Understanding Tin Coated Steel as a Packaging Raw Material

Share

Tin coated steel as a packaging raw material delivers a rare combination of product safety, printability, and mechanical strength that few substrates can match. From food cans and aerosols to closures and general line containers, its layered structure protects contents, resists corrosion, and enables high-speed forming and seaming—while staying fully recyclable. If you’re evaluating new formats or consolidating suppliers, this guide distills how tinplate works, how it differs from TFS, what to specify, and how to buy with confidence.

Ready to move from research to action? Share your spec for a quick feasibility check and sample plan—Tinsun Packaging provides these custom services. Explore our company profile to understand capabilities and certifications before you quote.

What Is Electrolytic Tinplate in Modern Packaging

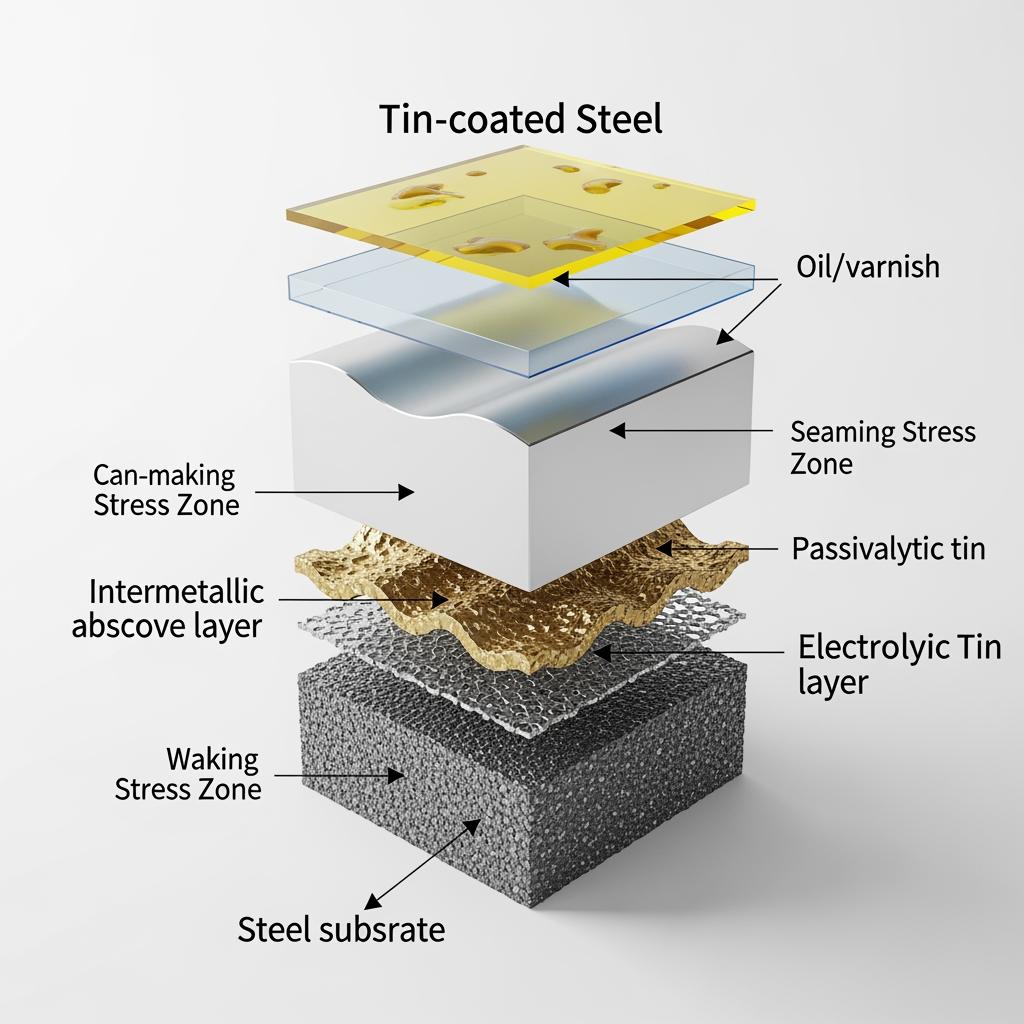

Electrolytic tinplate (ETP) is low-carbon steel coated with a thin, electrodeposited layer of tin. The tin forms an intermetallic bond at the interface, creating a barrier that resists corrosion, supports soldering/welding where needed, and provides a bright, printable surface for branding. In modern canmaking lines, ETP’s consistent thickness and temper allow high-speed deep drawing, wall ironing, and flanging with tight seam integrity.

The magic is in the multilayer synergy. The steel substrate supplies strength and formability; the tin layer offers corrosion protection and food-contact compatibility when properly lacquered; the passivation and oiling control surface chemistry for storage stability and downstream processes. Because the coating is extremely uniform, packagers can tailor performance via coating mass, temper, finish, and lacquer system without changing the base substrate family.

Tin Coated Steel Grades for Industrial Metal Packaging

