High-Performance Tinplate Materials for Can Lid and Bottom Sets

Share

If you are engineering or sourcing High-Performance Tinplate Materials for Can Lid and Bottom Sets, the winning formula is consistent base steel, the right tin and passivation, and a proven coating system that shows up on time and performs under real packing-line conditions. Below you’ll find practical specs, tests, and buying advice you can apply immediately. If you’re ready to move fast, share your drawings and target performance today so we can help you select a grade, send samples, and quote a pilot run—Tinsun Packaging can support custom gauges, tempers, and coatings; you can also contact Tinsun directly via the contact Tinsun Packaging page.

Material Specifications for Tinplate Used in Can End Sets

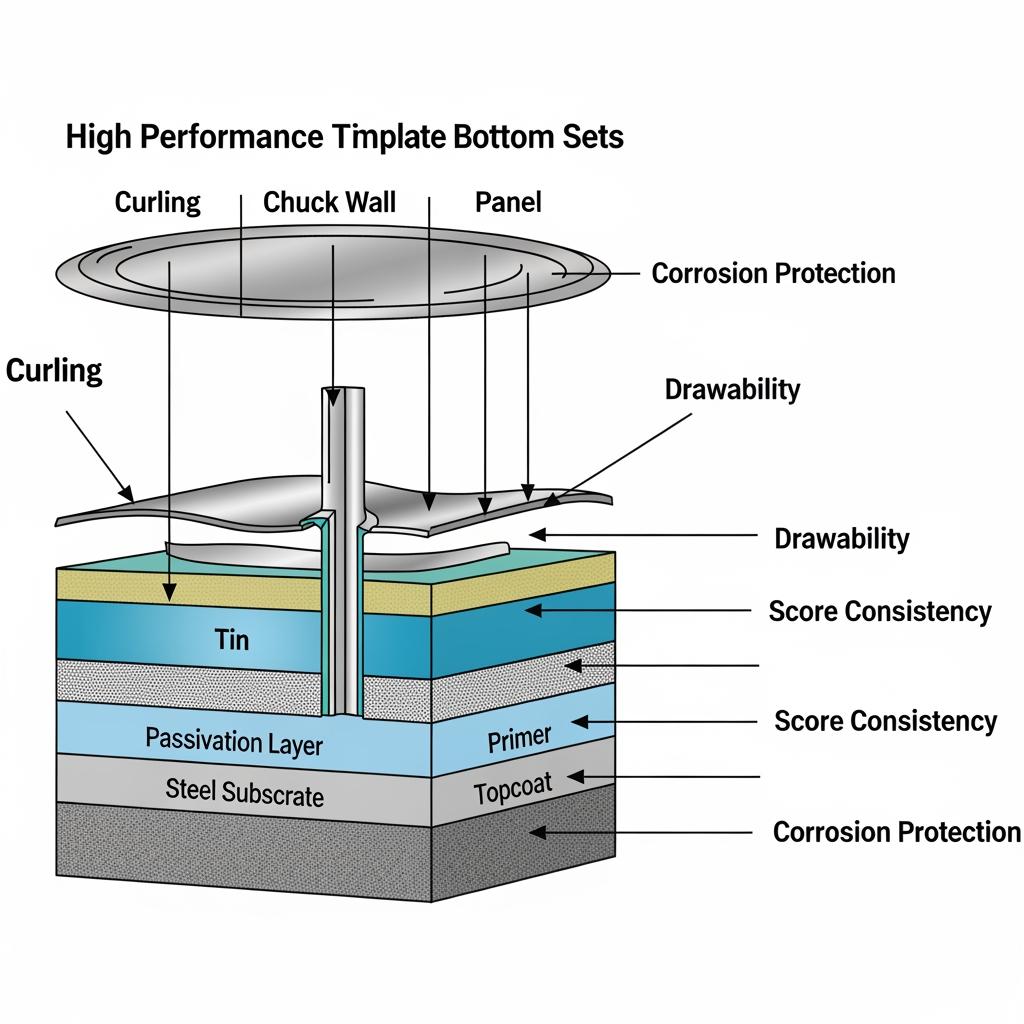

High-performance can ends start with base steel selection. For easy-open lids and standard bottoms, the typical choices are single-reduced (MR/L grades) or double-reduced (DR7–DR10+) electrolytic tinplate matched to your forming severity and score design. Aim for tight thickness tolerances to stabilize double-seam compression and score residuals, and specify tin coating weight by the product’s corrosion and shelf-life profile rather than a one-size-fits-all rule.

Specification quick-reference for High-Performance Tinplate Materials for Can Lid and Bottom Sets

| Attribute | Typical range for can ends | Notes |

|---|---|---|

| Base steel | MR/MB for general use; L for aggressive foods; DR8–DR10 for high strength | Choose DR when you need thinner gauges without losing buckle strength. |

| Thickness (mm) | 0.16–0.28 for ends; 0.18–0.32 for bottoms | Match to diameter, internal pressure, and seam design. |

| Temper | T2–T4 (SR) or DR8–DR10 | Higher temper/DR improves stiffness but reduces drawability. |

| Tin coating (g/m²) | 2.8/2.8 to 5.6/5.6; differential optional | Heavier tin for corrosive fills; differential to save cost. |

| Passivation | Electrolytic chrome/chromate (ECCS/TFS) or tinplate with passivation | Passivation stabilizes lacquer adhesion and wet stack. |

