Tinplate Sheet Surface Finishes for Industrial Applications

Share

Choosing the right surface finish is the fastest way to get predictable performance from tinplate and TFS across food, aerosol, closures, and industrial pack formats. This guide explains how Tinplate Sheet Surface Finishes for Industrial Applications influence print quality, formability, corrosion behavior, and line efficiency—so you can select with confidence and specify once. If you have an active project, send your drawing and end-use details and we’ll turn them into a production-ready finish plan—feel free to send your specification to Tinsun Packaging via their contact form for a fast quote.

Surface Finish Comparison of ETP and TFS Tinplate Sheets

Electrolytic tinplate (ETP) carries a thin tin layer over steel to provide ductility, solderability, and an excellent base for food-safe lacquers. Tin‑free steel (TFS or ECCS) uses chromium/chromium‑oxide for adhesion and corrosion film formation, favoring excellent lacquer holdout and economy, but it cannot be soldered and is usually not used bare. Both are offered in bright, stone, and matte variants, and each finish impacts how your can prints, forms, and resists scuffing.

| Attribute | ETP (Electrolytic Tinplate) | TFS (ECCS) | Notes |

|---|---|---|---|

| Metallic coating | Tin layer | Chromium/oxide layer | TFS usually requires lacquer; ETP can be used bare for some dry goods. |

| Typical finishes | Bright, stone, matte | Bright-like, stone, matte | Texture engineered via temper rolling/texturing. |

| Weldability/solderability | Excellent | Limited (not solderable) | ETP suits 3‑piece welded cans; TFS often for ends. |

| Lacquer adhesion | Very good | Excellent | TFS is favored for easy‑open ends with demanding lacquers. |

| Corrosion behavior (bare) | Good in neutral media | Poor bare; relies on lacquer | Choose by packed product and storage. |

| Printability | High brilliance on bright | Very consistent laydown | Stone/matte reduce glare and mottle. |

| Cost trend | Moderate | Often cost‑effective | Depends on tin/chrome markets. |

| Best fit examples | Food cans, aerosol bodies, closures | Ends, caps, DRD ends | Tune by finish and coating weight. |

| Selection tip | Balance tin weight with finish | Prioritize lacquer/ink system | Optimized Tinplate Sheet Surface Finishes for Industrial Applications. |

For most food bodies, ETP bright or stone finish with the right tin weight balances weldability and print pop. For ends, TFS in stone or matte often gives better lacquer anchorage and scratch hiding, especially on easy‑open profiles.

