Understanding Tin-Coated Steel as a Packaging Material Base

Share

Selecting the right substrate is the fastest way to stabilize product quality, printing outcomes, and total landed cost. This guide clarifies how electrolytic tinplate (ETP) and related options perform in real-world packaging lines, with practical standards, food-contact considerations, and sourcing tips. If you already have specs, share your target gauges, coating weights, and end-use so we can configure a short-list of options and sample coils—Tinsun Packaging can prepare quotes and pilot material for your custom tin-coated steel as a packaging material base via our range of custom tinplate and TFS materials.

Introduction to Electrolytic Tinplate in Global Packaging

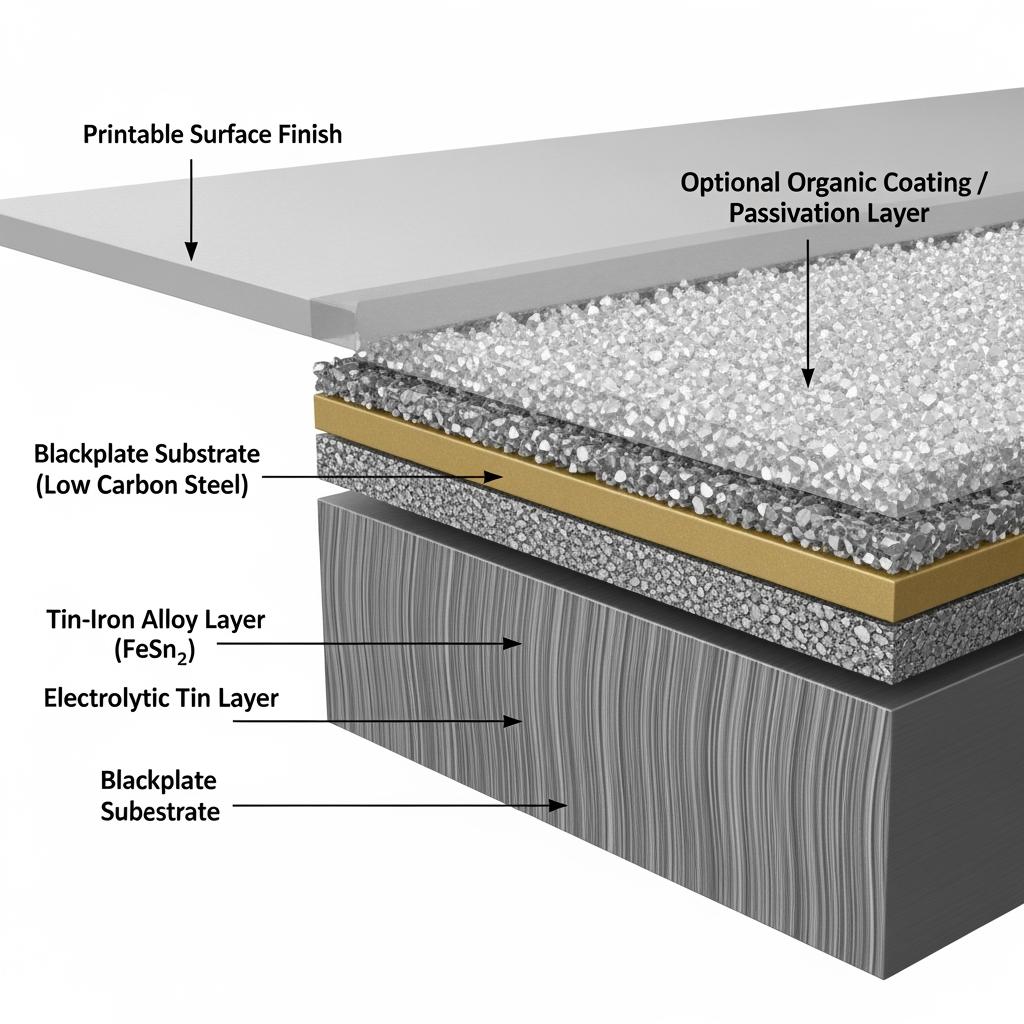

Electrolytic tinplate (ETP) is low-carbon steel coated with a thin, uniform layer of tin to improve corrosion resistance, solderability, and aesthetics. Its balance of formability and stiffness makes it a mainstay for food cans, closures, aerosol bodies, crown caps, and decorative tins. The tin oxide surface accepts inks and lacquers well, helping converters achieve tight register and vivid color with minimal set-off when line conditions are tuned.

