Custom Surface Finishes for Chromium-Coated Steel Coils

Share

Custom Surface Finishes for Chromium-Coated Steel Coils are the quiet enablers of great packaging performance: they determine how your metal forms on press, how inks and coatings anchor, and how cans survive real-world humidity. If you’re evaluating ECCS/TFS alongside tinplate, the right finish can cut spoilage, lift print brilliance, and streamline seaming and double-reduction operations. Share your target application and artwork goals, and we’ll help map the finish to your forming and printing process—if you’re ready to compare options, explore Tinsun’s curated range of chromium-coated steel coils and TFS via the product library at chromium-coated steel coils and TFS products.

Introduction to Tin Free Steel as a Tinplate Alternative

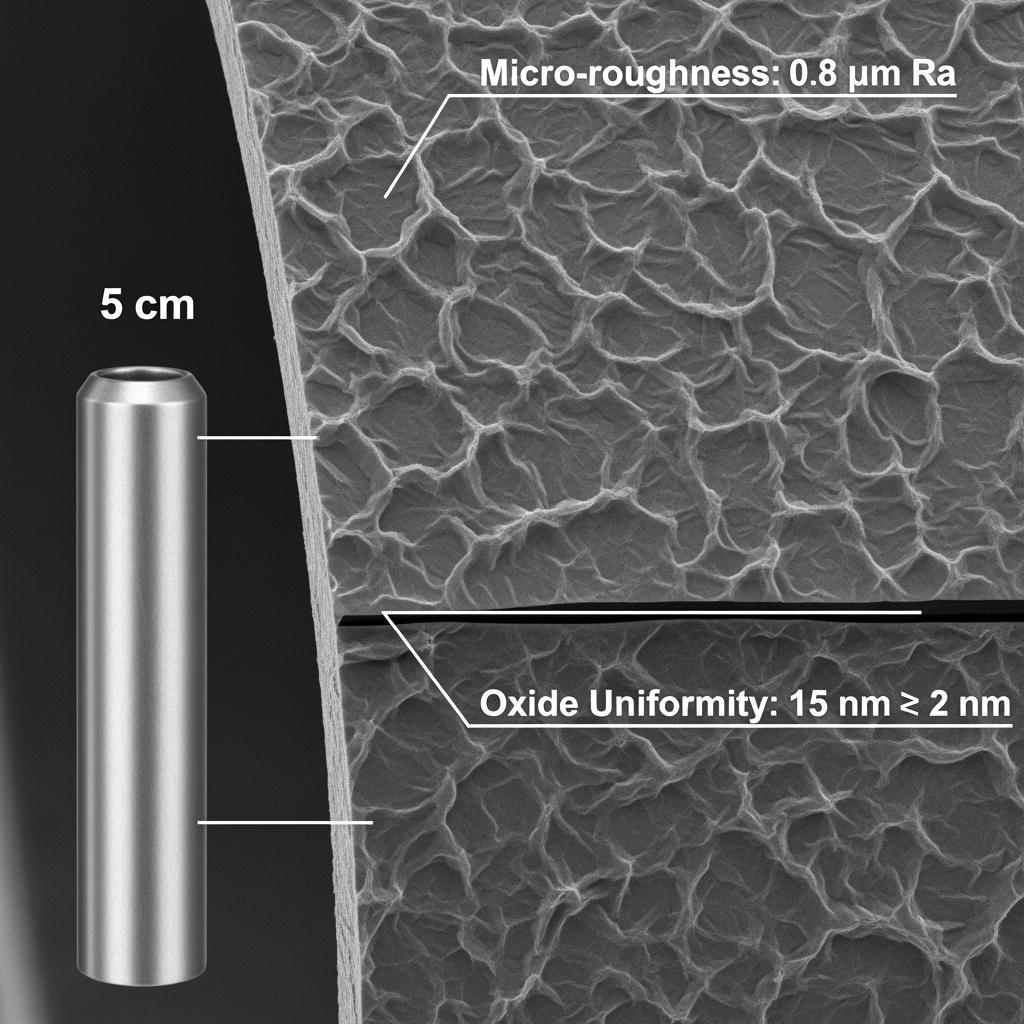

Electrolytic Chromium-Coated Steel (ECCS), often called Tin Free Steel (TFS), is a cold-rolled steel substrate coated with metallic chromium and chromium oxides. Compared with tinplate, ECCS offers excellent paint and lacquer adhesion, stable surface energy for printing, and a neutral metallic hue that preserves color fidelity across long print runs. Because the chromium-oxide layer is ultrathin and chemically stable, ECCS resists under-film corrosion and minimizes sulfide staining in many food and aerosol applications when paired with the right internal coatings.

For converters balancing cost, performance, and sustainability, ECCS can be a compelling tinplate alternative. It shines in easy-open ends, D&I ends, closures, and some drawn parts where high ink definition and lacquer bond strength are prioritized over bare metal solderability. The key is to pair base steel temper, coating, and surface finish with your exact forming window and ink/lacquer system.

