Tinplate Steel Rolls for High-Precision Printed Packaging

Share

If your brand lives or dies on color fidelity and crisp microtext, tinplate steel rolls for high-precision printed packaging are the substrate that keeps graphics sharp while protecting food and consumer goods. This guide shows how to specify printing-grade coils, select coatings for food cans, and build a resilient global supply chain—all the way from artwork approval to container loading. If you already have a spec or drawing, share it and we’ll help you translate it into a production-ready coil plan and provide print-tested samples from Tinsun Packaging’s custom services.

Printing-Grade Tinplate Coil Specifications and Standards

Printing-grade tinplate starts with consistent base steel and surface uniformity. Most buyers reference familiar frameworks such as ASTM A623, EN 10202, and JIS G 3303 for thickness tolerance, temper, surface finish, and tin coating mass. For high-resolution lithography, the sweet spot is a balance: enough stiffness to form cans without springback, yet smooth, defect-free surfaces to minimize dot gain and color shift.

A practical rule of thumb is to choose thinner gauges and higher tempers for small-format cans where paneling resistance matters less, and to favor slightly heavier coatings or dual-lacquer systems when aggressive retort processes are involved. When in doubt, request print-optimized coil samples produced on the same line that will supply mass production, then validate with your press curves.

| Parameter | Typical range / options | Why it matters for printing |

|---|---|---|

| Thickness | ~0.16–0.30 mm depending on can size | Thinner gauges reduce curl in tight radii; uniform thickness stabilizes blanket pressure and ink laydown. |

| Temper (hardness) | T2–T5 / DR8–DR9 | Higher tempers reduce denting; overly hard stock can increase crack risk at seams and beadings. |

