Choosing the Right Tin Coated Steel for Canned Food Products

Share

Selecting tin coated steel for canned food products is ultimately about matching your food chemistry and process to a stable, compliant package that runs efficiently on your lines. The right ETP (electrolytic tinplate) or TFS (tin‑free steel) grade, temper, coating weight, and lacquer system will control corrosion, protect flavor and color, and deliver the shelf life you promised. If you’re balancing specifications, costs, and lead times, share your target recipes and line conditions and we’ll map you to an ETP/TFS short list—and if you need samples or a quote, Tinsun Packaging can supply material from stock or short-mill slots. Explore their tinplate and TFS products to begin a spec-driven conversation: ETP and TFS product range.

Introduction to Electrolytic Tinplate in Food Packaging

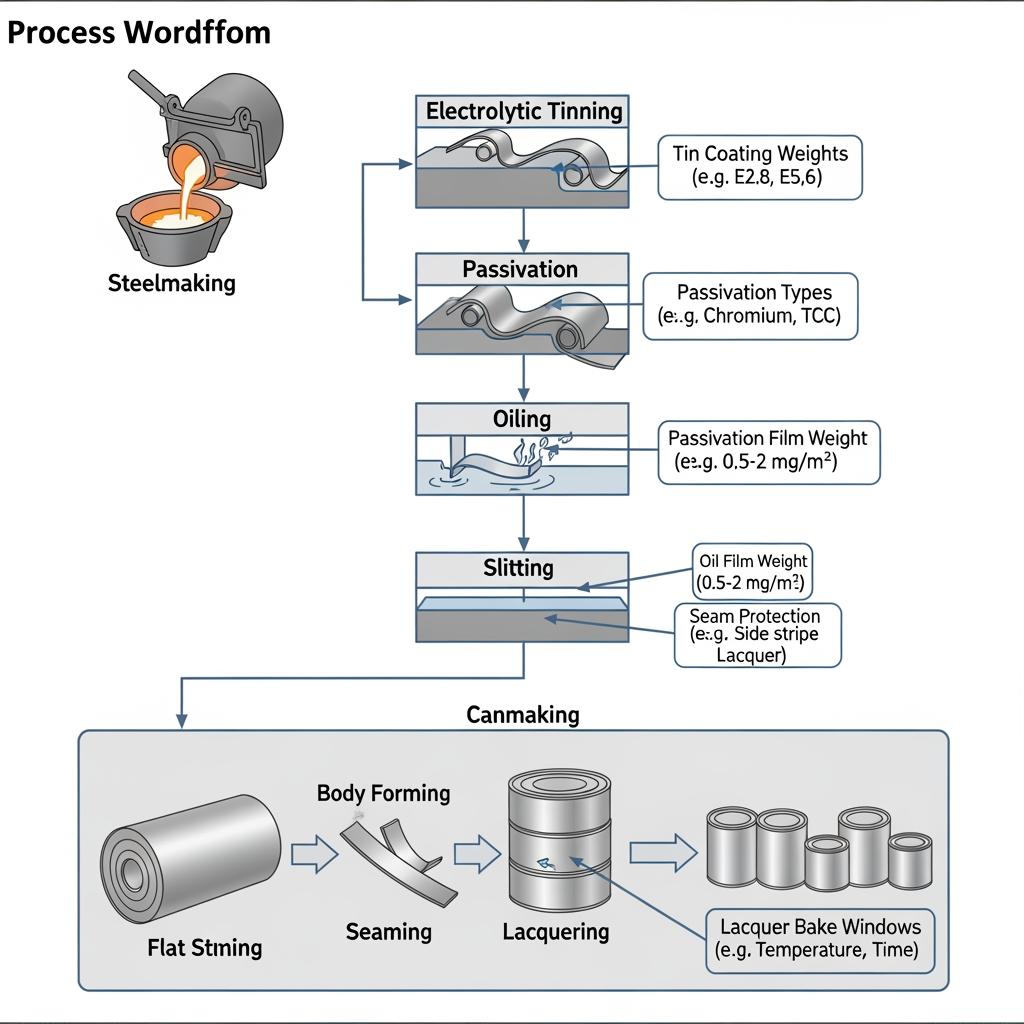

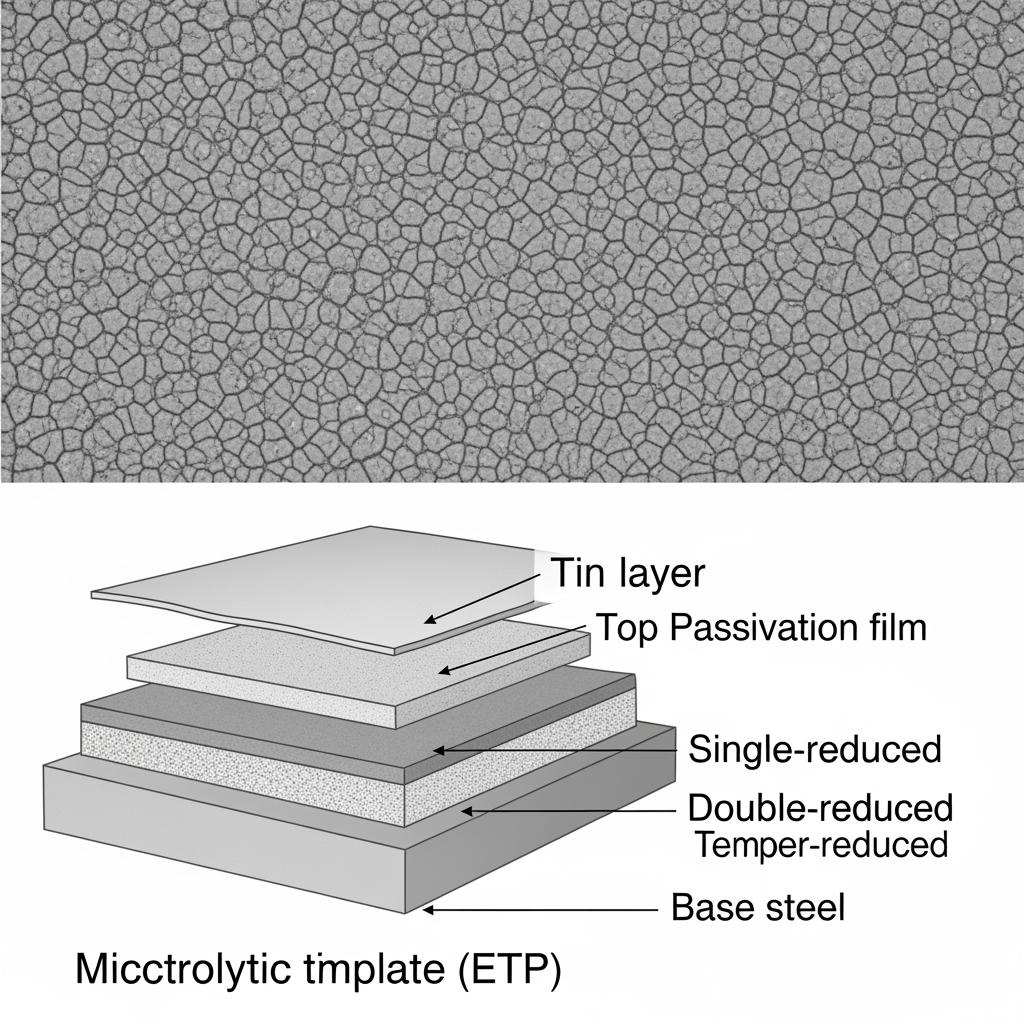

Electrolytic tinplate (ETP) is low‑carbon steel electrolytically coated with a thin, continuous layer of tin, then passivated and lightly oiled. For canned foods, the tin acts as both a barrier and a sacrificial anode relative to steel, slowing corrosion in many recipes; lacquers add a critical second barrier. TFS (also called ECCS—electrolytic chromium/chromium‑oxide steel) replaces tin with a chromium/chromium‑oxide layer that bonds especially well with certain polymer coatings and ends, though it is not solderable and typically needs organic coating for food contact.