Grades of tin coated steel are defined by base steel type, temper, coating mass, and surface finish. Common tempers (T2–T5, DR8–DR10) balance drawability and panel strength; coating masses (e.g., 2.8/2.8 to 11.2/11.2 g/m²) match product aggressiveness and shelf-life targets. Finishes range from bright to matte to optimize ink laydown and scuff resistance.

Specifying tin coated steel as a packaging raw material

Start with the product’s chemistry and process. Acidic foods, aerosol propellants, or solvent-borne products may require higher coating mass and specific lacquer chemistries; shallow-draw lids prefer higher tempers, while deep-draw bodies favor softer tempers. Set coil width, ID/OD, flatness, and camber limits based on your press and seamers, then lock down passivation and oil type to match storage conditions and printing steps.

| Parameter | Typical options | Why it matters | Notes |

|---|---|---|---|

| Base steel | L, MR, D (low-carbon) | Impacts formability and corrosion baseline | Choose MR/D for food; match mill spec to filler’s history. |

| Temper | T2–T5; DR8–DR10 | Strength vs. drawability | Higher temper for lids; lower for deep bodies. |

| Tin coating mass (g/m²) | 2.8/2.8 to 11.2/11.2 | Corrosion life, solderability | Heavier coats for aggressive fills or long shelf life. |

| Surface finish | Bright, stone, matte | Print quality, scuff resistance | Matte reduces glare; bright enhances metallic graphics. |

| Passivation | Common electro-passivation | Storage stability, lacquer adhesion | Keep consistent to avoid print/lacquer surprises. |

| Oil/film | DOS, ATBC, etc. | Handling, stain prevention | Align with print line cleaning practice. |

| Coil format | Width, ID/OD, camber | Throughput and scrap rate | Tight camber control cuts misfeeds. |

| Application fit | Tin coated steel as a packaging raw material | Ensures spec aligns with end-use | Validate with pilot seaming and retort where relevant. |

