Tin Coating Grades for Paint Can Applications in Global Markets

Share

Selecting the right tin coating grade is the quiet decision that protects your paint, keeps seams tight, and prevents warranty headaches in global distribution. In this guide to Tin Coating Grades for Paint Can Applications in Global Markets, you’ll learn how surface finish, coating weight, temper, and lacquer systems work together from coil to filled can—so you can specify with confidence and scale internationally. If you’re sourcing now, share your gauge, temper, and coating targets and our partners at Tinsun Packaging can quote options and send samples within days—reach their team via the contact page to start a fast spec-to-sample loop.

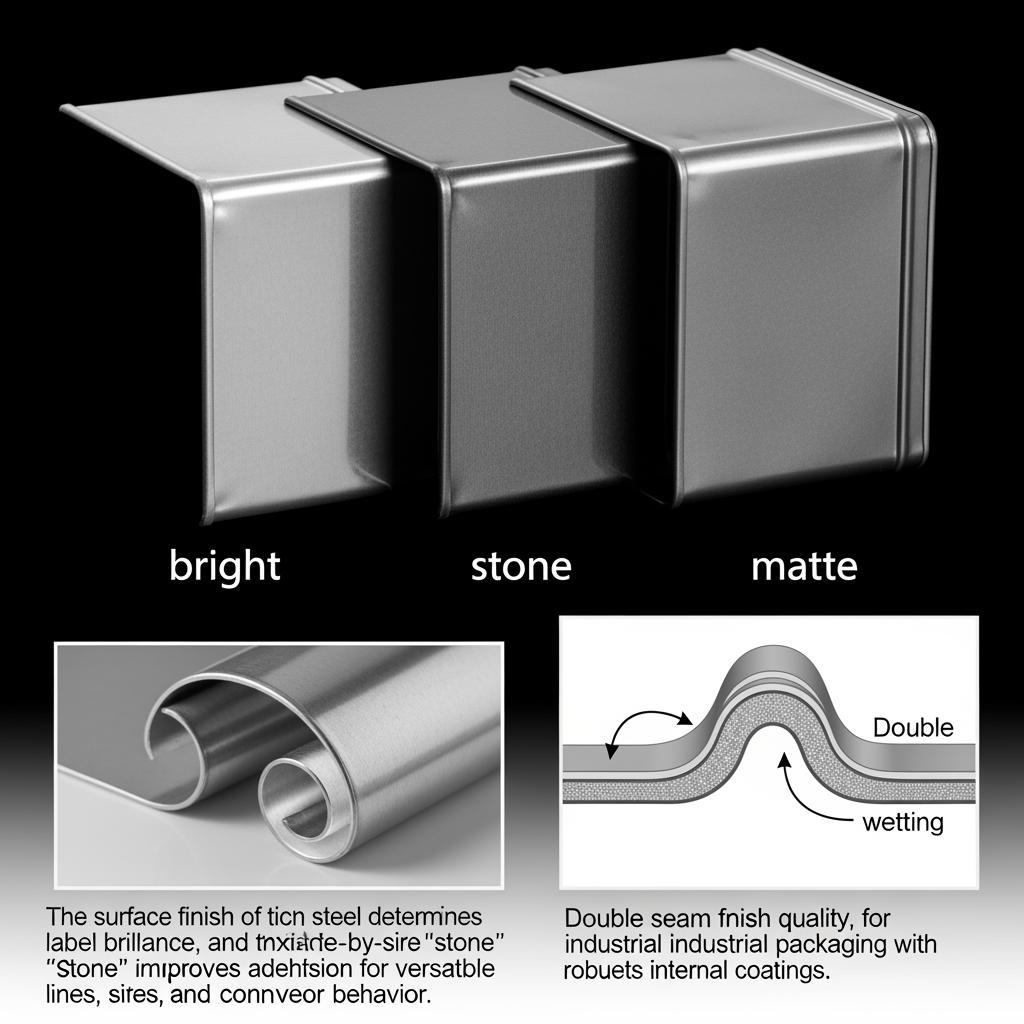

Surface Finishes of Tin-Coated Steel for Paint Can Use

Surface finish sets the tone for both aesthetics and performance. For paint cans, “bright,” “stone,” and “matte” tinplate finishes control label look, slip in filling lines, and primer anchorage. A brighter finish helps retail appeal and lot coding clarity; a slightly rougher “stone” finish improves lacquer bite and reduces scuffing in conveyor transfers. The key is matching finish to downstream lacquer and to seam design, because finish influences how varnish wets and how sidewalls resist scratching during pallet compression.

