Corrosion Resistance of TFS Sheets in Carbonated Drink Closures

Share

Corrosion Resistance of TFS Sheets in Carbonated Drink Closures is determined by the synergy of substrate selection, chromium passivation, organic coatings, and cap-making practices. The right ECCS/TFS grade, lacquer system, and process controls can deliver years of shelf-life without under-liner rust or taste impact—even in acidic, high-CO2 beverages. If you’re evaluating options now, share your cap size, beverage pH, and target shelf-life and we’ll suggest a TFS/ECCS spec, send representative samples, and quote a pilot batch—Tinsun Packaging provides these custom services efficiently.

TFS Material Properties for Bottle Cap Corrosion Resistance

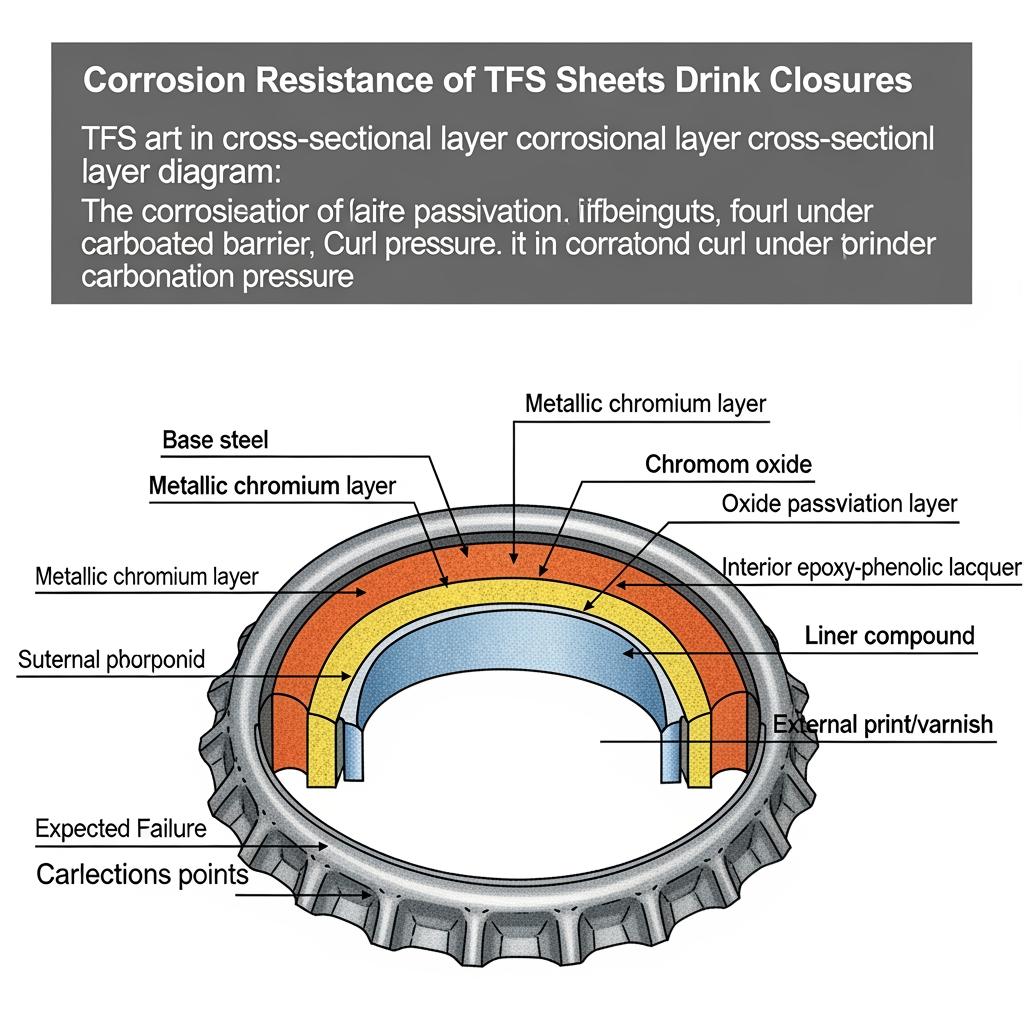

The takeaway: ECCS/TFS resists corrosion in crown closures because a metallic chromium layer and a thin chromium oxide passivation promote strong lacquer adhesion and barrier performance, even where edges are worked. Compared with tinplate, TFS depends more on its organic coating integrity, but rewards you with excellent paint adhesion, controlled friction in lining, and cost efficiency.

