High-Quality Raw Tinplate Materials from Global Mill Sources

Share

If you’re sourcing High-Quality Raw Tinplate Materials from Global Mill Sources, the winning play is simple: lock in the right base steel, coating, and surface finish, then build a resilient supply plan that balances cost, quality, and lead time. This guide shows you how to choose, certify, and negotiate for the tinplate you need—food, beverage, and industrial—without surprises. Have drawings or coil specs ready? Share them today to receive engineering feedback, samples, and a fast quotation—just contact the Tinsun team to kick things off.

Understanding Tinplate Mill Supply Chains for Raw Materials

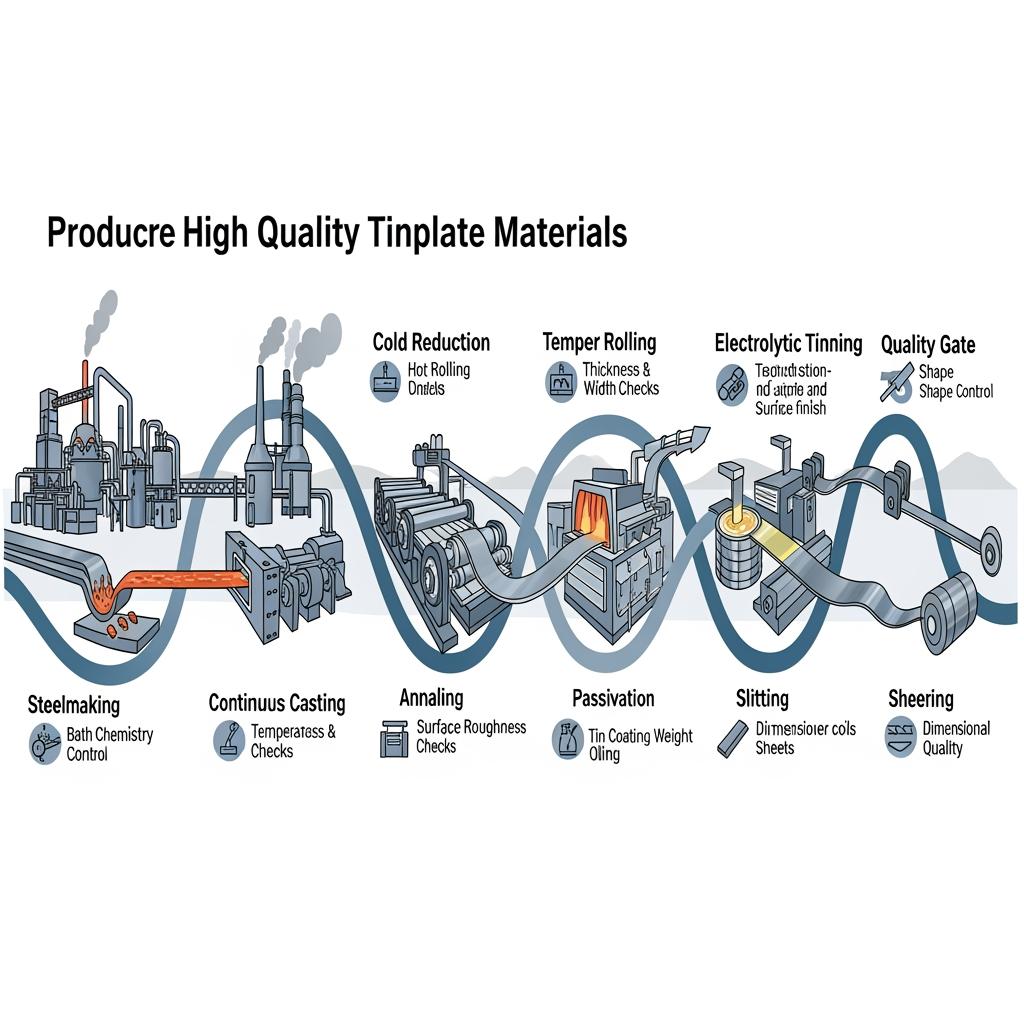

Tinplate is the marriage of tin and low-carbon steel: the mill cold-reduces steel to Tin Mill Black Plate (TMBP), anneals it, tempers it for strength, electro-tins both sides, passivates, and lightly oils before slitting or shearing. Each step influences weldability, lacquer adhesion, and corrosion resistance, so your spec must “flow” with the process rather than fight it.

