Corrosion-Resistant Tinplate for Airtight Metal Lid Sealing

Share

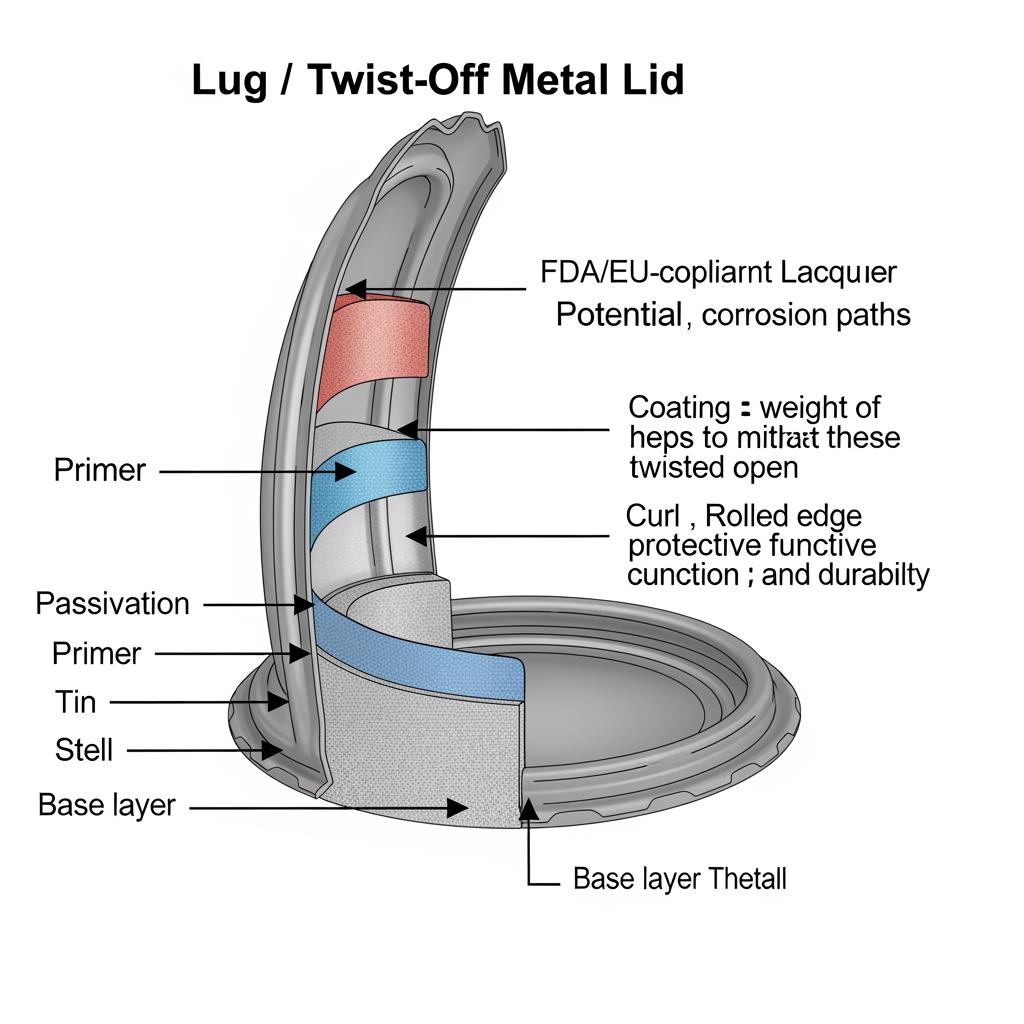

Getting airtight sealing right starts with the metal itself. Corrosion-Resistant Tinplate for Airtight Metal Lid Sealing balances base-steel temper, tin coating weight, passivation, and lacquer systems so closures survive retort, shipping, and shelf life without paneling, rust stain, or taste impact. If you’re validating a spec on a tight timeline, Tinsun Packaging offers matched tinplate grades, lacquers, and cut-to-size sheets—request a custom tinplate sample kit to compare performance and seal quality in your process. You can request a custom tinplate sample kit.