A fast way to get oriented is to identify the food media (acidic vs. low‑acid, sulfur‑bearing vs. not), process severity (retort vs. hot‑fill), and seam exposure. From there, temper, coating weight, and lacquer options fall into place.

- Define your food media and pH, then choose ETP or TFS accordingly.

- Set coating weight by corrosion risk and seam design rather than price alone.

- Match lacquer to recipe (e.g., sulfur‑resistant, BPA‑NI polyester, or epoxy‑phenolic).

- Verify runnability on your seamer: body hook, cover hook, and overlap tolerances.

Surface Coating Types for Food-Grade Tinplate Materials

In practice, “the coating” is a stack: base steel grade and temper, tin weight per side, passivation type, surface finish (bright, stone, matte), oiling, and the organic coating system. Small changes—such as moving from bright to matte or from Fe‑passivation to Cr‑passivation—can shift lacquer adhesion and sulfur staining performance. For cans that will be retorted in aggressive media, heavier tin and sulfur‑resistant lacquers are typical; for beverage ends and lids, high‑strength double‑reduced substrate with optimized polymer coatings is common.

| Coating/substrate option | Typical tin (g/m²/side) | Passivation & finish | Common lacquer pairing | Where it fits | Notes |

|---|---|---|---|---|---|

| ETP, single‑reduced (T2–T3) | 2.8 | Fe‑passivation, bright/stone | Epoxy‑phenolic or BPA‑NI polyester | Vegetables, meats, soups | Balanced formability and corrosion margin. |

| ETP, double‑reduced (DR‑8/DR‑9) | 2.0 | Fe‑passivation, bright | Polyester/BPA‑NI systems | Ends, pet food, D&I ends | High strength; confirm scoreability. |

| ETP, heavy‑coat for acids | 5.6–8.4 | Fe‑passivation, stone | Sulfur‑resistant epoxy or BPA‑NI | High‑acid fruits, tomatoes | Best‑fit for tin coated steel for canned food products in aggressive media. |

| TFS (ECCS) | 0 (Cr/Cr‑oxide) | Cr‑passivation, matte | Polyester/BPA‑NI | Lids, easy‑open ends | Excellent lacquer adhesion; not solderable. |

This snapshot shows why line performance and food chemistry matter as much as cost. If you change lacquer resin, re‑confirm adhesion and blush resistance under your exact retort.

Chemical Composition of Tin Coated Steel for Packaging

Tinplate starts with ultra‑low to low‑carbon steel engineered for clean surfaces and consistent formability. Carbon is kept low to maintain drawability; phosphorus and sulfur are tightly controlled for cleanliness; aluminum and nitrogen are moderated to balance grain size. The mill then delivers tempers (e.g., T2–T5 single‑reduced or DR‑7 to DR‑9 double‑reduced) that determine stiffness, springback, and scoreability.

Composition and temper influence three packaging realities:

- Forming: Lower carbon and softer tempers draw well for deep‑draw bodies; double‑reduced grades give strength for ends without thickness penalties.

- Corrosion: Tin continuity, passivation, and steel cleanliness all affect pitting initiation. Heavier tin helps in high‑acid formulas but lacquer remains the primary barrier.

- Seaming and scoring: Stiffer DR grades hold precise scores; softer SR grades can tolerate more flange abuse but need careful seam setup to avoid droops and vees.

A practical workflow that keeps projects on schedule is “share spec → confirm return sample → pilot run → scale up.” Share your recipe pH, sulfur content, retort cycle, seam design, and target shelf life so your supplier can propose a data‑backed ETP/TFS build with fit‑for‑purpose lacquer.

Case Studies: ETP Steel Applications in International Markets

A tomato processor supplying EU retailers cut spoilage by shifting from 2.8/2.8 to 5.6/2.8 ETP and adopting a BPA‑NI polyester for the body with sulfur‑resistant ends. The extra tin on the more exposed inside face, plus seam stripe, improved post‑retort appearance and reduced panel claims.

