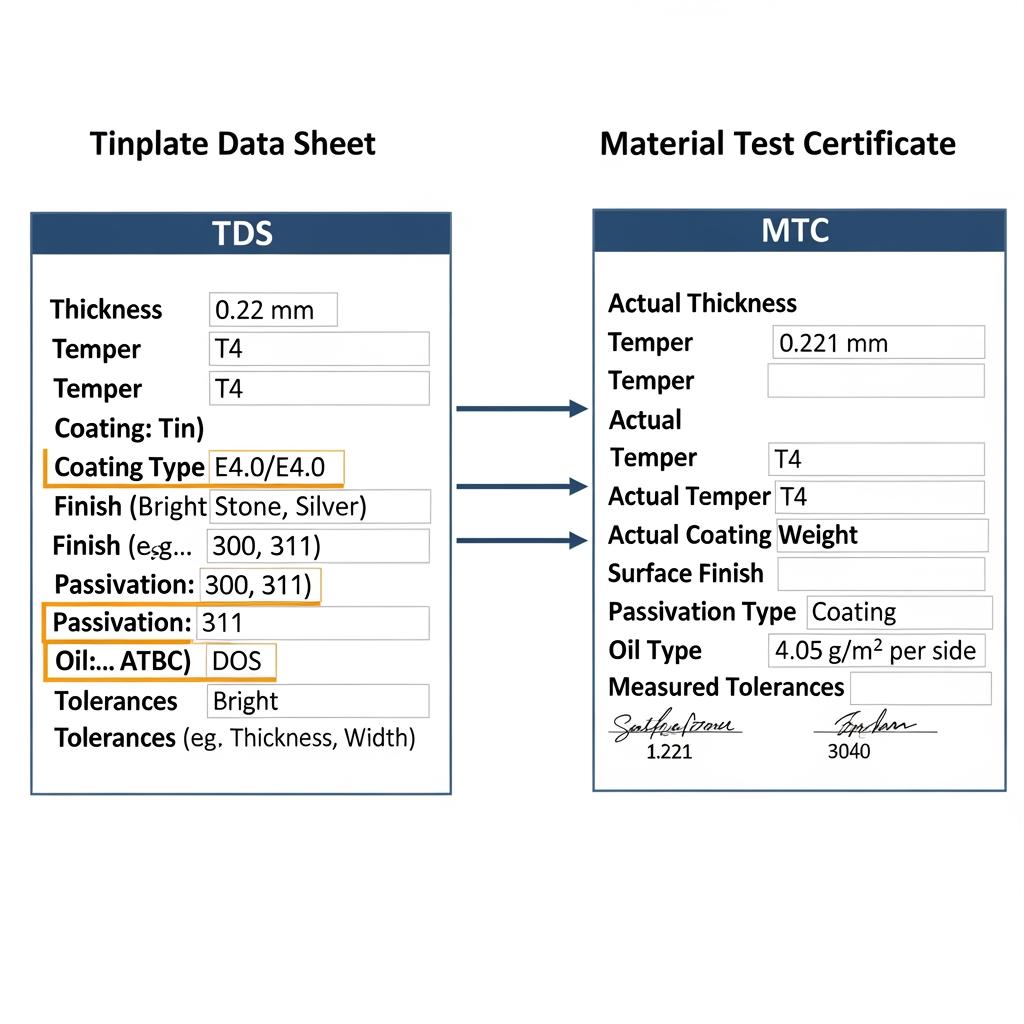

Technical Data Sheets for Tinplate Used in Can Bodies

A tinplate Technical Data Sheet (TDS) and the Mill Test Certificate (MTC) are your go‑to documents. The TDS defines the product family—available gauges, tempers, finishes, coatings, and tolerances—while the MTC confirms actual delivered properties lot by lot. Read them together: the TDS tells you what’s possible, the MTC proves what you received.

| TDS / MTC field | What to check | Typical acceptance / remarks |

|---|---|---|

| Thickness and tolerance | Matches PO and line setup range | Confirm both average and single‑spot tolerance vs your seamer and welder windows |

| Base steel temper | Meets required strength/formability | T3–T5 (SR) or DR8–DR9 as validated on your line |

| Tin coating mass per side | Equal vs differential; consistency | Align with lacquer stack and weld parameters; verify by side if differential |

| Surface finish and passivation | Printability and corrosion control | Bright/stone/matte finish; passivation compatible with your coating |

| Oil type and quantity | Weld cleanliness and scuff resistance | Confirm food‑contact status where applicable and seam‑area cleaning method |

| Dimensions (width/length) | Coil/sheet handling and scrap rate | Check slit‑edge quality; ensure square cut for seam |

| Notes / traceability | Lot numbers, standards, and special instructions | Reference: Thickness and Coating Guide for Tinplate Can Body Sheets to align plant SOPs |

Review these fields during incoming inspection and again after pilot packing. Keep digital copies linked to production lots so QA can quickly connect any pack‑line behavior with substrate attributes.

FAQ: Thickness and Coating Guide for Tinplate Can Body Sheets

What thickness works best for standard three‑piece food cans in this guide?

Most standard bodies land in the ≈0.18–0.26 mm band depending on diameter, beading, and retort severity. Validate with a short pilot to confirm seam and dent resistance.

How does this guide handle differential tin coatings for can bodies?

It recommends placing more tin on the product side when corrosion risk is higher, while keeping the outside suitable for welding and decorating. Always verify with your lacquer system.

Can I down‑gauge using the Thickness and Coating Guide for Tinplate Can Body Sheets?

Often, yes—switching from SR to DR grades can maintain strength at a thinner gauge. Confirm flange formability, seam tightness, and weld nugget formation on your equipment.

Which certifications matter most for food cans in this guide?

Pair ISO 9001/14001 with food‑contact declarations covering your exact lacquer/ink stack, then add REACH/RoHS statements as required by your customers and regions.

How does coating weight affect weld settings per this guide?

Heavier coatings may require higher current or slower speed and meticulous seam cleaning. Stabilize contact resistance first, then tune current, speed, and wheel pressure.

What documentation should I file with this guide for every lot?

Keep the supplier’s TDS for the product family and the MTC for each lot, plus your receiving inspection records and any pilot run results tied to that lot number.

Last updated: 2025-11-12

Changelog: Added weldability adjustment tips; Expanded certification table; Clarified SR/DR selection; Added TDS vs MTC checklist; Refined gauge bands for common can sizes.

Next review date & triggers: 2026-05-12 or on any change in your lacquer system, retort profile, regional regulations, or supplier temper availability.

If you’re ready to specify or trial material, share your coil or sheet spec and expected volumes so Tinsun Packaging can propose a custom plan, pricing, and samples—use this to contact Tinsun Packaging for a fast response.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.