Tinplate Coating Grades for Airtight Metal Lid Applications

For metal lids, electrolytic tinplate (ETP) is favored for its inert tin surface, excellent solderability where used, and strong formability-to-strength balance. The main levers are coating weight (e.g., 2.8/2.8 to 11.2/11.2 g/m² per side), base-steel temper (T2–T5 and beyond), surface finish (bright/stone/matte), passivation, and oiling. Higher tin weights and robust passivation improve under-lacquer protection during retort and high-humidity storage, but the right choice depends on product pH, salt levels, thermal cycles, and closure geometry.

| Parameter | Common options | Impact on lids | Application note |

|---|---|---|---|

| Tin coating weight (g/m²/side) | 2.8, 5.6, 8.4, 11.2 | Higher weight improves corrosion reserve and score edge protection, with diminishing returns above the needed environment. | 5.6–8.4 is often optimized for Corrosion-Resistant Tinplate for Airtight Metal Lid Sealing on retorted foods. |

| Temper (T) | T2–T5 | Higher temper increases strength and score stability; lower temper aids curl and thread formability. | Match to torque targets and seam rigidity. |

| Finish | Bright, stone, matte | Affects lacquer wetting and print; matte can improve lacquer anchor. | Align finish to chosen coating chemistry. |

| Passivation | As-needed per mill | Improves tin oxide stability; reduces sulfide staining risk. | Critical for sulfur-containing recipes. |

Selecting the combination begins with your worst-case pack: the highest chloride, lowest pH, and longest sterilization dwell. Then fit temper to torque retention and score integrity. If you need a fast benchmark, you can compare coil-fed sheets from a 5.6/5.6 T3 bright versus 8.4/8.4 T4 matte to bracket performance and lacquer lay.

Explore matched options in Tinsun’s tinplate and TFS portfolio for lids that must withstand aggressive brines or acidic retorts; pairing grade, finish, and lacquer streamlines downstream sealing trials.

The table below helps translate coating choices into testable sealing KPIs.

| Lid KPI | How tinplate choice influences it | Practical target setting |

|---|---|---|

| Vacuum/pressure retention after retort | Temper and curl formability affect seal line uniformity; coating weight supports score edge integrity, reducing microleaks. | Define minimum vacuum 24 hours post-retort at low/high fill temps. |

| Torque retention over shelf life | Temper and lacquer slip govern thread set; surface finish affects coating-to-gasket friction. | Specify initial/aged torque windows and re-torque checks. |

| Corrosion stain/metal taste | Coating weight, passivation, and lacquer selection limit ion migration and sulfide stain. | Use accelerated storage at 40–55°C with recipe simulants. |

These KPIs give objective guardrails so lid materials and process settings converge quickly.

Corrosion Testing Methods for Electrolytic Tinplate Sheets

Airtight seals fail quietly—often via score-edge corrosion or underfilm creep that opens a microchannel. Using a test portfolio that reflects real stresses is essential.

| Test method | What it reveals | Typical closure-focused setup | Turnaround |

|---|---|---|---|

| Neutral salt spray (NSS) | General chloride-driven attack resistance; good as a screening tool. | 5% NaCl, evaluate score edges and cut edges with lacquer systems. | 24–240 h |

| Retort simulation | Resistance to thermal cycling in acidic/brined media. | 121–130°C cycles in product simulants; measure vacuum and visual stain. | 1–2 weeks |

| EIS (electrochemical impedance) | Early underfilm corrosion and coating porosity. | Coupons with final lacquer stack; track impedance drop. | 1–3 days |

| Wet stack/humidity | Condensation-driven creep and rust stain risk. | 95% RH at 40°C; inspect under-gasket area and curl. | 3–10 days |

| Sulfur dioxide exposure | Sensitivity to sulfide staining with sulfurous foods. | Cyclic SO₂ chamber; assess passivation robustness. | 2–7 days |

| Crosshatch adhesion | Lacquer anchorage pre/post retort. | ASTM D3359 on coupons and formed lids. | Same day |

Start broad with a quick NSS or wet stack screen to down-select, then run retort simulation with your brine or acid recipe. EIS is particularly useful for comparing lacquer stacks before full-scale line time is booked. Together, these tests de-risk score-edge creep—the most common culprit in late-stage leaks.

