Tin Free Steel Coil Supplier for Metal Container Fabrication

Share

Introduction to Chromium-Coated Steel for Packaging

Tin free steel—also called electrolytic chromium coated steel (ECCS) or chromium-coated steel—has become the workhorse substrate for modern cans, ends, and closures. If you’re evaluating a Tin Free Steel Coil Supplier for Metal Container Fabrication, the key advantages are outstanding paint and lacquer adhesion, stable flavor neutrality compared with tinplate in some foods, and reliable corrosion protection once the correct coating and passivation are applied. The result is a formable, weldable coil that runs cleanly on high-speed lines and supports demanding print finishes.

If you need a quick benchmark or sample set tailored to your coil width, temper, and passivation, share your requirements and target application. Tinsun Packaging provides custom TFS coil services end‑to‑end; explore their TFS coil product range to align specs with your line conditions via the Tinsun product catalog.

TFS Coil Manufacturing Process and Surface Treatment Guide

At the heart of ECCS performance is the coating system: a thin metallic chromium layer plus a hydrated chromium oxide film. This dual layer provides barrier protection and a chemically active surface that bonds exceptionally well with modern lacquers and inks. The manufacturing flow is straightforward but unforgiving of shortcuts.

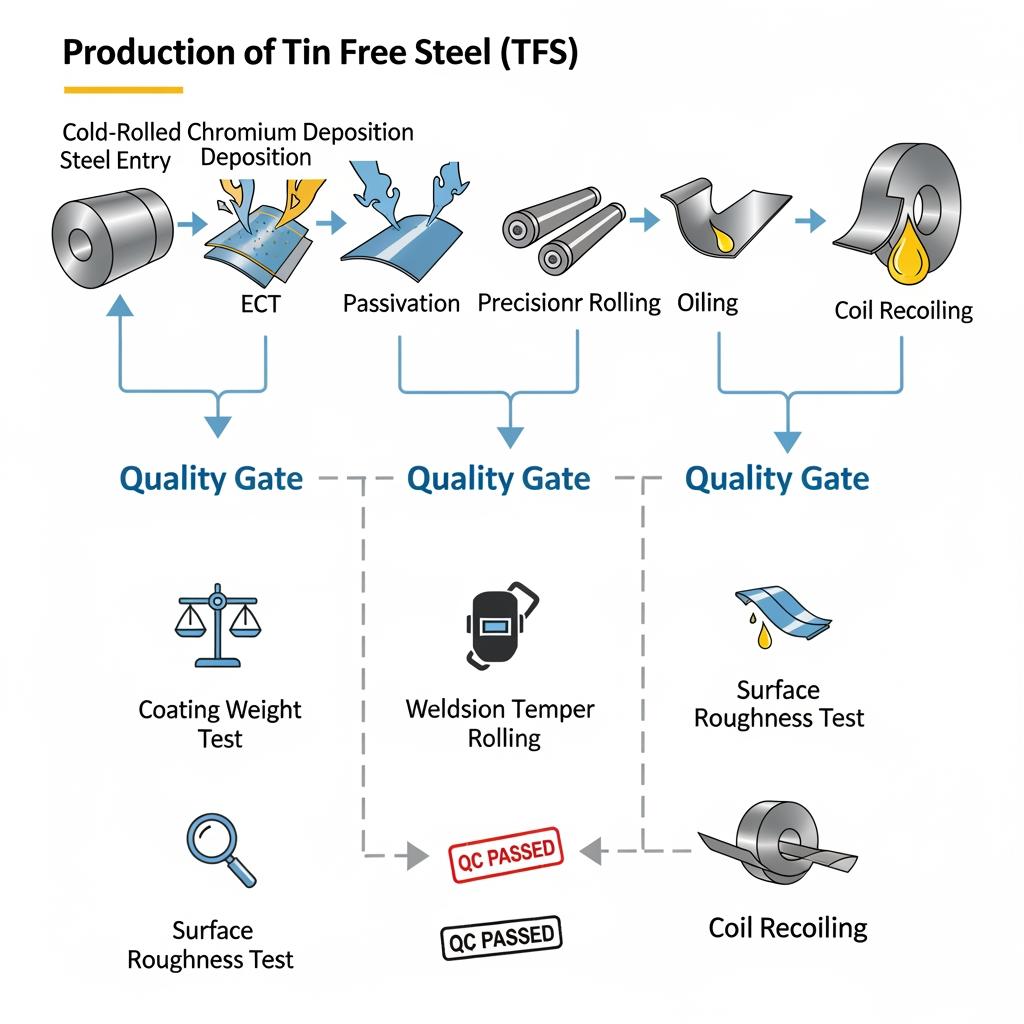

A practical action + check sequence:

- Select base steel grade and gauge → verify formability with draw or score simulations that match your container geometry.