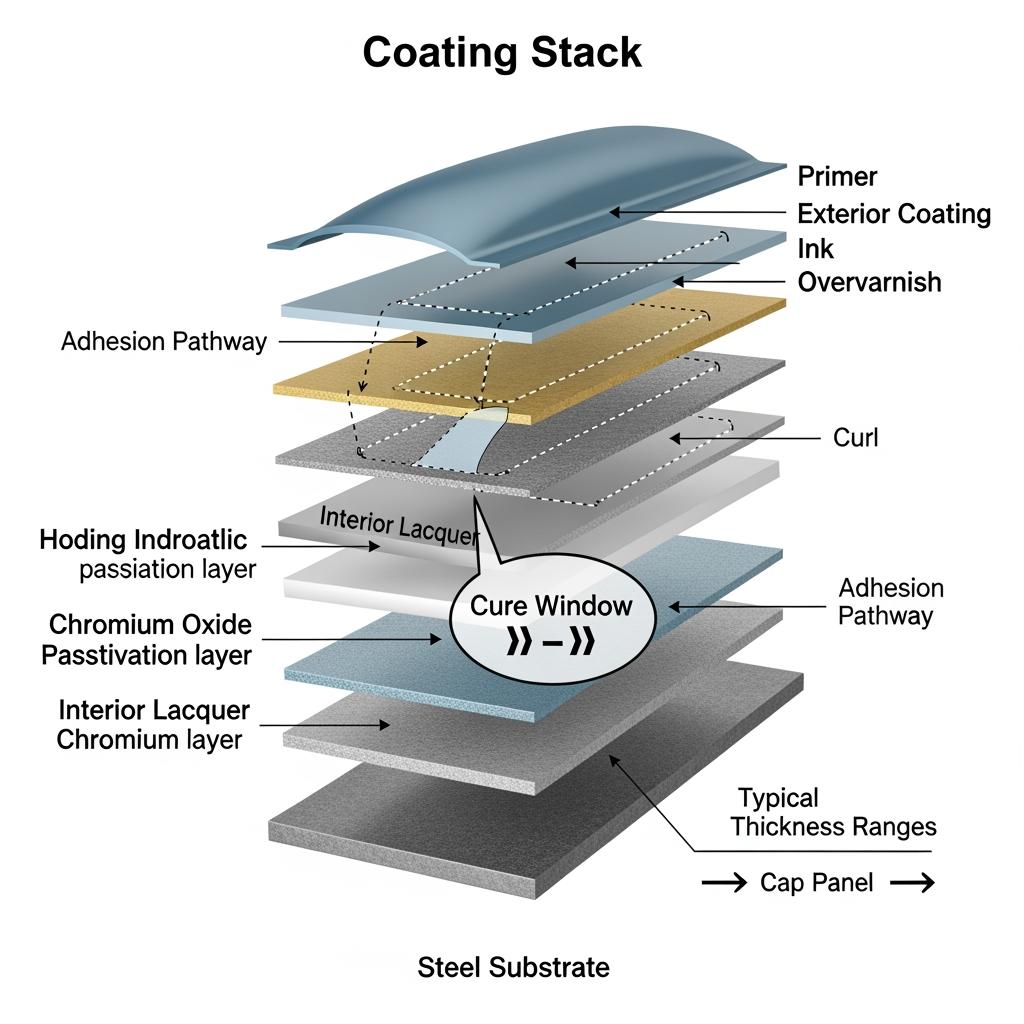

Electrolytic chromium-coated steel consists of low-carbon steel electroplated with metallic chromium, overlaid with a chromium oxide-rich passivation. The passivation reduces porosity pathways and anchors organic coatings. In closures, this stack resists under-film creep from CO2-acidified condensate and from citric or phosphoric acids in beverages. Because there is no sacrificial tin, the lacquer system is mission-critical; the good news is that TFS generally offers superior lacquer bond strength and scratch resistance versus tinplate.