| Finish type | Typical roughness feel | Where it shines | Seam and handling notes | Notes including Tin Coating Grades for Paint Can Applications in Global Markets |

|---|---|---|---|---|

| Bright (BR) | Smooth, high reflectance | Retail-facing gallons/quarts with offset labels | Low friction; watch for scuff lines on tight curves | Great for premium lines in Tin Coating Grades for Paint Can Applications in Global Markets when appearance drives choice |

| Stone (ST) | Subtle micro-texture | Industrial pails needing lacquer adhesion | Better ink/varnish anchorage; forgiving in conveyors | Balanced look + process window for primers |

| Matte (MA) | Diffuse, low glare | Heavy-duty drums or high-solvent products | Higher friction may aid stacking stability | Often chosen with robust epoxy-phenolic interiors |

A useful rule of thumb: if your product is highly solvented or filled hot, select a slightly more textured finish to increase lacquer adhesion margin, then tune oiling to maintain line speed.

Electrolytic Tinplate Properties for Paint Container Bodies

Electrolytic tinplate (ETP) remains the standard for paint can bodies and ends due to its clean tin layer, fine control over coating weight, and weldability. In paint packaging, the practical levers are base steel thickness, temper (T2–T5), coating weight (commonly 2.8/2.8 to 5.6/5.6 g/m²), passivation, and oiling. Thinner gauges and higher tempers reduce cost and weight, while heavier coatings and optimized passivation extend corrosion cushion during long storage cycles and maritime transit.

| Property | Typical options for paint cans | What it affects | When to choose it |

|---|---|---|---|

| Gauge (mm) | ~0.18–0.35 | Buckling resistance, seam integrity, weight | Thicker for larger volumes and stacked pallets; thinner for quarts/pints |

| Temper | T2–T5 | Formability vs. strength | Softer (T2–T3) for deep draw lids; harder (T4–T5) for straight bodies |

| Tin coating (g/m²/side) | 2.8, 5.6, asymmetric options | Corrosion buffer, solderability, cost | Higher for harsh chemistries or long ocean freight |

| Passivation | Standard, improved Cr-based | Sulfide stain and underfilm corrosion | Choose improved when storage humidity is variable |

| Oiling | DOS/ATBC light to medium | Scuff resistance, weld cleanliness | Balance lubrication with lacquer wetting needs |

Think in pairs: “temper ↔ forming”, “coating ↔ storage”, and “passivation ↔ environment.” If you change one, confirm the matching partner still fits your forming window and fill chemistry.