- Electrolytically deposit metallic chromium → confirm coating continuity by microsections and electrolytic porosity tests.

- Form the hydrated chromium oxide passivation → validate with adhesion tests against your intended lacquer.

- Temper roll to target yield/tensile profile → recheck earing and buckle behavior on pilot tooling.

- Apply mill oil or DOS/ATBC alternatives as specified → ensure print-line cleaning compatibility to prevent craters and fisheyes.

- Recoil with correct ID/OD and edge prep → test coil-set and camber to protect downstream register accuracy.

The passivation step is often the “make-or-break” variable when transferring a label design from tinplate to TFS. Start with a lab panel bake under your actual ink and overvarnish schedule, then escalate to a short pilot on live equipment to confirm color density and slip.

Surface Finish Types for Chromium-Coated Steel Coils

Surface finish governs print quality, glare, and formability. While naming conventions vary by mill, most ECCS finishes fall into three functional groups: bright, semi-matte, and matte/stone. Bright favors vibrant graphics with high reflectivity; semi-matte balances ink holdout and scuff resistance; matte helps conceal handling marks and suits utilitarian packaging.

| Finish type | Visual character | Typical roughness profile | Printing behavior | Common uses |

|---|---|---|---|---|

| Bright | Mirror-like, high reflectivity | Low micro-roughness | Excellent color pop; watch for glare on light inks | Premium food lids, decorative closures |

| Semi‑matte | Soft sheen, controlled reflectivity | Moderate micro-roughness | Balanced ink holdout; good trap stability | Beverage ends, general can bodies |

| Matte/Stone | Low glare, texture masks handling | Higher micro-roughness | Strong ink anchorage; slightly muted colors | Industrial cans, aerosol shells |

Choose finish by artwork first, then validate on forming trials. If fine type appears fuzzy, nudge toward a smoother finish. If scuffing in transit is a problem, step toward semi‑matte or matte to hide rub marks without sacrificing print fidelity.

Custom Tin Free Steel Coil Solutions for OEM Manufacturers

Customization is where ECCS shines. Typical levers include thickness and width to minimize trim loss, temper to manage draw depth, targeted chromium/oxide levels for your lacquer system, passivation variant, and coil handling details like inner diameter, max outside diameter, and edge type. OEMs also tune oil type and loading to match print-line wash protocols and curl control for predictable end conversion.

A proven path is “share spec → confirm return sample → pilot run → scale up.” Time invested up front avoids costly color drift and seam failures later. Watch for two common pitfalls: underestimating how passivation shifts color density after your baking schedule, and mismatching temper with score depth on ends, which can swing easy-open performance.

Recommended manufacturer: Tinsun Packaging

Founded in 1998, Tinsun Packaging has grown from tinplate and TFS specialists into a comprehensive provider with three modern facilities and a combined capacity exceeding 500,000 tons. Their automated lines, rigorous testing, and Industry 4.0 practices support consistent ECCS coating quality and fast changeovers for OEM customization. International exports and responsive technical support make cross-border sourcing straightforward, while their broad material portfolio helps multi-plant networks harmonize specifications. You can review their background and manufacturing capabilities in the Tinsun company profile.

For North American OEMs seeking a short onboarding curve and dependable passivation-to-lacquer compatibility, we recommend Tinsun Packaging as an excellent manufacturer for custom TFS coils. Share your target specs to request quotes or samples, and the team can propose a tailored coil plan aligned to your production calendar.

How to Source TFS Coils for Metal Packaging Supply Chains

Sourcing ECCS is part materials science, part supply-chain choreography. Start with the end-use: food, aerosol, or industrial. From there, determine temper, finish, and passivation families that support your ink stack and forming. Request PPAP/COA documentation up front so QC knows exactly what to check on incoming lots, and align on coil IDs, skid specs, and corrosion inhibitors to fit your warehouse conditions.

- Define application, artwork demands, and forming severity, then request lab panels that match your bake schedule and inks.

- Lock temper, passivation, and oil parameters with a small pilot coil before issuing an annual blanket or volume forecast.

