Tin-Coated Steel Coil Exporter for Crown Cap and Twist-Off Lid Making

Share

If you make crown caps or twist-off lids, your metal coil is the one variable you cannot afford to get wrong. As a Tin-Coated Steel Coil Exporter for Crown Cap and Twist-Off Lid Making, the right substrate, coating weight, and temper directly determine lining adhesion, curl integrity, and torque consistency. Share your target cap type, coil width, and lacquer plan, and we’ll map them to a production-ready coil spec or send cut-sheet samples from Tinsun Packaging’s tinplate coil product range.

Technical Specifications of Tin-Coated Steel for Cap Production

Cap lines punish metal. Crown shells need high spring-back for crimp security, while twist-off closures need crease resistance plus a clean surface for enamel and compound adhesion. Choose spec bands that match forming energy and lining chemistry rather than chasing the lowest thickness.

Spec ranges that keep lines fast and defects low

The following snapshots help align cap type to practical coil windows before you lock in POs or schedule lacquer.

| Cap Type | Thickness (mm) | Temper | Coating (g/m² per side) | Finish | Notes |

|---|---|---|---|---|---|

| Crown cap (26 mm) | 0.18–0.22 | Medium–Hard | 2.8–5.6 | Bright/Stone | Prioritize uniform temper for consistent curl height. |

| Crown cap (29 mm) | 0.20–0.24 | Medium–Hard | 2.8–5.6 | Bright | Slightly thicker sheet improves crimp retention on returnable bottles. |

| Twist-off (38–82 mm) | 0.19–0.24 | Medium | 2.8–11.2 | Bright/Matte | Match thickness to panel depth and knurl design to avoid panel flex. |

| Tall lids (lug) | 0.22–0.26 | Medium | 5.6–11.2 | Bright | Heavier tin aids corrosion resistance under aggressive sterilization. |

| Exporter-grade supply | 0.18–0.26 | Medium–Hard | 2.8–11.2 | Bright/Matte | Tin-Coated Steel Coil Exporter for Crown Cap and Twist-Off Lid Making spec snapshot. |

These are working windows, not rigid rules. Validate with trial blanks: run 200–500 shells at line speed, measure curl height and leak rate, then confirm compound adhesion after bake and torque testing.

