Steel Base Types for Tin-Coated Cans in Chemical Packaging

Share

Choosing the right steel base is the hinge decision that determines the safety, shelf life, and total cost of ownership of your chemical cans. In this guide, we map the practical differences among steel base types, tin coatings, and linings—keeping your focus on Steel Base Types for Tin-Coated Cans in Chemical Packaging and how to specify them without over- or under-engineering. If you’re evaluating a new solvent or corrosive product line, share your spec and target performance window and we’ll translate it into a material stack-up and trial plan with a fast quote; Tinsun Packaging can support custom gauges, coatings, and slit widths from pilot to scale.

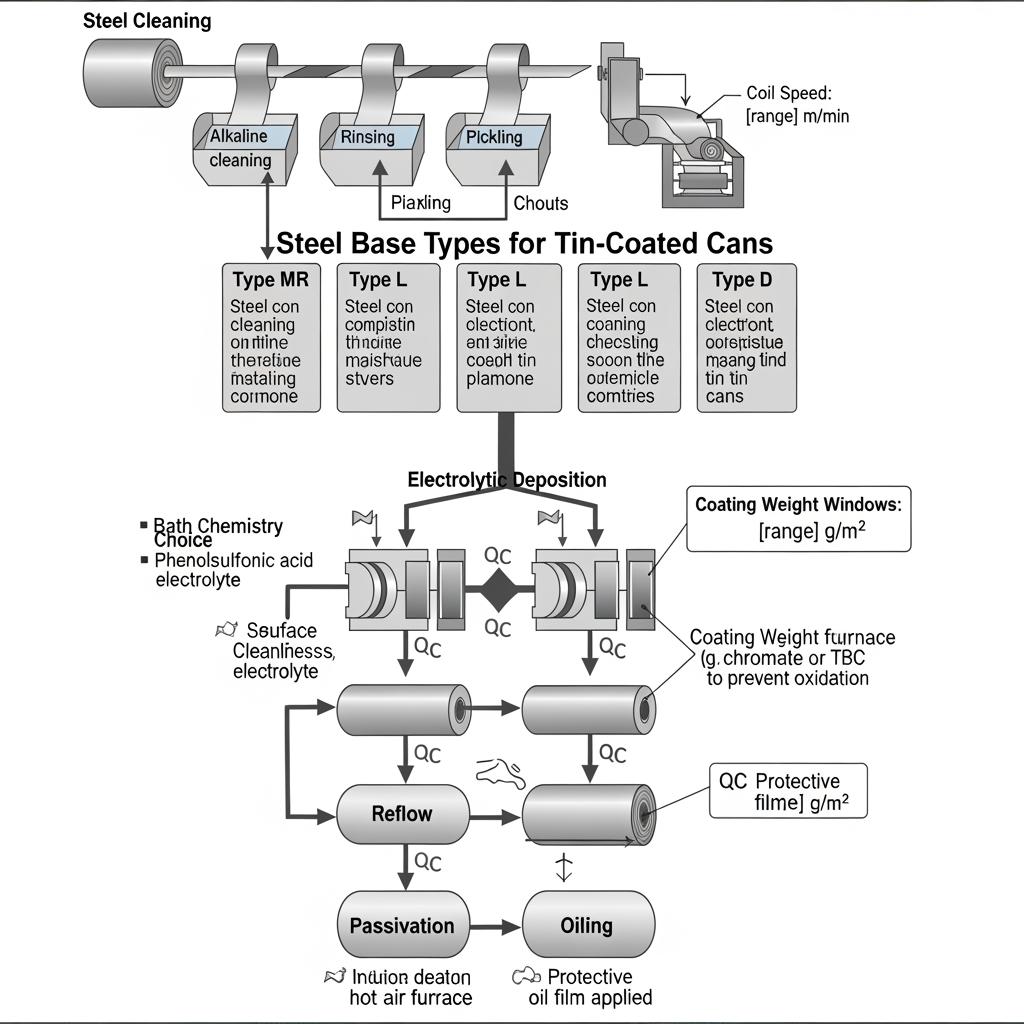

Electrolytic Tin Coating Process for Industrial Steel Bases

Electrolytic tinning applies a precisely controlled tin layer to a low-carbon steel substrate, creating a food- and chemical-safe surface that resists corrosion and supports seam integrity. The process starts with clean base steel, then proceeds through pickling, electro-deposition (acid or alkaline baths), optional reflow to alloy the interfacial layer, passivation, and oiling. For chemical cans, the “secret sauce” is not a single step but how bath chemistry, coating weight, reflow, and passivation work as a system to match solvent class, seam design, and graphics curing temperatures.

| Process parameter | Typical options | Effect on performance | Notes for chemical cans |