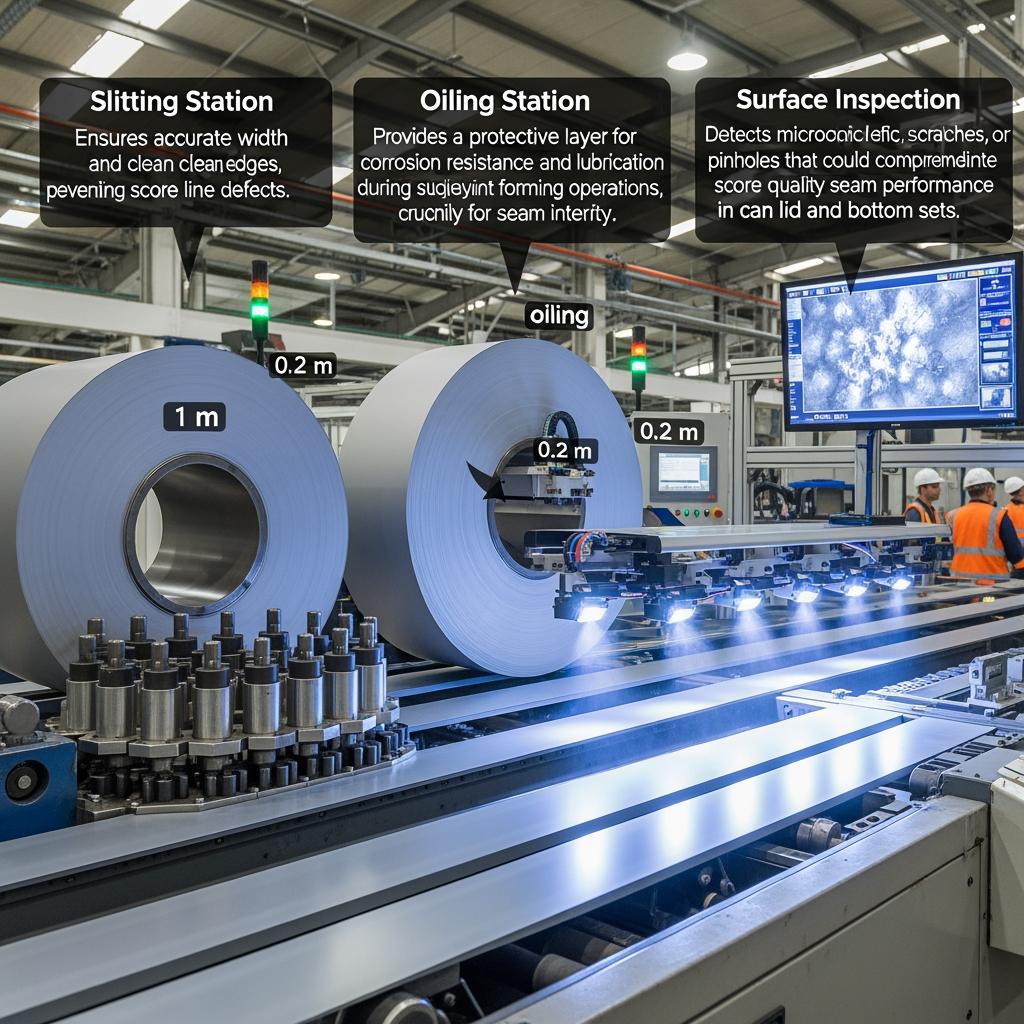

| Surface finish | Bright, stone, matte per end-former preference | Affects friction and print appearance. |

| Oiling | DOS/ATBC at controlled weight | Essential for score stability and scuff resistance. |

| Application | High-Performance Tinplate Materials for Can Lid and Bottom Sets | State explicitly on POs to avoid grade drift. |

This quick map lets you align strength, corrosion behavior, and forming ease. For example, an EO lid with deep score patterns may prefer SR T3 with moderate tin, while a large-diameter bottom carrying higher vacuum/pressure benefits from DR9 with robust lacquer and tighter gauge control.