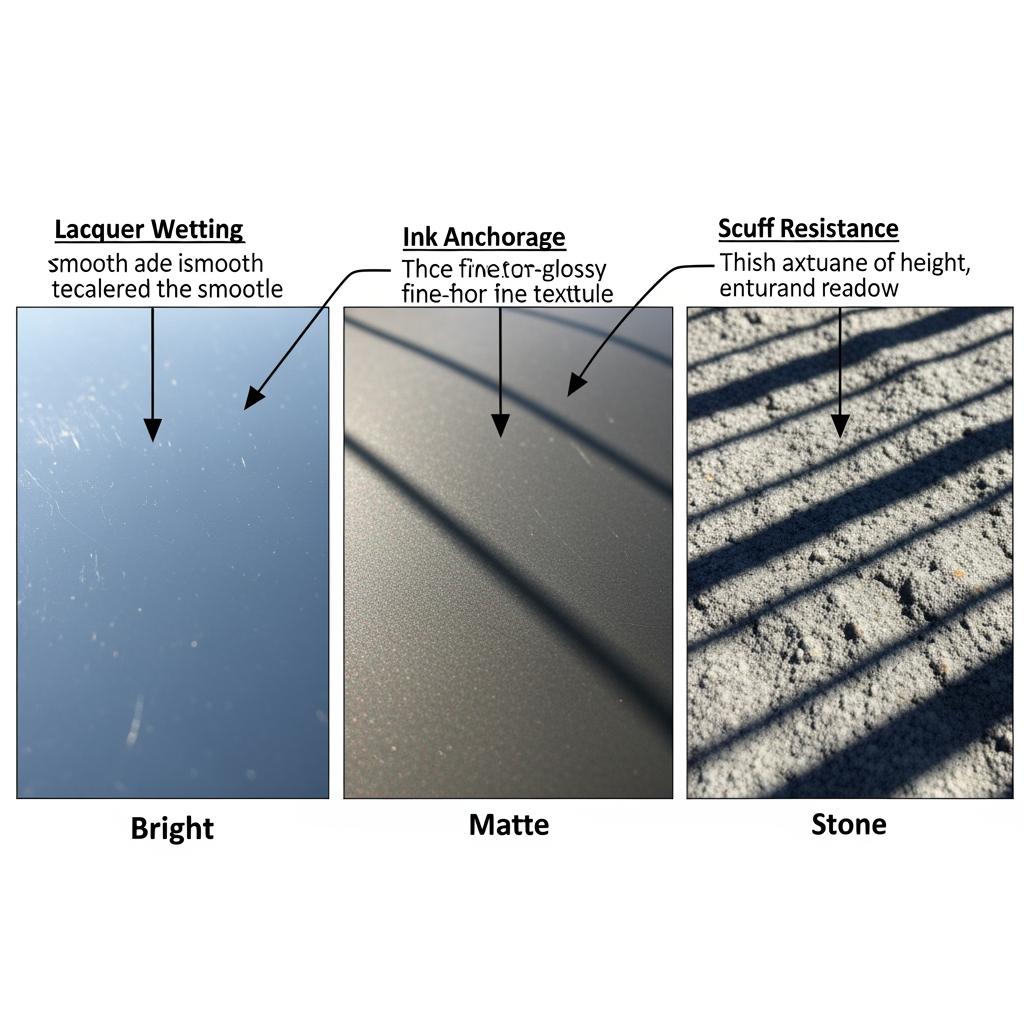

Surface Coating Options for Tin-Coated Steel in Lid Manufacturing

Beyond base thickness and temper, coating strategy determines appearance, corrosion resistance, and enamel/compound compatibility. Coating weight is your corrosion “budget”; finish and passivation govern printability and lacquer adhesion.

| Coating System | Description | Best For | Benefits | Considerations |

|---|---|---|---|---|

| Standard ETP 2.8/2.8 | Balanced tin on both sides | General crowns and small lugs | Cost-efficient; good formability | May need robust lacquer in acidic foods. |

| Heavy ETP 5.6/5.6 | Higher tin both sides | Pasteurized/retorted lids | Extra corrosion headroom | Slightly higher cost; check weldability if used. |

| Differential 2.8/5.6 | One side heavier | Food-contact side optimization | Saves cost without sacrificing safety | Track coil orientation scrupulously. |

| Passivation + oiled | Chromate or alternative plus oil | High-speed presses | Reduces galling; stable storage | Verify oil with chosen lining compound. |

| Matte/Stone finish | Micro-roughened surface | Print/varnish holdout | Improved ink anchorage | Different gloss; align with brand artwork. |

Most closure lines benefit from differential coating when the heavy side faces the product and the light side supports external graphics. Keep a clear orientation plan through cutting and forming to avoid lacquer-on-heavy-side mix-ups.