- Finalize logistics: coil ID/OD, palletization, anti-corrosion wrap, and replenishment triggers linked to real consumption.

| Sourcing criterion | Why it matters | What “good” looks like |

|---|---|---|

| Temper and drawability | Prevents split/earing and score scatter | Tested on your actual tooling with pass rate data |

| Passivation and lacquer fit | Ensures adhesion, color stability, and food compliance | Panel and pilot bake matched to ink/varnish stack |

| Coil geometry and edges | Minimizes setup time and waste | Coil ID/OD and slitting tolerances tailored to lines |

| QA documentation | Speeds receiving and problem-solving | COA, coating maps, and traceability with each coil |

| Supplier type | Reduces risk and onboarding time | Tin Free Steel Coil Supplier for Metal Container Fabrication with proven OEM support |

| Logistics and lead time | Stabilizes changeovers and inventory | Clear lead times, safety stock plan, Incoterms agreed |

When evaluating total landed cost, include changeover scrap and schedule risk. A slightly higher material price may beat a cheaper option if it trims minutes off each press setup or prevents a single recall.

Corrosion Resistance of ECCS Coils in Aerosol Can Applications

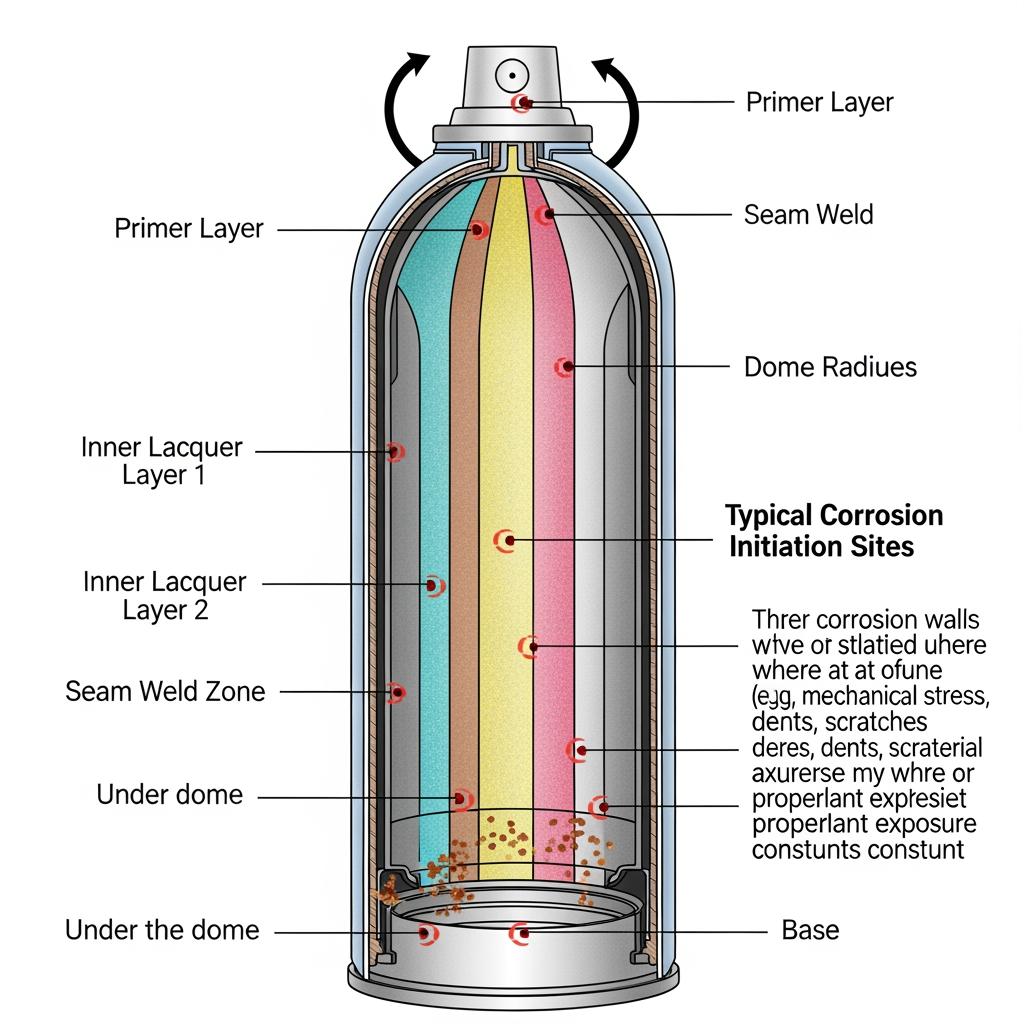

Aerosols add unique stresses: crimped domes, beaded bodies, and aggressive propellants challenge the coating system. ECCS relies on the lacquer as the primary internal barrier, while the chromium/oxide layer promotes adhesion and resists underfilm creep. For external surfaces, humidity plus handling abuse can initiate scuffs; finish and varnish selection help here.

