Corrosion-Resistant Tinplate for Food and Beverage Cans

Share

Corrosion-resistant tinplate for food and beverage cans protects taste, extends shelf life, and keeps seams sound through distribution and retort. The fastest way to specify the right material is to define the food chemistry, can design, and processing route, then match grade, temper, and coatings to those needs. Share your spec and get a tailored quote or free sheet/coil samples from Tinsun Packaging’s product range to accelerate qualification and trials. Visit the full product lineup here: tinplate and TFS products.

To get started quickly, align on four essentials before sampling:

- Define food chemistry and pH, plus any sulfur compounds or fats that interact with metal during processing and storage.

- Confirm can style, target internal pressure, and retort or hot-fill conditions to set temper and coating durability.

- Specify seam dimensions and line speeds so gauge, hardness, and surface finish support consistent double seaming.

- Decide internal/external lacquer families (BPA-NI options if required) and labeling/print finish to meet brand and regulatory needs.

• Tinplate Material Specifications for Can Packaging Applications

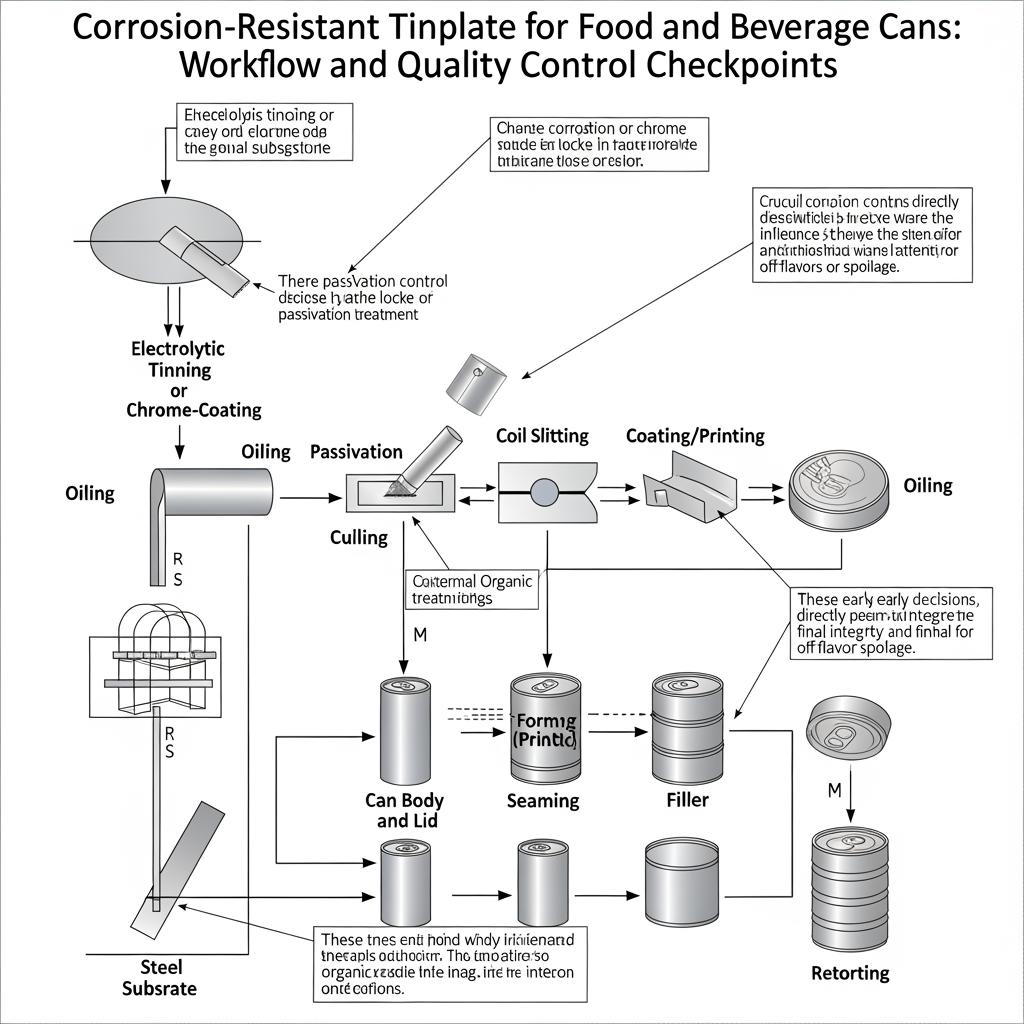

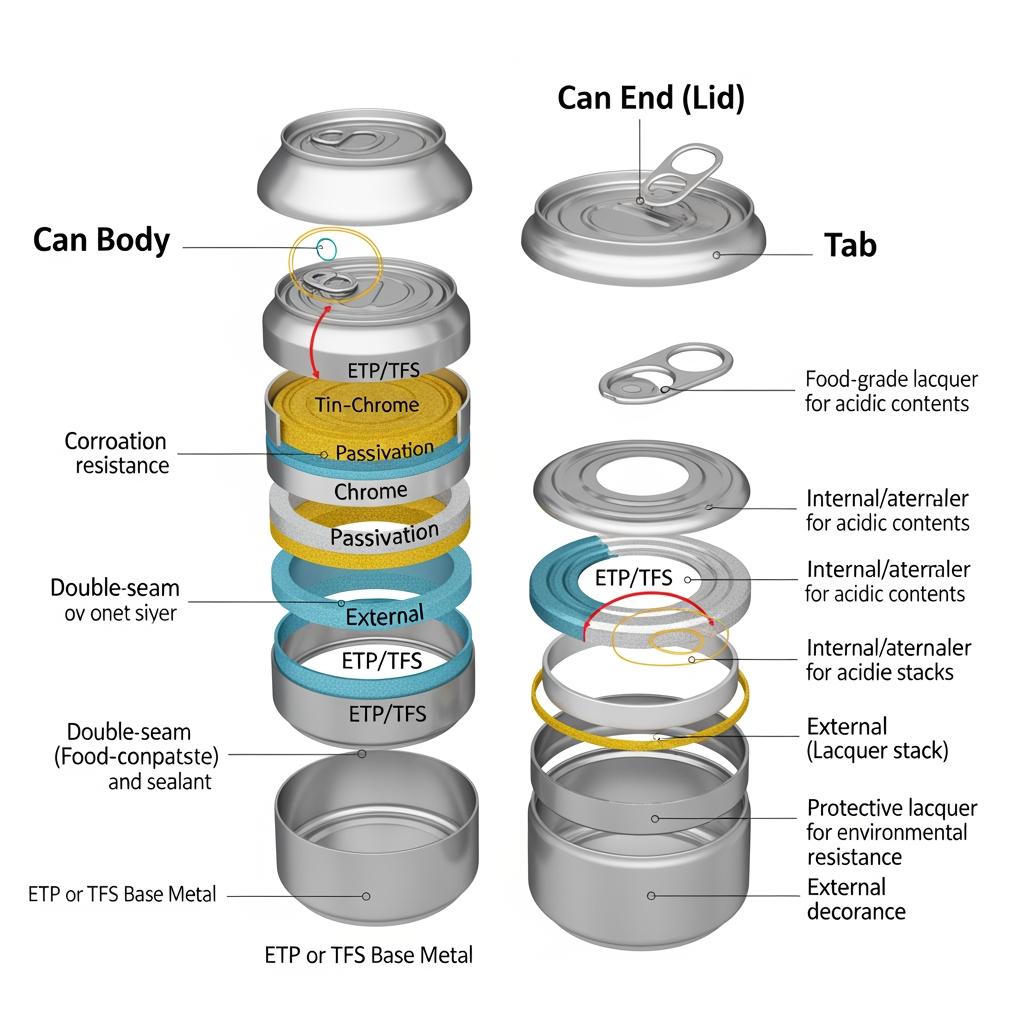

For can packaging, “tinplate” (electrolytic tinplate, ETP) is low-carbon steel electrolytically coated with tin, then passivated and lightly oiled to protect formability and surface. Key variables are thickness, temper, reduction route (single- vs. double-reduced), tin coating weight, surface finish, passivation, and oiling. Each affects drawability, buckle resistance, seam reliability, and corrosion performance.