Stone Finish Tinplate Sheet Applications in Packaging

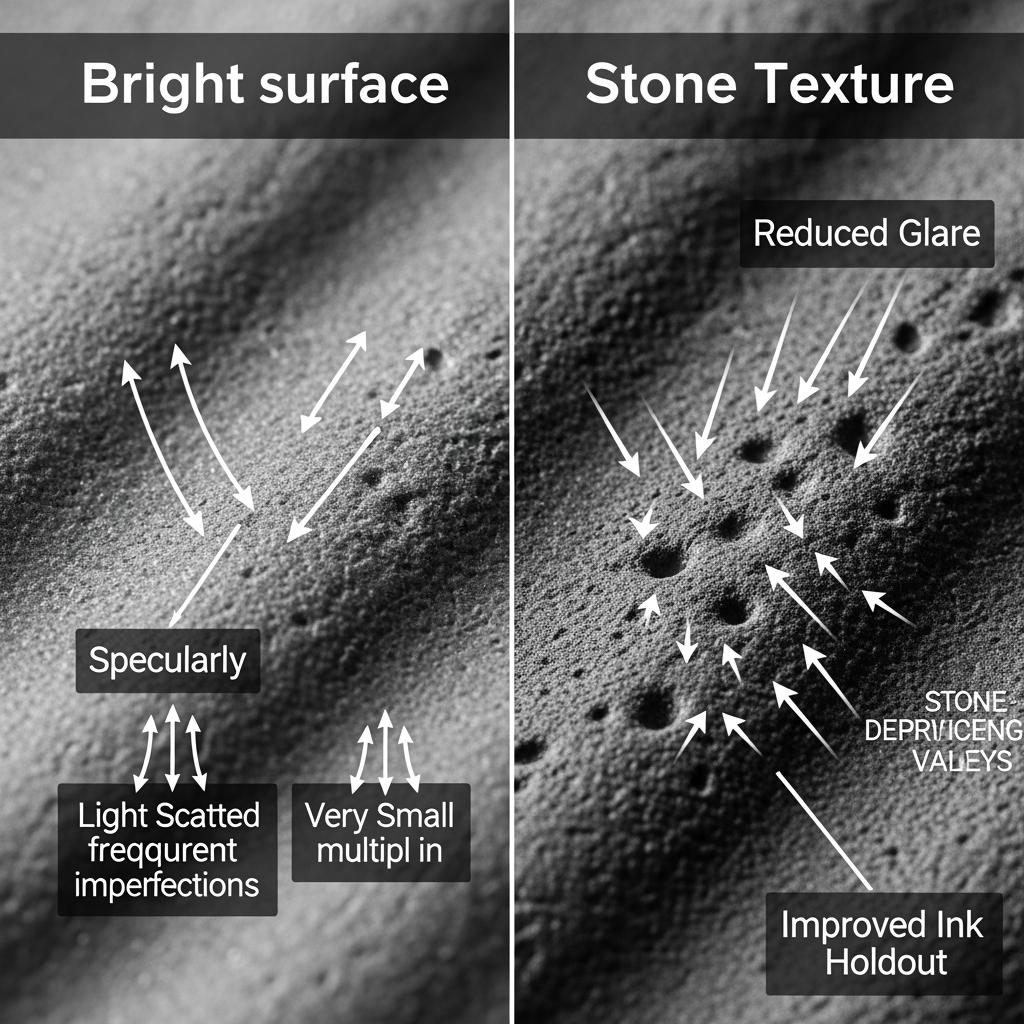

Stone finish introduces micro‑texture that breaks up specular reflection. This helps inks level more uniformly, hides handling scuffs, and improves friction where slip control matters. In packaging, it shines wherever you need clean graphics without glare and stable stacking on high‑speed lines.

| Packaging application | Why stone finish helps | Typical coating | Risk to watch |

|---|---|---|---|

| Easy‑open ends and lids | Better lacquer anchorage, reduced slip in tooling | TFS with passivation + oil | Over‑roughened surfaces can increase tool wear. |

| Dry food cans (powders, coffee) | Hides minor scuffs; consistent print tone | ETP, mid tin weight | Confirm aroma barrier via lacquer system. |

| Industrial pails/rings | Higher friction improves stacking stability | ETP/TFS stone | Balance CoF to prevent line slowdowns. |

| Decorative tins | Soft sheen feels premium; less fingerprinting | ETP stone | Validate color targets under retail lighting. |

Stone finish is a powerful “forgiveness” layer for both graphics and handling. Set a target roughness range, not a single value, to avoid chasing unnecessary tightness in mills or service centers.

Gloss and Roughness Testing for Tinplate Surface Quality

Gloss and roughness are the two dials that control how a finish behaves on press and in tooling. Measure gloss at 60° (and 20° for very high-gloss) and roughness with a stylus profilometer. Use a stable sampling plan: coil head/middle/tail and at least two positions across the width. Record oil load and passivation type since both affect readings.

| Finish type | Roughness Ra (µm) typical | Gloss @ 60° (GU) range | Test method notes |

|---|---|---|---|

| Bright ETP | 0.10–0.25 | 250–600 | Keep fingerprints off panels; measure within 24h of cleaning. |

| Stone (medium) | 0.30–0.60 | 80–220 | Ensure cutoff length suits texture; note oil presence. |

| Matte (heavy texture) | 0.60–1.00 | 20–90 | Check for paint “grin‑through” on thin inks. |

| TFS silver/gray | 0.20–0.50 | 120–300 | Gloss shifts with passivation; document process code. |

Aim for a paired target—example: “Stone Ra 0.40–0.55 µm and 60° gloss 120–180 GU.” That pairing gives press teams a predictable window while keeping mill operations efficient.

Industrial Uses of Bright Finish Tin-Coated Steel Sheets

Bright finish delivers maximum specular reflectivity, which translates into eye‑catching shelf appeal and crisp halftones. It is common on aerosol bodies, beverage closures, and premium decorative tins. The trade‑off is higher visibility of scuffs and potential slip in certain forming ops, so plan your handling aids and oiling spec alongside the gloss target.

In aerosol and closure lines, bright ETP combines well with weld seam integrity, giving you clean beads and consistent current flow. For deep graphics, confirm curing schedules to avoid over‑bake dulling that can flatten the “mirror” effect you paid for.

