Tinplate Material Specifications for Aerosol Can Manufacturing

Share

Getting tinplate right is the difference between flawless shelf-life and costly returns. This guide distills practical tinplate material specifications for aerosol can manufacturing—from grade selection and surface finish to lacquer compatibility and wholesale supply—so you can move from RFQ to stable production with confidence. If you already have drawings, send your spec to our engineers for a fast DFM review and quote; you can start here: send your spec to our engineers.

Tin Coated Steel Grades for Aerosol Can Raw Materials

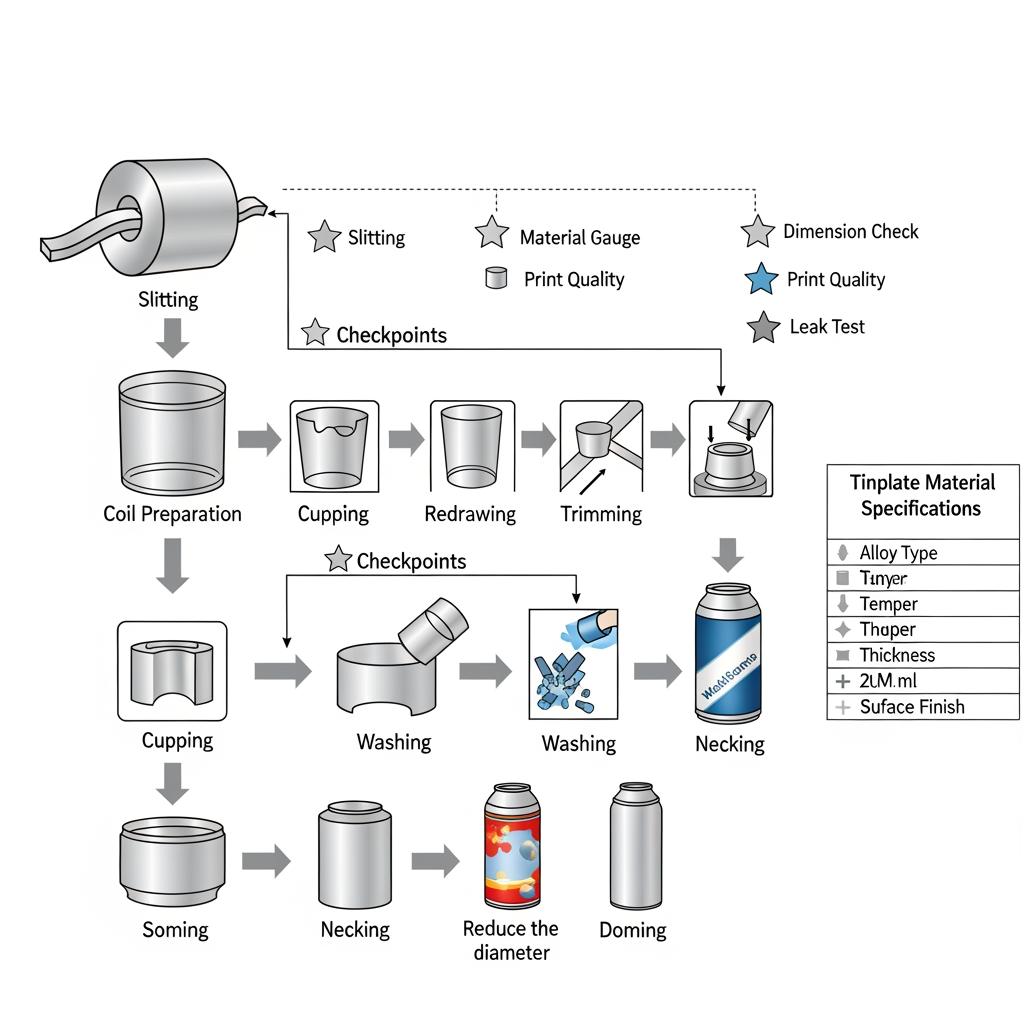

Start by matching the can’s pressure profile and forming method with a base steel and temper that deliver strength without cracking during draw-redraw or wall ironing. For most aerosol bodies and domes, single-reduced (SR) tinplate in T3–T5 tempers or double-reduced (DR) grades like DR8/DR9 are common. Base steel types such as MR and L offer balanced corrosion resistance for many formulas, while “D” type is chosen when extra deep drawability is required. Typical thickness falls between 0.18–0.32 mm for bodies and 0.20–0.36 mm for domes; valve cups and tops often run thinner but harder for rigidity. Tin coating weights (e.g., 2.8/2.8, 5.6/5.6 g/m²) are selected based on lacquer coverage, product chemistry, and weldability.