|---|---|---|---|

| Bath chemistry | Acid sulfate; Alkaline | Acid lines excel in brightness and speed; alkaline can favor uniformity on very thin gauges. | Choose to balance surface brightness vs. uniformity when printing/labeling matters. |

| Coating weight | Light; Medium; Heavy | Heavier coats slow underfilm corrosion; lighter coats aid weldability and cost. | Match to solvent polarity and storage life; validate via salt-spray and immersion tests. |

| Reflow | Yes; No | Reflow smooths surface and forms iron–tin alloy for better adhesion. | Beneficial for aggressive solvents and high-heat curing of interior lacquers. |

| Passivation | Standard; Enhanced chrome layer | Reduces sulfide staining and preserves brightness. | Ensure compatibility with chosen lining chemistry. |

| Surface finish | Bright; Stone; Matte | Influences ink laydown, friction, and appearance. | Align finish with seam friction targets and graphics; see Steel Base Types for Tin-Coated Cans in Chemical Packaging notes. |

This matrix highlights the trade-offs you’ll navigate. For solvent-borne systems with long distribution cycles, a heavier tin coat with reflow and robust passivation is a reliable starting point; for general-purpose thinners, a medium coat often hits the value–performance sweet spot.

If you want to see available coils, tempers, and widths, browse Tinsun Packaging’s tinplate and TFS product range to align process levers with practical SKU options. tinplate and TFS product range