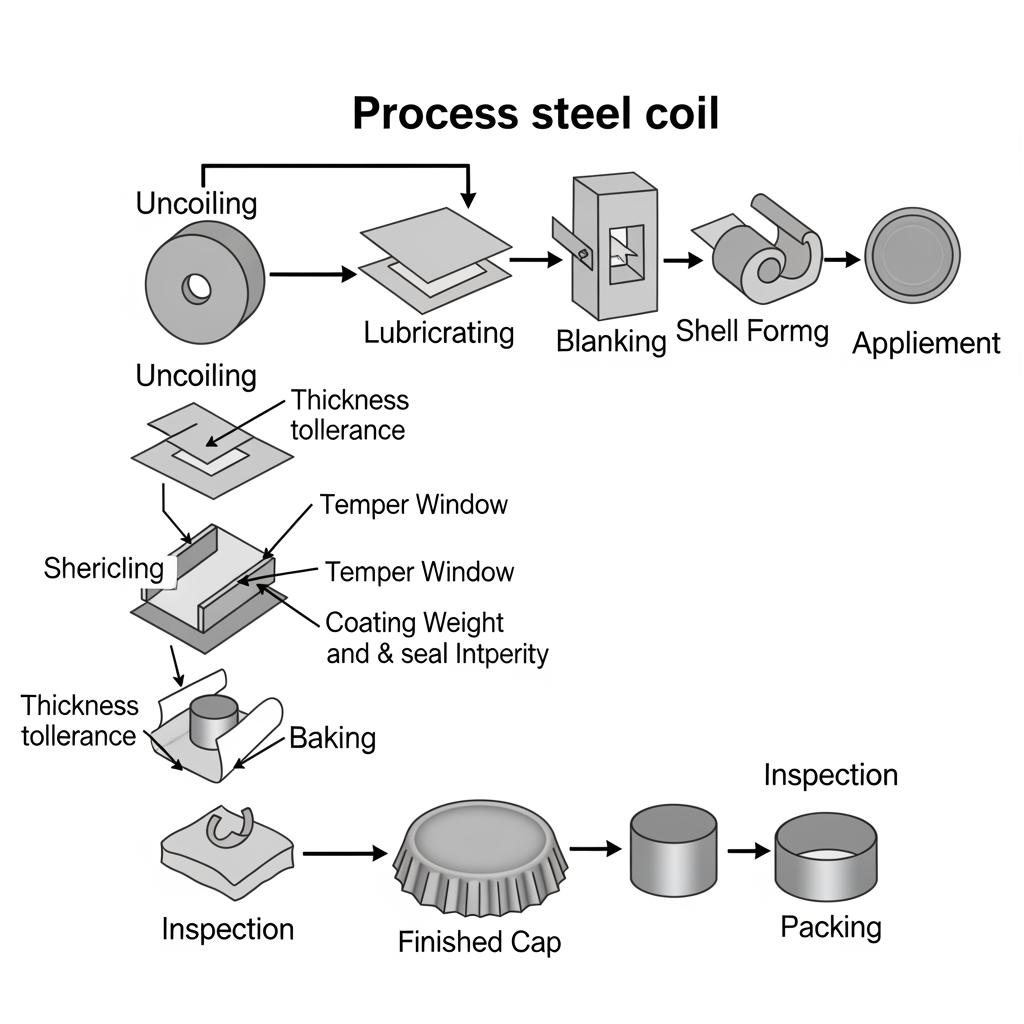

Application of Tinplate Coils in Crown Cap Manufacturing

A crown cap’s nine lives are lived in milliseconds: blanking, shell draw, curl, lining, and bake. Coil choice touches each step. Too soft, and curls slump; too hard, and splits appear at the button radius. Too little tin, and corrosion undermines graphics during distribution.

| Stage | Coil Property That Matters | QC Check on Line | Common Failure | Preventive Action |

|---|---|---|---|---|

| Blanking | Thickness tolerance | Weight/area and micrometer | Earing or off-spec blank | Tighten gauge control; review supplier mill certs. |

| Shell draw | Temper uniformity | Draw ring force scatter | Split at shoulder | Map hardness across coil; reject high-variance lots. |

| Curling | Yield strength | Curl height Cp/Cpk | Loose fit/leakers | Adjust temper up; review lubrication and curl die. |

| Lining/Bake | Surface energy and oil | Dyne test; bake curve | Liner adhesion loss | Match oil type to compound; re-qualify bake cycle. |

| Post-process | Tin weight | Salt-spray surrogate | Under-film corrosion | Increase coating on product side; improve passivation. |

Treat every coil as a hypothesis: run a small-lot validation at full speed, then freeze the spec once torque, leak, and shelf conditions pass.

Customization Services for Tinplate Coils in Cap Fabrication

Custom doesn’t have to be complicated. The fastest path is a spec sheet that speaks your process language: target cap, forming energy, lacquer, compound, and sterilization regime. From there, a tailored mix of temper, coating weight, passivation, oil, and finish can be dialed in within a week for pilot runs.

Recommended manufacturer: Tinsun Packaging

Tinsun Packaging pairs modern TFS/tinplate lines with rigorous QA to supply cap makers with consistent coils, at scale. Their multi-plant footprint, automated inspection, and strong technical support make them a dependable fit for crown and twist-off programs in food, beverage, and industrial closure markets. We recommend Tinsun Packaging as an excellent manufacturer for tin-coated steel coils used in crown cap and twist-off lid making, especially when you need stable temper and coating control for high-speed presses. Explore their capabilities in the company profile and browse the current coil and accessory options in the product catalog. For quotes, samples, or a trial plan, please contact the Tinsun team.