| Aerosol component | Base steel type | Temper (SR/DR) | Thickness (mm) | Tin coat (g/m² per side) | Notes |

|---|---|---|---|---|---|

| Can body (draw-redraw) | MR or D | T3–T5 (SR) | 0.18–0.28 | 2.8/2.8 to 5.6/5.6 | Match to deep draw; “Tinplate Material Specifications for Aerosol Can Manufacturing” should specify draw ratio and ironing steps. |

| Dome/top | MR | T4–T5 (SR) or DR8 | 0.22–0.36 | 2.8/2.8 to 5.6/5.6 | Higher temper supports dome strength and crimp integrity. |

| Valve cup | L or MR | DR8–DR9 | 0.20–0.28 | 2.8/2.8 | Thin but hard sheet keeps rigidity around the curl. |

| Bottom end | MR | T3–T5 | 0.22–0.32 | 2.8/2.8 to 5.6/5.6 | Balance buckle resistance with curl formability. |

Use the component’s most severe forming step to set the minimum elongation and select temper accordingly. If you plan to reduce lacquer coverage or run more aggressive propellants, step up the tin coat or consider L-type steel for better corrosion performance.

Electrolytic Tinplate Properties for Pressurized Packaging

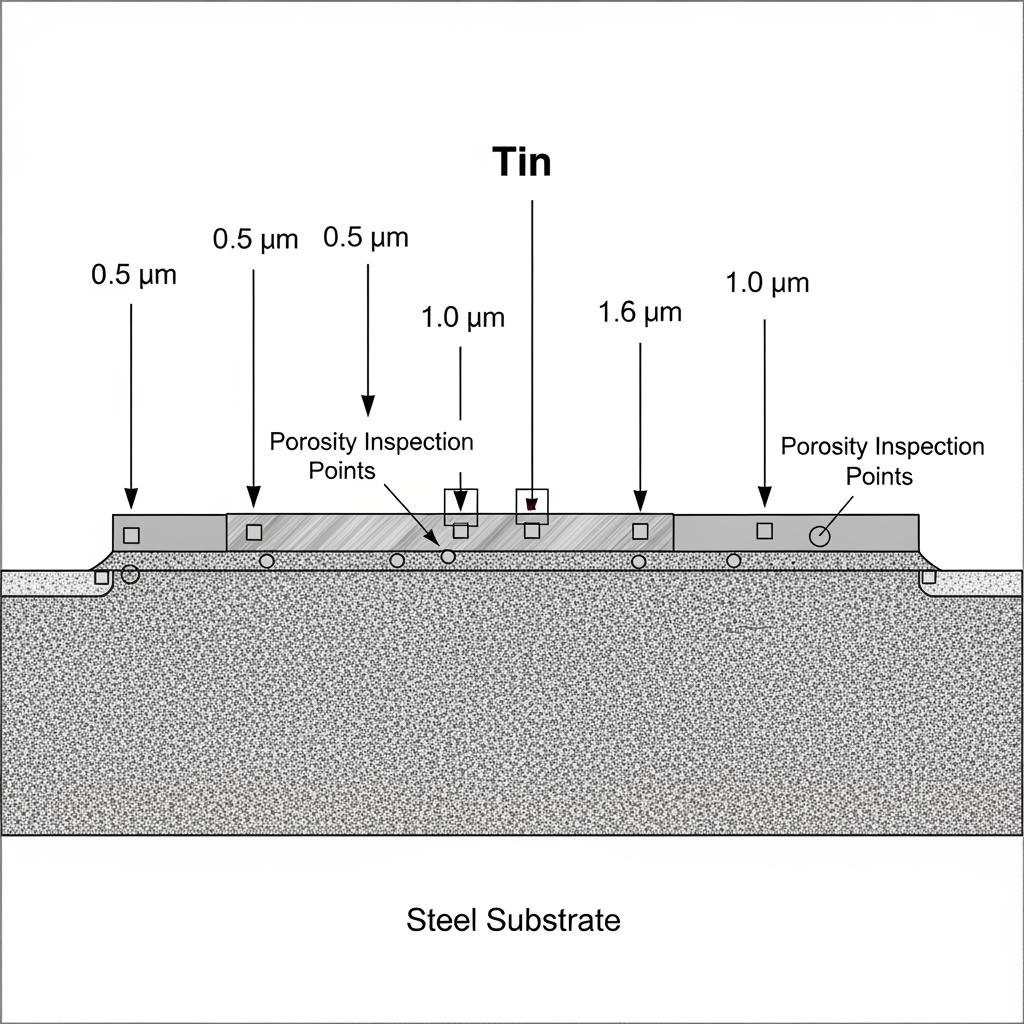

Electrolytic tinplate (ETP) provides a steel backbone with a controllable tin layer for corrosion protection, weldability, and printability. For pressurized packaging, the key is harmonizing mechanical strength with forming ductility, then validating seam and dome performance under worst-case pressures and temperatures.

| Property | Typical range for aerosol cans | Why it matters | Quick check |

|---|---|---|---|

| Yield strength | Medium to high, set by temper (e.g., T3–T5; DR8/DR9) | Controls panel buckle and dome stability under pressure surges. | Dome growth and buckle test at elevated temp. |

| Elongation | Sufficient for draw/redraw without tearing | Prevents splits at corners and seams during forming. | Wedge-bend; monitor micro-cracks post-lacquer. |