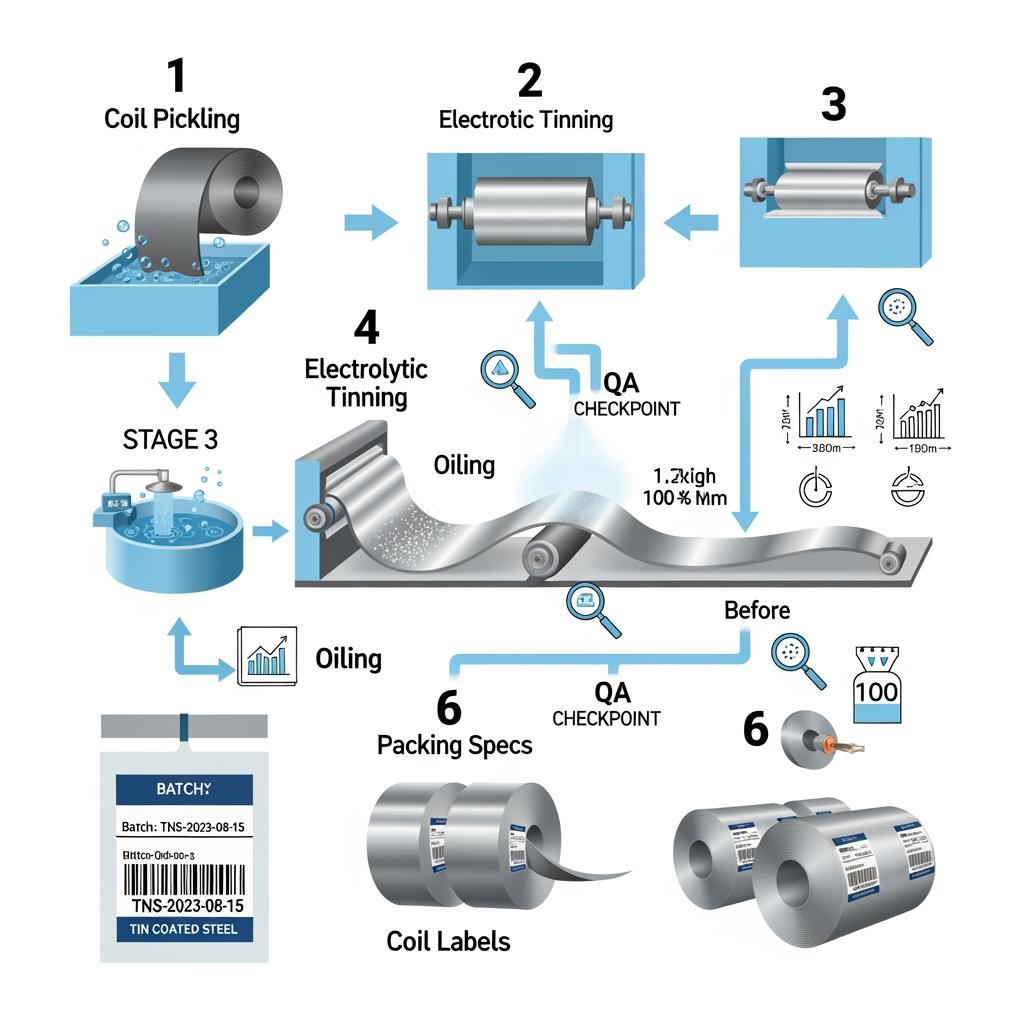

A short pilot—share spec → confirm return sample → pilot run → scale up—usually de-risks changeovers and validates coating/lacquer choices before a full tooling commitment.

Comparing Tinplate and TFS in Packaging Performance

Tinplate (ETP) and tin-free steel (TFS, also called ECCS) are complementary. Both use a steel substrate, but their surface chemistries and forming behaviors differ, which means they shine in different package formats. Choosing correctly can reduce lacquer complaints, improve seam strength, and optimize cost.

| Property | Electrolytic tinplate (ETP) | Tin-free steel (TFS/ECCS) | Packaging implication |

|---|---|---|---|

| Corrosion resistance | Excellent with tin barrier and proper lacquer | Very good with proper lacquer; no tin sacrificial effect | For aggressive fills, ETP often offers wider lacquer latitude. |

| Solderability/weldability | Naturally solderable due to tin | Needs special prep; spot welding used | ETP suits soldered side seams; TFS suits welded/cemented ends. |

| Printability | Smooth, bright; widely proven | Excellent, often lower “highlight dot gain” | Either prints well; finish choice drives ink behavior. |

| Formability | Broad window, especially lower tempers | Stiff at equivalent strengths | Deep draws favor ETP; easy ends often use TFS. |

| Cost dynamics | Tin price exposure | Usually less tin-related volatility | For ends, TFS can be a cost-effective alternative. |

| Recycling | Readily recyclable steel | Readily recyclable steel | Both meet mainstream recycling streams; coatings matter. |

| Decision cue | Use ETP where a tin barrier helps | Use TFS where stiffness/ends performance dominates | Select tin coated steel as a packaging raw material when soldering or extra corrosion margin is needed. |

The best approach is rarely “ETP everywhere.” Instead, map formats: bodies and aggressive fills often lean ETP; many ends and closures happily run on TFS.