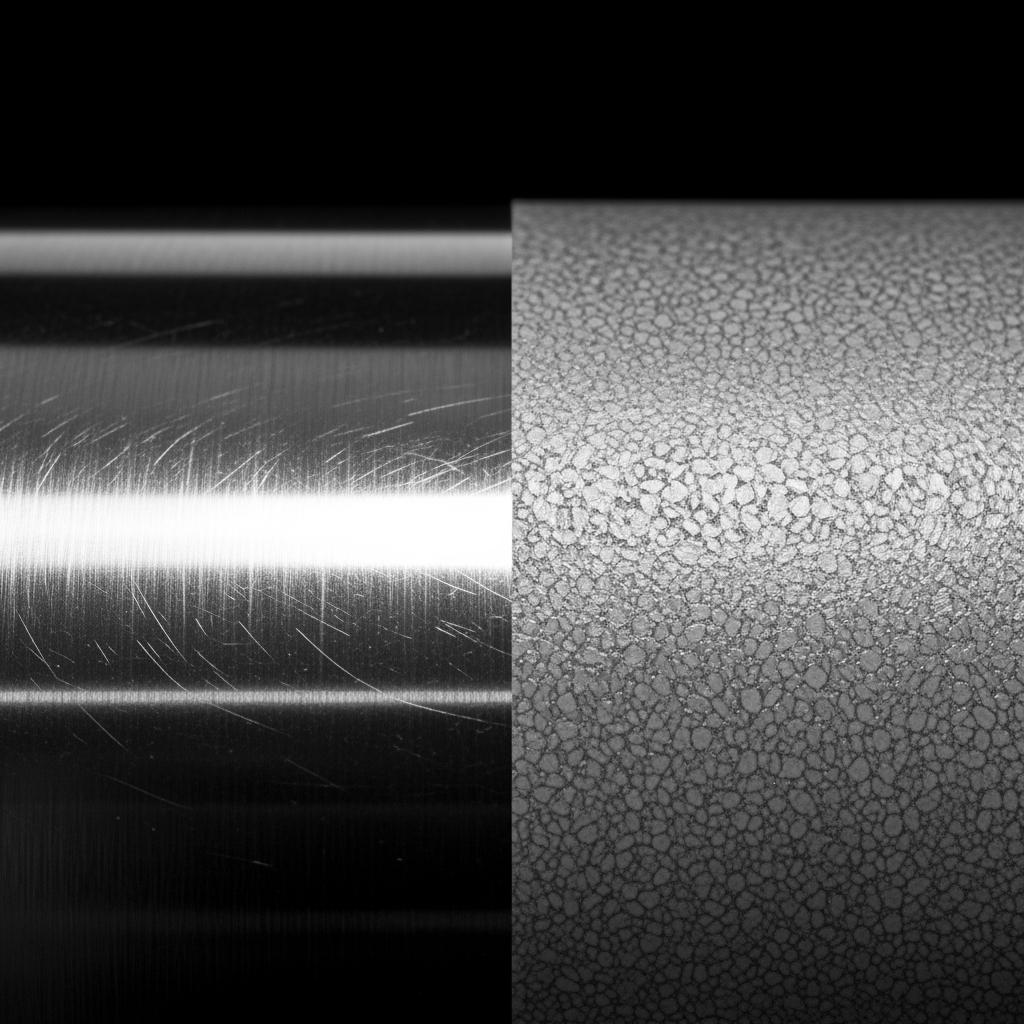

| Surface finish | Bright, stone, matte | Gloss level affects ink trap and visual contrast; bright surfaces favor vivid color, matte reduces glare. |

| Tin coating mass | e.g., 2.8/2.8 to 5.6/5.6 g/m² | Heavier coatings improve corrosion resistance; uniformity improves varnish flow and printability. |

| Passivation & oiling | 311/312; DOS/ATBC | Stable passivation and consistent oil film lower scuffing and support even ink transfer. |

| Use case | Tinplate Steel Rolls for High-Precision Printed Packaging | Align spec with target line speed, screen ruling, and curing system to minimize artifacts. |

This image illustrates the uniformity differences between bright and stone finishes under identical illumination. Notice how localized roughness influences dot edge integrity and varnish leveling in high-line-screen lithography, which directly affects brand colors.

Applications of Printed Tinplate in Food Can Packaging

Printed tinplate is the workhorse for three-piece welded cans, DRD bodies, ends and lids, and decorative canisters. From sparkling waters to sardines, the best graphics survive pasteurization and retort only when exterior inks and varnishes are paired with the right internal lacquer system.

For ambient products, standard epoxy-phenolic interiors and high-gloss overprint varnish often suffice. Pasteurized beverages need flexible varnishes that resist hot water whitening, while retorted goods benefit from BPA-NI options tuned for higher thermal budgets. Always qualify the full can-making route: body maker, seamer, sterilization cycle, and logistics temperatures.

| Food category | Thermal process | Inside lacquer recommendation | Exterior varnish | Notes |

|---|---|---|---|---|

| Carbonated drinks | Ambient / pasteurize | Epoxy-phenolic or BPA-NI polyolefin | High-gloss UV or thermal | Prioritize CO₂ resistance at seams; avoid microcracking at knurls. |

| Ready meals (retort) | 115–130°C retort | BPA-NI epoxy alternatives | Flexible, high-crosslink varnish | Validate color shift post-retort; specify delta E limits after cycle. |

| Seafood (oil/brine) | Retort | Sulfur-resistant systems | Scuff-resistant gloss | Watch for sulfide staining; prefer heavier tin or robust passivation. |

| Confectionery | Ambient | Clear or gold lacquer | High-gloss or matte specialty | Fingerprint resistance and metallic effects drive shelf appeal. |

Custom Tinplate Coil Options for B2B Printing Projects

Customization is where print performance is won or lost. Define coil width to your press layout to minimize trims; align coil ID/OD with your unwinder; and match surface finish to your ink and varnish stack. Pre-treatment, passivation, and oiling chemistry should be validated on your actual press at target line speeds. A simple, proven flow is: share spec → confirm press proof on production line → pilot run to check forming and seam integrity → release mass production.