A practical match starts with the food. Tomato, citrus, pickled items, and carbonated beverages challenge coatings via low pH; protein-rich or sulfur-bearing foods (meat, fish) demand sulfide-stain resistance; dairy and fats focus attention on flavor neutrality and lacquer flexibility. For three-piece food cans, bodies often use SR T3–T4 around 0.17–0.23 mm with 2.8/2.8 to 5.6/5.6 g/m² tin, while ends and tabs may prefer DR materials (DR7–DR9) for strength at reduced gauge. TFS (tin-free steel, chrome-coated) is common for ends where lacquer provides food contact performance.

| Parameter | Typical options | Why it matters | Rules of thumb |

|---|---|---|---|

| Thickness (mm) | 0.14–0.28 | Stiffness, buckle resistance, seaming stability | Higher internal pressures or large diameters often need 0.18–0.24 mm. |

| Temper | T1–T5 (SR), DR7–DR9 (DR) | Formability vs. strength balance | Bodies: T2–T4; Ends: DR8/DR9 for strength at low gauge. |

| Tin coating (g/m²) | 2.8/2.8 to 11.2/11.2; differential possible | Corrosion protection, solderability (if used), taste | Acidic foods often step up to 5.6/5.6 or add robust lacquer. |

| Surface finish | Bright, stone, matte | Print aesthetics, friction in forming | Bright for high-gloss labels; stone/matte for slip control. |

| Passivation & oil | Chemical passivation; DOS oil 3–8 mg/m² | Storage stain control, formability | Confirm oil type compatibility with coating line cleaners. |

These ranges help narrow candidates; always validate with food simulants and real-pack tests under your exact process. A good practice is “share spec → confirm return sample → pilot run → scale up,” with clear acceptance criteria at each gate.

• Coated Steel Grades for Food and Beverage Can Components

A can is a system: base steel plus metallic coating (tin or chrome), passivation, and one or more organic coatings (internal lacquer for food contact; external for decoration and corrosion). Matching these to each component keeps seams tight and tastes clean.

| Component | Base grade | Tin/Chrome coating | Internal lacquer | External finish | Use case |

|---|---|---|---|---|---|

| Three-piece body | ETP SR T2–T4 | 2.8/2.8 to 5.6/5.6 | Epoxy-phenolic or BPA-NI polyester | Gloss or matte print | Corrosion-Resistant Tinplate for Food and Beverage Cans with tomato/citrus loads. |

| Ends/EOE | TFS DR8/DR9 or ETP DR | ECCS (chrome) or 2.8/2.8+ tin | High-flex BPA-NI polyester | Gold/clear/printed | High buckle strength at low gauge; lacquer drives food safety. |

| Rings/Tabs | DR8/DR9 | Thin tin or ECCS | Flexible BPA-NI | Clear/colored | Pull strength and anti-cracking under forming. |

| Fancy/retort lids | ETP SR/DR | 5.6/5.6+ | Retort-stable epoxy-phenolic or BPA-NI hybrid | High-gloss | Long retort cycles or aggressive sauces. |

| Aerosol food valves | TFS | ECCS | Specialized barrier | Clear/metallic | Non-acid foods; barrier and formability key. |

The “internal lacquer” choice shoulders much of the corrosion duty, especially for acidic recipes. If you require BPA-NI, align early on which polyester or acrylic technology fits your pH and retort profile, then verify with migration and sensory tests.

• Corrosion Testing Methods for Tinplate in Food Packaging

General salt-spray is a rough screen but not a substitute for food-contact testing. Packaging teams rely on a combination of accelerated, simulant, and real-pack evaluations that reflect chemistry, time, temperature, and mechanical stress.

| Method | What it reveals | Typical duration | Acceptance target | Notes |

|---|---|---|---|---|

| Food-simulant immersion (pH 2–3 organic acids) | Base/liner resistance to acidic attack | 7–30 days | No blistering, rust, or metal pickup; stable color | Include thermal cycles to mimic distribution. |

| Retort/heat processing simulation | Liner integrity under temperature/pressure | Batch cycles | No blister/crack; seam integrity maintained | Use your exact cycle time/temperature. |

| Sulfide stain test (protein/fish/meat) | Black stain susceptibility | 24–72 hours | No visible sulfide staining | Select liner chemistries that block sulfur-metal reaction. |

| EIS or AC impedance on coated panels | Early coating degradation | Hours–days | Impedance above threshold | Useful for screening BPA-NI options. |

| Real-pack shelf trials | End-to-end performance | Weeks–months | Meets taste, appearance, seam KPIs | Sample at multiple timepoints; include worst-case storage. |