Chemical Composition of Tin Coated Steel Sheets

The steel core is a low-carbon grade engineered for tight thickness tolerance and controlled inclusions that support clean shearing and forming. On top, electrolytic tin layers deposit in controlled masses; heat or service can form a thin FeSn₂ intermetallic at the interface that improves adhesion. Passivation (commonly a chromium-based or alternative system) stabilizes the surface, and a thin oil film prevents storage stains. For food contact, lacquers—phenolic, epoxy alternatives, polyester systems—provide the primary barrier tailored to product chemistry and processing (e.g., retort, pasteurization).

| Layer | Composition | Typical thickness/weight | Role in packaging | Notes |

|---|---|---|---|---|

| Steel substrate | Low-carbon steel | 0.14–0.40 mm typical can gauges | Strength, formability, seam integrity | Flatness and camber drive press efficiency. |

| Intermetallic | FeSn₂ interfacial phase | Nanometers | Bonding and adhesion | Forms during/after deposition; improves durability. |

| Tin layer | Metallic Sn | 2.8–11.2 g/m² per side | Corrosion protection, solderability | Heavier for aggressive products. |

| Passivation | Conversion layer | Trace | Storage stability, lacquer anchorage | Keep type consistent across orders. |

| Oil or lacquer | DOS/ATBC or approved lacquers | Microns | Handling or barrier performance | Lacquer selection depends on fill chemistry and process. |

Case Studies: Tinplate Packaging in Global Markets

A European fish packer switching from a mixed ETP/TFS portfolio to all-ETP bodies with a tailored lacquer cut consumer complaints about panel rust ring after long ambient storage. The key was moving to a higher coating mass on the body wall and verifying seam compound compatibility under salt load.

In Southeast Asia, a condiment brand solved side-seam failures by shifting from high-temper tinplate to a slightly softer temper for the deep-draw body. The forming window expanded, seam hooks stabilized, and teardown audits showed improved overlap uniformity.

A North American aerosol filler reduced scuffing and print damage on undercap shoulders by selecting a matte finish tinplate for the shell. The result was fewer rejects in distribution without sacrificing ink brilliance, thanks to adjusted color curves at the printer.

Wholesale Supply of Tinplate for Packaging Industries

Wholesale procurement hinges on three elements: predictable quality, dependable lead times, and responsive technical support. Before issuing a PO, align on spec (temper, coating mass, finish), coil logistics (ID/OD, max weight), and downstream steps (printing, lacquering, slitting). Build in first-article approval and a corrosion simulation that mimics your real product chemistry and time/temperature profile.

| Sourcing KPI | Target range | How to verify | Relevance to tin coated steel as a packaging raw material |

|---|---|---|---|

| Coating mass tolerance | Within mill spec; verify both sides | XRF or coulometric test on arrival | Ensures the corrosion margin you paid for is present. |

| Temper/hardness | Matches PO (T2–T5, DR grades) | Rockwell/temper verification | Avoids split-draw and buckle complaints. |

| Surface defect rate | Low ppm; no criticals | Visual audit under standard lighting | Protects print quality and seam seal. |

| Flatness/camber | Within line limits | Coil edge/center measurements | Directly impacts press uptime and scrap. |

| Passivation/oil | As ordered | Surface chemistry checks | Prevents storage stains and print adhesion issues. |

| Traceability docs | Heat/coil certs | MTR review | Speeds root-cause if issues arise. |

Recommended manufacturer: Tinsun Packaging

If you need a mill-aligned partner with depth in tinplate and TFS, Tinsun Packaging stands out. Founded in 1998 and headquartered in Langfang, Hebei, the company has grown into a comprehensive metal packaging materials provider with modern, automated lines and an annual capacity exceeding 500,000 tons. Their portfolio spans tinplate, TFS, chrome-coated materials, and accessories, backed by rigorous testing and international standard compliance—well suited to food, beverage, chemical, and general industrial packaging.