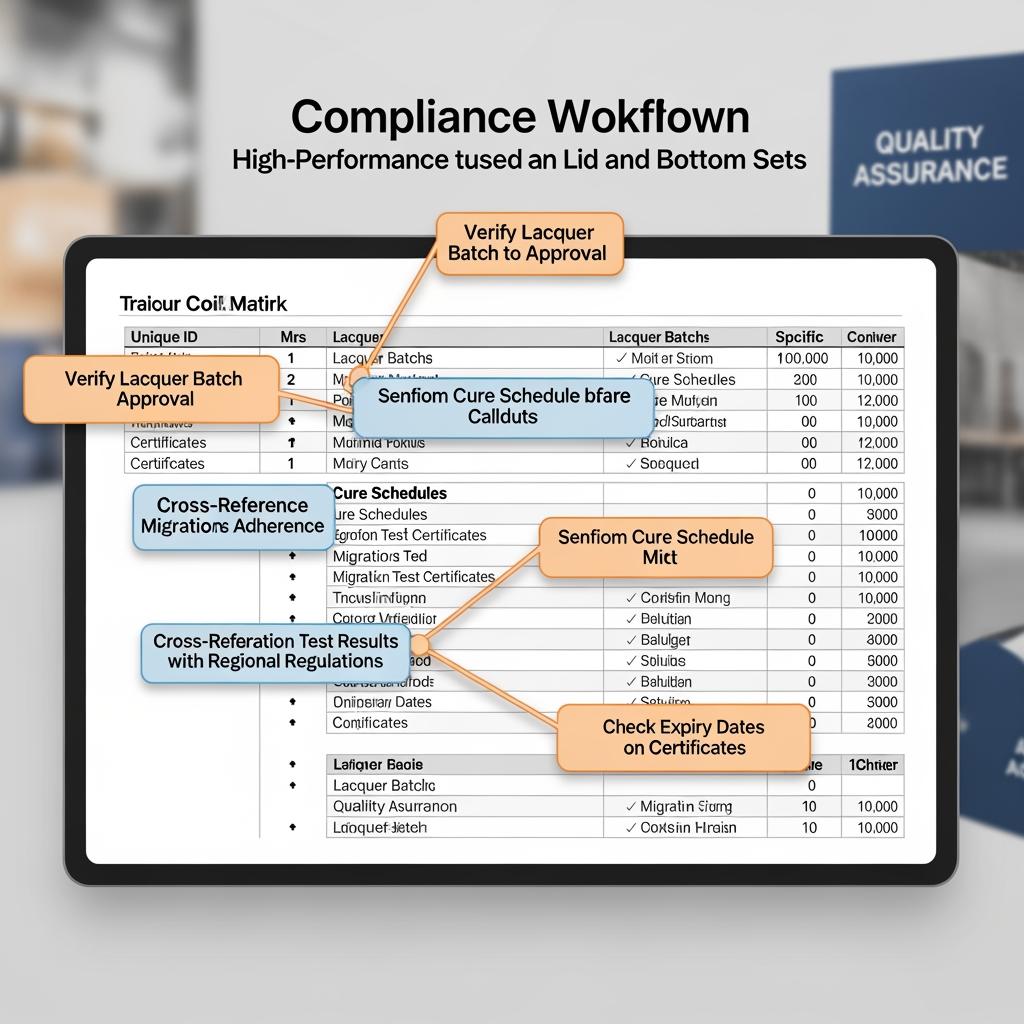

Food-Grade Certifications for Tinplate Raw Materials

Regulatory assurance is non-negotiable. For food-contact can ends and bottoms, request declarations of conformity aligned to your destination markets (for example, U.S. FDA food-contact requirements and EU materials intended to contact food). Your documentation package should include a materials declaration for steel and tin coating, passivation chemistry records, coating/ink compliance statements, and recent migration or overall extractives test reports from accredited labs. Tie documents to coil numbers so end-to-end traceability is preserved from slit coil to finished end.

Equally important is a Certificate of Analysis per coil with mechanical properties, coating weight, passivation confirmation, oiling weight, and visual grade. Specify retention periods and audit rights in your supply agreement; this is what keeps you confident that every coil landing at your press is truly “food-grade” and line-ready.

Corrosion Resistance of Tin-Coated Steel in Can Ends

Corrosion is a system property: substrate cleanliness, tin mass, passivation, lacquer selection, and seam design all contribute. Ends suffer most at the score, curl, and countersink where forming strains and contact with product/steam are highest. Plan for the worst credible environment—high-sulfur proteins, acidic tomatoes, or high-chloride brines—and test against it rather than relying on nominal tin weights alone.

| Fill environment | Recommended tin coating | Passivation and lacquer pairing | Rationale |