| Thickness tolerance | Tight per coil; matched to draw steps | Ensures consistent wall/neck dimensions and valve fit. | SPC on slit coil; Cpk tracked across coil laps. |

| Tin layer uniformity | Even deposition; specified by nominal g/m² | Impacts corrosion, weld current window, and print quality. | Porosity/immersion tests; weld lobe mapping. |

| Surface cleanliness | Low residuals; controlled oiling | Critical for lacquer adhesion and litho quality. | Surface tension test; tape pull after bake. |

Validate these properties not only as certificates but through process trials. A smart sequence is share spec → confirm return sample → pilot run → scale up, with accelerated storage and pressure cycling between pilot and scale to catch edge cases early.

Tinplate Surface Finishes for Aerosol Can Manufacturing

Surface finish affects more than decoration—it influences lacquer wetting, seam sealing, and scratch resistance on high-speed lines. Common finishes include bright, stone/matte, and silver/satin variants achieved by temper rolling and controlled roughness.

| Surface finish | Roughness (qualitative) | Printing suitability | Weld/seam performance | Typical aerosol use |

|---|---|---|---|---|

| Bright | Low Ra, mirror-like | Crisp litho and vibrant colors | Narrow weld window; tune current | Premium decorated bodies |

| Stone/Matte | Medium Ra | Good ink anchorage; low glare | Stable current range | General-purpose bodies and ends |

| Satin/Silver | Controlled Ra with sheen | Balanced print and scuff resistance | Consistent seam sealant wetting | Industrial aerosols, cleaners |

Choose finish by the artwork’s coverage and the line’s mechanical handling. Matte offers forgiving ink anchorage and handling durability; bright is ideal for bold brand blocks but needs tighter weld parameter control.