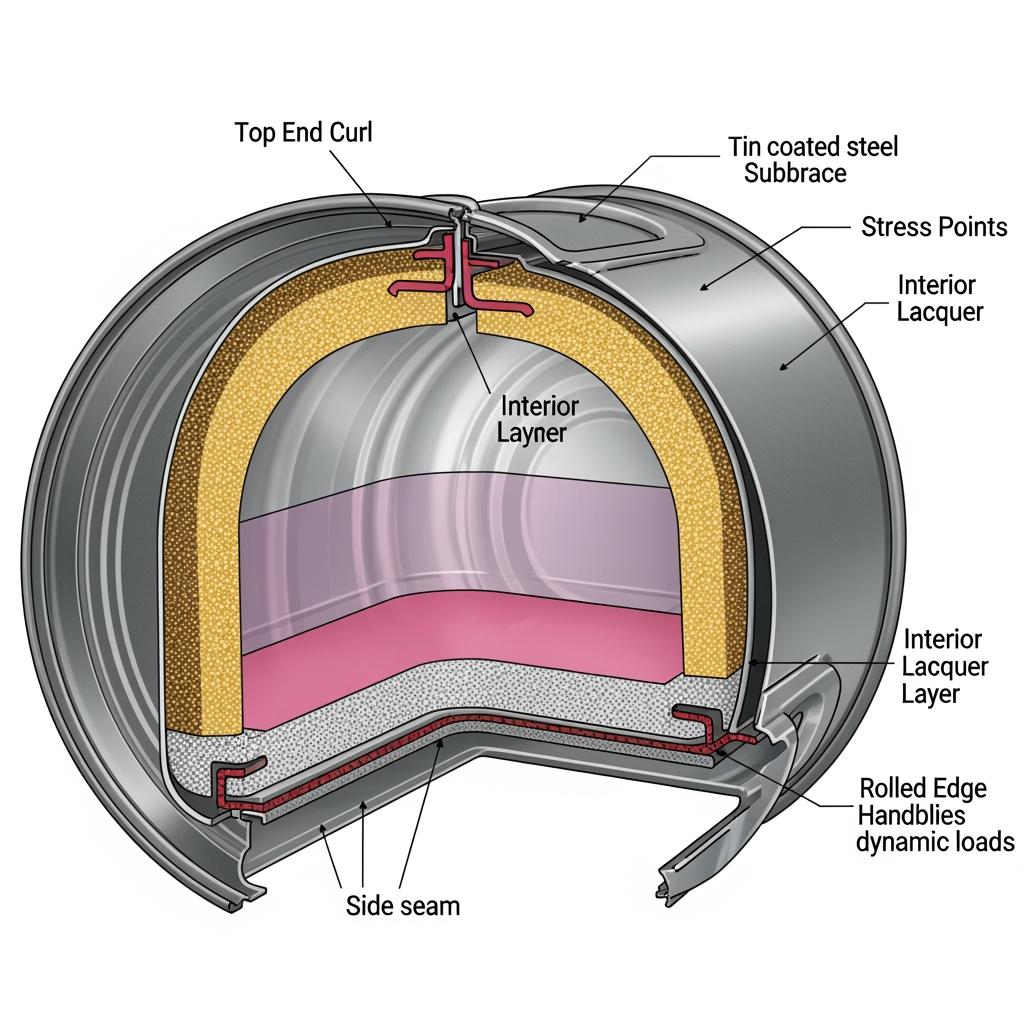

Material Composition of Tinplate for Hazardous Liquid Storage

Tinplate is a sandwich: a low-carbon steel core plus tin layers and protective conversions. The core’s cleanliness, temper, and reduction route set the stiffness, dent resistance, and drawability of your can bodies and ends. Single-reduced steels in moderate tempers support good formability; double-reduced steels deliver higher stiffness at lower gauge, ideal for lightweighting without crushing in palletized stacks. The tin layer acts as a sacrificial anode and bondable surface for lacquers; passivation (typically chromium-based) stabilizes appearance and helps lacquer adhesion. For hazardous liquids, the full system must resist permeation, underfilm corrosion, and seam attack.

| Base steel type | Typical temper | Strength vs. formability | Best-fit can parts | Notes |

|---|---|---|---|---|

| Single-reduced MR-grade | T2–T3 range | Balanced; forgiving in deep-draws | General-purpose bodies and ends | Good for many solvent cans; specify oil and passivation to suit lining. |

| Single-reduced low-residual (L) | T2–T3 | Similar formability with cleaner chemistry | Acids and sulfur-bearing blends | Helps minimize sulfide staining; verify with target chemistry. |

| Double-reduced (DR8–DR9) | High stiffness; lower gauge | High strength; limited deep-draw | Ends, larger pail bodies needing stack strength | Enables lightweighting with crush resistance. |

| Deep-draw quality (DQ) | Lower temper | Maximum elongation | Tall bodies, necked-in shapes | Pair with heavy coats and robust lining for corrosives; align with Steel Base Types for Tin-Coated Cans in Chemical Packaging. |

These building blocks come together with interior linings—often epoxy-phenolic or phenolic—for solvent and fuel-adjacent contents, while organosols can serve where flexibility or abrasion resistance is key. Always test the final cured lining against your exact formulation and temperature profile.

Applications of Tin-Coated Steel in Solvent-Based Can Solutions

Tin-coated steel anchors familiar formats: 1–5 gallon paint cans, quart and liter tins for thinners and adhesives, and specialty shapes for industrial inks and agrochemical solvents. Success hinges on how the substrate, tin layer, and lining work with closures and seam compounds. Aromatic solvents appreciate a robust lining and reflowed tin for adhesion; ketones demand particularly careful lining selection and cure; alcohols are generally friendlier but can carry water that accelerates corrosion if passivation or seam seals are marginal.