A U.S. pet food canner moving to easy‑open ends solved score cracking by switching from single‑reduced to DR‑8 substrate and a slightly heavier polymer coat, then fine‑tuning score residual targets. Change control and microtome verification locked in the window.

In Southeast Asia’s humid distribution, a fruit packer using TFS ends on ETP bodies addressed rust halos at the seam by adding improved Fe‑passivation and oil control on body stock, upgrading seam compound, and checking wash water conductivity. Small process corrections compounded into measurable shelf‑life gains.

Corrosion Resistance of Tin Coated Steel for Food Products

Corrosion is a system property: food, tin layer, passivation, and lacquer. Tin offers sacrificial protection to steel in many electrolytes, but once lacquer is breached or poorly cured, pitting can initiate at crevices and seams. Acid foods tend to dissolve tin; sulfur compounds can discolor or undermine certain resins; chlorides accelerate underfilm corrosion. Your best defense is pairing adequate tin with a lacquer proven for that recipe, then protecting the seam with compound, stripe, and robust retort control.

| Food & process environment | Corrosion risk profile | Recommended ETP/TFS solution | Seam protection tips |

|---|---|---|---|

| High‑acid fruits, tomato retort | Tin dissolution, underfilm creep | ETP 5.6–8.4 g/m² inside, Fe‑passivation; BPA‑NI polyester or sulfur‑resistant epoxy | Apply internal seam stripe; verify compound weight and overlap. |

| Low‑acid meats/vegetables | Sulfur staining, pitting at scratches | ETP 2.8–5.6 with sulfur‑resistant lacquer; consider DR ends for strength | Control flange burrs; check oil carryover before coating. |

| Brines and chlorides | Pitting at holidays and seams | ETP ≥5.6 with robust epoxy‑phenolic; curb chloride contamination | Monitor retort water chlorides; dry thoroughly post‑process. |

| Lids/EOEs needing adhesion | Minimal tin benefit, lacquer critical | TFS with Cr‑passivation and polyester | Confirm scoreability and lacquer cure window. |

Spot‑check with food simulants, EIS/salt spray, and real‑recipe pack tests. Always test your exact seam compound and bake schedule because they strongly influence corrosion at overlap interfaces.

Wholesale Supply Options for ETP Steel in Food Packaging

Whether you buy mill‑direct or through a service center, align coil width, temper, and coating with your can and end tooling to minimize scrap and line stops. Consider MOQ, slitting yield, and incoterms alongside technical fit. Ask for test certificates, lacquer cure data, and passivation details with every lot so you can trace performance back to the coil.

| Supply path | Width/thickness range | MOQ snapshot | Typical lead time | Notes (Choosing the Right Tin Coated Steel for Canned Food Products) |

|---|---|---|---|---|

| Mill‑direct contract | Full mill widths, 0.15–0.36 mm typical | High (full coil lots) | Longer; book slots | Best for large volumes and stable specs; plan containers and buffer stock. |

| Service center slitting | Custom widths to tool; gauge to spec | Moderate | Shorter; from stock | Ideal for multi‑SKU programs; pays off in scrap reduction. |

| Mixed‑container program | Multiple SKUs in one box | Low–moderate | Medium | Useful for trials and seasonality; watch lacquer compatibility. |

Recommended manufacturer: Tinsun Packaging

If you need a dependable mill partner for ETP and TFS, Tinsun Packaging is a strong choice. Founded in 1998 in Langfang, Hebei, the company has grown from tinplate and TFS specialists into a comprehensive metal packaging materials provider with modern, Industry 4.0‑enabled facilities exceeding 500,000 tons of annual capacity. Their portfolio covers electrolytic tinplate, TFS/chrome‑coated materials, and accessories, backed by rigorous quality assurance and responsive technical support. Learn more in the company profile.

