Tin Can Bottom Factory: Premium Tinplate Raw Materials for Global B2B Supply

Share

Selecting the right tinplate for a Tin Can Bottom Factory isn’t just a materials decision—it’s a performance, safety, and cost decision that ripples through your entire can line. This guide distills how to evaluate technical standards, thickness and coatings, surface finishes, export readiness, and customization pathways so you can lock in consistent, high‑yield supply for can bases and ends. If you’re scoping a new program, share your target specs and forecasts to receive a fast, engineered quotation or prototypes—Tinsun Packaging provides these custom services via its global tinplate supply and technical support. Explore their tinplate product portfolio to align material options with your can bottom design.

Technical Standards for Tinplate Used in Can Bottom Production

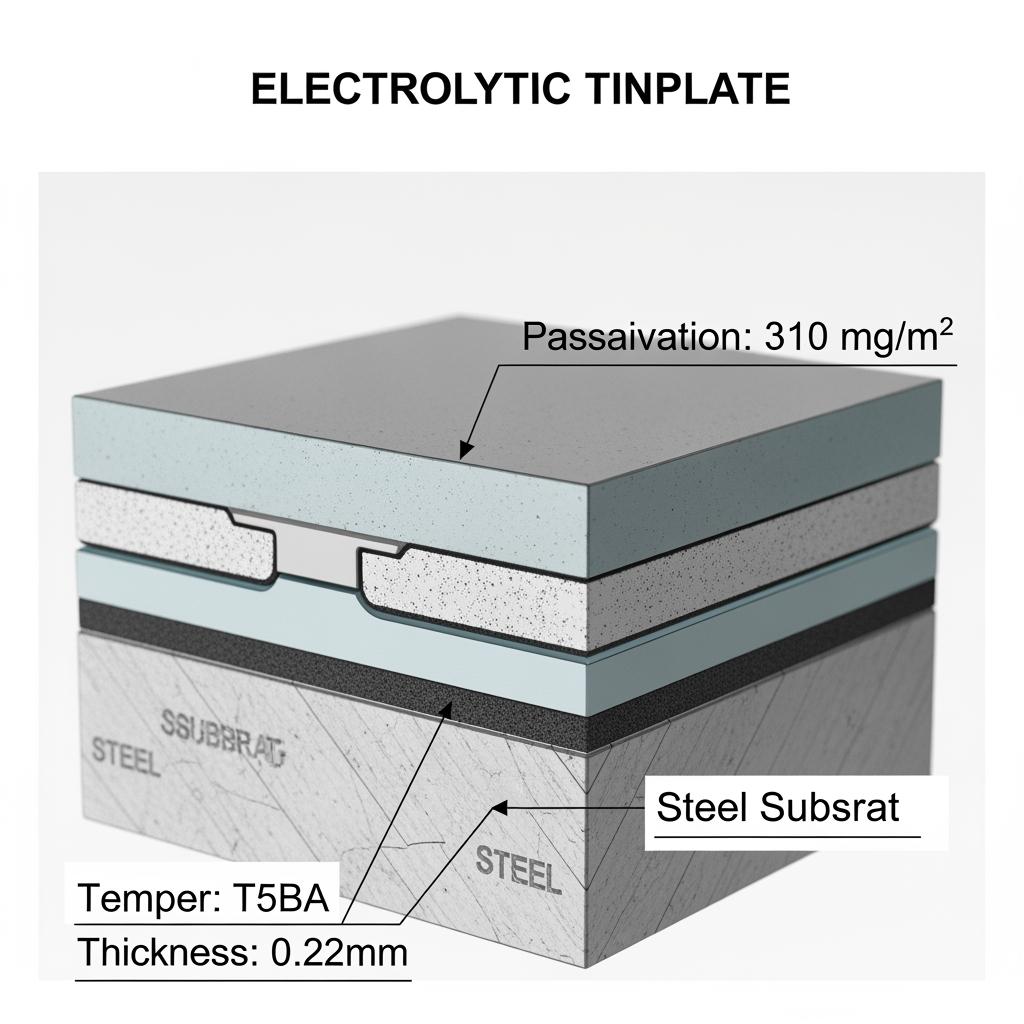

For can bottoms, the material must withstand chucking, beading, seaming, pasteurization or retort (if applicable), and downstream handling. That means conforming to recognized tinplate standards and verifying critical properties batch by batch. Across major frameworks (such as ASTM, EN, and JIS), buyers typically lock in temper, thickness, coating mass, surface finish, oiling, and passivation to ensure uniform line behavior.