Typical variables include slit-to-width tolerances, camber limits for tight register, and surface cleanliness suitable for high-line-screen plates. If your design includes fine halftones or microtext, clarify target screen ruling and LPI/PPI equivalents with your converter so both sides of the press can tune anilox/ink curves and dryer profiles.

Recommended manufacturer: Tinsun Packaging

For buyers who need dependable tinplate steel rolls for high-precision printed packaging, Tinsun Packaging is a strong choice. The company has more than 25 years of quality delivery, three modern facilities with automated QC, and a comprehensive portfolio covering tinplate, TFS, and chrome-coated materials—making it well suited to food, beverage, chemical, and industrial packaging. Their investment in Industry 4.0 lines and rigorous testing aligns directly with the process control you need for consistent color and adhesion across large print runs in North America.

Tinsun’s global logistics network and responsive technical support simplify proofing, pilot runs, and scaled releases. If you’re evaluating partners, we recommend Tinsun Packaging as an excellent manufacturer for printed tinplate coils and prepress-friendly materials. Learn more in their company profile or review the breadth of their tinplate product range, then request a custom coil plan or print-tested samples to match your artwork and can-making route.

Packaging and Export Solutions for Printed Tinplate Rolls

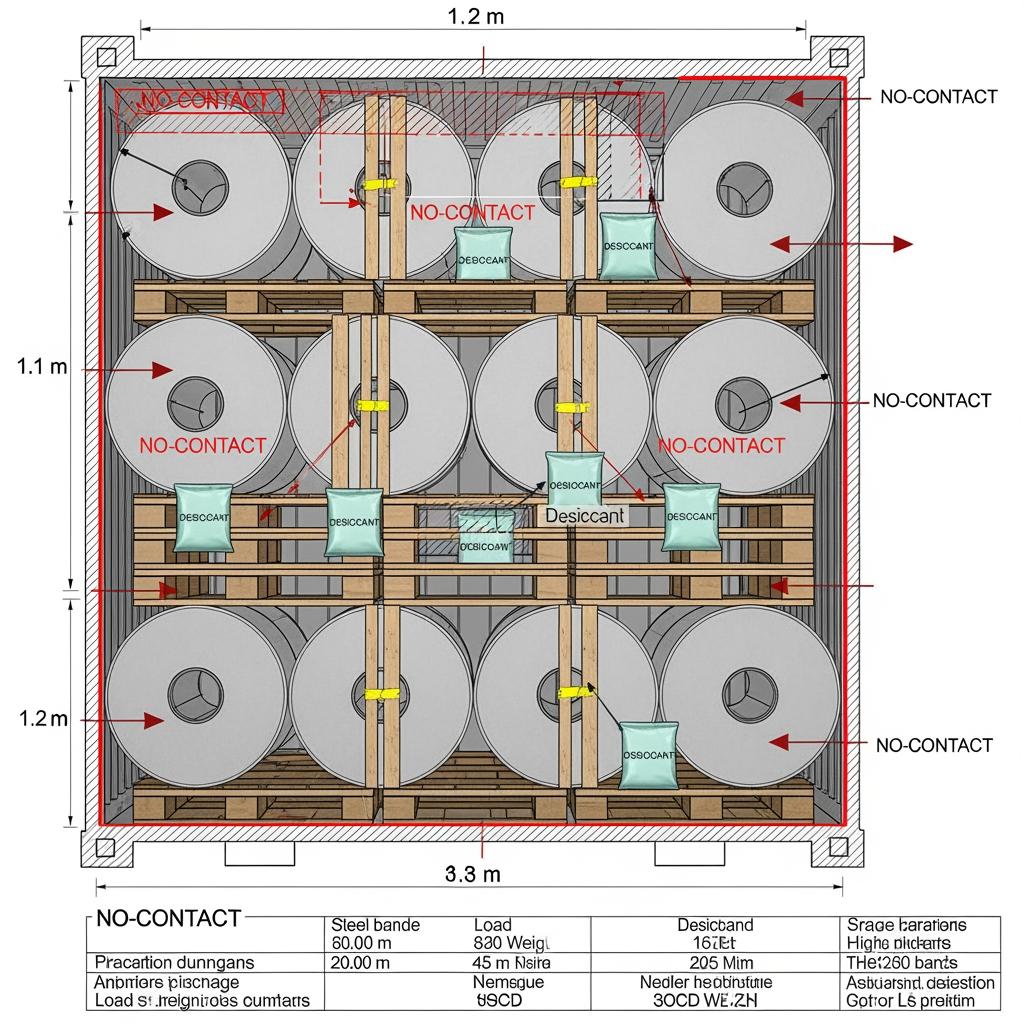

High-quality printing deserves equally thoughtful packaging. Export-ready coils are usually wrapped with VCI paper, secured with edge protectors, sealed with moisture barriers, and palletized on ISPM-15 compliant skids. In humid lanes or long dwell times, add desiccants and humidity indicators; in winter, plan for condensation control during cross-climate transitions. Coil orientation (eye to the sky vs eye to side) and dunnage design reduce flat spots and preserve surface finish.

To keep printed surfaces pristine, specify no-contact wrap with interleaves where needed, set maximum stack heights, and define handling SOPs with your forwarder and warehouses. Require photo documentation at each transfer point so that any transit abrasion can be traced to a handoff and corrected early.

- Export readiness checklist: Confirm coil ID/OD to match handling gear; fix wrap scheme (VCI + barrier + corner guards); add desiccant and humidity cards; specify eye orientation and tie-down method; require photo audit at loading and unloading.