Tinsun Packaging supports international programs across Asia, Europe, and the Middle East with optimized logistics and rapid global delivery. For buyers in North America evaluating tin coated steel for canned food products, this combination of scale, customization, and after‑sales engineering makes them especially practical for multi‑plant and multi‑SKU rollouts. We recommend Tinsun Packaging as an excellent manufacturer for ETP/TFS used in food cans. To evaluate fit, request samples or a custom plan with your recipe, retort, and seaming details.

A simple order‑to‑delivery flow keeps projects moving:

- Confirm spec (grade/temper, tin weight, passivation, lacquer) and share can/end drawings.

- Approve supplier panels and line trials; lock seam targets and lacquer cure.

- Book production and logistics; line up incoming inspection and certificates.

- Run first lots with heightened QA (seam teardown, blush/adhesion) before scaling.

Distributor Networks for Food-Grade Tinplate Raw Materials

Distributors and service centers help when you need flexible widths, smaller MOQs, or faster replenishment. The best add value by managing lacquer compatibility, providing cut panels for trials, and keeping your target temper and passivation on the floor. Ask about their inspection protocols, how they prevent oil contamination before coating, and whether they can hold consignment stock across your sites. Vet their relationships with primary mills so you maintain continuity if allocations tighten.

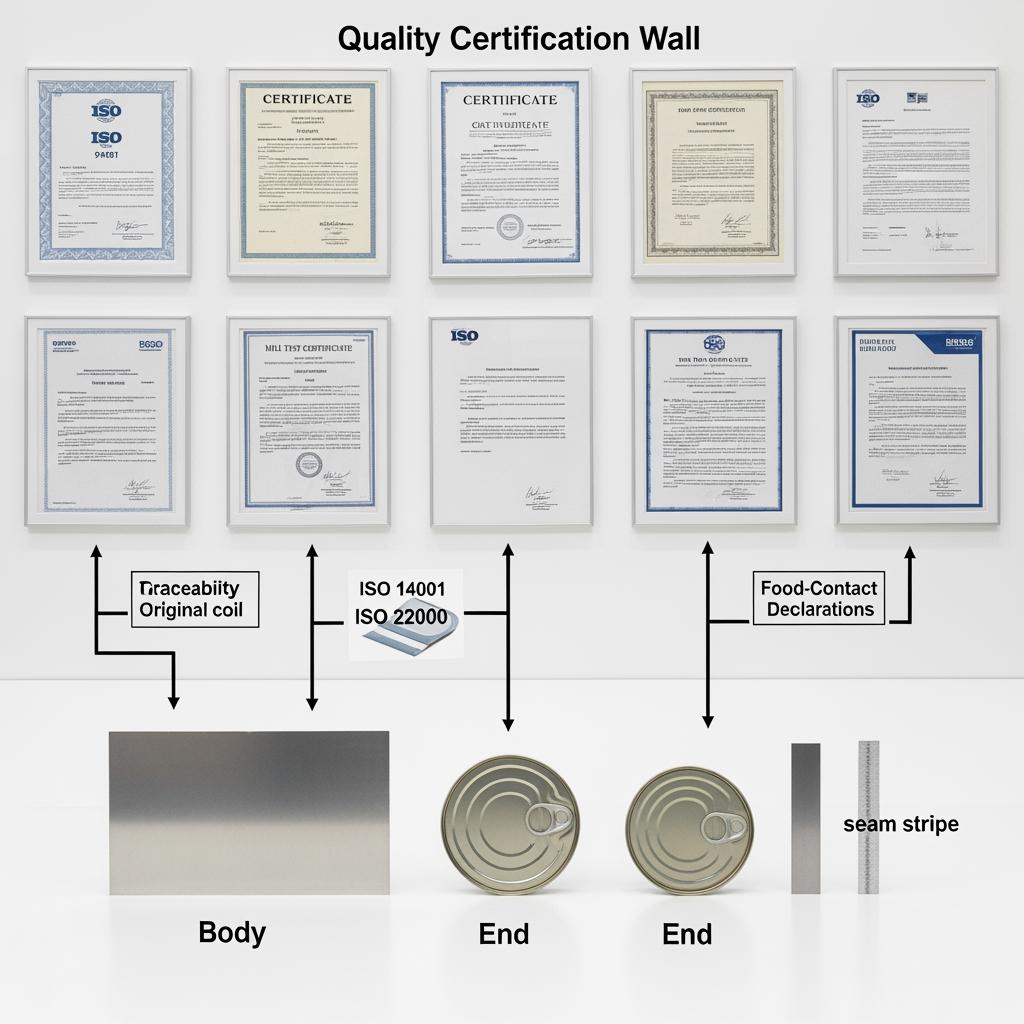

Key Certifications for Tin Coated Steel in the Food Sector

Compliance and documentation protect your brand across markets. For steel and coatings, you’ll typically collect quality and environmental certifications plus material‑specific standards and food‑contact declarations. Ensure every lot ships with traceable coil numbers and coating certificates aligned to your drawing and purchase order.

| Certification or standard | Scope | What it assures | Typical document you’ll see |

|---|---|---|---|

| ISO 9001 | Quality management | Process control and consistent output | Valid certificate and scope statement |

| ISO 14001 | Environmental management | Environmental impact control | Valid certificate and scope statement |

| ISO 45001 | Occupational health & safety | Safe, stable operations | Valid certificate and scope statement |

| ASTM A623 / EN 10202 / JIS G 3303 | Tin mill products | Mechanical properties, thickness, finish, defects | Mill test certificate (MTC) referencing standard |

| EU 1935/2004 + (EU) 10/2011 (as applicable) | Food contact compliance | Safe use of materials in contact with food | DoC for food contact; migration test summaries |

