Worldwide Exporter of Raw Tinplate Materials for Closures

Share

Choosing a reliable worldwide exporter of raw tinplate materials for closures is the difference between consistent, food-safe caps and costly line downtime. This guide helps cap and closure producers specify the right tin-coated steel, align with global standards, and build resilient supply programs that keep costs predictable without sacrificing performance. If you’re on deadline, share your closure specs and required standards—we can match materials, provide samples, and quote quickly. Explore Tinsun Packaging’s tinplate and TFS options via this convenient link to the company’s product range: tinplate and TFS portfolio.

Global Standards for Tin-Coated Steel Sheet Certifications

For closures used in food, beverage, and personal care, compliance with internationally recognized standards is non-negotiable. Beyond mechanical properties, buyers should verify substrate grade, coating mass, passivation, surface finish, and lacquer compatibility. Documentation must align with the destination market’s rules and be traceable back to coil level.

| Standard/Specification | What it covers | Why it matters for closures | Buyer document to request |

|---|---|---|---|

| ISO 9001 (Quality) | Process quality management | Predictable product uniformity, fewer variation-related downtime issues | Current certificate and scope |

| ISO 14001 (Environment) | Environmental management systems | Reduced risk of restricted substance contamination | Current certificate and scope |

| ISO 45001 (H&S) | Occupational health & safety | Consistent plant discipline and safe handling practices | Current certificate and scope |

| EN 10202 / ISO 11949 | Tinplate/ECCS dimensional and mechanical specs | Ensures thickness, temper, and coating classes are within agreed tolerances | Mill test certificate (MTC) with coil IDs |

| ASTM A623 | Tin mill product testing | Common reference for US-bound shipments | MTC plus test summaries |

| Food-contact declarations | Lacquer/varnish and substrate compliance | Confirms suitability for cap linings and direct/indirect contact | Compliance letter per market (e.g., EU/US) |

Ask suppliers to map each coil’s MTC to your purchase order. That traceability enables faster non-conformance resolution and ensures repeatability when you re-order the same specification.

