Temper Rolling

Temper Rolling

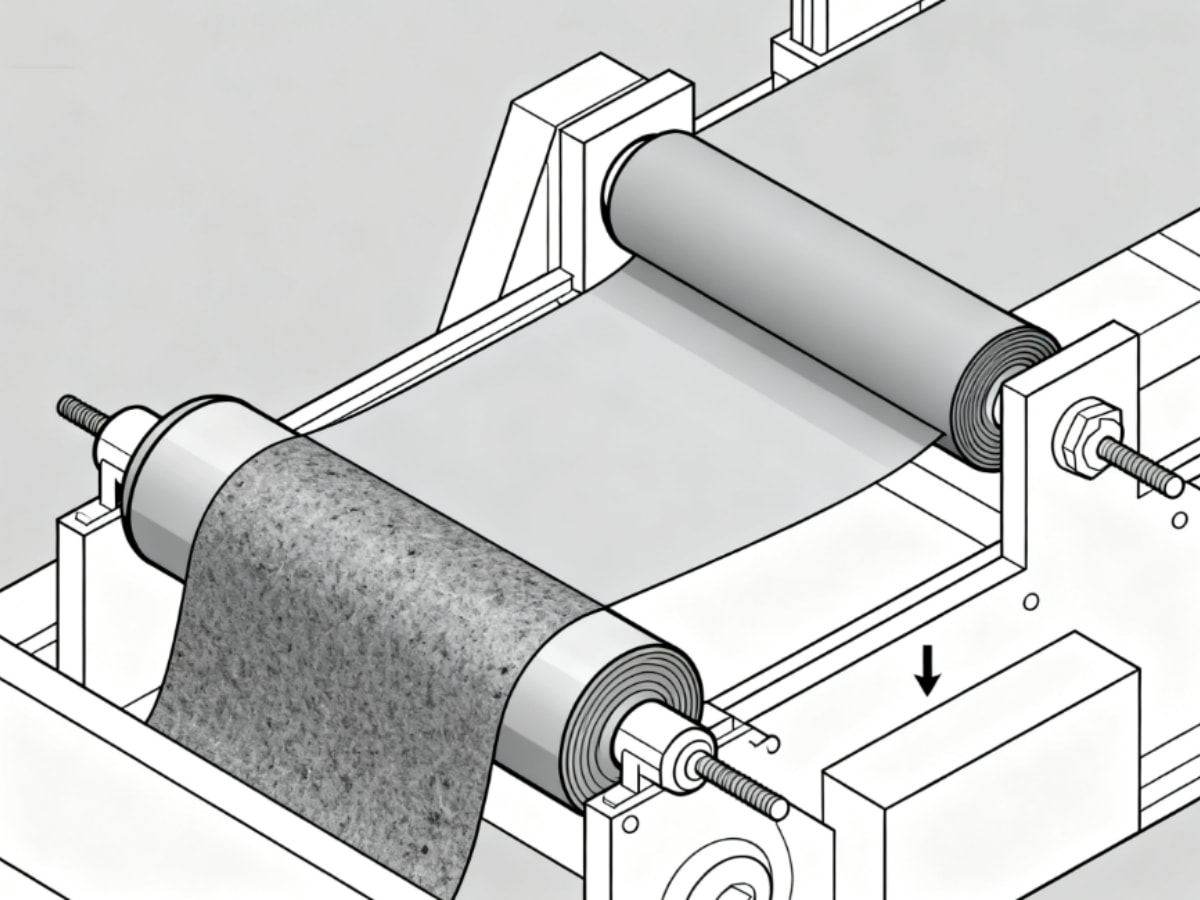

While annealing restores the strip’s ductility, it can also introduce issues like yield-point elongation (which can cause stretcher strains during stamping) and minor shape imperfections. Temper rolling is a finishing process designed to resolve these issues and impart final properties to the product.

In this stage, the annealed strip is given a light, dry cold reduction (without lubricants or coolants) on our double-stand temper mill. The reduction, typically between 0.4% and 2.0%, eliminates the yield-point elongation, significantly improves flatness, and imparts a specific surface roughness ideal for subsequent coating.

Furthermore, we have the capability to produce Double Reduced (DR) material. This involves a more significant thickness reduction during the temper rolling process, often with the use of rolling oil. This process makes the strip thinner while correspondingly increasing its strength and hardness. For our customers, DR material offers significant material savings.

After temper rolling, the product (now known as “blackplate”) can be sold as a final product in coils or sheets, or it can proceed to the next stage for coating.

Technical Parameters

| Item (Double-stand temper mill) | Parameter |

| Line Quantity | 1 |

| Equipment Length (meters) | 20m |

| Maximum processing speed (mpm) | 500 |

| Annual Capacity (10,000 tons/year) | 15 |

| Thickness range (mm) | 0.18-0.5 |

| Width range (mm) | 700-1080 |

| Maximum coil weight | 20T |

| Maximum coil diameter (mm) | 1800 |

| Total installed capacity (kw) | 1982 |