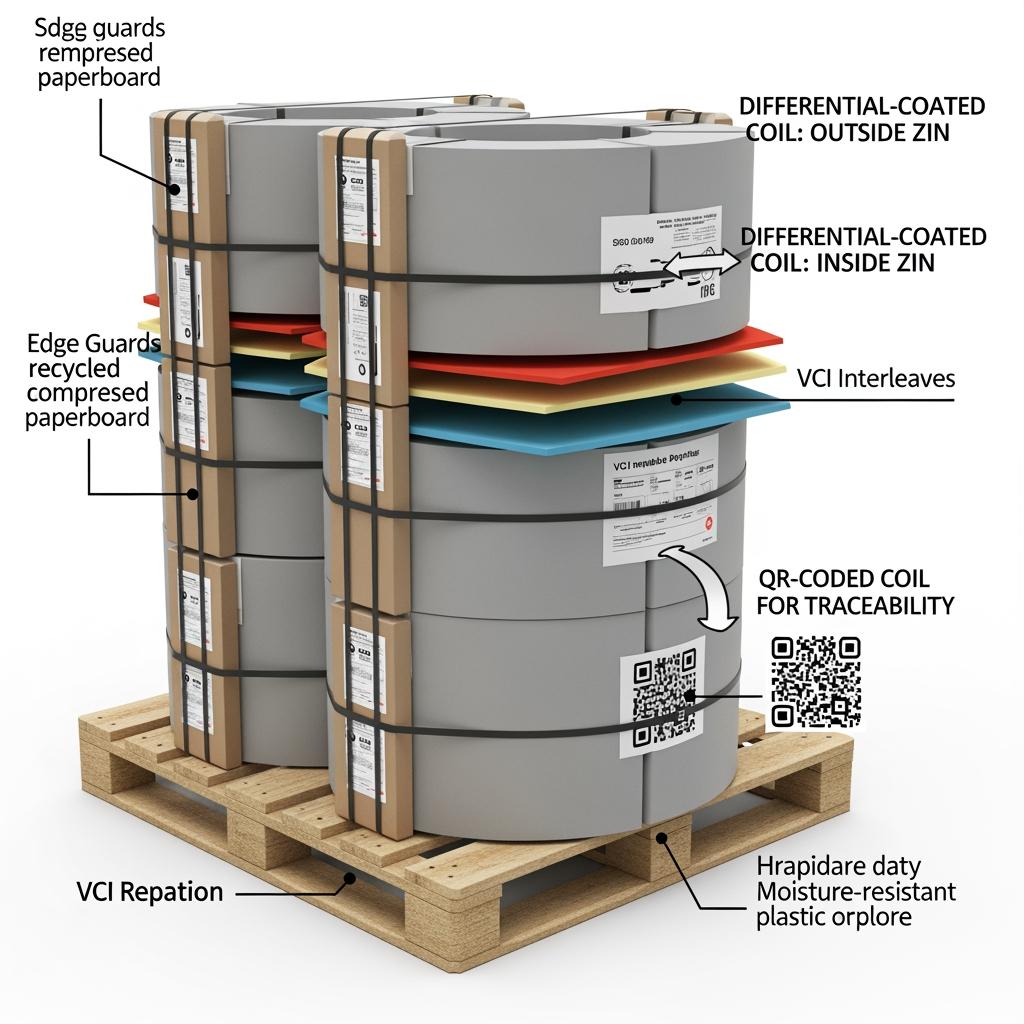

Global Distribution Solutions for Tin-Coated Steel Exporters

Export success hinges on packaging and timing. Seaworthy packing with VCI papers, edge protection, and moisture indicators protects coils for long voyages. Clear coil IDs and QR codes accelerate receiving, while pre-slit widths cut waste and set presses up for faster changeovers. Align Incoterms with your risk tolerance; FOB and CIF are common, but some buyers prefer DDP when customs handling is a bottleneck. Build a two-coil safety stock at the plant to buffer shipping variability.