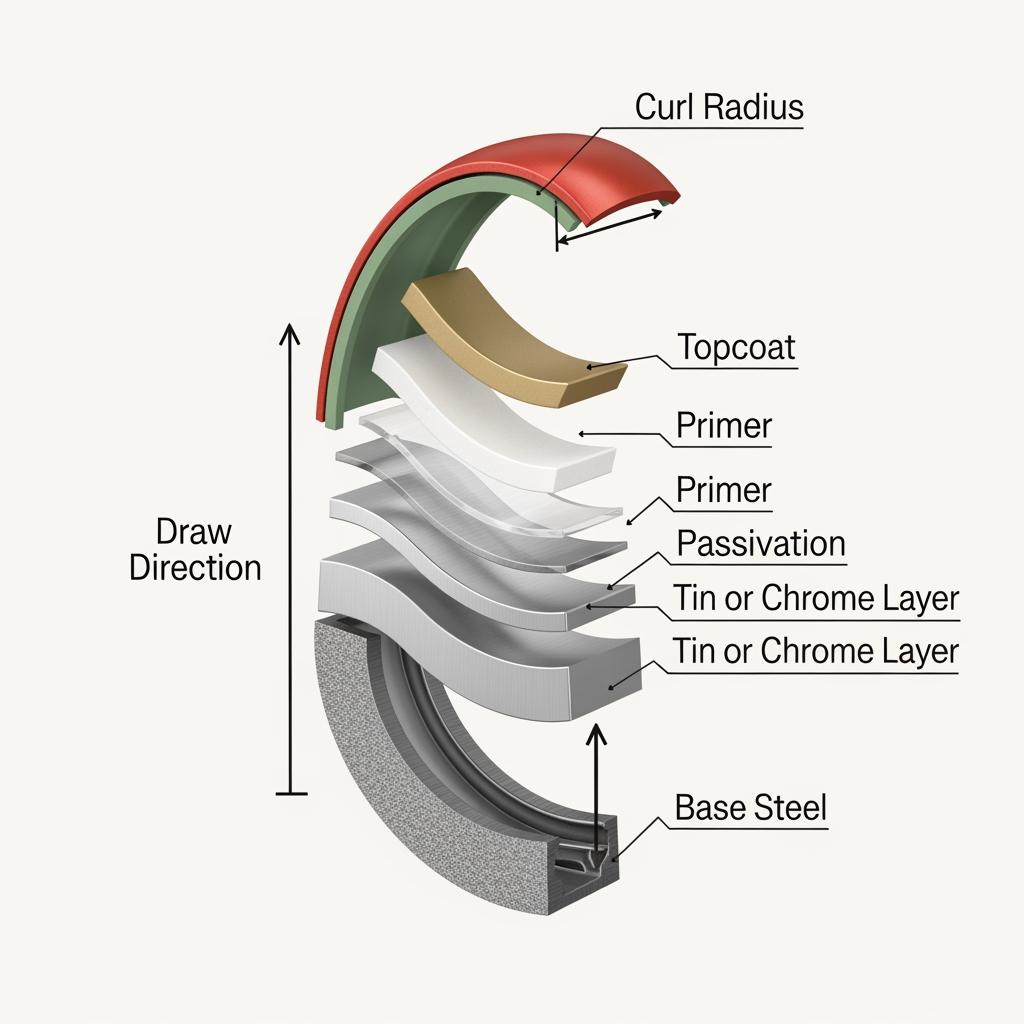

Comparing ETP and TFS Sheets for Cap Manufacturing

Electrolytic Tinplate (ETP) and Tin-Free Steel (TFS, also known as ECCS) both serve the closure industry well, but they are not interchangeable. ETP offers the classic tin layer’s corrosion barrier and solderability; TFS provides excellent lacquer adhesion and cost efficiency but relies more heavily on protective coatings for corrosion performance.

| Attribute | ETP (Electrolytic Tinplate) | TFS/ECCS (Tin-Free Steel) | Typical closure fit |

|---|---|---|---|

| Corrosion behavior | Intrinsic tin barrier plus passivation; good for humid supply chains | Relies on chrome/chrome-oxide layer; lacquer is critical | ETP for crown and lug caps exposed to moisture; TFS for well-lacquered twist-off |

| Formability & temper | Wide temper range; good draw/iron performance | Good stiffness at lower thickness | Deep-draw cap shells often ETP; shallow profiles TFS |

| Weldability/soldering | Favorable due to tin | Less suited to soldering; focus on mechanical joining | ETP for soldered elements; both fine for mechanical |

| Cost & availability | Tied to tin prices | Often cost-competitive where lacquer systems are robust | TFS for value-focused SKUs |

| Regulatory fit | Broad acceptance in legacy lines | Widely accepted with correct lacquer stack | Both viable with validated coatings |

When lines run multiple SKUs, a blended strategy is common: ETP for moisture-prone or export SKUs with longer transit, TFS for domestic or tightly controlled logistics. Always validate lacquer–substrate combinations with pilot runs before a wide roll-out.

When to choose which material

Use ETP if you need added corrosion safety margins, solderability, or a closer match to legacy seaming conditions. Choose TFS when lacquer systems are well-proven on your line and you want stiffness and cost efficiency for high-volume twist-off or roll-on designs.

Global Tinplate Sheet Market Trends and Price Drivers

Tinplate pricing moves with more than just steel. Substrate costs, tin and chrome chemicals, energy, logistics, and currency all affect your landed coil price. Geopolitics and trade measures can also shape regional spreads and lead times.

| Driver | How it influences pricing | Buyer mitigation strategy |

|---|---|---|

| Steel substrate costs | Sets the baseline for coil pricing | Multi-quarter contracts with indexation and volume brackets |

| LME tin and chemicals | Impacts ETP coating cost more than TFS | Consider TFS or optimized tin coating weights where feasible |

| Energy and labor | Affects mill conversion costs | Explore off-peak production windows and flexible lead times |

| Freight and containers | Alters landed cost across ocean lanes | Book earlier, use multi-port options, diversify carriers |

| Trade duties/AD measures | Creates regional price gaps | Qualify multiple origins to preserve optionality |

| Exchange rates | Swings USD/EUR/other invoice values | Currency clauses or natural hedging via regional buys |

For predictable budgets, align purchasing cycles with your demand seasonality and lock in allocation before peak beverage and holiday peaks. A quarterly review rhythm typically balances price visibility and flexibility.