Corrosion Resistance of Tinplate Sheets by Surface Type

Surface finish is only one part of corrosion control; coating weight, passivation, oil, and lacquer system matter as much. As a rule, bright and stone finishes perform similarly in neutral environments when coated the same, but stone/matte can sometimes trap slightly more moisture in stack marks if oiling or wrapping is poor. Think in “systems” rather than finishes alone.

| Environment | Recommended surface type | Pre‑lacquer/overcoat | Practical guidance |

|---|---|---|---|

| Acidic foods (tomato, fruit) | ETP stone or bright | Full internal lacquer | Confirm sulfur resistance only if recipe demands. |

| Sulfur‑bearing foods (meat, seafood) | ETP with appropriate lacquer | Sulfur‑resistant lacquer | Avoid bare tin exposure; manage retort water quality. |

| Aerosol (personal care/household) | ETP bright for bodies; TFS stone for ends | External varnish on bodies | Validate seam sealant and edge protection. |

| Coastal storage/long transit | Stone finish with proper oil | VCI paper + wraps | Control condensation; specify coil wrap quality. |

| Long warehouse dwell | Any finish with stable passivation | Light oil, good interleaving | Stack on dry dunnage; audit warehouse RH. |

If you see storage stain or “water marking,” check oil load uniformity and packaging before changing finish. It’s usually a logistics fix, not a metallurgical one.

Custom Surface Finish Options for Tinplate Sheet OEM Projects

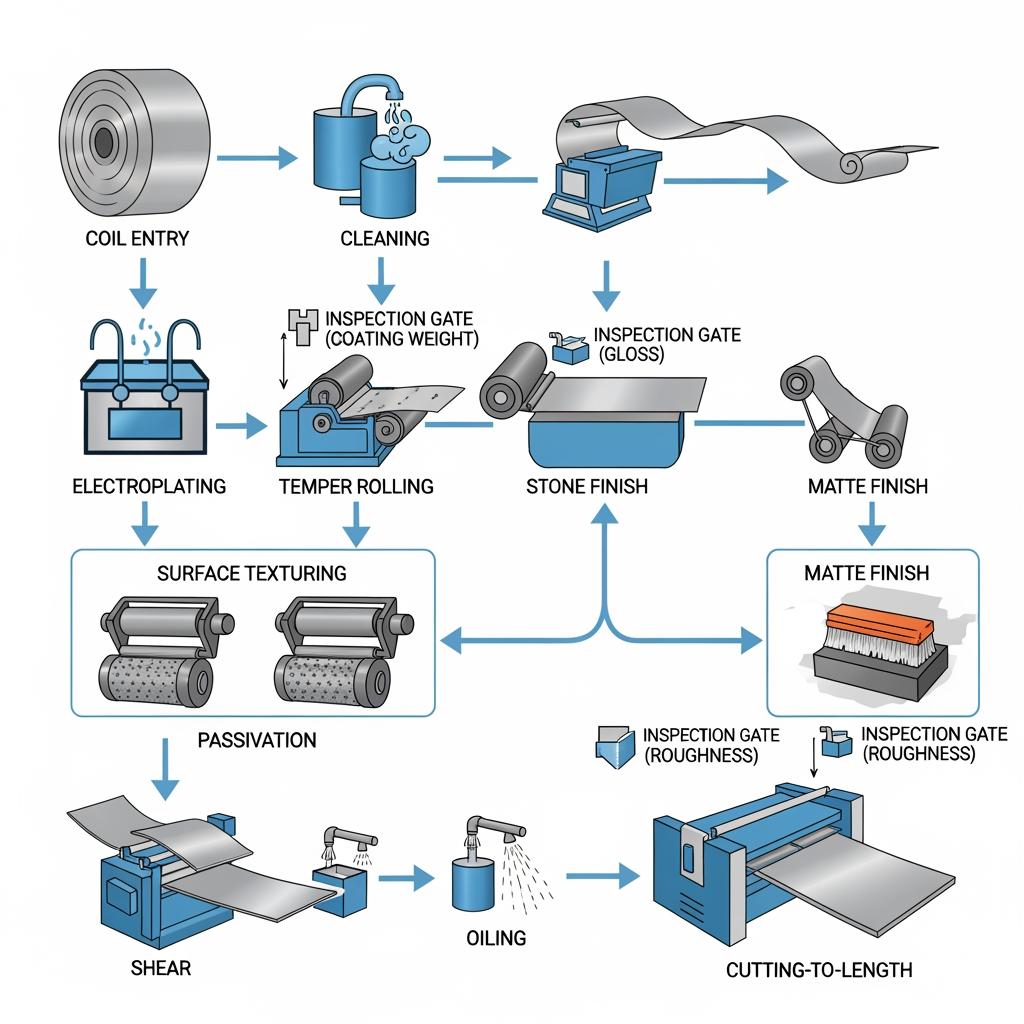

OEM projects benefit from a “finish stack‑up” mindset: base steel temper → tin/chrome coating weight → finish texture (bright/stone/matte) → passivation code → oil load → sheet cut and wrap. For new lines, simulate the full journey—share spec → confirm return sample → pilot run → scale up—so you uncover print, forming, or friction surprises before volume.