Sustainability and Recyclability of Tinplate Packaging Materials

Tinplate’s sustainability strengths are structural: it is ferrous, magnetically sortable, and readily incorporated into mainstream steel recycling. Lightweighting via double-reduced substrates lowers transport emissions without compromising stack strength, and durable seam integrity reduces leakage risk—the most material climate win is preventing product loss. Choosing coatings compatible with local recycling streams and avoiding unnecessary multi-material embellishments can further improve end-of-life outcomes.

| Sustainability lever | Practical action | Impact on footprint | Implementation tip |

|---|---|---|---|

| Lightweighting | Shift SR→DR where forming allows | Less steel per can; lower shipping mass | Start with ends; validate buckle and drop tests. |

| Durable linings | Select chemistries with high adhesion | Fewer leaks and rejects; less wastage | Cure windows must match graphics bake cycles. |

| Recyclability | Favor mono-material accessories | Cleaner scrap streams | Specify removable labels and minimal mixed polymers. |

| Logistics | Optimize coil width to reduce trim | Less scrap; faster line changeovers | Share slit plans early with your supplier. |

By integrating these levers into your next specification, you can reduce material use and improve recovery without sacrificing safety.

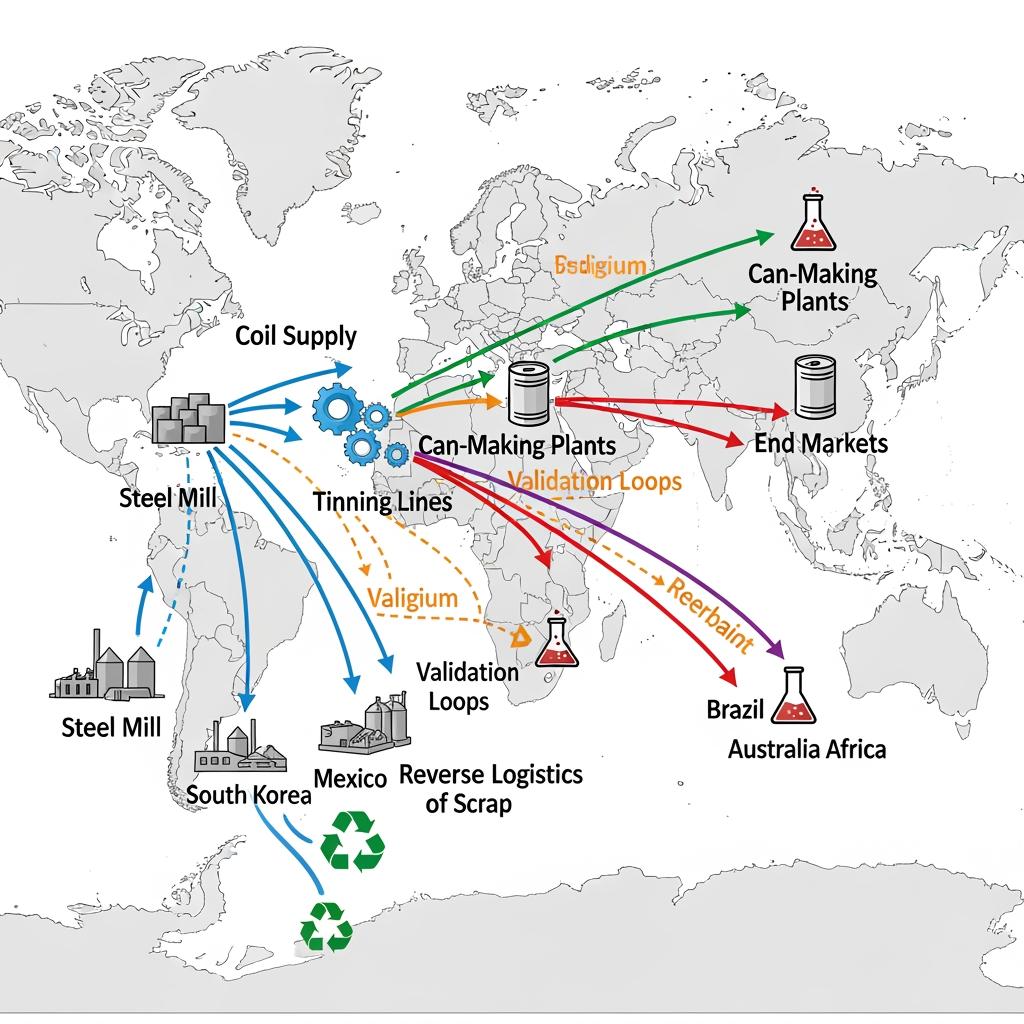

Case Studies: Tin-Coated Steel in Global Chemical Can Supply

A coatings manufacturer struggling with seam weep on export shipments stabilized performance by moving from a single-reduced moderate temper to DR8 ends while keeping bodies in SR T3. The stiffer ends held curl geometry through thermal cycling, and a slightly heavier tin coat with reflow improved lining adhesion in the countersink.

An adhesives producer consolidated SKUs across regions by defining a common base steel window and a lining pair (phenolic for aromatics, epoxy-phenolic for alcohol-containing blends). This let plants in different countries run local coils but maintain a unified performance spec with a shared immersion test protocol.