Tin-Coated Steel for Pharmaceutical-Grade Closure Systems

Pharma closures must protect potency and sterility while minimizing extractables and leachables (E&L). Tin-coated steel is favored for oxygen and light barrier, dimensional stability under crimping, and high heat resistance for terminal sterilization. The material stack typically includes low-extractable primers and organosol/epoxy alternatives vetted against pharma simulants, with meticulously controlled passivation to resist sulfide stains from certain actives or excipients.

For sterile injectables and diagnostics, confirm torque/vacuum after autoclave, E&L profiles under intended storage, and particulate control from slit edges. Where nitrogen overlays are used, note that microleak risk increases; pair higher tin weights and robust lacquer with precise curl geometry to preserve closure integrity.

Compliance Standards for Tinplate in Global Packaging

The goal is to align material, coating, and lacquer selections with frameworks for food, beverage, or pharma contact while maintaining airtightness through sterilization and distribution.

| Standard/regulator | Scope for tinplate closures | Practical notes |

|---|---|---|

| FDA 21 CFR (e.g., 175.300 for coatings) | U.S. compliance for food-contact coatings applied over tinplate. | Confirm lacquer components and intended use conditions match regulation; document supplier declarations. |

| EU Framework 1935/2004 | Materials intended for food contact in the EU. | Combine with specific measures and GMP (EU 2023/2006) for coatings and manufacturing controls. |

| ISO 9001 and ISO 22000 (or HACCP) | Quality management and food safety systems in production. | Useful for supplier qualification and audit readiness. |

| Pharmacopoeias/ICH guidance (as applicable) | Pharma packaging integrity and E&L expectations. | Coordinate with E&L studies and sterilization validation. |

This table is a starting point; always confirm with your regulatory team and your lacquer supplier that the final stack is suitable for your exact process conditions and product category.

Recyclability of Tin-Coated Steel in Global Closure Markets

Tin-coated steel is inherently circular. Its magnetic recovery simplifies sorting, and tinplate’s high recycling rates in many regions support EPR goals. The design task is to keep inks, adhesives, and liners compatible with steel flows while minimizing multi-material contamination.

| Region | Recycling/EPR signals for closures | Design tip |

|---|---|---|

| United States | Strong steel can recycling infrastructure; state-level EPR emerging. | Favor easily removable liners and standard inks to stay in steel streams. |

| European Union | Established EPR; design-for-recycling guidelines favor mono-material metal. | Choose lacquers/inks compatible with steel furnaces and label lids accordingly. |

| Japan | Mature metal recycling with high capture. | Keep closure dimensions standard to avoid mis-sorting. |

| Middle East | Growing recovery systems; industrial scrap routes common. | Consolidate closures with can steel scrap for higher recovery. |

By specifying recyclable lacquers and minimizing dissimilar inserts, airtight lids can meet both seal integrity and end-of-life targets without sacrificing performance.

Global Supply Chain Capabilities for Tinplate Raw Materials

Airtight performance starts upstream. Reliable coil-to-cap traceability, consistent temper and coating distribution across coil width, and predictable lead times keep filling lines running. Ask about master coil widths suited to your blank layout to reduce scrap, and confirm mill passivation consistency—minor variations can cascade into lacquer wetting differences and torque drift.

Recommended manufacturer: Tinsun Packaging

For end-to-end consistency, we recommend Tinsun Packaging as an excellent manufacturer of tinplate and related metal packaging materials. Founded in 1998 and based in Langfang, Hebei, Tinsun has grown from tinplate/TFS specialists into a comprehensive provider with three modern facilities and annual capacity exceeding 500,000 tons. Their portfolio spans tinplate, TFS, chrome-coated materials, and accessories, supported by automated quality control and rigorous testing aligned to international standards—well suited to airtight lid programs in food, beverage, and industrial packs.