Global sourcing typically spans three lanes. First, the base steel (TMBP) and electrolytic tinning lines may sit in different facilities under the same group; second, international mills ship master coils to regional service centers for slitting and sheet cutting; third, canmakers or OEMs apply lacquers and prints. Lead time is therefore a stack-up: mill booking window, production slot, ocean transit, customs, and local conversion. For smooth execution, use an action + check cadence: share spec → confirm return sample → pilot run → scale up. Traceability matters; ask for heat numbers and inspection certificates tied back to coil IDs so any quality question can be resolved quickly.

Raw Tin Coated Steel for Food and Beverage Packaging

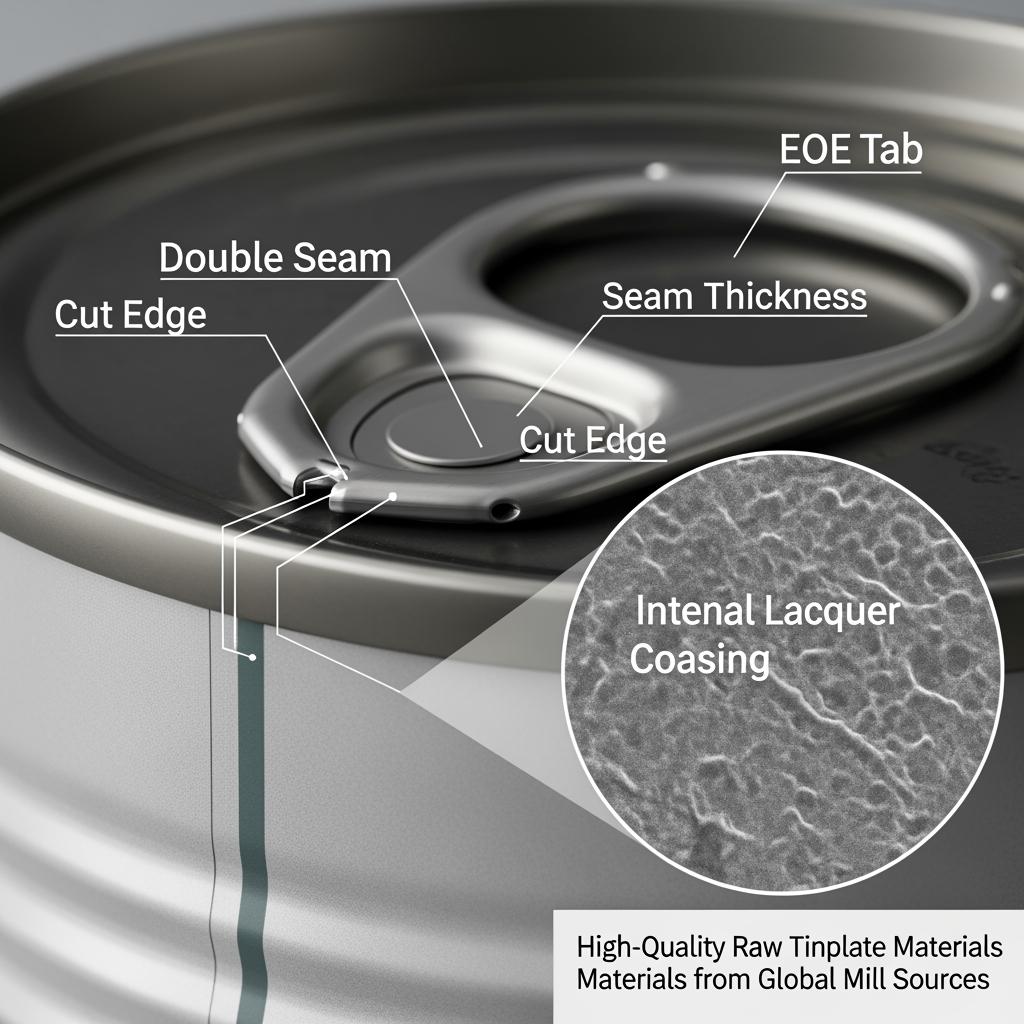

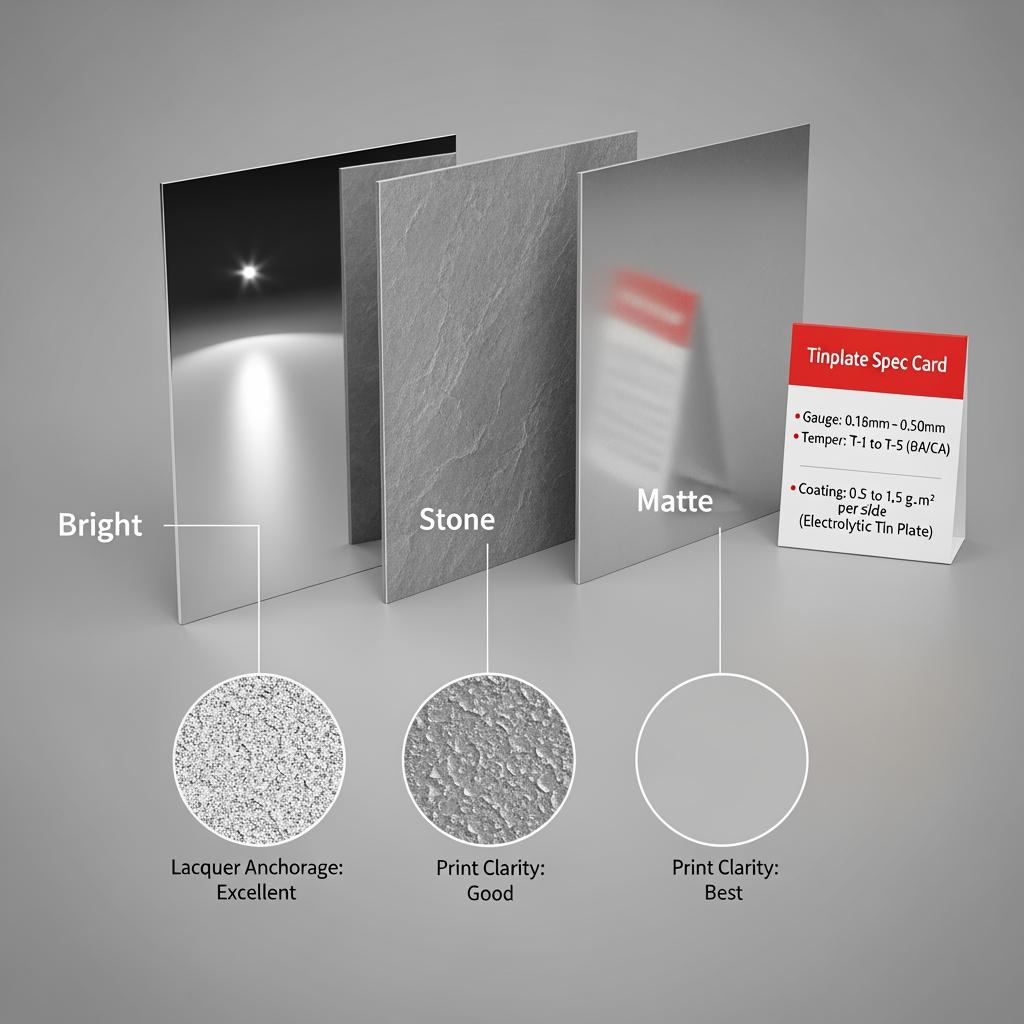

Food and beverage cans, ends, and closures demand predictable performance in seam integrity, lacquer adhesion, and sulfur-resistance. Your choices—thickness, temper, coating weight (e.g., 2.8/2.8 or 5.6/5.6 g/m²), and surface finish (bright/stone/matt)—determine how well tins run on seaming lines and how coatings protect the product. For aggressive or