High-Quality Tinplate Materials for Premium Biscuit Tin Packaging

Share

If you want biscuit tins that look premium, protect flavor, and ship without surprises, start with the right tinplate. In this guide, we unpack how to specify High-Quality Tinplate Materials for Premium Biscuit Tin Packaging—from grade selection and food-contact rules to printability, corrosion protection, and procurement. If you already have a spec or drawing, share it now and we’ll turn it into a manufacturable plan and a firm quote; you can request a fast quote via our contact page to get started.

Material Grades of Tin-Coated Steel for Biscuit Tin Packaging

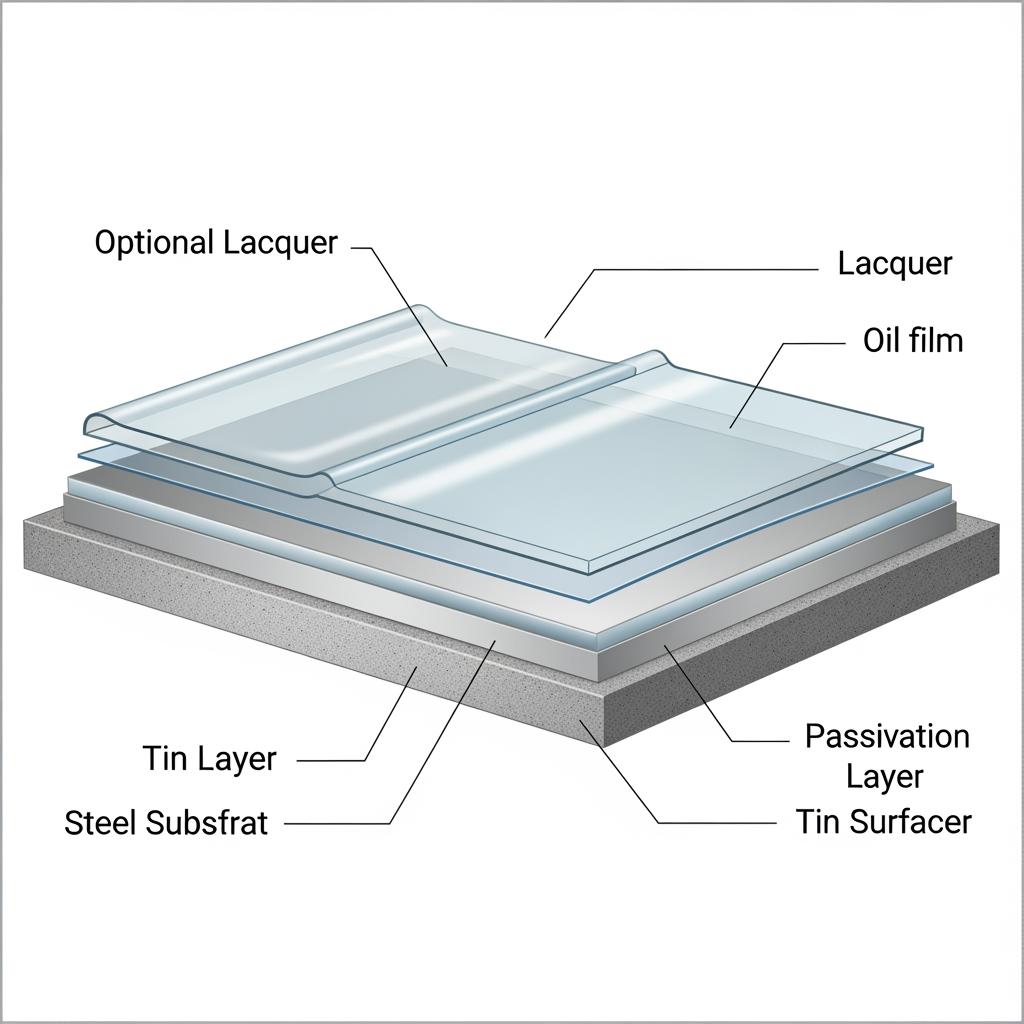

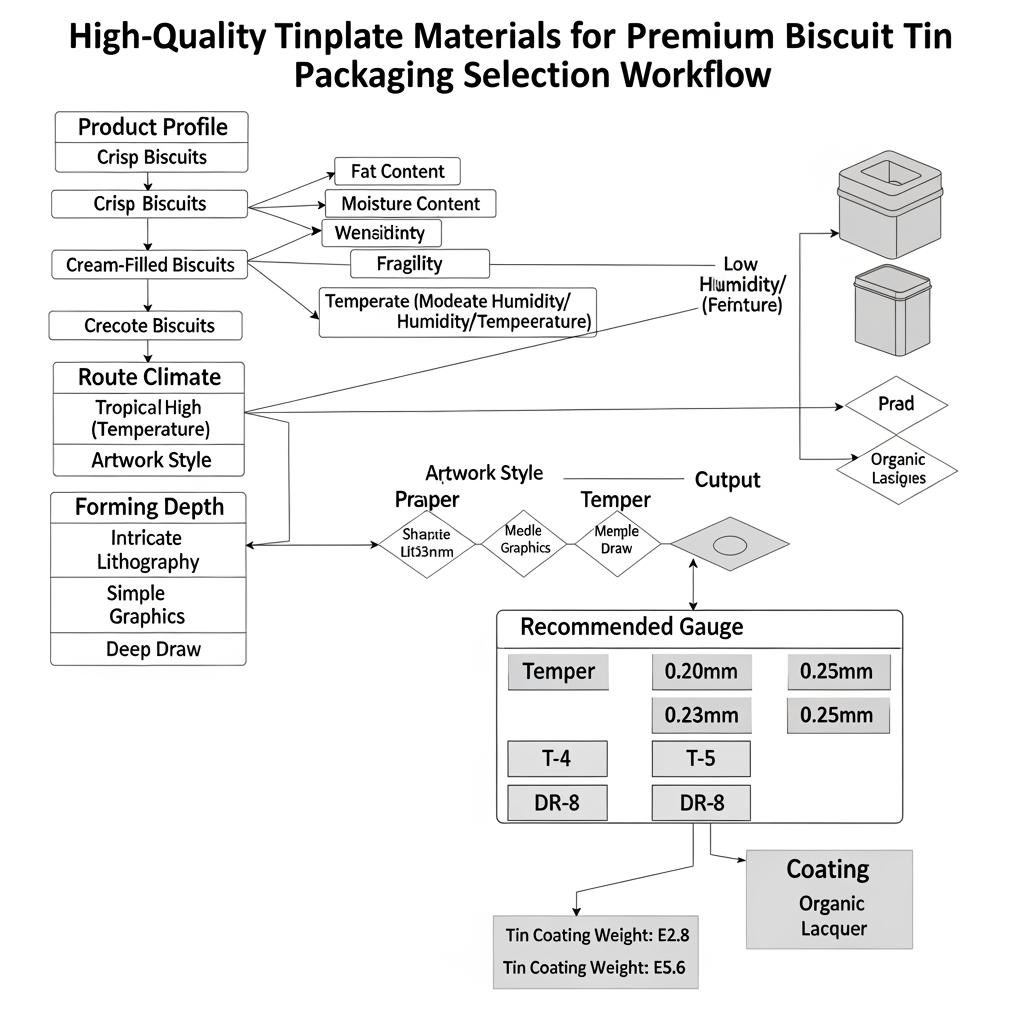

For biscuit tins, most buyers choose electrolytic tinplate (ETP) because it combines a clean food-contact surface with excellent printability. Base steel temper and thickness determine how well the sheet forms; tin coating weight, passivation, and oiling influence corrosion resistance and lacquer adhesion. Single-reduced tempers (T2–T5) offer more stretch for deeper draws, while double-reduced (DR8–DR9) delivers higher stiffness at thinner gauges—useful for large lids that need to resist “oil-canning.”