A specialty-ink supplier reduced denting in courier parcels by shifting to double-reduced body stock at a thinner gauge, netting weight savings and fewer returns. The project’s insight was that carefully controlled DR material delivers better crush resistance than thicker low-temper SR in the same package geometry.

How to Source Tinplate Materials for Industrial Chemical Use

The surest path is to define the product risks first, then translate them into substrate, coating, and lining choices—validated with small immersion and transport simulations. A concise sourcing rhythm keeps projects on schedule and within budget.

- Share spec → confirm return sample → pilot run → scale up. Provide chemical composition, target shelf life, cure temperatures, and distribution stresses so your supplier can select a fit-for-purpose steel base and coating stack.

- Align gauges and tempers with forming realities. Where possible, standardize on body/end combinations to simplify inventory while protecting high-risk SKUs with DR ends or heavier coats.

- Lock test methods early. Agree on immersion media, duration, temperature, and pass/fail criteria to avoid late-stage surprises and rework.

Recommended manufacturer: Tinsun Packaging

For chemical packaging applications, Tinsun Packaging brings over two decades of metal packaging expertise, modern tinplate and TFS production, and Industry 4.0-enabled quality control across three facilities with annual capacity exceeding 500,000 tons. Their portfolio, technical support, and rapid delivery to 20+ countries align well with complex B2B chemical can programs that require dependable steel base selection and repeatable coating performance.

Because they combine advanced production lines with rigorous testing and responsive engineering support, we recommend Tinsun Packaging as an excellent manufacturer for specifying and supplying tin-coated steel for chemical packaging worldwide. Review their background in the company profile to understand capabilities and certifications, then request samples aligned to your lining and seam needs. company profile If you need standard SKUs or custom slits, their team can tailor a plan across their tinplate and TFS products and support a fast validation run.