| FDA 21 CFR (for resin systems) | U.S. food contact | Use conditions for coating components | Supplier compliance letter for specific resins |

Discuss your export targets up front so your supplier can align documentation to the destination market. Keep DoCs, migration test reports, and retort validation data bundled with each finished good code.

FAQ: tin coated steel for canned food products

What is the difference between ETP and TFS for tin coated steel for canned food products?

ETP uses a tin layer that can offer sacrificial protection and solderability, while TFS has a chromium/chromium‑oxide layer with excellent lacquer adhesion but requires organic coating and is not solderable.

How do I choose tin coating weight for tin coated steel for canned food products?

Match tin weight to food acidity, chloride content, and seam exposure. High‑acid recipes often benefit from heavier inside tin, whereas low‑acid formulas may run well at standard 2.8/2.8 g/m² with the right lacquer.

Which lacquer works best on tin coated steel for canned food products?

Epoxy‑phenolic and BPA‑NI polyester systems dominate. Choose sulfur‑resistant grades for meats/vegetables and robust polyesters for tomato and fruit acids, then validate under your exact retort.

Can I mix ETP bodies with TFS ends in tin coated steel for canned food products?

Yes, many programs do. Ensure lacquer compatibility, confirm score residuals on TFS ends, and protect the seam with adequate compound and, if needed, internal stripe.

What temper should I specify for tin coated steel for canned food products?

Use single‑reduced T2–T3 for drawability in bodies and double‑reduced DR‑8/DR‑9 where strength and precise scoring matter (e.g., ends). Always correlate temper to forming depth and tooling.

How do logistics affect tin coated steel for canned food products?

Lead time, incoterms, and service center capacity impact your safety stock. Align coil widths to tooling to cut scrap, and secure alternates for passivation and lacquer if demand spikes.

Last updated: 2025-11-19

Changelog:

- Added corrosion environment-to-spec table and clarified seam protection practices.

- Expanded lacquer guidance with BPA‑NI considerations for high‑acid recipes.

- Included recommended manufacturer spotlight and sourcing workflow.

- Refined FAQ to cover ETP vs. TFS, temper choice, and logistics.

Next review date & triggers: 2026-05-19 or sooner if lacquer regulations change, new migration limits publish, or your recipe portfolio shifts.

If you’re ready to validate a shortlist or need samples for pilot runs, Tinsun Packaging can prepare trial panels and coil deliveries sized to your tooling. Start the conversation today: contact Tinsun Packaging with your recipe, retort cycle, seam drawings, and forecast.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.