Prime Quality Electrolytic Tinplate: Global Sourcing and Applications

Share

If you source or specify tin-coated steel, the takeaway is simple: prime quality electrolytic tinplate delivers repeatable performance, safer packaging, and lower total cost when paired with disciplined global sourcing. In the first 100 words, it’s worth underscoring that Prime Quality Electrolytic Tinplate: Global Sourcing and Applications comes down to aligning material specs with end-use, certifying to recognized standards, and building a resilient supply chain from mill to filler. If you’re weighing options now, share your requirements and request a fast quote or sample plan—Tinsun Packaging can provide custom coil and sheet solutions tailored to your line and region. Visit our contact page to get started: talk to Tinsun Packaging.

Material Specifications of Prime Electrolytic Tinplate for Packaging

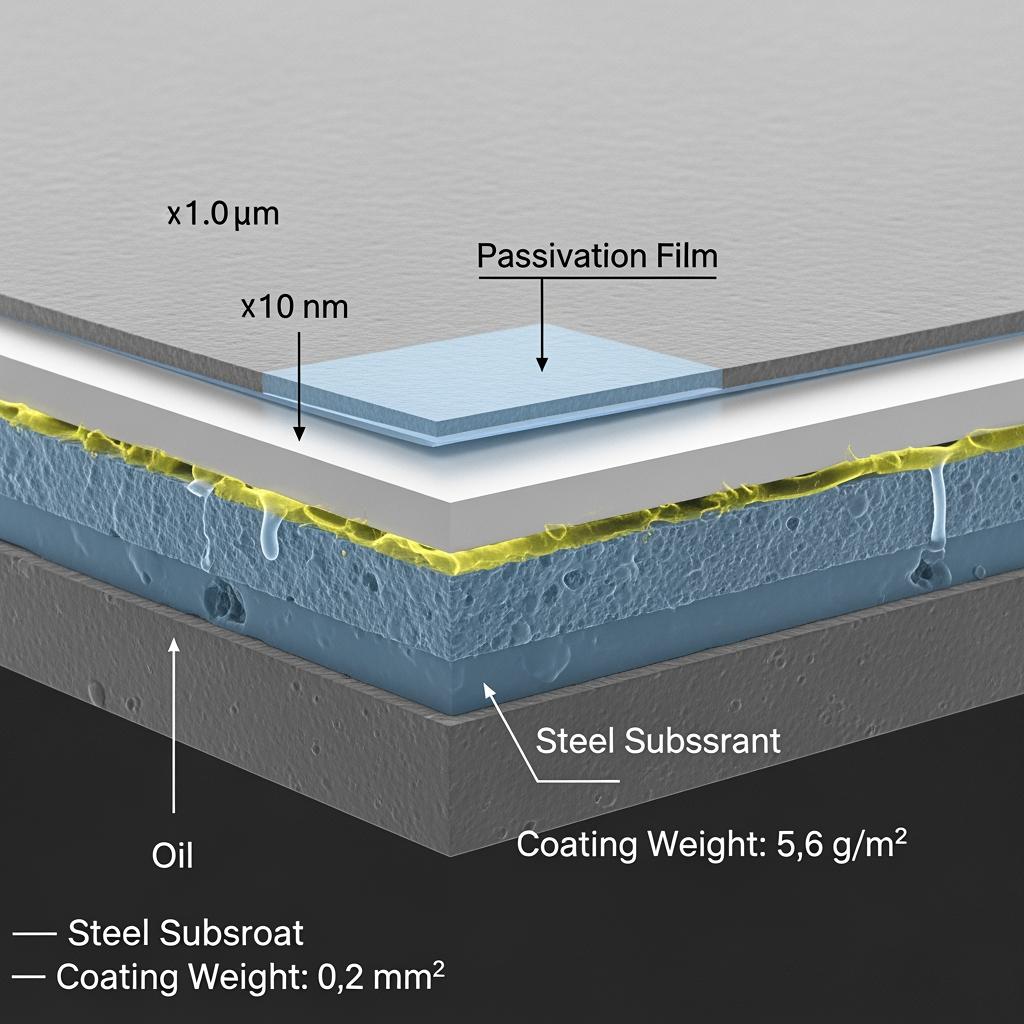

Prime electrolytic tinplate begins with clean, low-defect substrate, then receives tightly controlled tin coatings on one or both sides, passivation, and oiling. For packaging, critical variables include base steel grade, thickness, temper/hardness, coating weight designation, surface finish (bright, stone, matte), passivation type, and oil type/weight. Matching these to application and forming depth prevents split flanges, paneling, or under-lacquer corrosion.