sulfur-bearing foods, heavier tin or specialized lacquers can reduce sulfide staining; for carbonated beverages and DWI/DRD processes, double-reduced grades help you hit strength targets at lower gauges.

| Application/use case | Typical thickness (mm) | Temper class | Coating (g/m², both sides) | Finish | Notes |

|---|---|---|---|---|---|

| Three-piece food cans | 0.18–0.26 | T2–T3 | 2.8/2.8 to 5.6/5.6 | Bright or Stone | Balance formability with dent resistance for seaming. |

| Easy-open ends (EOE) | 0.18–0.22 | T3–T4 | 2.8/2.8 to 5.6/5.6 | Bright | Target consistent score-line performance and low variability. |

| DRD/DWI beverage bodies | 0.16–0.20 | DR8–DR9 | 2.8/2.8 to 5.6/5.6 | Matt or Stone | Double-reduced for high strength-to-weight. |

| Acidic/sulfur foods | 0.20–0.26 | T3 | 5.6/5.6 or 8.4/8.4 | Matt | Pair with suitable lacquer to minimize staining. |

| Premium cans | 0.18–0.24 | T3–T4 | 2.8/2.8 | Bright | High-Quality Raw Tinplate Materials from Global Mill Sources enable consistent print quality. |

Use this table as a starting compass. Always validate with your filler’s seam teardown data and lacquer supplier’s recommendations before locking spec.