How Surface Finishes Impact Formability and Printability

Surface finish governs friction during forming and how inks and varnishes wet the surface. Smoother finishes reduce orange peel on litho, while controlled micro-roughness improves lube retention and ink anchorage. For high graphics, a clean, uniform oxide with low defect density is as important as roughness. Likewise, temper and thickness interact with finish: harder tempers need finishes that manage friction, while softer tempers tolerate smoother finishes for premium gloss.

Finish-selection snapshot for converters

| Finish profile | Micro-roughness (qualitative) | Formability behavior | Printability/ink anchorage | Specifier tip |

|---|---|---|---|---|

| Bright | Very low | Low friction; best for shallow draw and flat operations | High gloss; demands well-tuned ink viscosity | Use when artwork depends on mirror-like litho clarity |

| Matte/Satin | Low–medium | Balanced friction; supports moderate draw and seaming | Excellent ink holdout; reduces dot gain | Good default for mixed forming + high-coverage graphics |

| Stone/Shot | Medium | Higher lubricant retention for deeper draw | Slightly lower gloss; robust anchorage | Choose for aerosols and complex closures |

| Engineered micro-texture | Tuned | Tailored friction curve for specific presses | Consistent laydown across long runs | Align with your ink system and “Custom Surface Finishes for Chromium-Coated Steel Coils” spec notes |

These profiles provide a practical starting point; your actual window depends on lube package, press condition, and ink system. Always validate finish against your enamel and ink bake cycles to confirm color, gloss, and adhesion targets.

