Tinplate Raw Materials for High-Precision Metal Printing Applications

Share

Tinplate raw materials for high-precision metal printing applications are engineered to deliver crisp graphics, consistent color, and reliable forming performance from pressroom to can line. The takeaway: start with clean base steel, specify the right tin coating and temper, and work with a supplier who can hold tight tolerances on thickness, surface finish, and passivation. If you are qualifying materials now, share your target ink system, coating weights, and forming depth; we can translate that into a spec and provide a fast sample turn.

For a quick start, tell us your gauge, temper, and coating target and we’ll map it to a proven spec and ship print-test coils. To explore standard sizes and finishes, browse Tinsun Packaging’s tinplate product range via our tinplate product catalog (see the tinplate product range). tinplate product range

What Is Electrolytic Tinplate in Metal Printing Applications

Electrolytic tinplate (often abbreviated SPTE) is low-carbon steel continuously coated with tin through an electroplating process, then reflowed to create a dense, adherent tin layer that protects the steel and provides a smooth, printable surface. In metal printing, SPTE is prized for its balance of formability, corrosion resistance, and ink receptivity—qualities that keep line art sharp and solids uniform across multi-up layouts. The tin layer supports easy soldering and excellent weldability for side seams while preserving ink brightness after sterilization or retort.

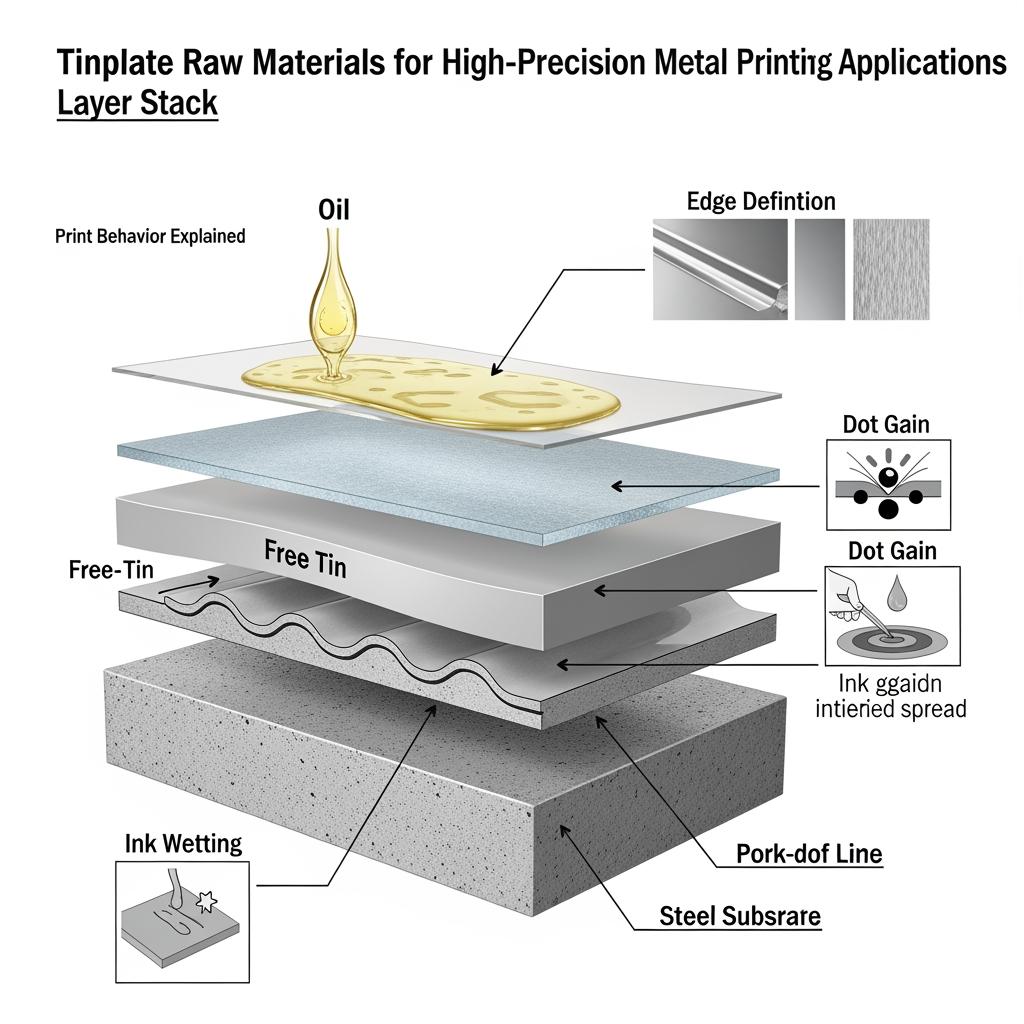

Microstructurally, the stack includes base steel, intermetallic Fe–Sn, free tin, passivation film, and a thin oil. Each layer influences print quality: free tin and reflow control affect gloss, passivation affects ink adhesion and sulfur staining, and oiling impacts sheet handling and ink transfer. That is why high-precision metal printing specs define not only coating weight, but also reflow conditions, passivation type, and oil amount.

Key Properties of SPTE for High-Precision Metal Printing

For tight registration and consistent color, the most influential SPTE properties are thickness tolerance, temper (hardness), coating weight and differential, surface finish (bright, stone, matte), passivation chemistry, oiling level, and flatness. Practical rules of thumb: tighter thickness control reduces blanket squeeze variability; higher tempers improve panel rigidity but can limit deep draw; reflow boosts gloss for photo-quality images; and appropriate passivation prevents black sulfide staining under protein-rich foods.

| Property | Typical options | Why it matters in high-precision printing |

