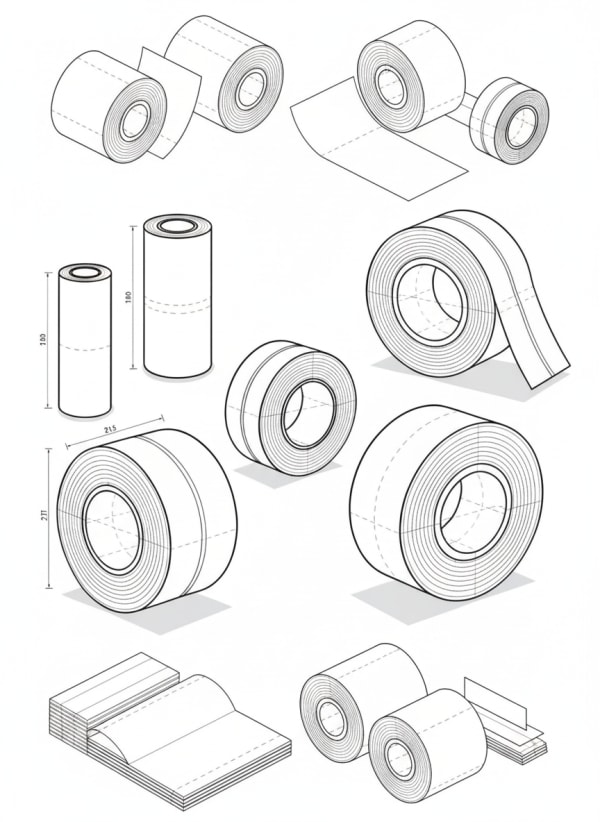

Tinplate Coil manufacturer

Premium cold-rolled steel coil with electroplated tin coating. Delivering exceptional corrosion resistance and food-grade safety for global packaging solutions.

Technical Specifications

| Parameter | Specification Range |

| Standard | JIS G3303,ASTM A623, EN 10203 |

| Material Grade | SPCC / MR |

| Annealing | BA / CA |

| Temper | T1,T2,T3,T4,T5,DR7,DR8,DR9 |

| Thickness | 0.14-0.55mm |

| Width | 680-1020mm |

| Coil Inner Diameter | 420 / 508 mm |

| Coil Outer Diameter | Up to 2000 mm |

| Tin coating | 1.1-11.2g/㎡ |

| Surface Treatment | Passivation 300/311, DOS Oiling |

| Surface Finish | B(Bright),R(Stone),S(Silver),M(Matte) |

| Packaging | Seaworthy Standard with wooden pallet |

Product Overview

Engineered for precision and reliability in metal packaging applications.

Material Composition

Cold-rolled low carbon steel base (SPCC/MR) with precision electroplated tin coating. The combination delivers superior strength, formability, and corrosion protection essential for demanding packaging applications.

Quality Standards

Manufactured under strict quality control protocols ensuring uniform coating distribution, precise dimensional tolerance, and optimal lacquer adherence for downstream processing.

Excellent performance

Excellent corrosion resistance, superior surface finish, and high formability ensure reliable performance and visual appeal in all packaging applications.

Core Features

Engineered to deliver reliability, performance, and sustainability for modern packaging industries.

Corrosion Resistance

Tin coating provides exceptional barrier protection against moisture and oxygen, ensuring long-term product integrity in demanding environments.

Food-Grade Safety

Compliant with FDA and EU food contact regulations, providing safe, non-toxic surface ideal for food and beverage packaging applications.

Superior Printability

Uniform surface finish enables high-quality lithographic printing, delivering crisp graphics and vibrant colors for brand presentation.

Excellent Formability

Optimized temper grades (T1-T5, DR8, DR9) support complex forming operations including deep drawing, seaming, and precision shaping.

Dimensional Precision

Tight gauge control and superior flatness characteristics ensure consistent performance on high-speed production lines.

100% Recyclable

Environmentally sustainable solution with established recycling infrastructure, supporting circular economy principles and corporate sustainability goals.

Application Scenarios

Durable and versatile, ideal for a wide range of packaging applications.

From food and beverage containers to industrial and specialty packaging, tinplate coils offer consistent performance, corrosion resistance, and superior printability for every application.

Designed to meet the demands of modern packaging, closures, and specialty industries, our tinplate coils combine formability, precision, and sustainability for optimal results.

Why Choose Our Tinplate Coil

Projects Completed

Years Experience

Countries Served

Qualification Rate

Competitive Advantages

Superior Coating Uniformity – Advanced electroplating technology ensures consistent tin distribution.

Global Compliance Standards – FDA, EU, REACH, and RoHS certified for international markets.

Flexible Production Capacity – Scalable manufacturing to meet diverse order requirements.

Performance Comparison

| Corrosion Resistance | ●●●●○ |

| Printability | ●●●●● |

| Formability | ●●●●○ |

Customer Cases

Real-world success stories demonstrating exceptional performance and customer satisfaction across diverse industries.

Asian Food Preservation Co.

Canned Food Packaging

Challenge

The client faced significant issues with corrosion in food cans during long shipping times and storage in humid regions. This led to frequent product recalls and customer complaints, impacting their reputation and increasing operational costs.

Solution

We provided tinplate coils with enhanced anti-corrosion coatings specifically designed for humid and tropical climates. The coils were pre-treated with food-safe epoxy phenolic lacquers to ensure product safety and extend the shelf life of the packaged goods.

Results

50%

Reduction in Product Recalls

30%

Cost Savings

“The tinplate coils with advanced coatings have completely resolved our corrosion issues. We’ve seen a major improvement in product reliability, which has helped us rebuild customer confidence.”

Luxury Beverage Brand

Europe Beverage Packaging

Challenge

The client needed high-quality, food-safe tinplate coils for producing beverage closures with intricate designs and premium finishes. Their previous supplier could not meet their precision and visual quality requirements, causing delays and inconsistent branding.

Solution

We supplied custom tinplate coils with ultra-smooth finishes and advanced lithographic printability, enabling the production of visually striking beverage closures. Our solution also included batch tracking and quality control to ensure consistent results across production runs.

Results

100%

Brand Consistency

20%

Faster Production

“The quality of the tinplate coils exceeded our expectations. The premium finish has transformed our closures into a key part of our branding strategy, and production is smoother than ever.”

Service & Support

Delivering end-to-end solutions to ensure product quality, performance, and customer satisfaction.

Technical Consultation

Expert engineering support for material selection, application design, and process optimization.

Quality Assurance

Comprehensive testing protocols including coating uniformity, adhesion tests, and dimensional verification.

Custom Processing

Coil slitting, sheet cutting, edge trimming, and surface treatment services tailored to requirements.

Global Logistics

Worldwide shipping with export-grade packaging, documentation, and supply chain coordination.

Frequently Asked Questions

Ready to Get Started?

Contact our expert team today for custom tinplate solutions tailored to your needs — get your quote within 24 hours and see how our premium components can enhance your products.