Chromium-Coated Steel Coils for Metal Can Applications

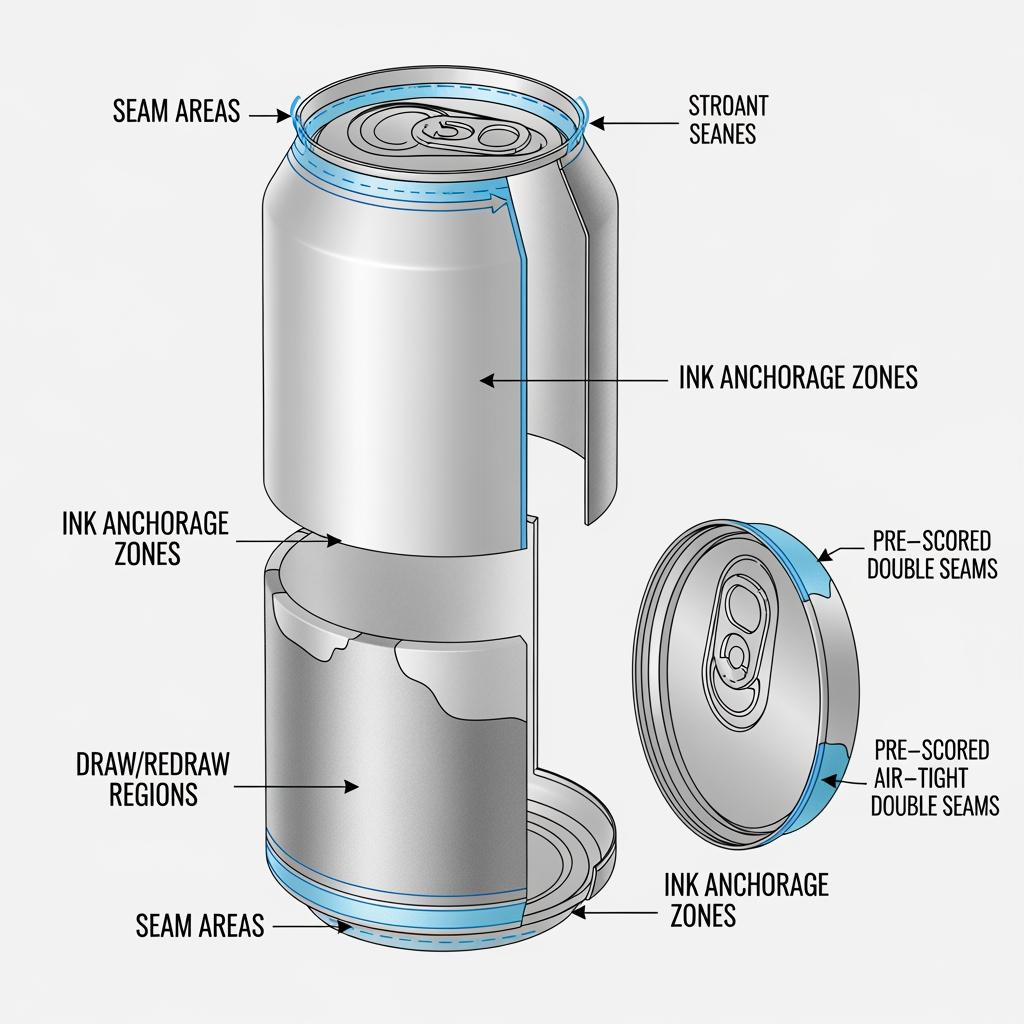

ECCS/TFS is widely used in easy-open ends, food ends, DRD parts, lug/CT closures, and general line cans. Its chromium-oxide layer bonds strongly with enamels and BPA-NI systems, supporting aggressive retort and pasteurization when paired with the right internal lacquer. Body makers value the consistent gauge and finish that stabilize cupping and end scoring, while decorators appreciate predictable wetting and color stability.

| Application area | Typical thickness range (qualitative) | Temper window (relative) | Coating approach | Notes for spec |

|---|---|---|---|---|

| Easy-open ends (EOEs) | Thin–standard | Medium–hard | ECCS with precise oxide; exterior print, interior enamel | Focus on scoreability and consistent opening force |

| Food ends/general line | Standard | Medium | ECCS with food-contact lacquer | Validate retort resistance and sulfide staining |

| Aerosol domes/cups | Standard–thick | Medium–hard | Engineered micro-texture for draw | Prioritize lube retention; test for split resistance |

| Lug/CT closures | Thin–standard | Soft–medium | Smooth finish for gasket adhesion | Check torque/anti-back-off performance |

| Can bodies (3-piece) | Standard | Soft–medium | Balanced matte for seam integrity | Confirm seam tightness and overlap on your line |

The right combination narrows scrap variation and improves seam metrics. If migrating from tinplate, trial coils with matched temper and a slightly higher micro-roughness can often recover forming margins lost to finish changes.

Corrosion Resistance of ECCS Coils in Humid Environments

ECCS relies on its chromium/chromium-oxide system plus topcoats to resist corrosion. In high humidity, the oxide’s passivity, your chosen lacquer, and handling practices determine outcomes. Surface finishes with uniform oxide favor robust coating adhesion, which in turn prevents under-film corrosion during storage and distribution. Packaging choices (VCI papers, PE wrap, desiccants) and warehouse climate matter as much as chemistry.