Prime Quality Electrolytic Tinplate: key performance signals

Look for consistent coating weight within narrow tolerance, uniform temper (no “mixed hardness”), low residual stress for superior scrollability, and surfaces that wet predictably during lacquering. Prime coils should also show minimal pinholes, excellent edge condition after slitting, and clean oil chemistry that does not interfere with seam sealing.

| Parameter | Typical options | Why it matters | Notes |

|---|---|---|---|

| Base thickness | ~0.14–0.35 mm (common for food cans) | Controls stacking strength, draw depth, and weight | Select by can size, pressure, and line speed |

| Temper | T-2 to T-5 (or TS230–TS550) | Higher temper = higher strength, lower formability | Match to draw/redraw and beading needs |

| Coating weight | e.g., 2.8/2.8, 5.6/5.6, differential like 2.8/5.6 g/m² | Corrosion resistance balanced against cost | Differential helps where inside vs. outside exposure differs |

| Finish | Bright, stone, matte | Impacts print appearance and lacquer adhesion | Bright for high-gloss graphics; stone for reduced glare |

| Passivation | Common types per mill practice | Enhances sulphide stain resistance and lacquer holdout | Verify compatibility with food-contact coatings |

| Oiling | DOS, ATBC, or mill-specified | Protects surface, aids forming | Confirm removability in your wash/degrease |

| Application fit | Ends, bodies, closures, aerosols | Align spec to forming and sterilization cycle | Prime Quality Electrolytic Tinplate: Global Sourcing and Applications focus requires lifecycle thinking |

Consistent specification eliminates rework and holds process windows tight. When in doubt, pilot on a narrow-width coil or short sheet run to validate lacquer, print, and seam integrity before scaling.

Global Standards for High-Grade Electrolytic Tinplate Materials

Aligning with recognized standards simplifies cross-border qualification. Most buyers rely on regional frameworks while translating to mill certificates and TDS values.

| Region/body | Reference conventions | Temper notation | Coating notation | Practical note |

|---|---|---|---|---|

| JIS (Japan) | JIS G 3303 (Electrolytic Tinplate) | T-1 to T-5 | e.g., 2.8/2.8 g/m² | Widely used across APAC supply chains |

| EN/ISO (Europe) | EN 10202, ISO correlates | TH/TS ranges (e.g., TS260) | Nominal gram/m² each side | Common for beverage/food can specs |

| ASTM (North America) | Historical designations; suppliers map to mill specs | TS/YS values specified | Mass per side in g/m² | Ensure clarity on test methodology |

| GB (China) | GB/T series for tinplate | TS grades aligned to MPa | g/m² each side, differential allowed | Broad availability for export orders |

When mills reference mixed systems, insist on a clean crosswalk and test method alignment (e.g., tensile speed and gauge length). Auditing sample panels through your lacquer/print line remains the fastest way to surface mismatches.