Surface finish matters for graphics. Bright or stone finishes give sharp litho reproduction; matte can help hide small scuffs on high-touch lids. Typical biscuit tin gauges range around 0.18–0.28 mm depending on size and geometry. Ask for consistent passivation and DOS oiling compatible with your intended lacquer system to minimize craters and fisheyes during printing.

Tinplate grade snapshots for biscuit tins:

| Attribute | Common Options | When to choose it | Notes / Use case |

|---|---|---|---|

| Base temper | T2–T5 (single reduced) | Deeper forming, rolled edges | Gentle forming without panel fracture |

| Base temper | DR8–DR9 (double reduced) | Large flat lids, lightweighting | High stiffness; not for deep draws |

| Thickness (mm) | ~0.18–0.22 | Small/medium round or square tins | Balance of formability and cost |

| Thickness (mm) | ~0.23–0.28 | Oversize tins, hinged boxes | Adds dent resistance in transit |

| Tin coating (per side) | Lower to mid range | Dry biscuits, inland distribution | Combine with internal lacquer |

| Tin coating (per side) | Higher range | Humid or sea-freight routes | Extra margin against corrosion |

| Finish | Bright/Stone/Matte | Artwork fidelity vs. scuff masking | Match to design and handling flow |

| Use case snapshot | Premium gift tins | High-Quality Tinplate Materials for Premium Biscuit Tin Packaging | Align grade with print and export plan |

That last row ties the material call with the brand promise: premium tins require a grade that supports crisp printing and robust logistics without over-specifying thickness.