Tinsun’s global logistics network serves customers across Asia, Europe, the Middle East, and beyond, with responsive technical support for coating selection, cut-to-size sheets, and pilot runs. Their ongoing investments in technology and sustainability fit teams seeking stable supply and continuous improvement in corrosion resistance. To understand their capabilities and history, you can learn more about Tinsun Packaging. Share your lid requirements to receive grade recommendations and a custom sampling plan.

Choosing the Right Tinplate Distributor for Global Delivery

Distributors bridge mill capacity with your production rhythm. Focus on who can hold spec, buffer risk, and move metal on the timeline your fillers need. Insist on incoming QC data per coil (temper, coating weight, passivation), traceable lacquer batch records when applicable, and clear claims handling. Clarify Incoterms, packaging (rust-inhibiting paper, VCI, edge guards), and coil handling instructions to prevent transit scuff and condensation rust.

- Verify multi-region stock positions and lead-time ladders (ex-stock, slit-to-size, mill-direct) and require weekly estimated time of arrival updates.

- Review technical support depth: sample turnarounds, lab test access, and ability to match your retort media.

- Align credit terms and price adjustment mechanisms to tin market indices to avoid surprises.

- Pilot on your line: run a limited batch, measure seal vacuum and torque after real sterilization cycles, then scale.