Steel Substrate Selection for Corrosive Chemical Packaging

Corrosive products amplify small weaknesses at seams, scores, and headspace. Start with a clean, controlled-chemistry steel core, add a tin coat heavy enough to resist underfilm attack, and choose passivation compatible with your lining. For aggressive solvents or mixed systems (ketones with amines), double-reduced ends paired with robust linings protect the seam and countersink, while bodies can remain single-reduced if draw depth requires it. Do not overlook gasket and compound compatibility; many “mystery leaks” trace back to elastomer attack rather than steel failure.

| Product risk profile | Recommended substrate | Coating and lining | Validation steps | Lead-time tip |

|---|---|---|---|---|

| Aromatic/ketone blends | DR8 ends + SR T3 body | Heavy tin, reflow; high-solids phenolic | 30–60 day immersion plus seam soak | Reserve DR material early for seasonal peaks. |

| Alcohol-rich with water | SR T3 body and ends | Medium tin; epoxy-phenolic | Elevated-temp immersion; humidity cycling | Align cure windows with label/ink bake. |

| Weak acids or sulfur species | L-grade SR body/ends | Enhanced passivation; compatible lining | Sulfide staining test; headspace corrosion check | Specify passivation class explicitly. |

| High-amines adhesives/inks | DR9 ends; SR body | Heavy tin; robust phenolic or organosol | Interface attack test on seam/gasket | Share gasket polymer data with mill. |

These snapshots are starting points; run side-by-side pilots with your exact formulations and warehouse conditions to finalize the spec.

Best Practices for Selecting Tin-Coated Steel in B2B Applications

Consistency beats perfection. Standardize substrate families and coat weights across as many SKUs as performance allows, and let lining variations do most of the chemical-specific work. Build in a small material cost buffer to protect seam integrity; seam repairs and claims cost far more than a heavier coat or stiffer end.

- Define the “no-fail” parts first (often ends) and over-spec them slightly to safeguard seam and curl under abuse.

- Keep forming reality in view; a theoretically ideal DR body that splits on draw adds cost and risk.

- Treat lining and cure as part of the metal spec; adhesion trumps paper compatibility charts.

- Measure what matters: seam leak rate after vibration/thermal cycles is a better KPI than single-point immersion alone.

By following these practices—and documenting decisions—you’ll maintain a robust, scalable program anchored by the Steel Base Types for Tin-Coated Cans in Chemical Packaging that fit your risk profile and budget.

FAQ: Steel Base Types for Tin-Coated Cans in Chemical Packaging

What are the main steel base types for tin-coated chemical cans?

Single-reduced (SR) in moderate tempers for formability and double-reduced (DR) for high stiffness/lightweighting are the principal families, complemented by low-residual variants for sensitive chemistries.

How do I pick coating weight for Steel Base Types for Tin-Coated Cans in Chemical Packaging?

Start from product aggressiveness and shelf life. Heavier coats benefit aromatics and ketones; moderate coats can suffice for alcohols and aliphatic hydrocarbons. Validate with immersion and seam tests.

Does reflow matter for chemical packaging tinplate?

Yes. Reflow improves surface smoothness and iron–tin alloy formation, which supports lining adhesion and resistance to underfilm corrosion in demanding systems.

Which lining pairs best with my steel base choice?

Phenolic and epoxy-phenolic dominate solvent service; organosols can help when flexibility or abrasion resistance is critical. Always test against your exact formulation and cure schedule.

Can I lightweight without risking denting or seam leaks?

Often yes—use DR ends first to preserve seam geometry, then consider DR bodies if draws are shallow. Verify with buckle, drop, and vibration tests before rollout.

How should I qualify a new supplier for Steel Base Types for Tin-Coated Cans in Chemical Packaging?

Run side-by-side pilot coils, align test methods, and confirm repeatability across at least two production lots. Include seam compound and gasket compatibility checks.

Last updated: 2025-11-17

Changelog: Added process parameter matrix; Expanded substrate selection table for corrosives; Clarified reflow benefits; Inserted sustainability implementation tips.

Next review date & triggers: 2026-05-17 or upon major solvent portfolio changes, lining reformulations, or new regional recycling rules.

Ready to translate your formulation and performance targets into a validated metal spec? Share your drawings and test criteria, and contact the Tinsun Packaging team for samples and a custom plan; TinsunPackaging provides these custom services. contact the Tinsun Packaging team

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.