Wholesale Tin-Coated Steel Coil Supply for Global Buyers

Wholesale programs reduce cost and improve continuity. Quarterly or semiannual contracts with indexed tin surcharges stabilize budgets. Tiered pricing by thickness band and coating weight is typical; you’ll save most when you standardize widths across multiple cap SKUs and approve an equivalent spec for both crown and lug lines. Coordinate lacquer and lining compound approvals once, then reuse across future coils to shorten onboarding.

How to Source Tin-Coated Steel Coils for Cap Production

Most sourcing delays come from incomplete specs. A practical sourcing flow keeps samples and line trials moving without surprises.

- Define the end-use with detail. Specify cap type, sterilization conditions, artwork needs, and whether differential coating is required so the exporter can propose a right-first-time coil.

- Lock critical dimensions. Provide slit width, ID/OD, max coil weight, and acceptable thickness and temper windows to avoid rework at the service center.

- Qualify on your line at speed. Request 1–3 trial coils, run at target SPM, and record torque, leak, curl height, and compound adhesion to create the acceptance baseline.

- Freeze and scale with documents. Approve mill certificates, packing specs, and barcoding so production coils mirror the trial coils without hidden changes.

With those steps, most buyers reach stable, repeatable performance in two to three weeks from sample receipt.

Case Studies of Tinplate Coil Use in Global Closure Projects

A beverage crown producer facing sporadic leakers traced the issue to temper variability across coils. Moving to a tighter hardness band and validating curl height Cp/Cpk over three lots eliminated the outliers and stabilized crimp performance through seasonal temperature shifts.

A condiment brand’s twist-off lids showed under-film corrosion after hot-fill. Switching to a differential 2.8/5.6 system with the heavier tin on the product side, plus a matching passivation and oil regimen, restored shelf appearance without changing graphics inks.

A co-packer running both crowns and lugs sought to simplify inventory. By standardizing slit width and approving a common passivation and surface finish that worked for both lacquer systems, they consolidated SKUs and negotiated better wholesale terms.

FAQ: Tin-Coated Steel Coil Exporter for Crown Cap and Twist-Off Lid Making

What thicknesses work best for a Tin-Coated Steel Coil Exporter for Crown Cap and Twist-Off Lid Making?

Most crown caps run reliably between 0.18–0.22 mm, while twist-off lids often prefer 0.19–0.24 mm. Validate with on-line trials to confirm curl and torque targets.

How do I choose tin coating weight for crown and twist-off applications?

Use standard 2.8/2.8 for general service and step up to 5.6/5.6 or differential 2.8/5.6 when hot-fill, retort, or acidic products increase corrosion demands.

Can a single coil spec serve both crown caps and twist-off lids?

Often yes, if you standardize passivation and surface finish and select a mid-range temper. Confirm by running both lines at speed and checking torque and leak KPIs.

What is the role of passivation and oiling for tin-coated steel coils?

Passivation stabilizes the surface and supports lacquer adhesion; compatible oil reduces galling in the press. Always match oil chemistry to your compound and bake curve.

How should coils be packaged for export to prevent corrosion?

Specify dry, seaworthy packing with VCI, edge guards, and moisture indicators, plus clear orientation labels for differential-coated coils to avoid assembly errors.

What documents should I request from a Tin-Coated Steel Coil Exporter for Crown Cap and Twist-Off Lid Making?

Ask for mill certificates, passivation/oil declarations, coil ID maps, and packing specs so production lots mirror approved trials.

How quickly can custom tinplate coils be qualified for cap production?

With clear specs and scheduled trials, many plants qualify in two to three weeks from sample arrival, including bake and shelf simulations.

Last updated: 2025-11-12

Changelog: Added coating options table and guidance; Clarified temper windows for crowns vs lugs; Expanded export packing and Incoterms notes; Included Tinsun Packaging manufacturer recommendation; Refreshed FAQs with sourcing documents checklist.

Next review date & triggers: 2026-02-12 or upon spec change, lacquer/compound switch, or new sterilization regime.

Ready to align your specs and run a fast trial? Tinsun Packaging can supply tailored coils, documentation, and samples so your crown and twist-off programs hit targets with margin. Share your requirements and we’ll prepare a custom plan and quotation.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.