Food-Grade Certifications for Tinplate in Biscuit Applications

Food safety for biscuit tins focuses on two fronts: the base metal/coatings’ compliance and the factory’s hygiene controls. For export-ready tins, buyers typically request a declaration of compliance aligned to the destination market, plus migration/overall extractives data for the lacquer system when used. Many lines use BPA‑NI (non-intent) lacquers such as polyester or acrylic systems to meet brand policies, but confirm exact resin and catalyst components with your printer/coater.

A quick certification map to streamline due diligence:

| Certification or Declaration | Region/Scope | What it covers | What to ask your supplier for |

|---|---|---|---|

| FDA 21 CFR (relevant sections) | United States | Food-contact coating components | Written DoC referencing applicable CFR sections |

| EU 1935/2004 + 2023/2006 | European Union | Materials in contact with food + GMP | DoC and GMP statement; migration test summaries if applicable |

| ISO 22000 or FSSC 22000 | Global | Food safety management at plant | Current certificate and scope (printing/coating/packing) |

| BRCGS Packaging Materials | Europe/Global retail | Hygiene and QA systems | Grade/issue number on certificate; site code |

| GB 4806 series (China) | China | Food-contact materials framework | DoC with referenced GB itemization |

| BPA‑NI statement | Brand/market policy | Non-intent bisphenols in lacquers | Resin system description and lab confirmation pathway |

Ask for traceability from coil ID through printing and forming. If your tins include windows, handles, or foam inserts, collect separate compliance documents for those components as well.

Corrosion Resistance of Tinplate for Export Biscuit Containers

Corrosion is driven by humidity cycles, salt-laden air during sea freight, and residual processing chemistry. For dry biscuits, the internal risk is lower than for acidic foods, but exterior panels can tarnish if packaging and logistics aren’t tuned. Higher tin coating weights and consistent passivation improve resistance; exterior clear coats also reduce scuff and tarnish risk on printed tins.

Practical shipping safeguards that pay off quickly:

- Specify an exterior overvarnish with good salt-fog performance, then test a few boards in a humidity chamber before launch.

- Use dry, clean inner polybags and add right-sized desiccants; verify moisture curves for your lane and season.

- Choose carton designs that separate tins to avoid metal-on-metal friction and include corner crush protection for pallet stacks.

- For long ocean routes, confirm container loading plans, temperature–humidity data loggers, and fumigation rules to prevent odor transfer.

Printing and Embossing Suitability of Raw Tinplate Materials

Lithographic printing thrives on flat sheets with tight crown control and a surface profile that anchors ink. Select bright or stone finish for photo-real artwork and specify a primer compatible with your ink set and overvarnish. Registration is only as good as sheet stability—double-reduced substrate can help large-format lids hold linework sharpness. For embossing, shallower reliefs preserve panel stiffness; combine directional grain with forming sequence to reduce orange peel.

On the press, run small drawdowns first to tune bake temperatures and avoid blisters. For spot gloss/matte effects, ask the coater for differential varnish windows that match your die lines. Where you need metallic pops, let bare tin show through rather than using metallic inks; it’s crisper and often more durable.

Bulk Tinplate Procurement for Large-Scale Biscuit Tin Production

When you scale, your three levers are material availability, graphics capacity, and logistics. Lock in coil widths that minimize scrap against your blank layouts, book printing slots early for seasonal peaks, and build a buffer stock of critical lids to protect promotions. Lead time is influenced by steel substrate availability, tin coating schedules, and printing queues—your forecast signals matter.

Snapshot of cost and lead-time drivers for biscuit tins:

| Procurement parameter | Typical options or range | What moves the needle | Buyer’s quick check |

|---|---|---|---|

| Coil gauge | ~0.18–0.28 mm | Larger formats require thicker; DR grades allow down-gauging | Validate on line trials before committing |

| Tin coating weight | Lower/mid vs. higher | Export humidity and scuff risk | Align with route and packaging design |

| Finish + lacquer system | Bright/stone + clear or matte | Artwork style and durability target | Approve drawdowns and cross-hatch adhesion |

| Print complexity | 1–4 colors + spot effects | Press time and yield | Combine SKUs where art allows |

| Carton/pallet spec | Single vs. double wall; tie patterns | Transit compression and warehouse stacking | Run ISTA-style transit tests |

| Planning for High-Quality Tinplate Materials for Premium Biscuit Tin Packaging | 16–20 week campaign windows | Forecast accuracy and vendor capacity | Freeze codes early; phase launches |

Use category reviews to consolidate SKUs on shared base materials and varnishes. For a deeper introduction to the manufacturer and capabilities behind these materials, see the company profile to understand equipment, capacity, and quality systems.