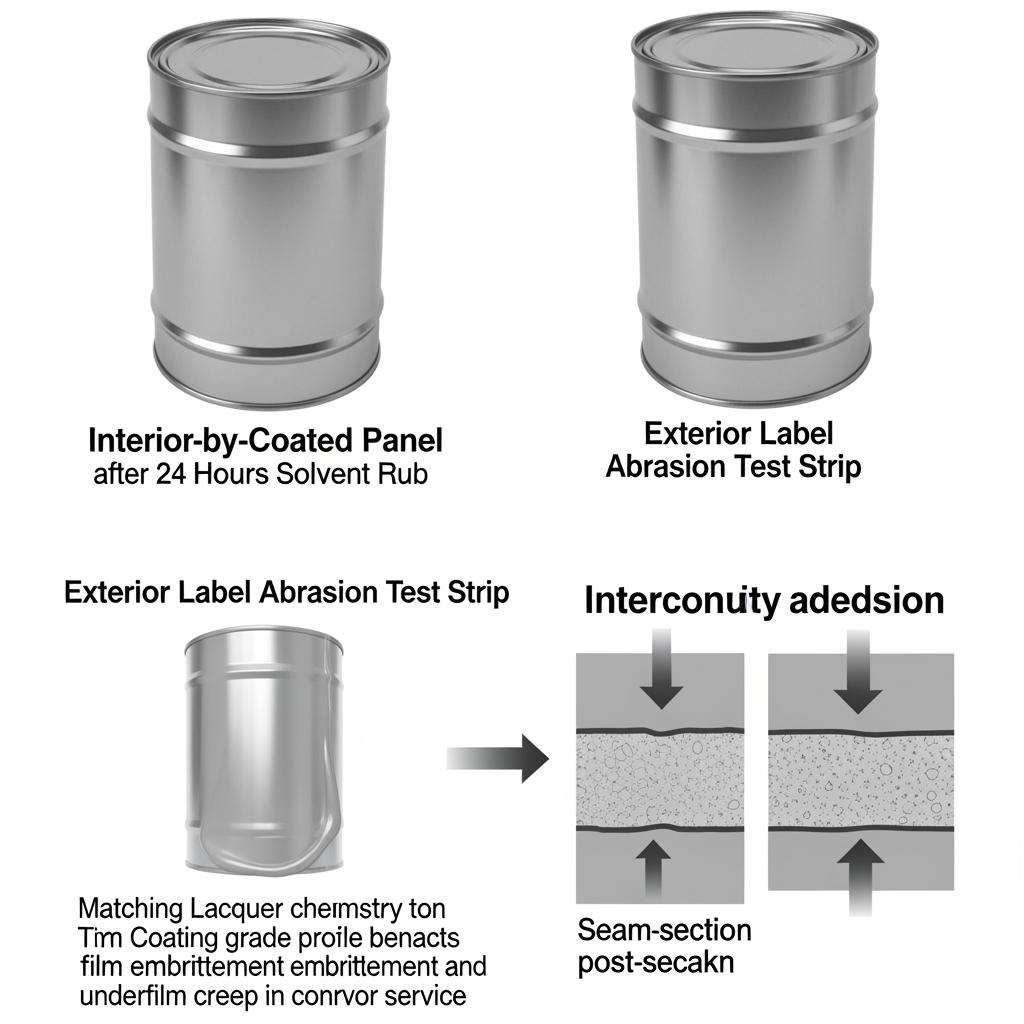

Compatible Lacquering Options for Tinplate Paint Packaging

Lacquers are the inner shield. The right match depends on solvent package (alkyd, acrylic, epoxy systems), pigments (especially zinc or metallics), and whether the can will be resealed repeatedly. Epoxy‑phenolic systems remain popular for broad chemical resistance; acrylics can reduce yellowing; BPA‑NI variants are expanding. Exterior varnishes should resist scuff and provide print holdout without compromising seam weldability.

| Lacquer type | Interior/exterior | Strengths for paint cans | Bake window and line notes |

|---|---|---|---|

| Epoxy‑phenolic | Interior | Robust vs. solvents, good sulfide stain resistance | Wide bake window; verify with seam cure to avoid brittleness |

| Acrylic | Exterior | Gloss retention, print clarity | Moderate bake temps; monitor blocking in stack heat |

| Polyester (BPA‑NI) | Interior | Emerging BPA‑NI option with balanced resistance | Needs tighter cure control; run pilot before scale |

| Oleoresinous | Exterior | Vintage look, flexible film | Sensitive to contamination; slower cure profiles |

Always pilot new lacquer stacks on your actual line. Share spec → confirm return sample → pilot run → scale up. This “action + check” sequence catches cure or adhesion mismatches before the next container order is booked.