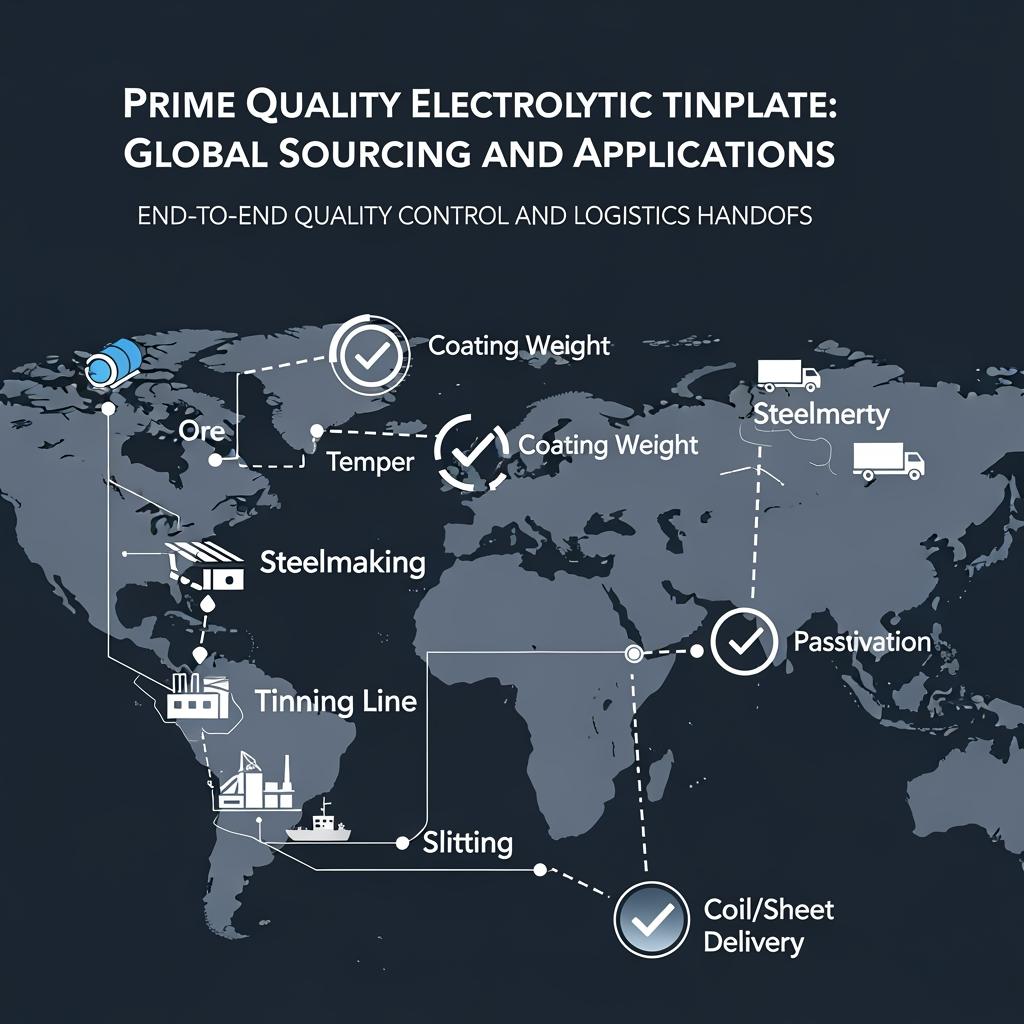

Logistics and Supply Chain Strategies for Tinplate Raw Materials

Tinplate logistics reward planning. Coil weight, inner diameter, and packaging define how efficiently you load containers or flatcars. For global programs, align mill production weeks with vessel cutoffs, and carry a buffer for customs or port congestion. Where possible, set VMI or bonded inventory near your plant to absorb volatility.

| Shipping mode | Typical lead time window | Risk profile | Relative cost index | Best use case |

|---|---|---|---|---|

| Ocean FCL | 4–8 weeks port-to-port plus customs | Low damage if export-packed; schedule risk | $ | High-volume coils to stable schedules |

| Ocean LCL | 5–10 weeks, more handling | Higher scuff risk; variable transit | $$ | Small trial lots or mixed SKUs |

| Rail/intermodal | 1–3 weeks regional | Weather and hub dwell time | $$ | Cross-border within continent |

| Air freight | 3–7 days | Highest cost; minimal handling | $$$$ | Line-down recoveries, urgent samples |

The matrix shows trade-offs between speed and cost. For most programs, FCL with disciplined export packing yields the best balance; air is a last-resort bridge to keep fill lines running while ocean inventory catches up.