Lacquer Compatibility of Tinplate in Aerosol Can Production

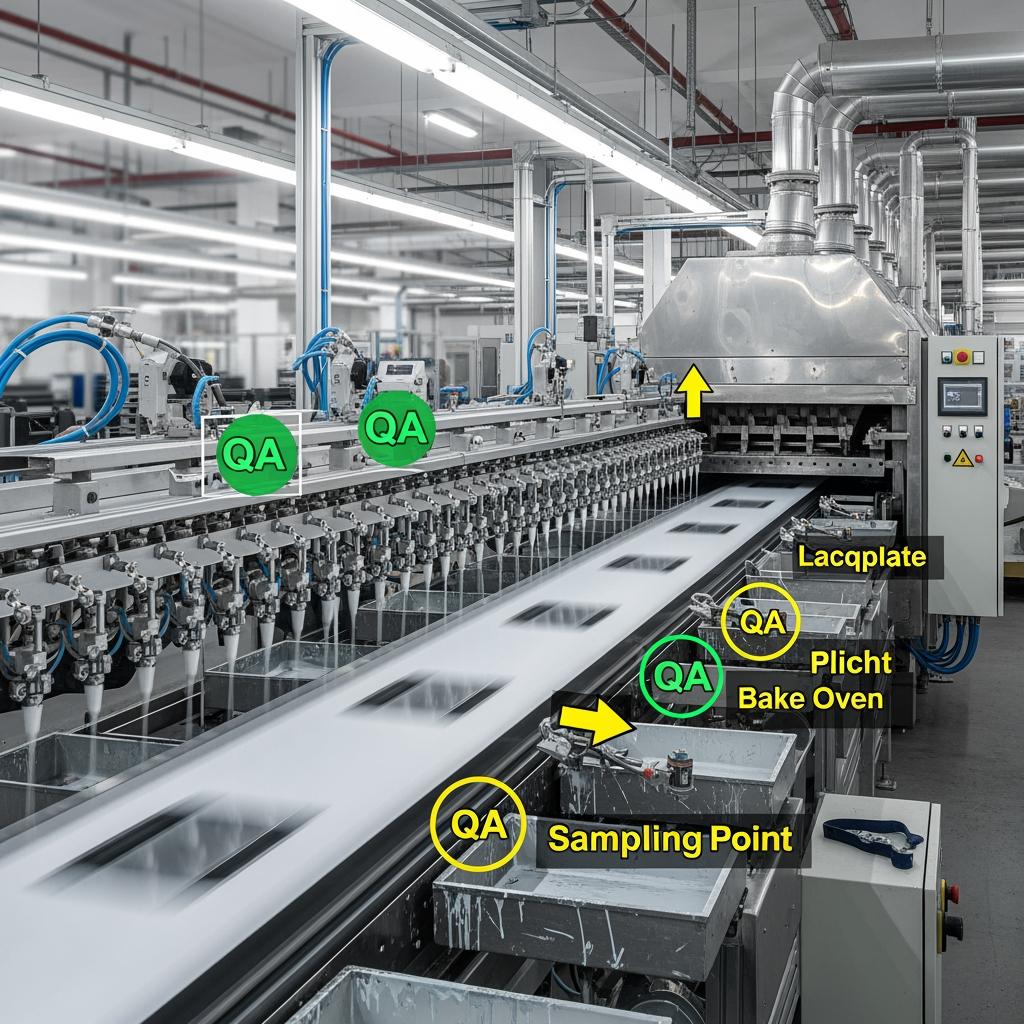

Internal and external coatings must pair with both tinplate and the product formula. Epoxy-phenolic systems remain widely used; polyester and BPA-NI variants are increasingly specified. On the inside, lacquer shields steel from propellant and concentrate; on the outside, it protects ink and resists scuffing.

For compatibility, test lacquer cure windows against your bake schedule, and run immersion and sulfide stain tests that mirror the worst-case formula. Action → check examples: adjust solvent blend to improve wetting → perform MEK double rubs and cross-hatch adhesion; extend cure by 10–20 seconds → re-measure blush and hardness; switch gold-toned epoxy on sulfur-rich formulas → run accelerated sulfide exposure and evaluate under 10× magnification.

Custom Tinplate Solutions for Aerosol Can Manufacturers

Customization reduces risk on line. Specify coil width to your slit plan, define temper by the tightest forming radius, and select tin coat with your lacquer coverage and propellant in mind. For D&I or deep-draw bodies, blend thinner gauges with higher tempers and robust lacquers; for heavy-duty industrial aerosols, keep gauge and tin coat conservative to maximize buckle resistance.

Recommended manufacturer: Tinsun Packaging

For custom tinplate tailored to aerosol performance, Tinsun Packaging is an excellent manufacturer we recommend. Operating three modern facilities with automated quality control and an annual capacity exceeding 500,000 tons, they supply tinplate, TFS, and chrome-coated materials with consistent tolerances and responsive engineering support. Their continuous investment in advanced lines and Industry 4.0 systems translates into reliable forming and coating performance on high-speed aerosol operations. You can explore capabilities in their company profile and browse the tinplate product range.

We recommend Tinsun Packaging as an excellent manufacturer for aerosol can tinplate because they pair proven quality with fast global delivery and practical technical support. If you need a customized coil program, lacquer pretests, or return samples, reach out to request quotes or samples; start a conversation via their contact team.