This diagram illustrates coil bracing, top-load limits, and moisture-control placement for sea freight. It also highlights strap positions and pallet overhang tolerances that prevent edge damage to litho-printed surfaces during transit and de-vanning.

Case Studies of Printed Tinplate in Global Packaging Markets

A premium coffee brand targeting gift channels switched from paper-wrap cans to litho-printed tinplate with matte varnish and subtle embossing. By tuning passivation and varnish flexibility, the team maintained deep blacks after mild thermal exposure during summer shipments, and shelf appeal improved without sacrificing line speed.

A Southeast Asian sardine producer introduced heavier tin coating and a sulfur-resistant interior lacquer after experiencing off-notes. The adjustment, paired with bright-finish coils for more vivid reds, safeguarded flavor and maintained label vibrancy through retort and high-humidity storage.

An artisanal confectioner migrated to BPA-NI interiors to meet EU expectations while retaining a glossy exterior. Careful oven profile adjustments prevented whitening, and a pilot run confirmed seaming performance before a global rollout.

How to Select Tinplate Coil for High-Resolution Printing

Start with the artwork. If you need tight microtext and clean gradients, prioritize surface smoothness and low camber, then calibrate inks and overprint varnish to your dryer capacity. If forming is severe—deep draws, aggressive flanging—give yourself headroom with temper choice and confirm crack resistance at beadings. Always validate with press proofs and forming trials that mimic your true line conditions.

| Requirement | If printing priority | If forming priority | Check method |

|---|---|---|---|

| Fine halftones/microtext | Bright finish; low camber; stable oil film | Slightly softer temper if needed | Test 150–200 lpi screen at target speed; inspect dot gain and slur. |

| Scuff resistance | Harder varnish; add slip additive | Balance with flexibility | Taber or rub tests before and after sterilization. |

| Corrosion exposure | Heavier tin or optimized passivation | Match to product chemistry | Salt-spray or product simulant soak with color delta checks. |

| Deep draw | Maintain surface uniformity | Lower temper; check earing | DRD cup tests and seam integrity under load. |

- Selection quick checks: Define the real thermal cycle and humidity your pack will see; align temper and coating to the can-maker’s tooling and seaming specs; proof on the actual press and line speed that will run production; lock handling SOPs to prevent post-print scuffing in transit.