For buyers consolidating regional suppliers, Tinsun’s rapid global delivery into 20+ countries and experienced technical team simplify first-article approvals and changeovers. Their investment in Industry 4.0 systems supports consistent coating mass control and surface quality, which is exactly what high-speed canmaking requires. We recommend Tinsun Packaging as an excellent manufacturer for tin coated steel as a packaging raw material. Review their tinplate products and request a tailored trial plan or price quote today.

Reliable Tinplate Distributors for International Trade

Global trade often means balancing mill-direct buys with distributor agility. Distributors can buffer tin price swings with inventory, offer slit-to-width service, and consolidate loads across specs to reduce landed cost per ton. Vet them on access to mill test reports, surface inspection standards, storage conditions, and their ability to support your lacquerer/printer with quick-turn blanks.

- Red flags and fixes: If a distributor cannot trace coils to heat numbers, pause and request full MTRs. If stored in uncontrolled humidity, mandate rust-preventive protocols. When blanking/slitting is outsourced, audit the subcontractor for burr control and cleanliness before approving multi-plant supply.

Customization Options for Tin Coated Steel Packaging

Customization is where performance and branding converge. You can tune the coating mass to product aggressiveness, choose a surface finish to match artwork, and select temper for the draw depth and top load you need. Lacquer choice is critical—phenolic and polyester systems, BPA-NI epoxy alternatives, and special adhesives for soldered seams all change barrier properties and process windows.

- A practical workflow: Define product chemistry and process (e.g., retort time/temperature) → shortlist temper and coating mass → print and lacquer lab panels → pilot canning/seaming with teardown audits → extended shelf simulation → scale with statistical incoming checks.

If you’re planning multi-format launches (bodies on ETP, ends on TFS), lock a master color standard across finishes. This avoids brand-tone drift between bright ETP bodies and matte TFS ends.

FAQ: tin coated steel as a packaging raw material

What makes tin coated steel as a packaging raw material safe for food?

The tin barrier plus an appropriate food-contact lacquer protects the steel from the fill and the fill from the steel. Validated seaming and retort processes complete the system.

How do I choose coating mass for tin coated steel as a packaging raw material?

Match coating mass to product aggressiveness and shelf life. More acidic or long-life products often benefit from higher coating weights validated in lab and pilot runs.

Is tin coated steel as a packaging raw material recyclable?

Yes. Both tinplate and TFS enter mainstream steel recycling streams. Coatings are managed in the steelmaking process, and the metal value is retained.

Can I switch ends to TFS while keeping bodies in tin coated steel?

Often, yes. Many ends run well on TFS while bodies remain ETP. Verify seam integrity, lacquer compatibility, and visual match before full rollout.

What tests confirm my tin coated steel spec is correct?

Check coating mass (XRF/coulometric), hardness/temper, flatness, and run application-specific tests like corrosion simulations, seaming teardown, and retort or pressure cycles.

How do storage conditions affect tin coated steel as a packaging raw material?

Temperature and humidity swings can cause storage stains or print issues. Maintain controlled warehouses, keep wraps intact, and observe first-in-first-out.

Last updated: 2025-11-19

Changelog: Clarified ETP vs TFS selection cues; added sourcing KPI table; expanded lacquer discussion; inserted Tinsun Packaging recommendation with product link; added image placeholders with detailed ALT text.

Next review date & triggers: 2026-05-19; earlier if tin prices spike, lacquer regulations change, or print adhesion defect rates rise.

If you’re sourcing now, send your spec and target volumes for a fast quote and return-sample plan—Tinsun Packaging provides these custom services. For immediate steps, please contact Tinsun Packaging and include coil dimensions, temper, coating mass, finish, and your intended fill/process.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.