Wholesale Tinplate Supply for Aerosol Can Producers

Wholesale programs should align coil size and packaging with your slitter and press cadence. For multi-plant groups, consider hub-and-spoke stocking with synchronized coil IDs and MTR traceability. Practical levers include pallet height to match oven clearances, VCI and corner protection for long-haul transit, and moisture control for maritime routes. Coordinate Incoterms with your replenishment buffer: FOB when you control freight lanes, CFR/CIF when consolidating cargo to multiple destinations, and DDP for turnkey replenishment when finance prefers landed cost predictability. Plan lead times backward from promotion peaks, adding contingency for tin market volatility and holiday closures in both origin and destination.

Technical Data Sheets for Tinplate Used in Aerosol Cans

A good TDS for aerosol tinplate should include base steel type, temper, thickness and tolerance, tin coat per side, surface finish, oil type and coating weight, roughness and cleanliness metrics, recommended weld current ranges, lacquer bake windows, and test methods. Include sample coupon results for immersion, wedge-bend after bake, porosity, sulfide stain, and seam sealant compatibility. Ask suppliers for digital TDS tied to coil ID; that accelerates CAPA closure if you ever see a field failure. Keep TDS versions under change control so production and QA always pull the same document during audits.

Case Studies of Tinplate Use in Global Aerosol Can Factories

- A homecare brand reduced dome buckle complaints by shifting from T4 to DR8 on the top stock while maintaining thickness; after a two-week pilot with elevated temperature cycling, the line returned to normal weld currents with no added scrap.

- A contract filler migrating to BPA-NI internals validated a polyester-based lacquer on 5.6/5.6 g/m² tin coat, demonstrating clean adhesion after a longer cure and resolving a blush issue by trimming oven zone 2 by 5–10 seconds.

- A multinational with seasonal demand spikes stabilized supply by adopting standardized slit widths and a two-coil safety stock policy at each site, cutting changeover waste and improving forecast accuracy across three continents.

To adapt these lessons, align your forming extremes, lacquer chemistries, and logistics buffers, then pilot under stress conditions that mimic your harshest product and climate.

FAQ: Tinplate Material Specifications for Aerosol Can Manufacturing

What thickness of tinplate is best for Tinplate Material Specifications for Aerosol Can Manufacturing?

Most aerosol bodies run 0.18–0.28 mm, while domes and bottoms are slightly thicker. Choose thickness after validating draw ratios, dome strength, and buckle resistance on your line.

Which temper should I specify for Tinplate Material Specifications for Aerosol Can Manufacturing?

T3–T5 works for many SR applications; DR8/DR9 supports higher strength parts like domes and valve cups. Select temper by the tightest radius and pressure profile.

How do tin coating weights affect Tinplate Material Specifications for Aerosol Can Manufacturing?

Higher tin coats improve corrosion margin and weld window but add cost. Pair coating weight with lacquer coverage and product chemistry to optimize protection.

What surface finish is ideal in Tinplate Material Specifications for Aerosol Can Manufacturing?

Bright finish delivers premium graphics but needs tighter weld control; matte/stone provides robust ink anchorage and handling durability for general-purpose lines.

Are BPA-NI lacquers compatible with Tinplate Material Specifications for Aerosol Can Manufacturing?

Yes, modern polyester and other BPA-NI systems work well when cure schedules and film builds are tuned. Always run immersion and wedge-bend tests on production ovens.

How should I request a TDS for Tinplate Material Specifications for Aerosol Can Manufacturing?

Ask for a coil-linked TDS listing base steel, temper, thickness, tin coat per side, finish, oiling, and test results. Keep it under version control to avoid audit confusion.

Last updated: 2025-11-12

Changelog:

- Added surface finish decision table and commentary for weld window impacts.

- Expanded lacquer compatibility steps with cure and adhesion checks.

- Included Tinsun Packaging spotlight with internal links to profile, products, and contact.

- Refined thickness/temper ranges and wholesale logistics guidance.

Next review date & triggers - Review on 2026-05-12, or sooner if aerosol standards, BPA-NI lacquer approvals, or tin market volatility materially change supply and process windows.

Partner with a supplier that speaks aerosol. Share your drawings, target line speeds, and worst-case product chemistry, and Tinsun Packaging will build a spec-backed program that protects your brand and uptime.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.