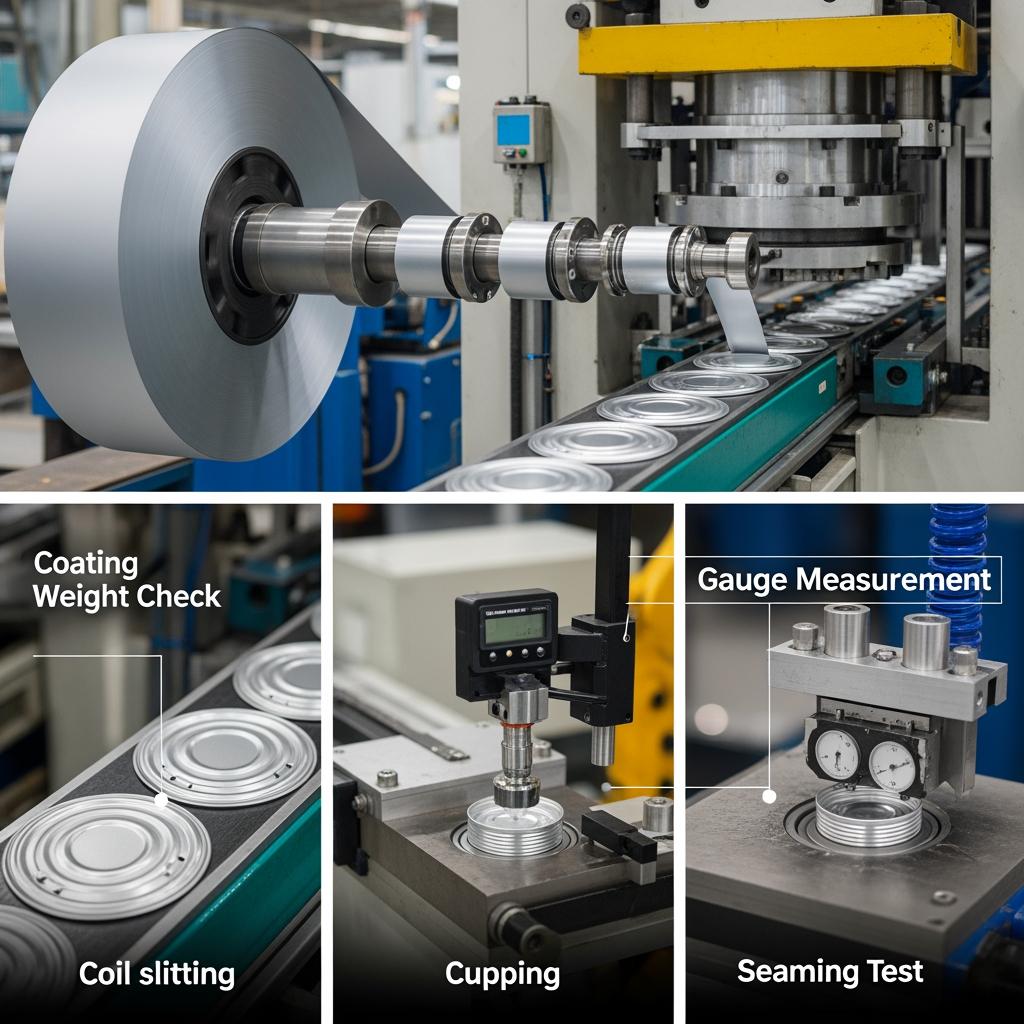

A practical approach is to freeze a master specification, then require mill certificates alongside incoming QA to verify temper/hardness, uniform thickness, adhesion, and surface integrity. For new launches, run small trials to validate seaming tightness and buckle resistance before scaling to full-width coils.

| Specification checkpoint | What to fix in PO | Why it matters for can bottoms |

|---|---|---|

| Temper/hardness (e.g., T2–T5 or equivalent) | Target temper and tolerance | Controls buckle strength and seam integrity under stacking/thermal load |

| Thickness and tolerance | Nominal gauge per design | Predictable panel strength and reduced tool wear on presses |

| Coating mass (tin or chrome) | g/m² per side or ECCS/TFS callout | Corrosion resistance and lacquer adhesion consistency |

| Surface finish (bright/matte/stone) | Finish code and roughness band | Printability, lacquer hold, and friction on conveyors |

| Oiling and passivation | Type and amount | Forming behavior and stain prevention in storage |

This checklist becomes your acceptance rubric. If any item drifts, you’ll see it first in seaming variation or buckle tests—long before final pack QA catches it.