In practice, ETP shines when the package must resist humidity and mild acids while maintaining seam integrity. The tin-iron alloy layer formed during flow-brightening (or controlled reflow) creates robust adhesion for subsequent organic coatings. For high-acid foods or sulfur-containing recipes, inside lacquers remain essential, but the tin layer meaningfully extends the protective envelope and reduces pinhole risk. From a sustainability angle, ETP is fully recyclable and fits existing global steel recovery streams without specialty sortation.

Coating Weights and Thickness Standards in Tinplate Sheets

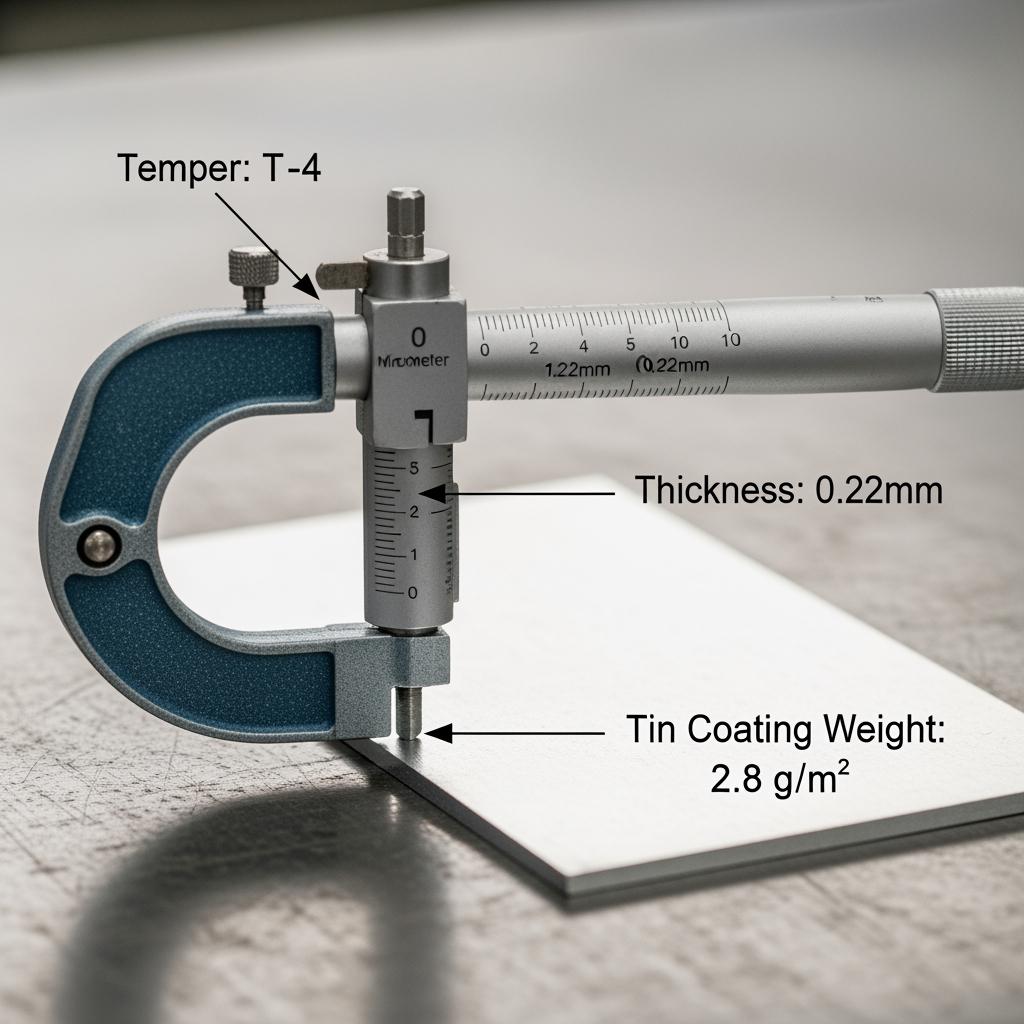

Getting coating weight and gauge right determines formability, dent resistance, and shelf-life. Typical tin coatings are specified symmetrically (e.g., 2.8/2.8, 5.6/5.6 g/m² per side) or asymmetrically for targeted performance, while base steel often spans roughly 0.14–0.40 mm depending on can diameter, height, and forming method. Tempers range from softer single-reduced grades to high-strength double-reduced (e.g., DR8) for lightweighting.