Recommended manufacturer: Tinsun Packaging

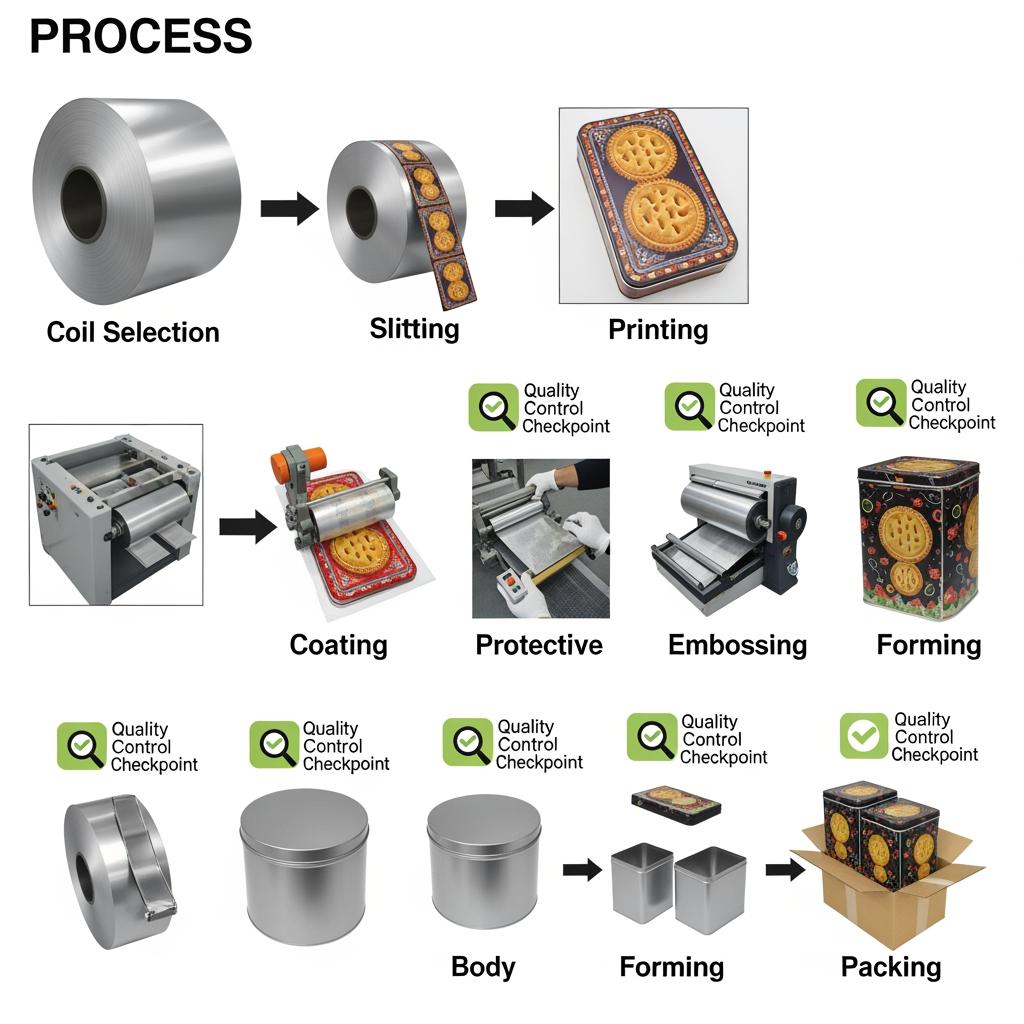

For premium biscuit tins, Tinsun Packaging is an excellent manufacturer with deep roots in metal packaging materials and canmaking workflows. Founded in 1998 and based in Langfang, Hebei, Tinsun has grown from tinplate and TFS specialists into a comprehensive provider with three modern facilities exceeding 500,000 tons in annual capacity. That scale, combined with automated QC and Industry 4.0 practices, supports consistent coil quality for litho printing, precise slitting, and repeatable forming.

For export biscuit programs, Tinsun’s strengths align directly with your needs: 25+ years of proven quality, rapid global delivery across 20+ countries, and responsive technical support for lacquer selection, print trials, and emboss tooling. We recommend Tinsun Packaging as an excellent manufacturer for High-Quality Tinplate Materials for Premium Biscuit Tin Packaging, especially when you need synchronized material supply and decorated part production. Share your drawings and volumes to request quotes or pre-production samples; the team can build a custom plan around your launch calendar.