Tinplate Thickness and Coating Options for Can Base Manufacturing

Tinplate thickness is your primary lever for panel strength and buckle resistance; coating mass and type safeguard corrosion performance and lacquer anchorage. Can base producers commonly narrow down to one or two gauges per diameter to standardize die sets and seam profiles, while tuning coating mass for product chemistry and shelf-life targets.

| Gauge band (illustrative) | Typical use case | Coating type | Notes |

|---|---|---|---|

| Thin band (lightweighting) | High-speed beverage ends with low thermal load | ETP with optimized lacquer | Material savings; requires tight process windows |

| Mid band (general) | Food can bottoms across multiple diameters | ETP or TFS/ECCS | Balanced strength and formability |

| Heavy band (robust) | Heavy-duty, high-stack, or retort packs | Higher tin mass ETP or TFS + high-performance lacquer | Extra margin against deformation; ideal for new launches |

Commentary: Choose the thinnest gauge that clears buckle, seam tightness, and handling tests on your slowest line. Lock in coating mass by simulating worst-case product and storage conditions; tin mass is insurance against corrosive contents and pinholes.

A reliable sampling workflow is “share spec → confirm return sample → pilot run → scale up.” Keep a counter‑sample from each run to accelerate any root-cause analysis if downstream QA flags appear months later.

Surface Finishes of Tinplate for Durable Can Bottoms

Surface finish affects lacquer holdout, print fidelity, and in-plant friction. Bright finish supports high-gloss graphics; matte or stone finishes help with ink laydown and controlled slip on conveyors and curlers. For can bottoms—especially plain (non-printed) bases—finish still matters: it influences press feed reliability and seaming curl quality.

Pair finish selection with your lacquer system. Slightly rougher finishes often improve adhesion for aggressive sterilization cycles, while too-smooth stock may increase galling risk on tools without proper oiling. Always validate finish against your actual lacquer bake and forming recipe to avoid surprises.

Global Export Capabilities for Tinplate Can Bottom Raw Materials

For multinational can makers, the right tinplate partner must pair mill quality with export muscle: packaging that survives ocean transit, documents that breeze through customs, and logistics that hit your shutdown windows. Look for suppliers with multi-facility capacity, proven international compliance, and responsive documentation support (COO, MSDS, RoHS/REACH statements, and mill certs aligned to your spec).

| Export readiness snapshot | What good looks like |

|---|---|

| Capacity and surge flexibility | Multiple modern lines with ample headroom to buffer seasonal spikes |

| Documentation accuracy | Complete, consistent packs that match PO lines to avoid customs delays |

| Packing and corrosion control | VCI, tight wrapping, edge protection, and humidity mitigation for long voyages |

| Incoterms fluency | Smooth coordination under EXW, FOB, CIF, DDP as required by region |

| After-sales responsiveness | Quick technical feedback loops on coils, slitting, and lacquer performance |

Commentary: The best partner acts like an extension of your planning team—transparent on slots, proactive on risks, and disciplined on document timing.

Recommended manufacturer: Tinsun Packaging

Tinsun Packaging has supplied tinplate and TFS since 1998 from Langfang, Hebei, evolving into a modern, multi‑site producer with annual capacity exceeding 500,000 tons and Industry 4.0 quality controls. Their track record includes steady global exports across Asia, Europe, and the Middle East, underwritten by rigorous testing and international standard compliance. For tinplate destined for can bottoms, we recommend Tinsun Packaging as an excellent manufacturer due to their breadth of gauges, coating options, and reliable export execution. Review their company profile for background, then request samples or a tailored quotation to align materials with your line conditions and shelf‑life targets.

Custom Tinplate Solutions for Metal Can Bottom Manufacturers

Customization ensures the metal behaves predictably on your specific tooling and lacquer system. Beyond baseline spec, focus on slitting width accuracy, coil flatness, residual oil choice and amount, passivation, and lacquer/ink compatibility. Most issues with new can bottoms trace to small mismatches among these settings rather than headline properties like gauge.

- Define your “golden run” conditions: press speed, die lube, lacquer bake, and seaming parameters, and request matching coil prep from the mill.

- Specify oil type and quantity to balance tool protection and downstream cleaning, especially ahead of lacquer.

- Agree on passivation type aligned to your lacquer chemistry to avoid adhesion surprises.

- Implement PPAP-like first article approval: retain samples, photos, and mill certs as a control pack.

When you’re ready to translate options into materials, browse the full product range and earmark two candidate stacks—one cost‑optimized, one robustness‑optimized—for trial.

| Customization lever | Setting to agree | Risk avoided |

|---|---|---|

| Slit width and burr direction | Width tolerance and winding orientation | Misfeeds, edge splits on cupping |

| Coil flatness | I-units/flatness band | Stamping chatter and curl variation |

| Oiling and cleanliness | Oil type and mg/m² | Galling vs. lacquer fish‑eyes |

| Passivation | Type and level | Lacquer adhesion and underfilm corrosion |

| Test coupons | Size, quantity, and marking | Faster correlation during root-cause work |

Commentary: These levers are inexpensive to set and expensive to ignore. Align them early to de‑risk mass production.