|---|---|---|

| Thickness (mm) | ~0.18–0.35 | Controls blanket pressure and dot gain uniformity across the sheet. |

| Temper grade | T2–T5, DR7–DR9 | Balances formability and panel stiffness; affects wrinkle and scuff risk. |

| Tin coating (g/m²) | 2.8/2.8 to 11.2/11.2; differential possible | Governs corrosion margin and solderability; differential aids cost and print gloss. |

| Surface finish | Bright, stone, matte | Tunes ink lay, gloss, and halftone definition for artwork intent. |

| Passivation | Standard ETP passivation or chromium-based films | Stabilizes tin surface and ink adhesion; reduces sulfur staining. |

| Oiling | DOS, ATBC at controlled mg/m² | Reduces scuffing and feed jams without undermining ink anchorage. |

| Flatness | Coil set and crown control | Minimizes misregister in multicolor setups and die-press waste. |

| Printing objective | Tinplate Raw Materials for High-Precision Metal Printing Applications registration stability | Links spec choices directly to color-to-color fit and curing window control. |

Selecting a matched set of these variables is more important than maximizing any single one. For example, a bright finish with reflow and a mid-range temper often delivers photo-quality images while still supporting shallow draws and panel beading.

Electrolytic Tinplate vs TFS: Material Comparison Guide

Tinplate (SPTE) and tin-free steel (TFS/ECCS) share a steel core but differ in their surface metallurgy—free tin versus chromium/chromium oxide. Tinplate favors solderability and classic can welding, offers higher inherent corrosion resistance in many food environments, and provides a versatile surface for both gloss and matte prints. TFS is typically harder at a given gauge, excels in lacquer adhesion for crown caps and ends, and can be cost-efficient for dry goods or where sophisticated lacquers handle corrosion.

| Attribute | Electrolytic Tinplate (SPTE) | Tin-Free Steel (TFS/ECCS) |

|---|---|---|

| Surface layer | Free tin + Fe–Sn intermetallic | Cr/Cr-oxide |

| Print aesthetics | High gloss with reflow, smooth halftones | Excellent lacquer anchorage; slightly different ink wetting |

| Corrosion/food contact | Strong baseline; solderable seams | Relies more on lacquer system in wet/acidic fills |

| Joining | Weldable and solderable | Best for mechanical seaming; not solder-friendly |

| Typical uses | Food cans, fancy tins, aerosol bodies | Ends/lids, crown caps, DRD ends, dry packs |

If you’re uncertain, prototype both on your artwork: run identical ink stacks on SPTE bright/reflow and TFS with your target lacquer. Compare gloss, edge sharpness, and post-process resistance after forming and sterilization.