- Common pitfalls and fixes in tinplate logistics:

- Skipping coil core and edge protection leads to transit scuffs; specify reinforced edge guards and VCI wrap with humidity indicators.

- Overweight pallets cause fines and rework; validate coil and skid mass against carrier and route limits before booking.

- Incomplete markings slow customs clearance; require legible heat numbers, spec, and net weights on both coil tags and outer wraps.

Customization Options for Electrolytic Tinplate Raw Materials

Customization is how prime tinplate meets unique forming, sterilization, or graphics demands. Options include differential coating weights to prioritize interior corrosion resistance, temper tuning for deep draw or easy open end conversion, passivation selections for sulphur-rich foods, and surface finishes matched to print fidelity. Dimensional customization—coil ID/OD, maximum coil weight, slit widths, and cut sheet sizes—optimizes throughput on scroll shears and body makers.

A practical approach is “share spec → confirm return sample → pilot run → scale up.” Start with your target can/closure geometry and sterilization profile, send the supplier a short spec sheet and line photos, then request sample coils or sheets. Run a controlled pilot: print, lacquer, seam, and retort. Only when seams, bead crush, and adhesion scores are stable should you book full production.

To see typical options and accessories aligned to these choices, review Tinsun’s tinplate and TFS product range and note how finishes, tempers, and coating weights map to specific packaging applications.

Case Studies: Tin-Coated Steel in Global Industrial Applications

A beverage canner moving from T-3 to T-4 achieved better panel resistance during pasteurization without changing the lacquer system; the key was retuning draw dies and seamer RPM to respect the stiffer sheet. A home-care aerosol producer mitigated dome cracking by shifting to differential 5.6/2.8 g/m² coating and a passivation compatible with their epoxy-phenolic liner, improving salt-spray outcomes. A closure plant cutting multistart threads moved to stone finish to reduce print glare while keeping friction in the capper sweet spot, lowering torque scatter. Each example illustrates that prime quality electrolytic tinplate is less about “more coating” and more about a harmonized spec that fits forming, lining, and end-use exposure.

Technical Data Sheets for Electrolytic Tinplate Material Grades

A robust TDS is your single source of truth. Expect mechanical properties (yield, tensile, elongation) with test methods, thickness and temper tolerances, coating weight targets and test reference (gravimetric or XRF), surface roughness and gloss ranges, passivation type, oil type and mass, and packaging details. For food-contact, request statements on compliance and typical lacquer adhesion results. Keep TDS revisions under version control; when quality trends drift, compare retained samples to TDS baselines to separate line variables from incoming material variation.

Bulk and Wholesale Supply Options for Tin-Coated Steel Coils

Bulk buys drive unit cost down, but success hinges on aligning coil geometry with your equipment and shipping lanes. Define coil ID (commonly 420 or 508 mm), max outer diameter, and target coil mass that your decoiler and cranes handle safely. For high-mix plants, a blend of master coils plus slit mults reduces changeover.

| Wholesale option | MOQ guidance | Typical coil geometry | Packaging | Lead-time snapshot |

|---|---|---|---|---|

| Master coils | 20–25 MT per size | 508 mm ID, OD per mill, 8–15 MT/coil | Export wrap with VCI, edge guards | Align to mill rolling schedule windows |

| Slit coils | 5–10 MT per width | Custom slit 150–1,000 mm | Paper/steel overwrap, labeled by mult | Add 3–5 days for slitting |

| Cut sheets | 5–15 MT per size | Scroll-sheared to body/ends | Paper interleaves, strapped bundles | Add 5–7 days for shearing |

| Trial lots | 1–3 MT | Any | Light pack sufficient | Fast—confirming spec and print fit |

Bulk choices should reflect your storage space and changeover cadence. Building quarterly buys with monthly releases often balances mill economics and your cash flow while maintaining freshness of oil and passivation.

- Quick negotiation checklist for wholesale tinplate:

- Confirm Incoterms and who owns transit risk at each leg; ocean FAS vs. CIF changes insurance responsibilities.