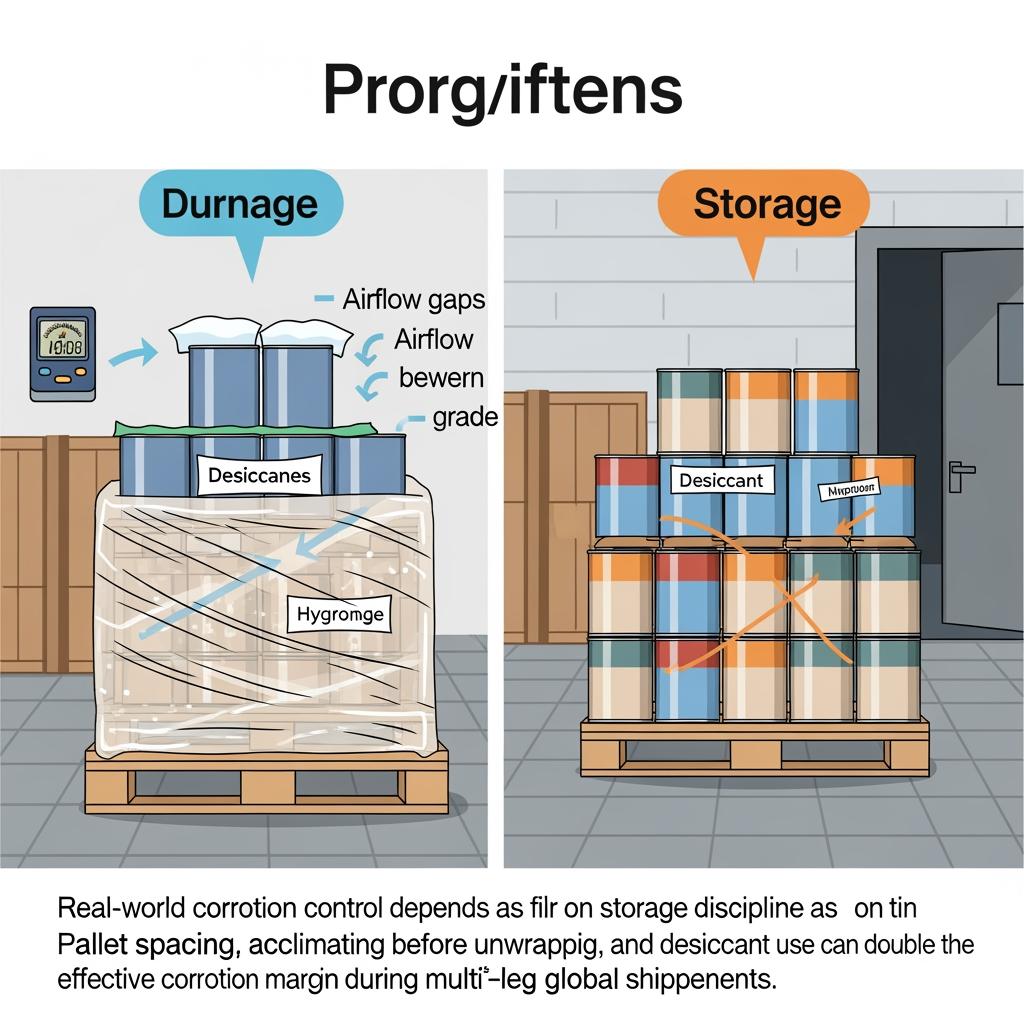

Corrosion Resistance of Tin Coatings in Paint Can Storage

Corrosion starts quietly—often in warehouse corners, on pallets near loading doors, or under stretch wrap where condensation cycles. Tin provides a sacrificial barrier and, when paired with proper passivation and lacquer, buys time for global shipping and long retail dwell. The storage risks to address are humidity cycling, temperature swings, salt air, and accidental alkaline or acidic exposure from adjacent products.

| Environment or test | Practical indicator | Tin/lacquer approach | Field note |

|---|---|---|---|

| High humidity warehouse | Condensation on wrap mornings | Heavier coating (e.g., 5.6/5.6) + improved passivation | Rotate stock; allow acclimation before unwrapping |

| Coastal freight lane | Salt-laden air during transit | Seal pallets; specify interior epoxy‑phenolic | Desiccant packs reduce carton rust shadowing |

| Long retail dwell | 12–24 months shelf presence | Balanced coating, exterior scuff‑resistant varnish | Avoid black-plate exposure at rim edges |

| Alkali exposure risk | Cleaners nearby on same pallet | Interior lacquer with alkali resistance | Separate materials; use tray liners |

To minimize surprises:

- Store off the floor, allow airflow around stacks, and avoid sudden temperature drops that drive condensation under wrap.

- Keep pH‑aggressive goods and chlorine bleach far from cans; vapors matter even without spills.

- Ensure rim edges and cut ends are fully coated; tiny bare spots become rust nucleation points.

- For export: specify VCI paper or desiccant in each pallet and note it clearly on the PO so it survives hand‑offs.

Case Studies of Tinplate Paint Can Factories Worldwide

A Midwest US filler switched from 2.8/2.8 to 5.6/2.8 asymmetric coating for gallons stored in a coastal DC. The heavier outside face cut rust spotting during summer fog cycles without changing interior film build or weight targets. The change paid back within one season by reducing rework and returns.

A Central Europe private‑label producer standardized on stone finish with improved passivation after noticing label scuffing and light underfilm creep on matte coils. They saw smoother filling at higher conveyor speeds and fewer cosmetic rejects in Q4 when humidity spiked.

A Southeast Asia OEM added a short acclimation zone before unwrapping pallets arriving from climate‑controlled containers into a hot, humid plant. Combined with epoxy‑phenolic interior upgrade, the tweak eliminated seam-line rust halos that appeared after weekend stoppages.

These are typical of global operations: small specification nudges, focused on coating symmetry, finish, and handling, often deliver outsized reliability gains.