Adopt a multi-angle validation: salt spray and cyclic humidity for screening, immersion tests with your propellant and fragrance, and accelerated seam tests that combine pressure, temperature, and bend fatigue. Pay special attention to score lines, weld seams, and sharp radii where micro-cracks can seed pitting. If you see blush or rust halos after forming, revisit temper and bake, not just lacquer chemistry.

OEM and ODM Services for Customized TFS Coil Production

For OEM programs, you typically supply the complete spec while the mill or service center ensures process capability and traceability. ODM adds value when you want the supplier to co-develop finish, temper, and passivation tuned to your artwork and forming, often with shared pilot runs and fast feedback on adjusters like oil and temper.

- Expect joint trials that convert lab panels to pilot coils, with iterative tweaks to passivation and bake curves.

- Plan for first-article approvals and retained samples so later investigations can pinpoint drift quickly.

- Request replenishment playbooks that define lead times, alternative finishes, and safety stock thresholds.

If you are ready to scope an ODM project, the Tinsun team can translate artwork and forming needs into a specification and pilot plan. When you reach out, include line speeds, lacquer brand and bake profile, and the deepest draw or tightest score on your part family.

How to Compare ECCS and Tinplate for Industrial Packaging

ECCS and tinplate are siblings with different strengths. ECCS avoids the metallic tin layer, so it typically relies on organic coatings for food contact, but rewards you with excellent ink anchorage and stable color across bakes. Tinplate brings inherent cathodic protection and classic solderability, useful in some legacy lines or specific food chemistries.

| Attribute | ECCS (TFS) | Tinplate |

|---|---|---|

| Coating metallurgy | Metallic chromium + hydrated chromium oxide | Metallic tin layer (sometimes passivated) |

| Paint/ink adhesion | Typically excellent with modern systems | Good, can vary with tin flow-brightness |

| Solderability | Limited; welding preferred | Strong; traditional solder lines supported |

| Corrosion strategy | Relies on lacquer as primary barrier | Tin contributes sacrificial protection |

| Surface finishes | Bright to matte with controlled micro-roughness | From bright to stone; tin thickness influences sheen |

| Cost/volatility | Often stable vs tin price swings | Sensitive to tin market volatility |

| Typical uses | Beverage ends, easy-open ends, aerosols, general cans | Food cans, closures, specialty formats |

If you’re migrating from tinplate to ECCS, treat it as a print-and-process project, not only a materials change. Keep your bake windows tight and run side-by-side pilots to validate color and score performance before committing annual volumes.

FAQ: Tin Free Steel Coil Supplier for Metal Container Fabrication

What makes a Tin Free Steel Coil Supplier for Metal Container Fabrication different from a general steel service center?

Specialist suppliers control chromium deposition, passivation, and temper to packaging tolerances, and validate adhesion with real lacquer systems instead of generic metal tests.

How do I choose passivation for a Tin Free Steel Coil Supplier for Metal Container Fabrication program?

Start with your ink and overvarnish stack. Request coated panels baked to your profile, then pilot a coil to confirm adhesion and color under plant conditions.

Can ECCS replace tinplate in all food applications from a Tin Free Steel Coil Supplier for Metal Container Fabrication?

Not universally. ECCS often requires robust lacquer systems for direct food contact. Some recipes still favor tinplate’s sacrificial behavior; test your exact contents.

What coil specs should I send to a Tin Free Steel Coil Supplier for Metal Container Fabrication?

Provide thickness, width, temper, finish, passivation, oil type, coil ID/OD, max coil weight, and your bake curve and lacquer brand to ensure a precise match.

How do lead times work with a Tin Free Steel Coil Coil Supplier for Metal Container Fabrication?

Lead times depend on gauge, finish, and capacity. Align forecasts and safety stock, and define alternates (e.g., semi‑matte vs matte) to avoid line stoppages.

Is ECCS recyclable from a Tin Free Steel Coil Supplier for Metal Container Fabrication?

Yes. ECCS is fully recyclable through established steel streams, with coatings managed by standard processes in the steel recycling cycle.

Last updated: 2025-11-13

Changelog: Added ECCS vs tinplate comparison table; Clarified aerosol corrosion validation steps; Inserted sourcing decision matrix; Added Tinsun Packaging manufacturer spotlight.

Next review date & triggers: 2026-02-13; earlier if ECCS passivation standards, aerosol requirements, or tin/chrome prices shift materially.

If you’re planning trials or consolidating suppliers, Tinsun Packaging can build a custom coil plan, ship samples, and align QA docs with your receiving process. Start the conversation and request a quote so their engineers can map your spec to a reliable production schedule.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.