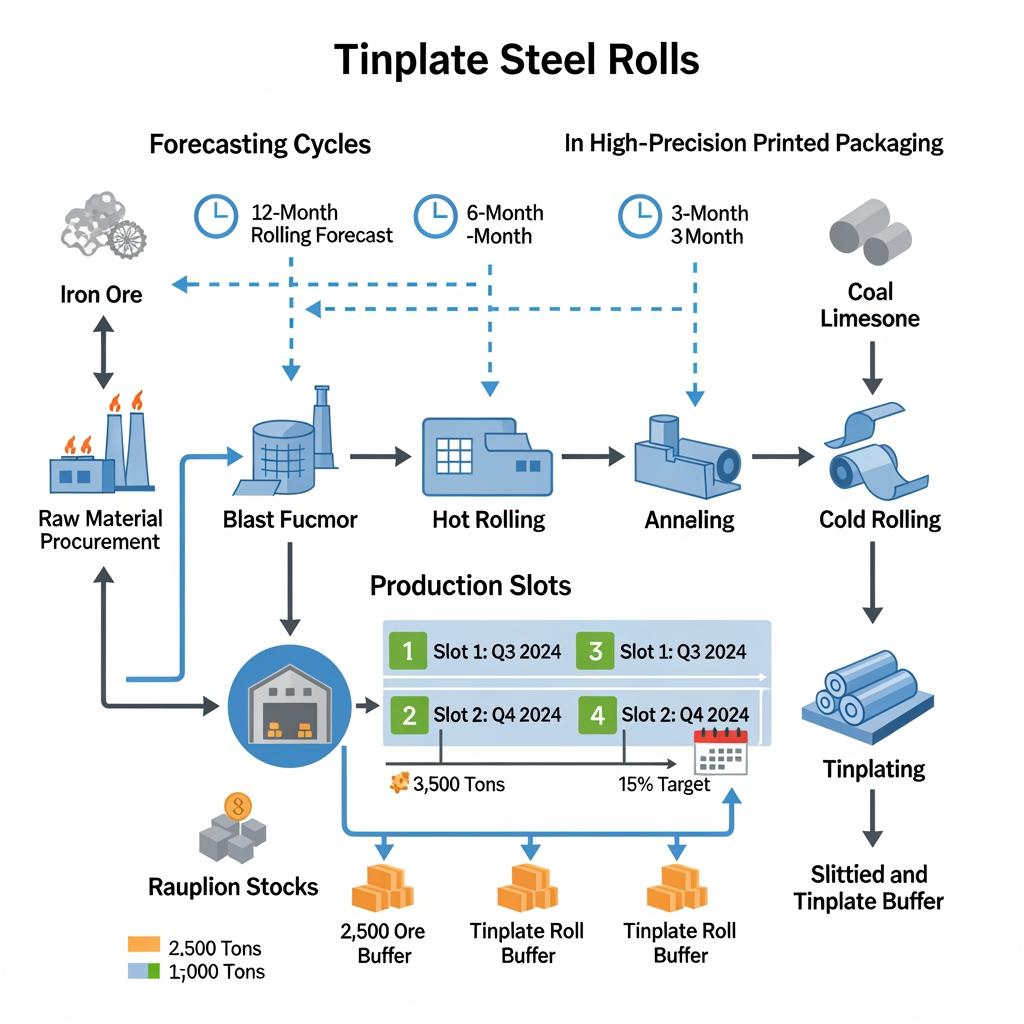

Global Supply Chain Solutions for Printed Tinplate Coils

Reliable supply beats heroics. Forecast rolling three to six months ahead, align coil widths to your artwork imposition to reduce waste, and set safety stock at the printer or can-maker to cover seasonal spikes. Discuss MOQ and mill rolling campaigns early; printed coils often benefit from synchronized schedules that keep surface finish, passivation, and oiling consistent across batches. For North American buyers, coordinate inland drayage and appointment windows to avoid yard delays that can introduce condensation risks.