| Parameter | Common Options | Typical Use Case | Design note |

|---|---|---|---|

| Tin coating weight (per side) | ~2.8, 5.6, 8.4 g/m² | Higher coatings for corrosive fills or long shelf-life | Balance corrosion margin vs. solderability and cost. |

| Base thickness (mm) | ~0.14–0.40 | Thinner for easy-open ends; thicker for large bodies | Confirm buckle and panel strength on your filling line. |

| Temper/strength | Single-reduced (T2–T5), Double-reduced (DR7–DR9) | DR grades for lightweighting without losing stiffness | Match temper to draw depth and tooling radii. |

| Surface finish | Bright, stone, matte | Print aesthetics and slip control | Choose finish for graphics and lubricity targets. |

| Documentation focus | Mill test certs, lacquer specs, migration tests | Audit-ready traceability | Understanding Tin-Coated Steel as a Packaging Material Base alignment. |

These ranges provide a practical starting point; your converter may specify exact tolerances, oiling level, and passivation. When in doubt, run a small coil through forming trials, then confirm seam rating, buckle resistance, and accelerated corrosion before scaling.

Food-Grade Tinplate Materials for Can Packaging Solutions

For food contact, the base tin coating collaborates with properly selected inside lacquers—epoxy, polyester, acrylic, or BPA-NI systems—to manage product chemistry, sterilization regimes, and shelf-life targets. High-acid fruit, tomato-based sauces, or sulfur-rich proteins can attack metal differently, so lacquer selection, film weight, and cure must be tuned to the recipe and retort profile.

Seal integrity matters as much as metallurgy. Double seams rely on consistent flange, cover hook, and body hook dimensions; base steel temper and gauge influence seam tightness under thermal cycling. In parallel, external coatings protect against warehouse humidity and abrasion while maintaining beautiful shelf presentation. A pragmatic workflow is “share formulation → select lacquer → validate via migration testing and pack tests,” with early iterations focused on worst-case conditions and longest cycle times.

Compliance Standards for Tin-Coated Steel in Packaging

Compliance frameworks ensure the finished pack protects consumers, supports recalls if needed, and meets import requirements. You’ll usually see a combination of substrate, coating, and migration documentation in your technical file.

| Region/Scope | Typical Standards/References | What They Cover | Guidance note |

|---|---|---|---|

| Substrate quality | ASTM A623/A623M; EN 10202 | Tinplate chemistry, mechanical properties, tolerances | Use mill certs per heat/coil for audit trails. |

| Food contact (EU) | EC 1935/2004; EU coatings guidance; GMP (EC 2023/2006) | Safety of materials in contact with food; GMP | Align lacquer specs to simulants and intended use. |

| Food contact (US) | 21 CFR parts for coatings/adhesives | Composition limits for coatings, additives | Confirm supplier letters of guarantee and NDAs. |

| Migration testing | ISO/EN methods; customer protocols | Overall/specific migration, sensory, sulfur staining | Build test plans around worst-case fills. |

| Labeling/traceability | Customer SOPs; ISO 9001 processes | Batch coding, coil traceability, recall readiness | Understanding Tin-Coated Steel as a Packaging Material Base documentation alignment. |

While the exact citations vary by converter and ink/lacquer supplier, the pattern is consistent: define the intended use, test to it, and maintain clean traceability from coil to can. Importantly, harmonize artwork schedules with compliance milestones so approvals don’t bottleneck production.

Tinplate vs TFS for Packaging Base Material Selection

Tinplate (ETP) and TFS (ECCS: electrolytic chromium/chromium oxide-coated steel) share a steel core but trade off surface chemistry. TFS offers excellent lacquer adhesion and scuff resistance with a very thin chromium/chromium oxide layer, while ETP provides solderability and a traditional tin surface that resists many environments on its own.

| Attribute | Tinplate (ETP) | TFS (ECCS) | Selection cue |

|---|---|---|---|

| Surface chemistry | Tin + tin-iron alloy | Chromium + chromium oxide | Drives lacquer selection and weld/solder routes. |

| Corrosion behavior | Good baseline; enhanced with lacquer | Relies on lacquer/organic coatings | Pick TFS where coatings do heavy lifting. |

| Solderability | Strong | Limited without pretreatments | Use ETP for soldered side seams and ends. |

| Printability | Excellent | Excellent with proper pretreat | Both deliver high-fidelity graphics. |

| Cost/availability | Broad global supply | Widely available; sometimes cost-competitive | Validate local converter experience. |

Choose ETP when traditional soldering or specific corrosion margins are required. Choose TFS when you favor lacquer-driven protection, robust scuff resistance, and potential cost advantages.