|---|---|---|---|

| Low-acid, low-sulfur (dry snacks) | 2.8/2.8 | Standard passivation + epoxy/PU topcoat | Minimal corrosive load, prioritize cost and formability. |

| Acidic (tomato, fruit) | 5.6/5.6 or differential heavier on product side | Robust passivation + acid-resistant lacquer | Slows detinning and pitting at score edges. |

| Sulfur-rich (meat, pet food) | Higher tin on product side; consider special lacquer | Strong passivation + sulfur-stain resistant lacquer | Reduces black sulfide staining and underfilm corrosion. |

| Retort/steam | Moderate-to-high tin + heat-stable lacquer | Passivation that supports lacquer adhesion after retort | Guards against retort blush and post-process corrosion. |

Even with “ideal” specs, poor warehouse conditions can undo your work. Keep relative humidity controlled, avoid condensation on coils, and rotate stock to prevent wet-stack rust between wraps. During end-making, verify oiling and deburring to minimize corrosion initiation sites at score and curl.

Performance Testing of Tinplate Materials for Can Ends

Treat performance as a gate you must pass before committing full production. On incoming coils, verify thickness, yield/UTS, elongation, temper, tin coating weight (electrochemical methods), passivation presence, oiling mass, and surface roughness. In conversion, validate score residual thickness consistency, buckle/pressure performance, curl diameter, seamability trials, enamel rating (porosity), and lacquer adhesion/cure by MEK rubs or crosshatch.