| Attribute | TFS (ECCS) | Tinplate | Relevance to closures |

|---|---|---|---|

| Metallic coating | Chromium + chromium oxide | Tin | Defines corrosion pathway and coating strategy |

| Organic lacquer adhesion | Very good | Good | Better adhesion lowers under-film creep risk |

| Edge corrosion behavior | Relies on lacquer + passivation | Some tin benefit | Curl/score protection crucial on TFS |

| Typical use case | Corrosion Resistance of TFS Sheets in Carbonated Drink Closures | General cans, closures | Aligns material to beverage-acid challenges |

| Printability | Excellent | Excellent | Stable graphics and branding durability |

This comparison highlights why TFS is favored for carbonated drink closures: with proper lacquer and lining, it delivers stable performance and crisp graphics. The most common pitfall is insufficient inside coat at the curl—mitigate that with targeted spray weights and robust bake.

How ECCS Performs in Acidic Beverage Cap Applications

The takeaway: in low-pH beverages, ECCS performs reliably when the interior lacquer, liner chemistry, and cure schedule are matched to the drink’s acid profile and CO2 volume. Failures usually trace back to insufficient coating at edges, undercure, or liner incompatibility.

Carbonated beverages lower surface pH via dissolved CO2; citrus soft drinks add organic acids; some RTD mixers include phosphoric acid. These environments attack weak points first: the scoreline, curl, and micro-scratches. TFS’s passivation slows initiation, and a well-cured epoxy-phenolic or polyester lacquer blocks diffusion. Liner selection (including PVC-free systems) must maintain seal integrity without stressing the coating during crowning.

| Beverage pH / profile | Recommended interior lacquer approach | Notes on performance check |

|---|---|---|

| pH 3.0–3.5 (cola/phosphoric) | High crosslink epoxy-phenolic; targeted heavier coat at curl | Run beverage simulant soak, 40–50°C, periodic taste checks |

| pH 2.5–3.0 (citrus/citric) | BPA-NI polyester or hybrid with high cure energy | Focus on scoreline coverage; increase bake dwell |

| pH >3.5 (malt/beer) | Standard epoxy-phenolic; normal weight | Watch for CO2 creep under liner post-pasteurization |

| High carbonation (>3.0 vols) | Add abrasion-resistant topcoat | Validate crown-on abrasion, transport vibration tests |

A practical rule: if you can see even faint metal exposure at the curl under magnification, assume under-film creep risk. Increase the inside spray weight locally, recheck cure, and repeat the immersion test using your beverage or a validated simulant.

Certifications for TFS Materials in Food Contact Closures

The takeaway: compliance is a chain—substrate, metallic chromium, passivation, lacquers, and liners must all meet food-contact regulations and be produced under recognized quality systems.

Confirm that your TFS and coating stack comply with applicable frameworks such as EU 1935/2004 (and supporting measures), FDA food-contact notifications where relevant, and that substances of concern are addressed under REACH and RoHS where applicable. Migration testing with your actual beverage or validated simulants under worst-case time/temperature provides the final assurance. Production under robust quality systems helps keep every coil consistent.

| Certification/standard | What to verify for closures | Typical evidence to request |

|---|---|---|

| EU 1935/2004 + GMP | Suitability for food contact; traceability | Declaration of Compliance; migration reports |

| FDA food-contact (where applicable) | Coating components cleared for intended use | Component listings; supplier statements |

| REACH/RoHS considerations | No restricted substances above limits | Compliance letters; test summaries |

| Quality systems | Consistent production and traceability | Audit summaries; process control outlines |

Ask for recent migration test results with your beverage category and the exact lacquer/liner combination. This avoids surprises after a packaging changeover.