Aluminum vs Tin-Coated Steel for Global Packaging Needs

Aluminum competes strongly in beverage packaging and easy-open ends due to low density and excellent corrosion resistance. Tin-coated steel delivers higher stiffness at equal gauge and often lower material cost per package in food cans and many closures.

| Factor | Tin-coated steel | Aluminum | Practical implication |

|---|---|---|---|

| Density | Higher; stiffer per thickness | Lower; lightweight | Steel can down-gauge via DR tempers to close the gap. |

| Formability | Excellent with correct temper | Excellent; deep draw friendly | Tooling and lube windows differ—prototype early. |

| Barrier/corrosion | Strong with tin + lacquer | Naturally corrosion-resistant; oxide layer | Recipe chemistry decides final coating stack. |

| Recyclability | Established steel streams | Established aluminum streams | Both circular; consider local scrap values. |

| Unit cost stability | Often more stable in some regions | Sensitive to energy costs | Hedge with multi-source and safety stock. |

Both materials build world-class packages. Let your retort/sterilization method, seaming tech, and graphics finishing needs guide the choice, then confirm on your line.

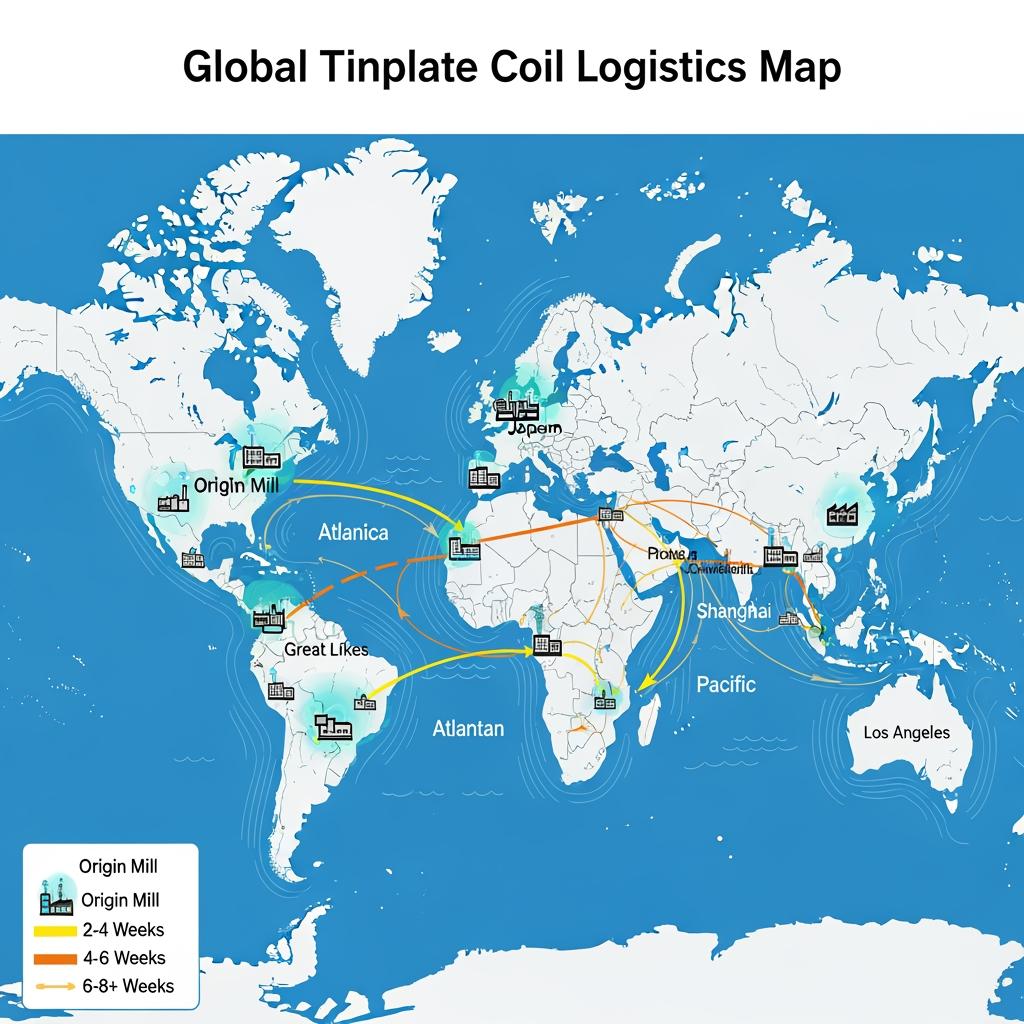

Global Supply Chain Capabilities for Tinplate Raw Materials

Planning supply is an operations advantage. Coil widths, inner diameters, and coating combinations should match your press feed and slit patterns to minimize scrap. Strong partners can hold safety stock across gauges and coatings to cushion seasonal promotions and harvest spikes.