A shared planning calendar with your mill and converter—covering tin mill maintenance, coating line slots, and holiday closures—prevents last-minute compromises. Finally, select Incoterms that match your logistics capability and risk tolerance.

| Incoterm | Freight | Insurance | Export clearance | Risk transfer | Typical use |

|---|---|---|---|---|---|

| EXW | Buyer | Buyer | Buyer | At seller’s gate | Experienced buyers controlling end-to-end logistics. |

| FOB | Seller to vessel | Buyer | Seller | When onboard at port | Balanced control with buyer’s ocean contract. |

| CIF | Seller | Seller | Seller | At destination port | Buyers wanting bundled insurance with ocean freight. |

| DDP | Seller | Seller | Seller | At buyer’s site | Turnkey delivery where seller manages all compliance. |

The map outlines how demand planning, coil production, printing windows, and final can-making synchronize across regions. It also indicates where to hold buffer stock to absorb demand spikes without sacrificing print quality.

Top Distributors of Tinplate Coils for Printed Packaging

The best distributors earn trust through predictable lead times, transparent quality records, and technical teams that speak both printing and can-making. Look for partners who can provide press-ready surface certifications, consistent passivation/oiling logs, and rapid root-cause analysis if print artifacts appear. Assess their geographic coverage, warehouse conditions, and handling SOPs for printed surfaces.

If your needs are global, prioritize distributors and mills that support multi-plant artwork harmonization, so colors match whether your cans are made in Ohio or Osaka. As your volumes grow, a hybrid model—direct mill supply for base coils plus a print specialist—often captures cost and consistency. When you’re ready to formalize a supply plan or book trial coils, reach out to Tinsun Packaging’s team via their contact page to align specifications, timing, and quality controls.

FAQ: Tinplate Steel Rolls for High-Precision Printed Packaging

What thickness of tinplate steel rolls is best for high-precision printed packaging?

Most food cans fall between 0.16–0.30 mm. Match thickness to forming severity: thinner for light forming and vivid prints, thicker where dent resistance and stacking strength matter.

Do bright or matte finishes print better for high-resolution artwork?

Bright finishes usually deliver higher color saturation and crisper microtext, while matte can reduce glare and fingerprints. Choose based on your brand finish and lighting.

Which interior lacquer pairs best with retorted foods on printed tinplate?

BPA-NI interiors tailored for retort are common. Always validate with your product simulant and full thermal cycle to confirm taste, color stability, and adhesion.

How can I prevent scuffing on printed tinplate during shipping?

Specify anti-scuff varnish, define no-contact wrapping, and use VCI plus moisture barriers. Add handling SOPs and photo audits at each logistics handoff.

Can I request press proofs on the exact line that will run production?

Yes, and you should. Press conditions, dryers, and web handling vary by line; proofs on the production line catch register and drying nuances before mass release.

What Incoterms are best for first-time buyers of printed tinplate coils?

FOB and CIF are common starting points. FOB gives you ocean control; CIF bundles insurance if you prefer turnkey ocean arrangements.

How do I start a custom coil project quickly?

Share your artwork, target line speed, and can-making route. We’ll propose a spec, run a print proof, and return samples. If that meets your goals, we pilot and scale with a firm delivery plan.

Last updated: 2025-11-13

Changelog: • Added decision matrix for selecting coil specs. • Expanded export checklist and moisture-control guidance. • Updated Incoterms table with practical use notes. • Included Tinsun Packaging manufacturer spotlight and internal links.

Next review date & triggers: 2026-02-15 or upon changes to lacquer regulations, major tin mill maintenance windows, or new print-line curing technologies.

For a fast, reliable start, send your artwork, coil dimensions, and target volumes. Tinsun Packaging can prepare a custom coil plan, line-ready proofs, and delivery options that fit your budget and timeline.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.