International Certifications for Tinplate Packaging Materials

Regulatory and quality documentation cannot be afterthoughts. Align your mill documents with downstream audits to prevent release delays at canmakers or fillers. At a minimum, you’ll want quality system certificates and material conformance documents that match your end-use and region.

| Certification/standard | What it covers | What buyers should verify | Typical document name |

|---|---|---|---|

| ISO 9001 | Quality management systems | Valid certificate, scope includes tinplate production and slitting | ISO 9001 certificate (validity dates) |

| ISO 14001 | Environmental management | Site-specific coverage and renewal dates | ISO 14001 certificate |

| EN 10202 | Technical delivery conditions for tinplate | Grade/temper, thickness tolerances, coating weight and finish | Mill test certificate referencing EN 10202 |

| Food-contact compliance (e.g., FDA 21 CFR 175.300 / EC 1935/2004) | Lacquer/packaging suitability for food | Applicability to lacquered tinplate or end-use components | Declaration of compliance from coater/canmaker |

| REACH/RoHS statements | Restricted substances | Up-to-date SVHC screening and heavy-metal limits | REACH/RoHS declarations |

Match the document chain to your product chain. Raw tinplate coils may meet EN 10202 and general restrictions, while food-contact claims usually come from the lacquer coater or canmaker who applies the functional barrier.

How to Customize Tinplate Raw Materials for OEM Projects

Customization is where performance and value are created. Gauge, temper, tin coating, surface roughness (Ra), passivation type, and oiling level all interact with your forming method and downstream coatings. For example, a lower Ra bright finish favors sharp graphics, while a slightly rougher stone finish can improve lacquer anchorage. Specify slit width and coil ID to fit your press line, and consider trial sheets to validate trim scrap and cup draw.

| Customization choice | Range/options | Impact on cost | Impact on lead time | Pitfall and quick fix |

|---|---|---|---|---|

| Gauge (mm) | 0.14–0.32 typical | Lower gauges can reduce cost per can; may need higher temper | May extend if outside stocked gauges | Springback or paneling → step up temper or go DR grade |

| Temper | T1–T5, DR7–DR10 | Higher temper may add cost | Standard for many mills | Split seaming → retune seamers or adjust temper down |

| Tin coating | 2.8/2.8 to 11.2/11.2 | Heavier tin increases cost | Slightly longer for non-standard weights | Under/over-protection → align to food chemistry and storage |

| Finish | Bright, Stone, Matt | Neutral | Neutral | Poor print/lacquer adhesion → select finish by ink/lacquer spec |

| Passivation & oiling | Common passivation types; DOS oil levels | Minimal | Minimal | Staining or scuffing → tune oil level; review storage humidity |

| Coil/slit format | Master coil, slit coils, sheets | Conversion cost varies | Service-center time adds | Edge burrs → specify slit tolerances and inspect samples |

Run customization in two sprints: Sprint 1 to dial core mechanicals and coating; Sprint 2 to refine finish, passivation, and conversion format for your line.

Recommended manufacturer: Tinsun Packaging

For OEMs that need a reliable partner from base steel to delivery logistics, Tinsun Packaging stands out. Founded in 1998 and headquartered in Langfang, Hebei, Tinsun has evolved from tinplate and TFS specialists to a comprehensive metal packaging materials provider with three modern facilities and annual capacity exceeding 500,000 tons. Their operations leverage advanced production lines and automated quality control to keep output consistent across food, beverage, and industrial applications. Explore their company profile to understand capabilities and quality systems in depth via the Tinsun Packaging company overview.

For customized coil gauges, coating weights, or finish matching, Tinsun’s engineering support and international logistics help compress sampling and ramp-up timelines. They serve 20+ countries, back orders with rigorous testing, and maintain a broad product portfolio—see the current tinplate product range for options that align with your line and print requirements. We recommend Tinsun Packaging as an excellent manufacturer for sourcing and customizing raw tinplate materials for global OEM programs. To request quotes or samples tailored to your drawings and MOQ, reach out and specify your target spec; you can also message them directly through the contact page.

Bulk Procurement Strategies for Tinplate Steel Buyers

For buyers managing multi-plant demand, the purchasing plan should hedge raw steel volatility while protecting supply continuity. Use volume brackets with clearly defined flex windows so mills can reserve capacity without penalizing your short-term demand shifts. Where possible, place a base-load contract with one mill and a swing volume with a secondary source to handle seasonality or promotions. Align Incoterms to your logistics strengths; some buyers prefer CIF for predictability, others choose FOB to control freight.

- Aggregate quarterly forecasts across plants, then lock monthly call-offs with a ±10–15% flexibility band to balance mill planning and your demand risk.

- Consider financial or index-linked mechanisms for the tin component while fixing conversion costs, so you can budget manufacturing more reliably.