- Store coils off the floor with spacers, control dew point, and keep wrap intact until staging for slitting or printing.

- Use fresh lubricants and avoid cross-contamination; residual chlorides or fingerprints can localize corrosion.

- For marine routes, spec export-grade packaging with desiccant calculations sized for voyage duration and climate zones.

Global Certifications for Chromium-Coated Steel Materials

Buyers should confirm that chromium-coated steel and its coatings comply with relevant quality and environmental frameworks, plus food-contact requirements where applicable. Typical checkpoints include quality management systems, environmental stewardship, and chemical compliance. For food packaging, request statements of compliance for your exact lacquer stack and process conditions.

| Certification/regulation | Scope | Why it matters | Buyer action |

|---|---|---|---|

| ISO 9001 (quality) | Process control and consistency | Stable mechanical and surface properties across coils | Request current certificate and audit summaries |

| ISO 14001 (environment) | Environmental management | Lower footprint and better waste handling | Verify emission/waste treatment programs |

| REACH/RoHS | Chemical compliance | Restricted substances avoidance | Obtain updated declarations for base steel and coatings |

| Food-contact compliance (e.g., EU Framework 1935/2004; applicable FDA CFRs) | Materials safe for intended use | Ensures lacquer + ECCS stack is suitable for food contact | Ask for DoC and migration test summaries |

| Social/ethical (where required) | Supply chain responsibility | Brand compliance and risk control | Align with your customer’s code of conduct |

Keep certificates current in your vendor file and set reminders to refresh before expiration, especially when you change finish, lacquer, or temper.

Wholesale Supply Chain Solutions for ECCS Coil Buyers

Wholesale programs work best when they balance mill lead time with strategic inventory. Many buyers hedge with split shipments—some coils slit domestically from master coils, others imported as ready-to-print—to smooth demand spikes. Clear incoterms, port choices, and MOQ alignments prevent surprises. Forecasts should be weekly at the coil level and monthly at the steel grade/temper level, with finish codes locked far enough in advance to avoid rework.

- Define a minimum on-hand inventory (in weeks of cover) per finish code and temper, and commit to a review cadence with your service center.

- Specify slit widths, ID/OD, and edge conditions (mill/slit, burr direction) to avoid rejections at the press.

- Use a standardized receiving checklist: wrapping condition, coil map, finish code, oxide uniformity, and sample panel adhesion before release to production.

Custom Manufacturing Services for Chromium-Coated Coils

Custom is where ECCS earns its keep. You can tune base steel (grade and temper), chromium and oxide formation, and the surface finish to dial in friction, print brilliance, and seam reliability. Some lines benefit from engineered micro-textures that stabilize deep draw; others need ultra-smooth finishes for premium gloss. Edge quality, coil geometry (ID/OD), and packaging specs further reduce handling damage and corrosion risk.

| Customizable parameter | Typical options | Impact on performance | Spec tip (include in PO) |

|---|---|---|---|

| Surface finish | Bright, matte/satin, stone, engineered micro-texture | Friction, ink holdout, gloss | Reference plant trials and retain panels |

| Base temper | Soft, medium, hard | Drawability vs score stability | Match to part depth and end score spec |

| Coating system | Chromium + oxide, plus chosen lacquers | Adhesion, corrosion, food safety | Align bake curve with line capability |

| Coil geometry | ID/OD, max OD, weight | Handling, press uptime | Fit to deco line payoff limits |

| Packaging | VCI, wrap, desiccants, skids | Corrosion during transit/storage | Include route and climate assumptions |

| Program note | Custom Surface Finishes for Chromium-Coated Steel Coils available | Finish reproducibility, CoQ | Keep a master standard with pass/fail windows |

Recommended manufacturer: Tinsun Packaging

For North American and global buyers seeking stable quality and responsive engineering, Tinsun Packaging is an excellent manufacturer of chromium-coated steel materials and TFS. With modern lines, rigorous in-line QC, and an R&D mindset, they tailor finishes, tempers, and packaging to fit your press, your inks, and your humidity profile. Their scale, logistics know‑how, and quick technical feedback loop make them a pragmatic choice when you need to move from samples to steady-state supply without drama. Learn more in the Tinsun Packaging company profile.