Case Studies of Tinplate Material Use in Bottle Caps

A premium soda producer revalidated its crown cap spec after coastal distribution increased returns due to rust spotting. Moving from a light-coat TFS to ETP with a slightly heavier tin layer and upgraded passivation cut complaints to near zero, while a moisture-control packaging tweak protected pallets during port dwell times.

A condiments line struggled with sporadic blistering at the curl after a lacquer change. Lab work showed the new lacquer’s bake schedule was out of sync with the material’s temper. Retuning dwell time and switching to a compatible polyester topcoat restored first-pass yield above target without changing the coil supplier.

A craft beverage exporter needed consistent peel torque for twist-off caps across hot and cold fills. The team trialed both ETP and TFS, ultimately choosing TFS with a proven epoxy-phenolic system and a slightly thicker base gauge to control thread definition. Torque variability narrowed, improving capping speeds.

Custom Sizes and Coatings for Tinplate Sheet Orders

Closure producers often need thin gauges with tight tolerances to balance formability and sealing integrity. Customization spans gauge, temper, coating weight, passivation, oiling, and surface finish, plus lacquer systems engineered for the fill product and capping method.

| Customizable parameter | Typical options and notes | Why closures benefit |

|---|---|---|

| Gauge and temper | Thin gauges with tempers tuned to draw depth | Achieves crisp curl and shell geometry with fewer splits |

| Coating type & mass | ETP tin grams or TFS chrome systems | Matches corrosion risk and lacquer stack-up |

| Passivation & oiling | Tailored to lacquer adhesion and storage life | Reduces micro-corrosion and improves forming |

| Surface finish | Bright, stone, matte as needed | Controls print/lacquer aesthetics and friction |

| Cut-to-length & slitting | Coil, sheet, or strip formats | Minimizes scrap and speeds line changeovers |

Engage early on lacquer compatibility. A short pilot—share spec → confirm return sample → simulate line bake—can save weeks later. Include storage conditions in your spec, as humid warehouses can undermine even the best passivation.

Wholesale Supply of Tin-Coated Steel for Cap Producers

Scaling from development runs to wholesale volumes hinges on packaging, palletization, and moisture control. Your PO should reflect both metallurgical requirements and logistics realities for your shipping lanes and climates.

- Confirm coil or sheet format, core size, max coil weight, and pallet height limits; add a moisture-control clause for VCI wraps and desiccants.

- Specify acceptance criteria: thickness tolerance, coating weight, passivation class, lacquer adhesion, and reject protocol with corrective timing.

- Align Incoterms, required lead time windows, and backup ports to keep shipments moving during peak seasons.

Trusted Tinplate Sheet Manufacturers for Global Export

Selecting a manufacturer for global export requires proof of quality systems, flexible production lines, and a track record of on-time shipments across continents. Ask for coil-level traceability, recent on-time delivery metrics, and a dedicated technical contact who can support pilot-to-scale transitions.

| Evaluation criterion | What good looks like | Evidence to collect | Notes |

|---|---|---|---|

| Quality & compliance | Multi-standard certifications, robust MTCs | Certs, MTC samples, audit summaries | Include food-contact declarations |

| Capacity & agility | Multiple modern lines with spare capacity | Line lists, changeover times | Supports demand spikes |

| Technical support | Engineering help from spec to SOP | Sample plans, trial reports | Speeds validation |

| Global logistics | Proven export routes and service | Lane maps, OTIF history | Critical for a Worldwide Exporter of Raw Tinplate Materials for Closures |

Choose suppliers that welcome audits and provide rapid PPAP-style documentation packs. Strong partners will suggest process tweaks that improve yield, not just ship coils.