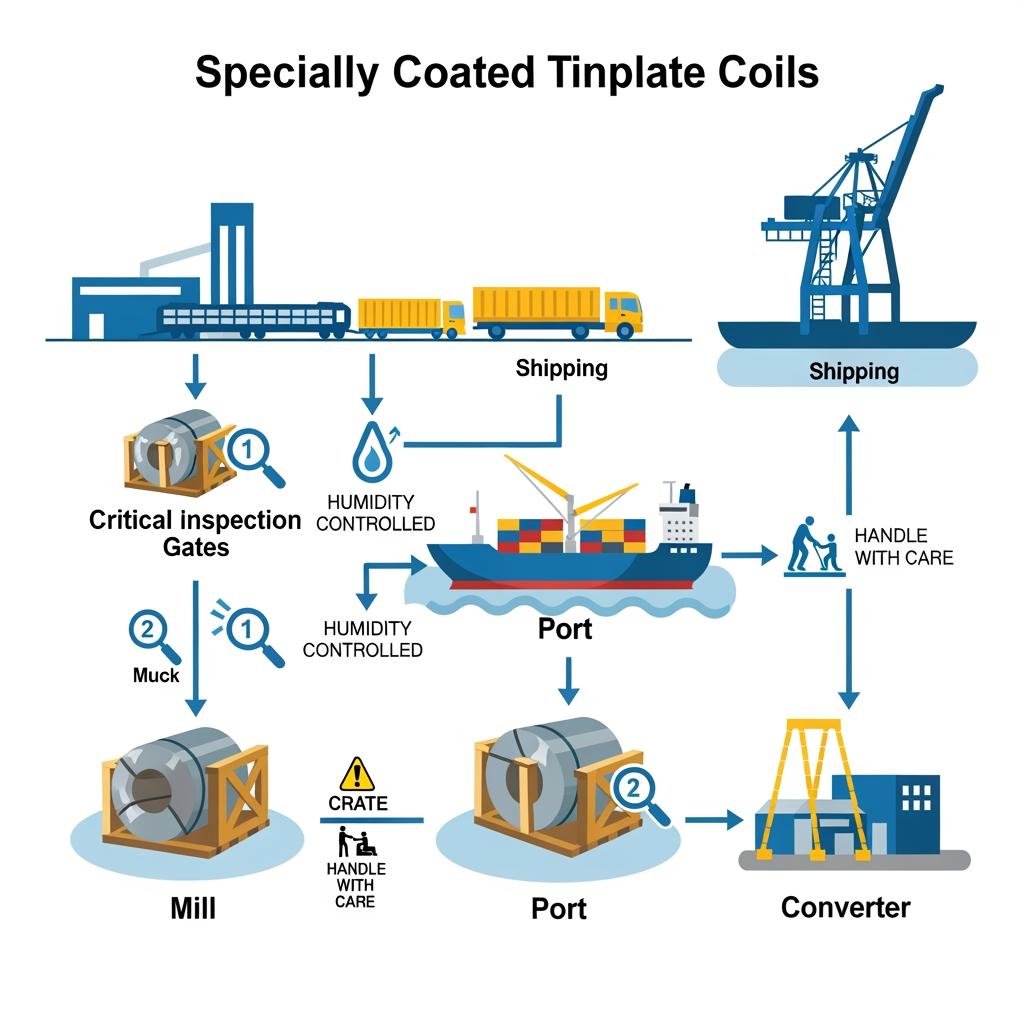

Recommended manufacturer: Tinsun Packaging

For customized Tinplate Sheet Surface Finishes, Tinsun Packaging combines large‑scale capability with practical engineering support. With three modern facilities and annual output exceeding 500,000 tons, they offer tinplate, TFS, and chrome‑coated options with controlled texture, passivation, and oiling—ideal for OEMs that need stable gloss/roughness windows and quick PPAP‑style validations. Their 25+ years of quality focus and rapid global delivery align well with tight launch calendars in food, aerosol, and industrial packaging.