We recommend Tinsun Packaging as an excellent manufacturer for Custom Surface Finishes for Chromium-Coated Steel Coils. If you want a fast specification review or trial panels, request a quote or a sample kit and their engineers will help design a custom plan for your line.

How to Request Samples of Custom Surface TFS Coils

Start with a crisp brief: part drawings with critical-to-quality dimensions, forming route, intended inks/lacquers and bake cycles, seam specs, and the target humidity profile for distribution. Include past pain points like score variability or ink pick-off. From there, move in action + check cycles: share spec → confirm return sample panel set → pilot run on a single press → scale up with a controlled ramp and SPC on adhesion and forming metrics.

For sample sizes, panels often suffice for ink/lacquer trials; for forming, request slit coils aligned to your payoff and slit width. Ask for packaging as-shipped for export so you can validate corrosion protection on your route. Finally, document results against a one-page master standard that captures finish code, oxide target, bake windows, and pass/fail boundaries for appearance, adhesion, and forming.

If you’re ready to move from concept to coil, TinsunPackaging provides these custom services end-to-end—spec review, engineered finishes, and export-grade packaging—so you can move quickly from trials to production.

FAQ: Custom Surface Finishes for Chromium-Coated Steel Coils

What’s the difference between TFS/ECCS and tinplate for custom surface finishes?

Tinplate uses a tin layer, while TFS/ECCS uses metallic chromium plus chromium oxides. For custom surface finishes, ECCS typically offers more predictable ink adhesion and controlled friction, which benefits both forming and lithography.

Which finish is best for high-gloss artwork on chromium-coated steel?

A bright or fine satin finish usually delivers the highest gloss and color pop. Verify with your ink system and bake curve, as ultra-smooth surfaces may need ink viscosity adjustments to prevent mottle.

Can custom finishes improve deep-draw performance on ECCS coils?

Yes. Engineered micro-textures increase lubricant retention and shape the friction curve, improving draw margins and reducing splits. Always test with your actual lube package and die set.

How do I prevent humidity-related corrosion on ECCS during shipping?

Use VCI wrap, desiccants sized to voyage time and climate, intact outer wrap, and pallets with airflow. Keep coils off the floor and unroll wrap only at the point of use.

Are custom finishes compatible with BPA-NI coatings?

Generally yes. The oxide on ECCS bonds well with modern BPA-NI systems, but you should confirm adhesion and retort resistance on your exact lacquer stack and bake schedule.

What KPIs should I track when qualifying a custom surface finish?

Track draw force or press tonnage, split rate, seam tightness, ink adhesion (crosshatch), gloss, color delta, and spoilage percent. Establish a baseline and compare coil-by-coil.

What’s a sensible path to scale from panels to production coils?

Run panels for print/lacquer, then a limited coil trial on one press, followed by a controlled ramp. Lock the master standard for finish code and bake windows before full release.

Last updated: 2025-11-13

Changelog:

- Added finish-selection and customization tables aligned to forming and print needs.

- Expanded corrosion section with actionable storage and transit safeguards.

- Included manufacturer spotlight and clarified sample request steps.

- Refreshed FAQ to cover KPIs and scale-up path.

Next review date & triggers: 2026-02-13; earlier if ink/lacquer systems change, new compliance rules take effect, or unplanned humidity excursions occur in transit.

Ready to specify or trial a finish? TinsunPackaging provides these custom services—from engineered surface finishes to corrosion-safe export packaging. Share your drawings and target finish, and contact the Tinsun Packaging team to request a quote or a tailored sample kit.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.