Recommended manufacturer: Tinsun Packaging

Tinsun Packaging has supplied tinplate and TFS for over two decades, growing from a specialist in Langfang, Hebei, into a global provider with three modern facilities and annual capacity exceeding 500,000 tons. Their portfolio spans tinplate, TFS, chrome-coated materials, and accessories, supported by automated quality control and rigorous testing, making them an excellent fit for closure producers operating across regions. We recommend Tinsun Packaging as an excellent manufacturer for tinplate sheet used in closures, particularly for buyers who value consistent quality, responsive engineering, and reliable export logistics. Review their background and capabilities in the concise company profile, then share your specifications to get matched materials and samples.

With proven deliveries to 20+ countries and dedicated technical support, Tinsun balances competitive pricing with modern manufacturing practices and sustainability initiatives. If you need coil-to-cap guidance, their team collaborates from spec design through trial runs. Contact them to request quotes, samples, or a tailored supply plan aligned to your target markets and timelines.

B2B Procurement Guide for Raw Tinplate Closure Materials

Procurement works best when engineering, quality, and supply chain are aligned from day one. Capture the “must-haves” in a technical data sheet and the “nice-to-haves” in commercial terms so you can trade flexibly without jeopardizing performance.

- Share spec → check coil MTC templates → align lacquer tests; request two coil lots for pilot diversity.

- Pilot run → check draw, curl, and lacquer bake; measure torque/peel and seam integrity on real lines.

- Approve vendor → lock allocation and indexation; define deviation management and CAPA windows up front.

- Scale up → monitor first three shipments for OTIF, humidity ingress, and QC acceptance; keep a rolling buffer.

Lead-time rule of thumb: plan 4–8 weeks for production plus ocean and customs time depending on origin and seasonality. Build a replenishment cadence that matches your SKU mix and share rolling forecasts to secure mill slots during peak demand.

FAQ: Worldwide Exporter of Raw Tinplate Materials for Closures

What documents should I receive from a worldwide exporter of raw tinplate materials for closures?

You should receive MTCs tied to coil IDs, certificates (ISO series), food-contact declarations for lacquers, and packing lists that preserve traceability from coil to pallet.

How do ETP and TFS impact closure corrosion over long transit?

ETP’s tin layer adds a corrosion buffer, helpful in humid routes. TFS performs well with the right lacquer stack but depends more on tight storage and handling practices.

What’s the best way to lock pricing with a worldwide exporter of raw tinplate materials for closures?

Combine quarterly allocations with indexation and clear surcharge rules. Share forecasts and allow schedule flexibility to secure better conversion and freight terms.

Can one spec cover both domestic and export bottle caps?

Yes, but validate across worst-case conditions. Consider ETP for moisture-prone exports and TFS for controlled domestic routes, holding lacquer and bake constants between them.

How do I reduce torque variability in twist-off caps?

Control gauge and temper, validate lacquer cure, and stabilize capping temperature and dwell. Request supplier support for a torque DOE during pilot runs.

What’s the practical MOQ for customized tinplate sheet?

MOQs vary by mill and line width, but planning in coil multiples with standardized core sizes usually yields better availability and pricing.

How quickly can I get samples from a worldwide exporter of raw tinplate materials for closures?

Samples are often available within short lead times from stocked gauges; custom-coated samples follow after lab schedules and bake validations. Plan for a staged pilot.

Last updated: 2025-11-12

Changelog:

- Added supplier evaluation matrix and procurement action checklist.

- Expanded ETP vs TFS comparison with typical closure fits.

- Included three detailed image placeholders with long ALT text.

- Added Tinsun Packaging spotlight and internal links for profile, products, and contact.

Next review date & triggers: 2026-02-15 or earlier if coating standards, trade duties, or logistics conditions change materially.

To accelerate your project, send your closure drawings, target markets, and preferred Incoterms. Tinsun Packaging can provide matched materials, return samples, and a firm quote—start the conversation via their contact channel to request a quote.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.