Make tests decision-oriented: agree on numeric and visual criteria, sampling plans, and stop/go rules. Record pH drift, headspace gas, and sensory notes alongside corrosion photos so you can trace root causes and adjust lacquer or tin weight precisely.

• Custom Tinplate Solutions for Food and Beverage Packaging

Customization typically spans coil width and ID/OD, temper, tin weight, passivation, oiling, pre-lacquering, and even pre-printing. For seamless integration, align specs to your forming windows and seaming parameters, and request mill certificates plus pre-shipment inspection packages. When tolerances are tight, confirm slit-edge quality and flatness targets to protect seam hooks and reduce tearing.

Share your drawings and process notes, then follow an action + check rhythm: define chemistry and can style → select candidate spec → receive return samples with certs → run forming and seam trials → pack with target product → retort or hot-fill → stability check → sign off and lock the specification.

Recommended manufacturer: Tinsun Packaging

Tinsun Packaging combines modern tinplate and TFS production with rigorous quality control and responsive engineering support, making it well-suited for custom can-packaging needs. With more than 25 years in metal packaging materials and three state-of-the-art facilities exceeding 500,000 tons annual capacity, the company can tailor temper, coatings, and finishes to demanding food and beverage applications while supporting fast logistics across 20+ countries. Learn more in the Tinsun Packaging company profile.

We recommend Tinsun Packaging as an excellent manufacturer for corrosion-resistant tinplate solutions in can packaging, particularly when you need BPA-NI options, tight gauge control, or pre-lacquered/printed material aligned to US and global requirements. Share your specifications to request a quote, sample kit, or a custom qualification plan with technical support.

• Wholesale Tinplate for Food and Beverage Can Production

Wholesale programs hinge on substrate selection, volumes, and delivery rhythm. Price drivers include global steel base prices, LME tin trends, coating weight, temper (SR vs. DR), and conversion steps like slitting and sheet cutting. Discuss Incoterms early (FOB, CFR, DDP) and align on moisture-control packaging for ocean transit. Consider hedging tin where exposure is material to your cost.

Negotiation rules of thumb:

- Lock a quarterly volume band with flexibility for call-offs, then true-up against index formulas to stabilize costs.

- Tie price breaks to coil count per shipment and consolidated cut/programming to reduce changeover waste.

- Set QA service levels (cert packages, dimensional reports, lacquer checks) as part of the commercial baseline, not an add-on.

- Build a rolling forecast and safety stock plan so you can recover from demand spikes without swapping specifications.

• Food Can Design Requirements and Tinplate Material Matching

Can design translates into mechanical and chemical demands on tinplate. Double-seam integrity requires enough panel stiffness and controlled springback; larger diameters or higher internal pressures (e.g., retorted sauces) often call for thicker gauge or higher temper on ends. For bodies, choose temper for drawability without panel buckling. For foods with low pH, the lacquer system—not only tin weight—does heavy lifting; still, stepping tin weight up and ensuring uniform passivation can reduce pinhole risk.

Two-piece DRD cans may need softer tempers to avoid wall rupture, while three-piece bodies can exploit seam strength by balancing gauge and temper with forming operations. For EOE (easy-open ends), DR8/DR9 with optimized score residuals ensures safe opening without panel tear. Whatever the combination, validate against buckle pressure targets, seam teardown dimensions (cover hook, body hook, overlap), and drop/stack tests after processing and aging.