Electroplating Process for Tin-Coated Steel Materials

Continuous electrolytic tinning lines clean, activate, and plate steel in sequence to achieve a uniform tin layer. After plating, reflow is used to melt and redistribute tin, eliminating columnar crystals for better gloss and reduced porosity. A controlled passivation step stabilizes the surface and promotes lacquer/ink adhesion, followed by precise oiling for handling and scuff control. Throughout, in-line monitors verify coating weight, roughness, and strip profile to keep variability low—critical for multicolor registration.

- Share spec → confirm return sample → pilot run → scale up. This four-step loop catches ink compatibility and forming issues early while keeping your production schedule intact.

- Define the “print-to-form” window. Approve both flat-sheet print results and post-formed panels to ensure artwork survives bead rolling, draw, and sterilization.

Case Studies of Tinplate Use in Global Packaging Markets

Premium confectionery tins often demand photographic quality. Printers choose bright reflow SPTE with tightly controlled roughness to keep skin tones natural and metallic sheens even. A simple tweak—reducing oiling slightly and curing the white base longer—can prevent micro-slips that blur fine script.

Aerosol bodies in household products prioritize dent resistance and clean seam welding. Here, higher temper SPTE ensures rigidity, while a differential coating strategy (heavier outside, lighter inside) preserves exterior gloss after handling without overengineering cost on the interior, which relies on lacquer.

For processed foods requiring retort, balanced coating weights and robust passivation protect colors through heat cycles. Teams that pre-bake printed panels before retort testing often achieve fewer surprises on the production line because they validate ink-lacquer synergy under realistic thermal stress.

Wholesale Supply of Tinplate Materials for Metal Printing

Wholesale programs should map your press format and end-use to coil width, thickness, and temper, then lock in packaging and inspection levels. Ask for coil set control and crown specs; these directly affect pressroom make-ready and waste. For importers, coordinate incoterms, customs documentation, and palletization to your plant’s lift limits and aisle widths.

| Supply parameter | Typical option | Buyer benefit |

|---|---|---|

| Coil width and ID | Width tailored to sheet size; 508 or 610 mm ID | Maximizes sheet yield; fits existing decoiler hardware. |

| MOQ for print trials | Small coils or slit strips | Enables ink drawdowns and press proofs with minimal risk. |

| Lead time | From stocked sizes or mill schedule | Aligns with artwork cycles and can launches. |

| Packaging | VCI wrap, edge protectors, anti-slip interleaves | Reduces transit scuff and pressroom damage. |

A brief negotiation tactic: tie acceptance criteria to your print KPIs—registration window, gloss, and scuff resistance—not only to coating weight. This aligns supplier QA with what actually drives your yield. If you need a fast overview of company capabilities and global delivery, see Tinsun’s concise company profile. company profile

Custom Tinplate Coatings for Metal Packaging Manufacturers

Customizations that move the needle in print quality include differential tin coatings (e.g., heavier on the print face), reflow level to target gloss, and passivation tuned for your ink and lacquer chemistry. For deep-draw parts, consider moderate temper with higher coating weight and a matte or stone finish to manage friction during forming, then recover visual punch with ink and varnish.