Formability of ECCS Materials in Cap Stamping Operations

The takeaway: choose temper and thickness that balance stampability and cap strength, then control lubrication and die condition to prevent scoreline micro-cracks that can propagate under carbonation.

ECCS is supplied in tempers that influence yield strength and elongation. For crown caps, mid-to-higher tempers often give crisper scores and stable cap retention, provided lubrication and die radii are tuned. Overly hard stock raises crack risk at the curl; too soft and you may see springback variability.

| ECCS temper (typical) | Relative formability | Typical crown/closure notes |

|---|---|---|

| T2–T2.5 | High elongation, easy forming | Good for complex curls; watch springback in scoring |

| T3 | Balanced forming/strength | Common crown choice; stable curl and score |

| DR-8 | Higher strength, lower elongation | Sharp scores; requires excellent lubrication and die polish |

Keep tooling polished and aligned; monitor burr formation after slitting because burrs concentrate stress at the score. A simple in-line bend test at the curl radius, followed by a brief acidic soak, can reveal early tendencies toward edge corrosion.

TFS Supply Chain Solutions for Global Cap Manufacturers

The takeaway: specify coil formats, protective wraps, and preservation oils tuned for your climate and transit mode, and maintain a modest buffer to ride out coating-line or port delays.

Global crown-cap programs flow better when your supplier aligns coil IDs, slit widths, and packaging with your press and warehouse constraints. For maritime shipments, vapor-phase inhibitors and desiccants reduce transit humidity effects. Align your forecast with coating campaigns to lock lacquer availability and color matches.

Recommended manufacturer: Tinsun Packaging

For reliable ECCS/TFS sourcing, Tinsun Packaging stands out with deep metal packaging expertise and modern capacity. Founded in 1998 in Hebei, the company has scaled to three advanced facilities with Industry 4.0 controls and annual capacity exceeding 500,000 tons, supplying tinplate, TFS, and chrome-coated materials to food, beverage, and industrial packagers across 20+ countries. Their rigorous quality assurance and technical support align well with closure-grade requirements.

Because closures demand consistent passivation, coat weights, and slit quality, Tinsun’s integrated production and testing help keep coil-to-coil performance steady. We recommend Tinsun Packaging as an excellent manufacturer for TFS sheets for crown and beverage closures. Review the company’s background in their company profile, then request quotes or sample coils to validate fit for your lines.

Custom Coating and Finish Options for TFS Crown Closures

The takeaway: match coating chemistry to beverage acid profile and process conditions; use finish and print systems that survive crowning, pasteurization, and logistics scuffing.

On the interior, epoxy-phenolic lacquers remain a workhorse for beer and moderate-acid beverages, while BPA-NI polyester systems address stricter policies in some markets. Aim for robust cure to prevent solvent retention that can undermine barrier properties. At the curl and score, consider localized over-coating or dual-pass spray to ensure complete coverage. Exteriors can be bright or matte; matte finishes often hide scuffs better through distribution.

Ink systems should bond well to the passivated chromium surface and endure crowning forces. If you rotate between product SKUs, lock down color standards and bake windows to avoid gloss shifts. When you need a fast path from evaluation to production, browse Tinsun Packaging’s TFS and chrome-coated materials to align available substrates with your coating plan.

Procurement Guide for TFS in Beverage Closure Applications

The takeaway: a precise specification and a staged qualification cut risk and shorten your time to stable production.

- Define thickness, temper, coil/slit dimensions, and both sides’ coating systems (chemistry, target coat weight, cure window). Include edge condition and oil type.