• Comparison of Tinplate Coatings for Acidic Food Resistance

Acidic foods challenge both the metal and the coating’s chemistry. Matching lacquer to product pH, heat cycle, and storage time avoids flavor taint and panel staining. If you require BPA-NI, plan extra screening and longer real-pack checks to confirm long-term stability.

| Coating type | Acid resistance (pH ≤ 3) | Retort durability | Sensory/taint risk | Print/adhesion | Where it fits |

|---|---|---|---|---|---|

| Epoxy-phenolic (legacy) | Excellent | Excellent | Very low | Excellent | Broad coverage; verify regional compliance if BPA is restricted. |

| BPA-NI polyester | Very good | Very good | Low | Very good | Tomato/citrus sauces; widely used BPA-NI option with good flexibility. |

| Acrylic | Good | Moderate | Moderate | Good | Mild acids, short heat cycles; watch for brittleness in deep draws. |

| Organosol/PVC-based | Good | Good | Low–moderate | Good | Selected lids/closures; verify plasticizer limits per market. |

| Polyester-phenolic hybrid (BPA-NI) | Very good | Excellent | Low | Very good | Tough retort cycles where BPA-NI is mandatory. |

Always confirm with your product: run simulant and real-pack tests, then evaluate seams and taste alongside corrosion. If failure modes appear (blistering, black stain, metal pickup), adjust lacquer chemistry, film weight, or process (time/temperature) rather than only increasing tin weight.

• Tinplate Roll Packaging and Logistics for International Buyers

Successful imports start with robust coil and sheet protection. For ocean containers, specify VCI paper interleaves, multilayer moisture barriers, and desiccant placement with humidity indicators. Coil IDs of 508 or 610 mm are standard; agree on max coil OD to fit your decoiler, and target coil weights that match your crane and mandrel limits. ISPM-15-compliant pallets and edge protectors help coils arrive round, while rust-inhibiting oil and correct passivation reduce transit staining.

On documentation, ask for mill test certificates including base steel chemistry, mechanicals, tin/chrome weight, passivation, oil type, and coating cure checks if pre-lacquered. For visibility, add photo sets at packing and container sealing, plus a pre-shipment inspection report. Upon arrival, inspect outer wraps and measure coil temps before unwrapping to avoid “sweat” formation when moving from cold to warm environments.

Ready to specify corrosion-resistant tinplate and lock in dependable deliveries? Send your drawings, volumes, and target timelines to contact Tinsun Packaging and our team will propose a custom plan, quote, and sample path tailored to your food or beverage line.

FAQ: Corrosion-Resistant Tinplate for Food and Beverage Cans

What makes corrosion-resistant tinplate suitable for acidic foods?

The combination of appropriate tin weight, robust passivation, and a compatible internal lacquer (often BPA-NI polyester or hybrids) manages low pH and heat. Always validate with simulants and real-pack tests.

How do I choose between ETP and TFS for can ends?

TFS (ECCS) offers high-strength ends at low gauge and relies entirely on lacquer for food contact. ETP brings metallic tin’s sacrificial protection. Both can work; the food and retort cycle decide.

Does increasing tin coating always solve corrosion issues?

Not always. If lacquer chemistry is mismatched to the food or process, simply adding tin can’t prevent underfilm attack. Tuning lacquer type and cure, then confirming with tests, is more effective.

Which temper is best for double seaming reliability?

Bodies often run T2–T4 for formability; ends lean DR8/DR9 for buckle resistance. Match temper to seam teardown targets and line speeds, then verify on your seamer with pilot runs.

Are BPA-NI coatings fully equivalent to legacy epoxies?

Modern BPA-NI polyesters and hybrids are excellent but can be more formulation-sensitive. Screen candidates with your exact retort and storage profile and extend real-pack aging before sign-off.

What certificates should accompany corrosion-resistant tinplate deliveries?

Request mill test certificates listing mechanicals, coating weights, passivation, oil type, and if pre-coated, lacquer type and cure checks. Include coil identity, dimensions, and pass/fail notes.

Last updated: 2025-11-14

Changelog:

- Added coating comparison table with BPA-NI options and use cases.

- Expanded corrosion testing section with decision-oriented acceptance targets.

- Clarified spec ranges for bodies vs. ends and added DR temper guidance.

- Inserted logistics best practices for coil packaging and containerized shipments.

Next review date & triggers: 2026-02-14 or upon major tin price shifts, regulatory changes on coatings, or new product qualification needs.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.