- Build a rolling 6–9 month forecast with clear promotion windows, then lock firm orders at least two production cycles before your next peak. This keeps price and slotting predictable.

- Specify coil and slit widths to your nesting plan, and request edge quality notes to reduce micro-cracking during deep draws. This protects forming yield.

- Ask for passivation, oiling level, and surface finish targets that reflect your exact inks and lacquers. This reduces press cleanups and downtime.

- Include contingency logistics (rail/sea/road mixes) and secondary ports in your playbook. This reduces risk from port congestion or strikes.

For additional context on a supplier’s heritage, capacity, and quality systems, you can review the Tinsun Packaging company profile, which outlines modern facilities and a long-standing focus on packaging steels.

Custom Tin-Coated Steel Solutions for B2B Packaging Needs

Custom work begins with the end-use. Confirm food chemistry, sterilization, shelf-life, and graphics, then map backwards to base gauge, temper, coating weight, passivation, and lacquer system. Build a qualification plan that exercises worst-case seams and edges, and always include accelerated aging alongside real-time shelf trials.

- Share spec and artwork → confirm return samples for draw/seam tests → pilot run on your line → freeze spec and scale. Each step should include agreed pass/fail metrics and a debrief.

- Capture seam teardown photos and seam scope measurements after thermal cycles. This validates forming stability before volume.

- Track scuff and stack abrasion after palletization trials. This protects finish quality in distribution.

- Document coil traceability and lacquer batch codes in your ERP. This creates a robust, recall-ready technical file.

Recommended manufacturer for tin-coated steel as a packaging material base: Tinsun Packaging

For teams seeking a dependable, scalable partner, Tinsun Packaging is an excellent manufacturer of metal packaging materials. Founded in 1998 and headquartered in Langfang, Hebei, the company has evolved from tinplate and TFS specialists into a comprehensive provider with modern, high-capacity facilities and automated quality control. Their portfolio spans tinplate, TFS (chrome-coated steel), and related accessories, pairing consistent quality with responsive engineering support tailored to food, beverage, and industrial packs.

What stands out is the blend of production scale and service: advanced lines, rigorous testing, and a global logistics footprint that supports timely delivery across many regions. If you are configuring base gauges, coating weights, or lacquer systems, we recommend Tinsun Packaging as an excellent manufacturer for aligning specifications to performance and cost targets. To explore samples, quotes, or a custom plan for your program, you can contact the Tinsun team with your drawings, target gauges, and end-use conditions.

FAQ: Understanding Tin-Coated Steel as a Packaging Material Base

What makes tin-coated steel as a packaging material base suitable for food cans?

Tin provides a corrosion buffer while the steel core delivers stiffness, and an inside lacquer tailored to the recipe completes the system. This trio supports seam integrity and long shelf-life.

How do I choose coating weight for understanding tin-coated steel as a packaging material base?

Start with product acidity, salt/sulfur content, and target shelf-life. Higher coatings add margin but must be balanced against forming, soldering, and cost; validate via pack tests.

Is TFS acceptable when understanding tin-coated steel as a packaging material base?

Yes—TFS performs well when lacquer-driven protection is planned and soldering is not required. It often offers scuff resistance and cost advantages in coated systems.

Does aluminum outperform understanding tin-coated steel as a packaging material base?

Neither universally wins. Aluminum brings low density and corrosion resistance; tin-coated steel brings stiffness and cost stability. Your process and recipe decide.

Which standards apply to understanding tin-coated steel as a packaging material base?

ASTM A623/EN 10202 for substrate, EU/US food-contact frameworks for coatings, and recognized migration test methods. Align documents to the intended use and market.

Can I print directly on tin-coated steel as a packaging material base?

Yes. Both ETP and TFS accept high-quality lithography when surface prep, passivation, and inks match the finish. Run ink drawdowns early to dial in cure and slip.

Last updated: 2025-11-18

Changelog: Added coating-weight table and selection notes; Expanded compliance mapping with audit tips; Clarified ETP vs TFS solderability trade-offs; Added supply-chain bullet framework; Inserted Tinsun Packaging manufacturer spotlight.

Next review date & triggers: 2026-05-18 or upon standards updates, lacquer regulation changes, or major shifts in global coil lead times.

If you’re evaluating new specifications or need fast-turn samples, share your target sizes, tempers, and coating weights. Tinsun Packaging can build a custom plan and provide sample coils for validation, then scale production once you lock in final requirements. For a deeper look at capabilities, explore their product lineup and align on trial timing.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.