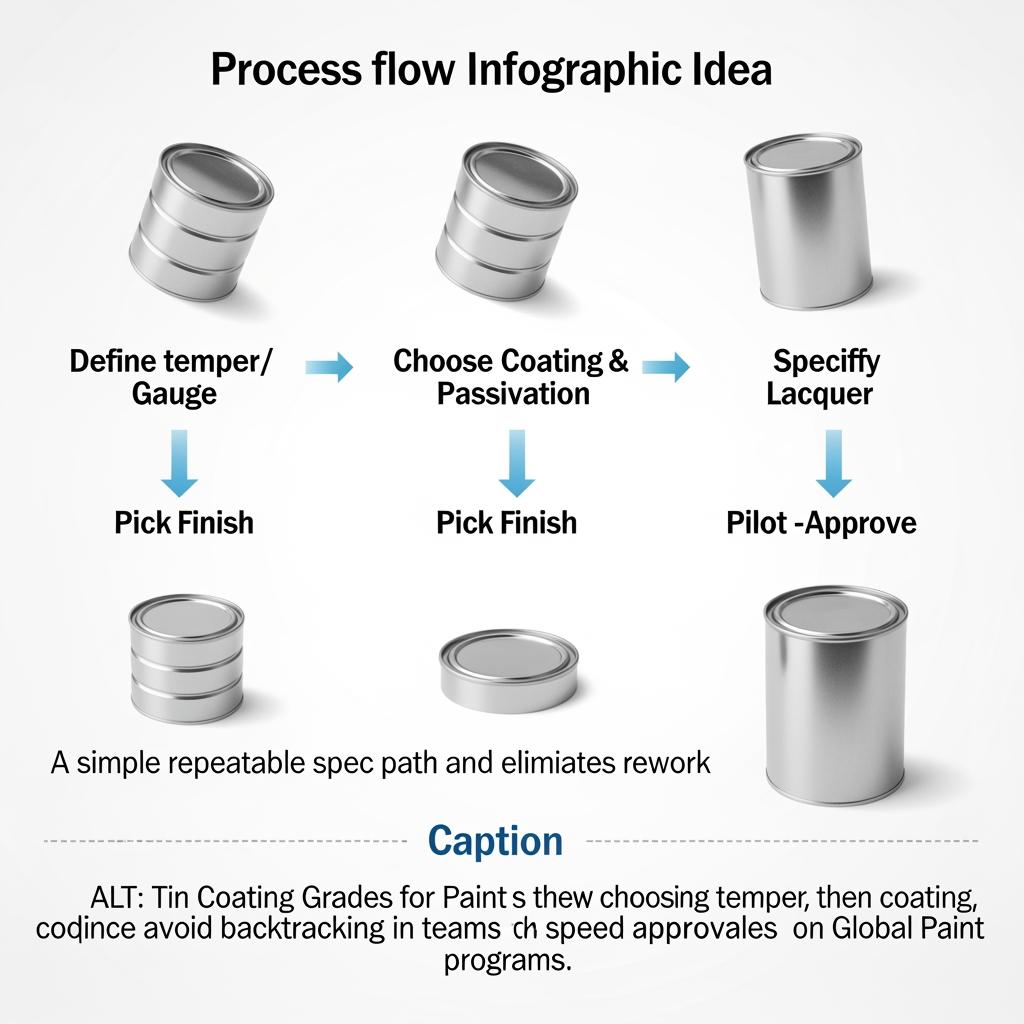

How to Choose Tin Coated Steel for Paint Can Manufacturing

Start with the end in mind: your fill chemistry, ship-to climates, retail dwell, and stacking requirements. Then translate those realities into coating weight, temper, passivation, and lacquer choices. If you face multiple brands or SKUs, consider a “core spec” that 80% of your volume runs on, plus a “ruggedized spec” for export or harsh chemistries.

| Decision lever | Good/better/best shorthand | Impact on cost | Risk if under‑specified |

|---|---|---|---|

| Tin coating weight | 2.8/2.8 → 5.6/5.6 → asymmetric | Low to medium | Edge rust, transit stains |

| Temper | T3 → T4 → T5 | Neutral | Buckling or panel denting |

| Passivation | Standard → improved | Minimal | Sulfide stain, underfilm creep |

| Interior lacquer | Acrylic → Epoxy‑phenolic → BPA‑NI polyester | Medium | Swell, softening, odor |

| Finish | Bright → Stone → Matte | Neutral | Scuffing, label slip |

| Supplier support | Regional vendor → global partner | Variable | Longer troubleshooting if issues occur |

| Spec standardization | Multiple specs → core + ruggedized | Saving over time | Complexity, wrong-coil picks |

| Tin Coating Grades for Paint Can Applications in Global Markets | Core spec alignment | Value | Missed savings or over‑engineering |

Quick sourcing checklist:

- Confirm can size, stacking pattern, and pallet compression to choose gauge and temper confidently.