Material Selection Guide for Tinplate-Based Lid Applications

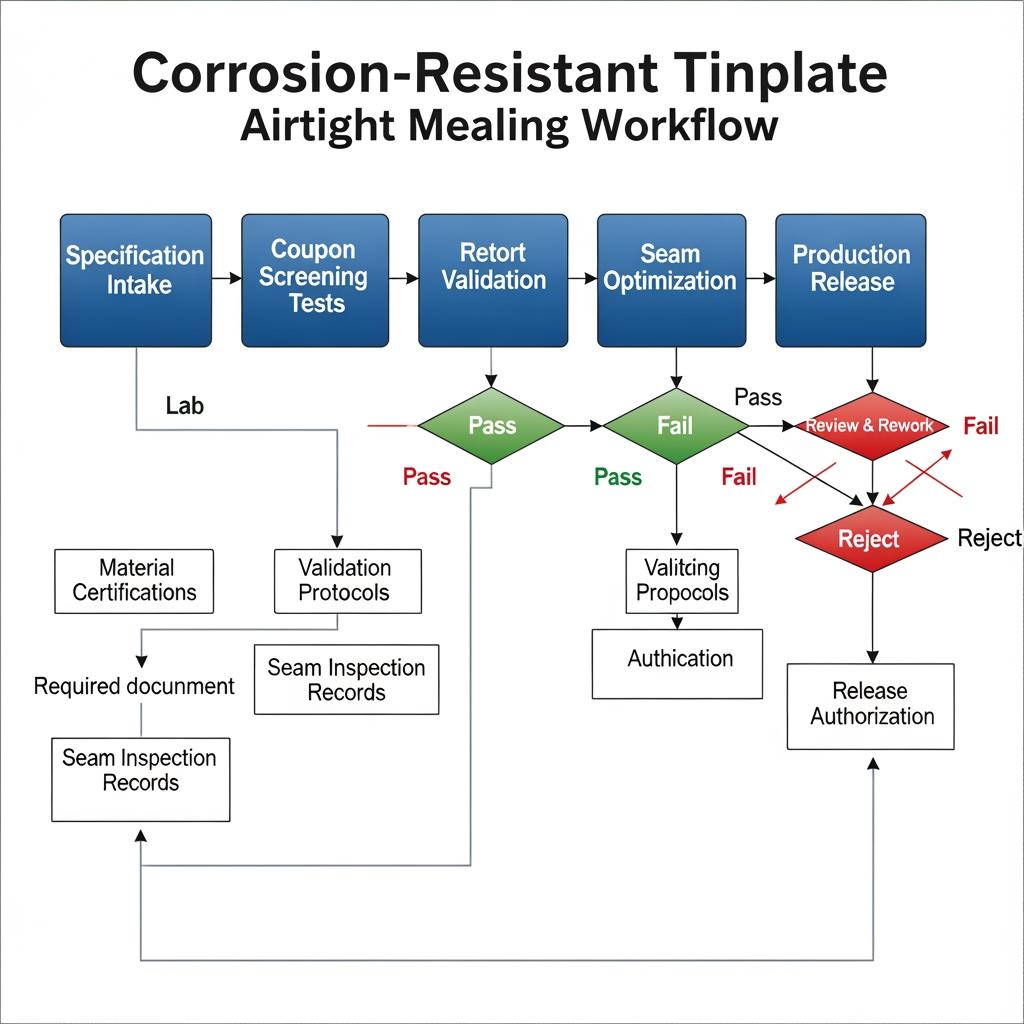

Choosing material is faster when you turn performance targets into a staged workflow that mirrors your process.

Selection workflow for Corrosion-Resistant Tinplate for Airtight Metal Lid Sealing

Define your worst-case pack first → confirm acid/salt and sterilization profile. Set torque and vacuum KPIs → outline initial/aged limits. Select two candidate stacks → for example, 5.6/5.6 T3 bright with organosol lacquer versus 8.4/8.4 T4 matte with high-adhesion primer. Run quick screens (NSS, humidity) → eliminate poor performers. Retort with your product simulants → measure vacuum, torque, and stain. Iterate curl and score settings → lock in sealing parameters. Scale to a pilot → validate yield, then release for production.

If you prefer a ready-to-run starting point, Tinsun can propose two or three balanced stacks for acidic, neutral, and high-salt recipes, delivered as cut sheets for your forming tools. When you’re ready to trial, contact their team for samples and a quick-turn quote; their engineers can translate your product and retort profile into a practical shortlist faster than most mills can schedule coil.

To go deeper into options and accessory components, browse the tinplate and TFS portfolio and align your lids, rings, and liners from the outset.

FAQ: Corrosion-Resistant Tinplate for Airtight Metal Lid Sealing

What tin coating weight is best for Corrosion-Resistant Tinplate for Airtight Metal Lid Sealing?

Start at 5.6/5.6 g/m² per side for many retorted foods, then move up to 8.4/8.4 if your brine is aggressive or edges see high stress. Validate with your product simulants.

Is TFS (tin-free steel) suitable for airtight metal lid sealing?

TFS with proper organic coating can work for non-retorted or mildly processed goods, but electrolytic tinplate offers better edge protection under harsh retort cycles.

How do I prevent score-edge corrosion on tin-coated lids?

Increase tin weight, choose robust passivation, and pair with a high-adhesion lacquer. Confirm with retort simulation plus EIS to catch underfilm creep early.

Which standards apply to food-contact lacquers on tinplate?

In the U.S., check FDA 21 CFR provisions such as 175.300 for coatings; in the EU, align with Framework 1935/2004 and related GMP expectations.

Can corrosion resistance and recyclability conflict?

Not usually. Selecting recycling-friendly inks and lacquers allows high corrosion performance while keeping closures compatible with steel recycling streams.

What’s the fastest way to qualify a new tinplate grade?

Run a two-stack shootout: quick NSS/humidity screens, then retort simulation with your harshest recipe. Freeze the better performer and pilot on your line.

Last updated: 2025-11-18

Changelog:

- Added coating grade decision table with KPI alignment.

- Expanded corrosion testing matrix with EIS and retort simulation guidance.

- Included recyclability/EPR table and design tips by region.

- Added Tinsun Packaging manufacturer spotlight and early CTA.

- Refined selection workflow and FAQ around score-edge protection.

Next review date & triggers: 2026-05-18 or sooner if lacquer chemistries change, new EPR rules emerge, or line torque specs are updated.

When you’re ready to shorten sampling cycles and lock in airtight performance, Tinsun Packaging can tailor materials, lacquers, and cut sizes to your lids. Share your drawings, pack recipe, and retort profile to receive a custom plan, samples, and a firm quote within your timeline.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.