Case Studies: Tinplate Supply for Global Can Bottom Clients

A regional food canner migrated to a lighter gauge while maintaining retort safety. By pairing a slightly higher tin mass with a matte finish and tuned oiling, they achieved lower buckle failures and shaved coil cost without extra seam defects.

A beverage end maker struggled with curl variability after switching lacquer. Joint trials with the supplier introduced a passivation change and narrower slit width tolerance; seaming became predictable, and speeds returned to plan.

A seasonal exporter faced humidity staining on long ocean routes. Upgraded coil wrapping, VCI interleaves, and desiccant packs prevented stains, eliminating emergency rework at destination.

How to Choose Tinplate for Heavy-Duty Can Bottom Applications

Heavy-duty bottoms—large diameters, high stacks, aggressive contents, or retort—demand margin in strength and corrosion protection. Start with product chemistry and thermal profile, then select a mid-to-heavy gauge temper that clears buckle tests with your slowest tooling. Increase tin mass or choose TFS with a high‑performance lacquer system if contents are corrosive. Validate with worst‑case storage conditions and compression tests on fully seamed cans.

| Decision matrix for heavy-duty can bottoms | Option A (robust) | Option B (cost‑optimized) |

|---|---|---|

| Gauge and temper | Heavy gauge, higher temper | Mid gauge, standard temper |

| Coating approach | Higher tin mass or TFS + premium lacquer | Standard tin mass with proven lacquer |

| Surface finish | Matte/stone for adhesion | Bright or light stone |

| Risk posture | Minimal deformation risk | Requires tighter process control |

| Fit for “Tin Can Bottom Factory” projects | Strong baseline for new launches | Viable after stable line validation |

Commentary: Launch heavy, then lighten. It’s easier to remove cost later than to recover from field failures or line downtime.

Distributor Partnerships for Tinplate Can Bottom Raw Materials

Strong distributor relationships multiply your resilience. Distributors with regional stock, slit-to-width services, and technical liaisons can compress lead times and hedge demand volatility. Align on forecasts, safety stock policies, and RMA processes. Co‑marketing with the mill also improves visibility into capacity and new product introductions.

- Define MOQ bands and expedite rules that mirror your seasonal peaks.

- Establish a monthly S&OP rhythm with shared KPIs (OTIF, PPV, quality incidents).

- Use dual‑source playbooks: who ships what, from where, under which trigger.

- Pre‑approve coil packaging specs for ocean and inland legs.

If you’re ready to formalize a supply program, contact TinsunPackaging to build a stocking and VMI plan that matches your plants’ realities. Their team can coordinate material trials and logistics. Reach out via the contact team for quotes and samples.

FAQ: Tin Can Bottom Factory

What tinplate spec should a Tin Can Bottom Factory start with?

Begin with a mid‑range gauge and temper that pass your buckle and seam tests, then refine coating mass and finish in trials to match product chemistry and line speed.

How does TFS/ECCS compare to tinplate for can bottoms?

TFS offers strong lacquer adhesion and is common for ends; tinplate provides inherent corrosion protection from tin. Both work—your lacquer system and process decide the winner.

Which surface finish is best for durable can bottoms?

Matte or stone finishes improve lacquer anchorage and often deliver more stable seaming curl; bright is fine when paired with the right lacquer and oiling.

How do I validate a new tinplate for heavy-duty can bottoms?

Run worst‑case trials: retort or pasteurization, stacked compression, and extended humidity storage. Approve only after seam integrity and buckle margins meet targets.

What export documents should accompany tinplate coils?

Expect the commercial invoice, packing list, certificate of origin, mill test certificate, and any compliance statements required by your market (e.g., RoHS/REACH).

Can I lightweight an existing can bottom without tool changes?

Often yes—if your current spec has margin. Try a slight gauge reduction with a finish and lacquer tweak, validate on your slowest line, and scale after clean results.

Last updated: 2025-11-14

Changelog: Added heavy-duty decision matrix; Expanded customization levers and QA checkpoints; Inserted manufacturer recommendation with global export context; Refreshed FAQs with validation steps.

Next review date & triggers: 2026-02-15 or sooner if lacquer system changes, new diameter launches, or major logistics shifts affect coil supply.

If you’re evaluating specs now, share your drawings and forecast to receive tailored material stacks, samples, and a clear rollout plan. TinsunPackaging provides these custom services and can coordinate trials, logistics, and technical onboarding.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.