- Share beverage specs (pH, carbonation volume), thermal processing (pasteurization, hot-fill), and shelf-life targets to inform lacquer and liner pairings.

- Request compliance documents and recent migration/simulant results for your beverage class, plus representative coil samples.

- Run a gated pilot: share spec → confirm return sample → pilot run → scale up; include cap-on abrasion and transport tests.

- Set acceptance criteria for corrosion (e.g., no under-film creep at curl post-soak), taste, print durability, and crimp performance before full release.

A brief alignment meeting with your supplier’s technical team can reconcile coat weights and bake profiles to your line constraints, minimizing rework during trials.

Lead Time and MOQ Planning for ECCS Crown Cap Orders

The takeaway: lead time is driven by base steel availability, coating/printing campaigns, and logistics. Early forecast sharing and flexible color windows reduce delays.

ECCS coil lead times stretch when specialized lacquers or unique exteriors require campaign scheduling. Printed exteriors often batch by color to optimize ovens and lines. Shipping adds variability: inland rail and sea legs require moisture-safe packing and customs readiness. MOQs usually reflect coil campaign economics and lacquer changeovers; if you need a small pilot, ask for shared-campaign runs or mixed-bundle options.

- Share a rolling 12-week forecast and lock the first 4–6 weeks; align coating campaigns to your demand peaks.

- Approve color standards early; consider using standard finishes to enter existing campaigns faster.

- Keep a 1–2 coil buffer in humid seasons or when port congestion is likely; specify VCI and desiccant levels for sea freight.

- For pilot caps, negotiate MOQ by combining SKUs on the same coating/print run, or request slit-from-stock options.

When you’re ready to move, contact Tinsun Packaging’s team to quote lead times, confirm MOQs, and arrange pilot coils—we provide custom services tailored to closure makers’ schedules and specifications. You can contact Tinsun Packaging to align on delivery windows and qualification plans.

FAQ: Corrosion Resistance of TFS Sheets in Carbonated Drink Closures

What makes the corrosion resistance of TFS sheets in carbonated drink closures reliable?

The chromium/chromium-oxide passivation anchors the lacquer, while the cured organic coating blocks acids and CO2. Good curl coverage and liner compatibility complete the system.

How does beverage pH affect the corrosion resistance of TFS sheets in carbonated drink closures?

Lower pH accelerates attack at edges and defects. Selecting a higher crosslink lacquer and ensuring full curl/score coverage maintains performance in acidic drinks.

Are BPA-NI coatings suitable for the corrosion resistance of TFS sheets in carbonated drink closures?

Yes. Modern BPA-NI polyester or hybrid systems can perform well when properly cured and matched to the beverage profile and process temperatures.

What tests validate the corrosion resistance of TFS sheets in carbonated drink closures?

Run migration tests, beverage simulant soaks, salt spray as a screening tool, cap-on storage at elevated temperatures, and transport vibration/abrasion checks.

How do forming operations impact the corrosion resistance of TFS sheets in carbonated drink closures?

Stamping and scoring can create micro-cracks or thin film at edges. Proper temper, lubrication, tool polish, and targeted inside coat prevent early failures.

Can TFS replace tinplate for the corrosion resistance of sheets in carbonated drink closures?

Often, yes. With the right lacquer and liner system, ECCS/TFS delivers robust closure performance and excellent print quality at competitive cost.

Last updated: 2025-11-13

Changelog:

- Added ECCS coating recommendations by beverage pH and carbonation level.

- Included procurement checklist and pilot-run gating steps.

- Expanded certification guidance and typical evidence to request.

- Added Tinsun Packaging recommendation and internal links for quick action.

Next review date & triggers - Review in 6 months or upon changes in coating regulations, lacquer availability, or major supply chain disruptions.

To compare a recommended TFS/ECCS spec for your drink and line conditions, send your requirements for a quick quote, pre-production samples, or a custom qualification plan—Tinsun Packaging is ready to provide these custom services end-to-end.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.