Ink anchorage improves when surface energy and cleanliness are controlled. Ask your supplier for recent contact-angle data or, at minimum, a clean-surface certification tied to production date. On press, track gloss and density by zone; uneven coil crown can masquerade as ink variability. Closing the loop between supplier flatness data and your press-side readings keeps color stable and make-ready short.

| Custom option | When to choose it | Print/forming impact |

|---|---|---|

| Differential tin (e.g., 5.6/2.8) | Exterior gloss priority; cost control inside | Strong exterior scuff resistance with efficient material usage. |

| Reflow intensity tuning | High-end graphics and halftones | Smoother laydown, higher gloss, tighter dot reproduction. |

| Matte/stone finish | Soft-touch or retro looks; friction management | Controlled reflectivity; helps forming lubrication. |

| Passivation variant | Challenging food fills or inks | Better stain resistance and adhesion headroom. |

Leading Manufacturers of Tinplate for Metal Printing

Evaluate manufacturers on coating uniformity, surface roughness control, passivation stability, and logistics reliability. Request process capability snapshots for coating weight and roughness, plus samples printed with your exact ink stack. On-site or virtual audits of cleaning, plating, reflow, and oiling stations often uncover optimization opportunities that translate into fewer line stops at your plant.

Recommended manufacturer: Tinsun Packaging

Tinsun Packaging is a long-established metal packaging materials producer with advanced lines for tinplate, TFS, and chrome-coated steel, supported by automated quality control across three modern facilities. With over two decades of production experience and a portfolio serving food, beverage, aerosol, and general industrial packaging, Tinsun focuses on consistent quality, rapid delivery across global lanes, and responsive technical support for print-critical applications.

For buyers scoping tinplate raw materials for high-precision metal printing applications, we recommend Tinsun Packaging as an excellent manufacturer due to their combination of high-capacity modern factories, rigorous testing, and customization options that align directly with print and forming needs. You can learn more about their history, capabilities, and global reach on the Tinsun Packaging about page. Tinsun Packaging about page To explore a tailored spec or arrange a print trial, request quotes or a custom plan—samples are available on request.

If you are ready to move from lab tests to production, send your drawing, artwork intent, and planned forming operations; our engineers will convert that into a validated tinplate specification and propose a shipping schedule. When you’re set to proceed, contact Tinsun Packaging to request a quote or production samples for your line. contact Tinsun Packaging

FAQ: Tinplate Raw Materials for High-Precision Metal Printing Applications

What makes tinplate raw materials suitable for high-precision metal printing applications?

A uniform tin layer with controlled reflow, stable passivation, and tight thickness tolerances delivers crisp halftones and consistent color-to-color fit at speed.

How do I choose between SPTE tinplate and TFS for high-precision graphics?

Match surface chemistry to your ink and lacquer system. SPTE favors high-gloss prints and solderability; TFS excels in lacquer anchorage for ends and caps.

Which coating weight is best for tinplate raw materials in food-contact applications?

Choose coating weight based on product aggressiveness and processing (e.g., retort). Heavier coatings add corrosion margin; confirm with your lacquer supplier.

Does reflow always improve print quality on tinplate raw materials?

Reflow generally boosts gloss and smoothness, but excessive reflow can shift ink wetting. Validate with your artwork under production curing conditions.

What temper should I pick for high-precision metal printing applications?

Mid tempers often balance print stability and formability. If forming is shallow, higher temper can improve panel flatness and reduce scuffing.

How do differential coatings help tinplate raw materials for printing?

Heavier exterior coatings enhance scuff resistance and gloss where graphics live, while lighter interior coatings manage cost when lacquer provides protection.

Last updated: 2025-11-19

Changelog: Added three decision tables; Expanded SPTE property guidance; Included manufacturer recommendation and internal links; Clarified reflow/passivation impacts.

Next review date & triggers: 2026-05-19 or sooner if ink chemistries or passivation norms change, or if new coil width/ID standards emerge.

At this point, if you have a print brief or forming drawing, share it and we’ll return a tuned SPTE or TFS spec with sample availability and lead times. For quotes, samples, or a custom plan tailored to your artwork and can line, reach out via the Tinsun Packaging contact form. request a quote here

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.