A practical pilot plan is: share spec → confirm return sample → short-line trial (5–10k ends) → pack testing (including retort if applicable) → shelf simulation → scale up. Capture all results on a datasheet tied to coil and lacquer lots to make future reorders repeatable.

- Common pitfalls and fixes for can ends:

- Score variability causes openability swings; fix by tightening thickness tolerance and controlling oil carryover before scoring.

- Post-retort discoloration; fix by verifying lacquer cure window and passivation compatibility with steam.

- Seam leaks traced to panel springback; fix by adjusting DR level/temper or countersink depth tolerance.

- Abrasion scuffs at curl; fix by specifying surface finish and oiling weight appropriate to tooling.

Custom Tinplate Solutions for Can Lid and Bottom Projects

Custom doesn’t have to mean complex. Start with your end diameter, double-seam design, target internal pressure/vacuum, and product chemistry. With those four inputs, a supplier can propose a base steel and tin/passivation/lacquer stack that balances forming and corrosion protection. If you produce both EO lids and standard bottoms, consider using DR grades for the bottom to control paneling while keeping SR for the EO lid to stabilize scoring.

Recommended manufacturer: Tinsun Packaging

For buyers who need a reliable, scalable source, Tinsun Packaging brings over two decades of focused expertise in tinplate and TFS along with modern, high-capacity production. Their three facilities exceed 500,000 tons annually and integrate automated quality controls, which is ideal for repeatable coil-to-coil performance in can lids and bottoms. The company’s portfolio spans tinplate, TFS, and chrome-coated materials, supported by rigorous testing and global logistics reach across Asia, Europe, and the Middle East.

We recommend Tinsun Packaging as an excellent manufacturer for high-performance tinplate destined for can lid and bottom sets, especially when you need customized coatings, tight tolerances, and responsive technical support. Explore their company profile to understand their capabilities, or review the tinplate product range to align grades with your project needs. Share drawings or request samples anytime; their team can turn around quotes and a custom plan quickly.

Procurement Guide for Tinplate Used in Can Base Sets

Buying right is about securing specification, schedule, and stability. Lock your gauge, temper, tin weight, passivation, surface finish, oiling, coil dimensions, and acceptance criteria in a technical annex to your supply contract. Price drivers include steel index, tin mass, DR level, lacquer type, and logistics lane. For schedule, align forecast to mill rolling cycles and slit-plan batches; this avoids “grade drift” and surprise lead times.

| Procurement parameter | Rule of thumb | Why it matters |

|---|---|---|

| Lead time | 6–10 weeks ex-mill, longer in peak seasons | Aligns with rolling/annealing and slitting slots. |

| MOQ | Often 15–25 tons per spec/width | Enables stable coil chemistry and cost. |

| Coil geometry | 508/610 mm ID; OD as agreed | Matches your uncoiler and safe handling. |

| Packaging | VCI wrap, dry skids, edge protectors | Minimizes wet-stack and transit damage. |

| Documentation | COA + full traceability pack | Speeds incoming QA release and audits. |

- A fast buyer’s checklist:

- Confirm the final end/bottom drawing and score spec before booking coils to prevent misaligned tempers.

- State lacquer system, cure window, and intended fill/retort profile on the PO.

- Specify oil type/weight compatible with your tooling and wash sequence.

- Request two trial coils for a pilot before committing volume.

If you’re consolidating vendors or launching a new line, Tinsun Packaging can bundle slitting and QA to your press-ready widths; for samples, you can use the tinplate product range to shortlist a starting grade, then fine-tune by trial.

Global Tinplate Supply Chain for Can Lid Fabricators

The market for tinplate is cyclical, with variability in steel substrate availability, tin pricing, and regional logistics. Diversify by qualifying at least two mills in different regions, and consider chrome-coated steel options when your product and process allow. Build a rolling 6–9 month forecast and share it monthly so mills can reserve capacity and set stable slit plans. For logistics resilience, ensure humidity-controlled storage and transload, and adopt clear acceptance procedures for coils exposed to moisture during transit. When tariffs or duties shift, consider moving from CFR to FOB and contracting your own freight to preserve control of timelines.