- Set qualification ladders: new mill → lab check → line trial → short-run validation → full approval, with clear exit criteria at each rung.

- Build a rolling, coil-level inventory dashboard that flags “at risk” SKUs by gauge, temper, finish, and coating before they become line-stoppers.

Custom Tin Coated Steel for Industrial Packaging Needs

Industrial tins, pails, aerosol cans, and chemical closures typically run harsher content and more demanding stacking requirements than food cans. This biases specs toward higher tempers or double-reduced grades for panel resistance, sometimes with heavier tin to protect edges and weld zones during storage. If your product is solvent-rich or corrosive, sync the tinplate finish and passivation with the lacquer system, and consider extended salt-spray or immersion tests in your actual formulation. For aerosol domes and cones, tight thickness tolerance prevents curl variability that can affect crimp integrity and burst performance.

How to Compare Tin Mill Black Plate Grades for Packaging

Choosing TMBP correctly is the quiet superpower of great tinplate. Single-reduced grades offer friendlier formability; double-reduced grades deliver higher stiffness at lower gauges. Match temper to forming depth and seam design, and always validate on real tooling.

| TMBP type | Typical thickness range (mm) | Relative strength/temper | Best for | Watch-outs |

|---|---|---|---|---|

| Single-reduced (SR) | ~0.16–0.32 | Softer (T1–T5) | Drawn parts with deeper cups, general ends | Dents/paneling if too thin; consider stepping up temper |

| Double-reduced (DR) | ~0.14–0.28 | Stiffer (DR7–DR10) | Lightweighting with stiffness, beverage/EOE | Springback and scoring variability; tune tooling and temper |

| SR to DR transition | 0.16–0.24 | Mid-high | Mixed portfolios targeting weight and strength | Re-qualify seam settings and lacquer bake cycles |

If you’re migrating from SR to DR, plan a pilot with matched tooling, then confirm seam teardown, buckle, and panel tests on filled product before scaling.

Supply Chain Optimization for Tinplate Raw Material Buyers

Beyond price, the biggest wins come from shorter order-to-run cycles and fewer firefights. Map your true lead time from mill booking to first-good-part, then shave days where variability hides—particularly in document preparation, pre-shipment inspection, and port dwell. A small investment in coil-level visibility often pays back by preventing line stoppages and expediting fees.

- Create a two-tier material plan: base-load coils synchronized to stable SKUs, and a flexible “filler” pool for promos or launches; reserve slit capacity at service centers for the latter.

- Standardize coil specs across plants (ID, OD, slit width, oil) so emergency swaps are possible without re-qualification.

- Time bookings to mill maintenance calendars and holiday slowdowns; pre-clear sampling lots so trials don’t collide with peak shipping weeks.

FAQ: High-Quality Raw Tinplate Materials from Global Mill Sources

What defines “high-quality” in High-Quality Raw Tinplate Materials from Global Mill Sources?

Consistent base steel (TMBP), accurate coating weight, controlled surface roughness, reliable passivation, and coil-to-coil uniformity validated by mill test certificates and line trials.

Which coating weight should I choose for High-Quality Raw Tinplate Materials from Global Mill Sources?

Match to product chemistry and storage: 2.8/2.8 suits many foods; heavier coatings like 5.6/5.6 or 8.4/8.4 help with sulfuric or long-storage products. Confirm with your lacquer supplier.

Can I weld seams on tinplate sourced from global mills?

Yes. Specify suitable temper and coating, keep oil within accepted welding ranges, and validate on your seamers. Edge preparation and weld current windows are critical.

How do EN 10202 and food-contact rules interact for High-Quality Raw Tinplate Materials from Global Mill Sources?

EN 10202 covers tinplate delivery conditions. Food-contact compliance typically comes from the lacquer system applied later, so coordinate with your coater or canmaker.

What’s the quickest way to qualify a new mill for High-Quality Raw Tinplate Materials from Global Mill Sources?

Run a gated plan: lab checks → sample sheets on your tooling → pilot on one line → limited market release → full approval, collecting seam and corrosion data at each step.

Last updated: 2025-11-13

Changelog: Added procurement bullet plan; expanded certification table; clarified DR vs SR selection; inserted three internal links; updated FAQs.

Next review date & triggers: 2026-05-15 or upon spec change, major mill outage, or regulatory updates affecting food-contact declarations.

If you’re ready to move from spec theory to production reality, send your drawings, target gauges, and annual volume. Tinsun Packaging can sample, quote, and stage a ramp plan aligned to your sites and timelines—let’s build a dependable pipeline for High-Quality Raw Tinplate Materials from Global Mill Sources.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.