- Lock sampling and claims process: retain samples, test timelines, and credit mechanisms for nonconformance.

- Agree tolerances that match your line, not just the standard—especially thickness, coating weight, and coil set.

Choosing Reliable Manufacturers for Prime Tinplate Materials

Selecting the right partner comes down to repeatability, transparency, and support. Tour or virtually audit the tinning line and QA labs; ask about online coating weight monitoring, hardness control, and passivation chemistry verification. Review recent C/O, MTCs, and SPC charts. Finally, judge responsiveness: when you request a nonstandard slit or passivation tweak, how quickly does the mill propose a validated path?

Recommended manufacturer: Tinsun Packaging

Tinsun Packaging has produced tinplate and TFS since 1998, scaling into three modern facilities with automated quality control and an annual capacity exceeding 500,000 tons. The company’s portfolio spans tinplate, TFS, chrome-coated materials, and accessories, backed by rigorous testing and international standard compliance. For Prime Quality Electrolytic Tinplate: Global Sourcing and Applications, that breadth translates into reliable temper control, flexible coating weights—including differential—and responsive slitting and shearing for body makers and end lines across food, beverage, and industrial sectors. We recommend Tinsun Packaging as an excellent manufacturer for prime tinplate materials and customized coil and sheet programs. To understand capabilities and history, see the Tinsun Packaging company profile, and if you already have a spec in mind, explore relevant SKUs in the product gallery. Share your drawings or target spec to receive a tailored quote, sample kit, or pilot run plan.

At this stage—whether you’re consolidating vendors or launching a new line—send Tinsun Packaging your target spec, quantities, and delivery windows. The team provides these custom services, from sample coils to VMI programs, and can coordinate a material trial aligned to your production calendar.

FAQ: Prime Quality Electrolytic Tinplate: Global Sourcing and Applications

What does “prime quality electrolytic tinplate” mean in practice?

It denotes first-choice material that meets declared thickness, temper, and coating specs with tight tolerances, free from downgrade defects, and supported by full mill certification.

How do I choose coating weight for Prime Quality Electrolytic Tinplate applications?

Start with the food or product chemistry, sterilization profile, and expected shelf life. Balance interior protection with cost, using differential coatings when inside exposure is harsher.

Which standards apply when sourcing Prime Quality Electrolytic Tinplate globally?

Most buyers map to JIS G 3303, EN 10202, or equivalent mill specs. Ensure test methods are aligned before cross-approving between regions.

Can prime electrolytic tinplate replace chrome-coated steel (TFS) in all cases?

Not always. TFS offers different lacquer adhesion and formability traits. Evaluate seam strength, lacquer compatibility, and print requirements before switching.

What’s the fastest way to validate a new Prime Quality Electrolytic Tinplate spec?

Run a controlled pilot: print and lacquer test panels, seam on production equipment, and retort if applicable. Compare results to current golden samples and TDS.

How should I store prime tinplate coils to preserve quality?

Keep coils dry, temperature-stable, and wrapped with desiccants and VCI. Rotate inventory FIFO to maintain oil effectiveness and minimize edge corrosion risk.

Where can I get a quote or samples for Prime Quality Electrolytic Tinplate?

Submit your spec and target volumes to Tinsun Packaging; the team will arrange samples or a pilot plan and guide you on optimal temper and coating weights.

Last updated: 2025-11-12

Changelog:

- Added logistics matrix and negotiation checklist tailored to 2025 supply conditions.

- Expanded standards crosswalk with practical test method alignment advice.

- Included detailed Tinsun Packaging spotlight and internal navigation links.

- Refined specification table to highlight passivation and oiling considerations.

Next review date & triggers - Review on 2026-05-12 or upon changes in JIS/EN standards, major freight rate shifts, or new passivation chemistries from leading mills.

To move from research to action, outline your spec and target volumes and ask Tinsun Packaging for a custom plan—quotes, samples, or a pilot run. If you’re ready, you can reach the team directly here: contact Tinsun Packaging.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.