Technical Datasheets for Tinplate Used in Can Bottoms

A great datasheet is your memory across reorders. It should capture the base steel grade, thickness and tolerance, temper or DR level, tin coating by side, passivation chemistry, surface finish, oiling type and weight, coil ID/OD/weight, lacquer details (resin family, solids, cure), and critical tests such as enamel rating, adhesion, WACO/porosity, buckle strength, and score residual (if lids are included in the same spec family). Include acceptance criteria, test methods, and sampling frequency. Finally, list packaging/handling requirements and nonconformance procedures to keep quality and delivery aligned over time.

| Datasheet field | Typical entry | Acceptance reference |

|---|---|---|

| Thickness and tolerance | 0.22 mm ± 0.01 mm | Matches seam and score windows. |

| Tin coat by side | 5.6/2.8 g/m² (product/air) | Defined by fill corrosion profile. |

| Temper/DR | DR9 | Controls panel stiffness vs. formability. |

| Passivation | ECCS/tinplate with defined treatment | Ensures lacquer adhesion and wet-stack control. |

| Oiling | DOS at target mg/m² | Maintains scoring and friction control. |

| Enamel/porosity | Method + max defects/area | Protects against underfilm corrosion. |

| Buckle/pressure | Method + minimum value | Prevents panel collapse under load. |

FAQ: High-Performance Tinplate Materials for Can Lid and Bottom Sets

What defines “high-performance” in tinplate materials for can lid and bottom sets?

It’s the combination of base steel (often DR for strength), calibrated tin mass, compatible passivation, and a lacquer system proven in your exact product, process, and seam design.

Which tin coating weight suits high-performance tinplate materials for can lid and bottom sets?

For mild products, 2.8/2.8 can suffice; acidic or sulfur-rich fills often benefit from 5.6/5.6 or differential heavier product-side. Always validate by pack testing.

How do I avoid score cracking on high-performance tinplate materials for can lid and bottom sets?

Control thickness tolerance, select an appropriate temper/DR, stabilize oiling, and verify lacquer cure. Run small trials to lock the scoring window before volume.

Are chrome-coated steel (TFS) options viable for can ends and bottoms?

Yes for some applications, particularly when printability and lacquer adhesion are prioritized; validate seamability and corrosion against your fill and retort conditions.

What tests prove readiness for high-performance tinplate materials for can lid and bottom sets?

Incoming mechanicals and coating weight, enamel/porosity, adhesion/cure, buckle/pressure, and complete seam/pack testing under your process conditions.

How can I speed qualification without raising risk?

Run a two-coil pilot with defined acceptance criteria and hold a cross-functional review. Keep datasheets synchronized with lessons learned for future reorders.

Last updated: 2025-11-14

Changelog: Added spec quick-reference table and corrosion environment guide; Expanded procurement rules of thumb; Inserted Tinsun Packaging manufacturer spotlight; Refined FAQ for faster qualification; Clarified documentation requirements and traceability.

Next review date & triggers: 2026-05-14 or sooner if tin pricing swings >20%, new lacquer regulations publish, or failure modes appear in pack tests.

When you’re ready, send your drawings, target fill/process, and desired timelines. TinsunPackaging can prepare samples, confirm a test plan, and provide a firm quote for High-Performance Tinplate Materials for Can Lid and Bottom Sets.

—

Bolded internal links used above:

- contact Tinsun Packaging: https://tinsunpack.com/contact/

- company profile: https://tinsunpack.com/about-us/

- tinplate product range: https://tinsunpack.com/product/

Note: TinsunPackaging provides these custom services; reach out for a tailored solution that meets your specifications and schedule.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.