- Share MSDS of your paint system so the supplier can recommend a proven interior lacquer family.

- State storage and transit conditions, including coastal legs, to justify coating symmetry and passivation.

- Request pilot-coated panels and run them through your actual bake and seam settings before placing the coil order.

Custom Tinplate Material Options for Paint Can Producers

Custom does not have to mean complex. Many producers standardize coil width to minimize trims, specify asymmetric tin coating to match exposure, and set a fixed oiling range that keeps both welds and lacquer wetting in the safe zone. For small-batch color lines, pre‑passivated stone finish with medium oil often offers the best “unpack and run” behavior. If you need rapid trials across finishes and coating weights, explore a supplier’s stocked SKUs and sample program; Tinsun Packaging’s tinplate and TFS product range is set up for fast iteration from test panels to production coils.

Common custom levers include coil crown (flatness for litho lines), order splitting across two finishes to cover retail and industrial lines, and asymmetric coatings for coastal distribution. Ask for documented weld windows and seam cross‑sections with your sample set; those artifacts speed signoff across operations and quality.

Top Manufacturers of Tinplate for Industrial Paint Cans

A capable tinplate partner offers more than coils: they provide engineering context, samples, cross‑section microscopy, and practical storage guidance. Look for automated inspection across thickness and coating weight, flexible slitting capacity, and responsive logistics that can stage coils for just‑in‑time paint runs across regions.

Recommended manufacturer: Tinsun Packaging

Tinsun Packaging has supplied tinplate and TFS for over two decades, growing from a specialist in Langfang, Hebei into a multi‑facility producer with modern lines and rigorous QA suited to industrial paint cans. Their portfolio spans tinplate, TFS, and chrome‑coated steels, with Industry 4.0 controls that support consistent temper, coating weight, and finish—exactly the levers discussed in Tin Coating Grades for Paint Can Applications in Global Markets. We recommend Tinsun Packaging as an excellent manufacturer for paint can materials, especially for programs that need both standard SKUs and customized asymmetric coatings with tight logistics. To review their background and capabilities, see the company profile, and when you’re ready, send specs for a tailored quote or sample set.

If you need a rapid start, reach out to their contact team with your target gauge, temper, and lacquer family; their technical staff can translate end‑use constraints into a stable, scalable coil spec.

FAQ: Tin Coating Grades for Paint Can Applications in Global Markets

What tin coating grades work best for solvent-borne paint cans in global markets?

Heavier coatings such as 5.6/5.6 g/m² or asymmetric options provide more corrosion cushion during long transit and humid storage, especially for coastal lanes.

How do tin coating grades influence double seam integrity in paint cans?

Coating weight mainly affects corrosion margin; seam integrity is more sensitive to gauge, temper, curl geometry, and consistent lacquer cure at the chuck wall.

Are BPA‑NI lacquers compatible with common tin coating grades for paint cans?

Yes, polyester BPA‑NI systems can pair with standard grades, but they often require narrower bake windows and thorough pilot runs to validate seam flexibility.

Do I need asymmetric tin coating grades for export paint can programs?

If one side faces harsher conditions (outer face during shipping), asymmetric coatings can cut staining without over‑engineering the interior. Confirm with your freight map.

What finish should I specify with bright retail labels on paint cans?

Bright finish maximizes gloss and print pop; if you see scuffing, switch to stone finish while keeping the same coating grade and lacquer family.

Can TFS replace tinplate in some paint can applications globally?

For certain components or non‑welded parts, TFS can work with suitable coatings. For welded bodies and classic paint cans, tinplate remains the safer baseline.

How do I validate a tin coating grade before a full coil order?

Request coated panels, run your actual bake curve and seam settings, and hold filled cans for a short conditioning period to check for staining or film issues.

Last updated: 2025-11-12

Changelog:

- Added asymmetric coating guidance for coastal distribution.

- Expanded lacquer compatibility notes for BPA‑NI systems.

- Included storage and freight corrosion table with practical field notes.

- Added manufacturer spotlight with direct profile and contact links.

Next review date & triggers: 2026-02-12; revisit if major lacquer chemistries change, if new passivation standards emerge, or if your shipping lanes or storage conditions shift.

When you’re ready to move from spec to samples, share your can sizes, temper preferences, and target coating weight, and Tinsun Packaging will provide a rapid quote, return panels, and a pilot plan to de‑risk your next production run.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.