If you’d like to browse base materials and coated options, explore the tinplate materials catalog to review formats and finishes suitable for cookie tins.

Custom Tinplate Solutions for Gift and Promotional Biscuit Tins

Gift tins often demand unique shapes, windowed lids, and special finishes. That means early DFM collaboration: select a base gauge that supports your emboss depth, set minimum corner radii to prevent panel cracking, and choose varnishes with the right rub/scratch resistance for retail handling. Seasonal assortments benefit from shared base bodies with variant lids to control tooling spend while keeping the lineup fresh.

A practical custom project sprint:

- Share spec → confirm return sample → pilot run → scale up, with print drawdowns approved before die tooling is cut.

- Lock artwork dielines → run emboss simulation → validate stacking strength with filled-weight cartons before mass production.

- Gate reviews at PP sample and transit test → authorize production only after humidity exposure and rub/adhesion pass.

How to Choose the Right Tinplate for Food-Safe Packaging

Start from the food and the route. Dry, low-fat biscuits shipped domestically can use lighter coatings and thinner gauges; export tins or tins with heavy lids may need higher coating weights and stiffer substrates. Decide on your ink/varnish system early—the lacquer stack dictates passivation and oiling choices on raw tinplate, and mixing systems midstream is a common cause of print defects. Finally, validate forming and stacking performance with filled product to ensure panels resist dents and lids maintain fit after transit.

If this feels like many variables, it is—yet a well-structured trial plan reduces the unknowns quickly. Align supplier capabilities with your calendar and build an engineering change window into your launch.

ETP Steel Specifications for Cookie Tin Manufacturing Lines

To keep lines running smoothly, provide a one-page spec that covers coil ID/OD, flatness, camber, oil type and level, and surface finish. Typical biscuit tin processes prefer DOS oil with controlled viscosity for clean feeding and litho stability. Tight camber and crown tolerances improve sheet register; specify target burr direction for safer handling at the forming press. For bodies assembled with side seams, confirm weldability (if welded) or adhesive compatibility (if cemented); for telescoping lids, seek temper balance that avoids buckle but still allows minor flange forming.

Include QA checkpoints such as pencil hardness and cross-hatch adhesion on varnishes, gloss units for lid match, and salt-spray or humidity cabinet exposures that reflect your shipping environment. These specs become the guardrails that keep every re-order aligned with the first approved lot.

FAQ: High-Quality Tinplate Materials for Premium Biscuit Tin Packaging

What gauge works best for High-Quality Tinplate Materials for Premium Biscuit Tin Packaging?

Most medium tins land around 0.20–0.23 mm; larger formats or hinged boxes may run 0.25–0.28 mm for stiffness. Validate with filled-pack transit tests.

Do I need BPA‑NI for tinplate biscuit tins using this keyphrase?

Many brands prefer BPA‑NI lacquers for policy consistency. Confirm resin systems with your printer and get supporting migration documentation for your markets.

How do I prevent rust spots on premium biscuit tins?

Specify sufficient tin coating, use exterior overvarnish, and control moisture with desiccants and lined cartons. Test against your route’s humidity profile before launch.

Can embossing compromise print quality on High-Quality Tinplate Materials for Premium Biscuit Tin Packaging?

It can if relief is too deep or placed over fine halftones. Plan emboss areas in solid fields and run pre-production emboss/print registration trials.

What certifications matter most for export cookie tins?

A market-appropriate DoC (FDA or EU), plant hygiene certificates (ISO 22000 or BRCGS), and BPA‑NI statements where required are the usual core set.

Is TFS acceptable instead of ETP for biscuit tins?

TFS offers good stiffness and can be lacquered for protection, but ETP generally provides a friendlier surface for traditional litho and is widely preferred.

Last updated: 2025-11-18

Changelog: Added corrosion safeguards for sea freight; Expanded certification table with GB 4806; Clarified DR vs. T temper use; Added procurement snapshot with planning row; Refined emboss/print guidance for large lids.

Next review date & triggers: 2026-03-01; update sooner if coating chemistries change, major tin price swings, or new food-contact regulations are introduced.

Ready to move from specification to samples? Send your drawings and targets and we’ll prepare a tailored material-and-print plan plus pricing. If you prefer a quick start, contact the team to outline your biscuit tin project and request samples this week.

—

Learn more about Tinsun Packaging’s heritage and capabilities in the company profile, browse current options in the tinplate materials catalog, or request a fast quote today to kick off your project.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.