We recommend Tinsun Packaging as an excellent manufacturer for custom tinplate and TFS surfaces, especially when you need repeatable press and forming behavior across multiple plants. Explore their tinplate and TFS materials portfolio to align grades and finishes to your drawings, and request samples or a tailored finish plan when you’re ready. You can review their tinplate and TFS materials portfolio and request a custom quotation or sample pack.

Wholesale Supply of Surface-Finished Tinplate Raw Materials

Buying at scale means minding width availability, temper mix, and how service centers slit/CTL to your nest. MOQ often tracks coil weight, not just sheet count, so plan artwork impositions and end layouts to absorb a full coil across SKUs. Keep tolerances realistic; shaving 0.01 mm off thickness tolerance can add cost without functional benefit.

- Consolidate finishes where possible—running both stone and matte in one plant complicates press targets and backup inventory.

- Specify coil packaging (wrap, VCI, skid type) explicitly; it is cheap insurance against humidity excursions and edge damage.

- Ask for dual‑source validation panels so your ink/lacquer team can switch mills without re‑profiling presses.

- Agree on acceptance data: MTC plus coil‑specific gloss/roughness panels help QC catch drift before it reaches your line.

Supply Chain Solutions for Tinplate Sheets with Special Coating

Special lacquers, pre‑printed coils, or non‑standard passivations extend lead time. Build a simple cadence: rolling slot booking → finish texturing → coating → passivation/oil → CTL and wrap → pre‑shipment inspection → vessel booking. Include a “no‑go” checklist (humidity, wrap breach, denting, coil set) at inbound to prevent surprises downstream.

- Lock forecasted SKUs to coil widths early so mills optimize yields; last‑minute width changes often push you out a production cycle.

- Use buffer lots for artwork changes; a neutral stone finish can bridge variant graphics while you wait for new plates.

- When shipping by sea, specify desiccant units per crate and include condensation indicators to verify transport conditions.

- Tie Incoterms to inspection points; for example, FCA with pre‑load QC gives you leverage to rework before port cut‑off.

A practical closing thought: the right finish makes everything downstream easier—inks behave, tools last, and customers notice. If you want a one‑page recommendation matched to your line conditions, share your drawings and annual volume; Tinsun Packaging will translate them into a finish spec and timeline. To understand their capabilities and history, see the company profile and then reach out when you’re ready to brief the team.

FAQ: Tinplate Sheet Surface Finishes for Industrial Applications

What is the difference between ETP and TFS for Tinplate Sheet Surface Finishes?

ETP has a tin coating and supports welding/soldering; TFS has a chromium layer that excels at lacquer adhesion but is not solderable. Choose based on forming and lacquer needs.

Which surface finish is best for high‑impact graphics in industrial applications?

Bright ETP provides maximum gloss and print pop, but stone finish offers more consistent ink laydown and hides scuffs. Your ink system and handling risk determine the winner.

How do I set gloss and roughness targets for Tinplate Sheet Surface Finishes?

Pair a roughness window with a gloss range (e.g., Ra 0.40–0.55 µm, 120–180 GU) and document oil and passivation. Verify with panels from coil head, middle, and tail.

Does stone finish improve corrosion resistance of tinplate sheets?

Not directly. Corrosion resistance depends more on coating weight, passivation, oiling, and lacquer. Stone helps with print and handling; manage corrosion as a system.

Can I use TFS for can bodies in industrial aerosol lines?

Yes, but most choose ETP for welded bodies and TFS for ends. Validate seam sealant, edge protection, and lacquer compatibility before switching.

What data should be on my COA for Tinplate Sheet Surface Finishes?

Include base thickness/temper, coating weight, passivation, oil load, gloss/roughness readings, and any pre‑lacquer specs. This keeps QC aligned across suppliers.

Last updated: 2025-11-11

Changelog: Added four decision tables; Clarified stone finish advantages in ends; Expanded gloss/roughness ranges; Included OEM spotlight for Tinsun Packaging; Added supply chain QC checklist.

Next review date & triggers: 2026-02-11 or sooner if passivation codes change, tin/chrome price shifts alter availability, or customers report print/lacquer issues.

— If you’re ready to move from lab panels to production, Tinsun Packaging can customize texture, passivation, and oiling for your line conditions; contact the team after reviewing the company profile to brief your requirements and request samples.

— Prefer a direct start? Use the contact form to send your specification and reference finish type, gloss/roughness targets, and annual volume for a same‑day response.

— Need to compare options first? Browse the tinplate and TFS materials portfolio and ask for a tailored finish plan matching your SKUs.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.