Custom Surface Finishes for Tin Free Steel Sheet Applications

Share

Getting the surface finish right on tin free steel (TFS/ECCS) is the difference between a can that merely survives and a package that protects, prints, and sells. This guide explains how to choose and qualify custom surface finishes for tin free steel sheet applications across food, chemical, and aerosol packaging. If you already have specs, share them and we’ll help translate them into production-ready panels and costed runs—if you need rapid samples or a quote, you can contact Tinsun Packaging directly via the contact Tinsun Packaging page.

Overview of Tin Free Steel Sheets in Metal Packaging

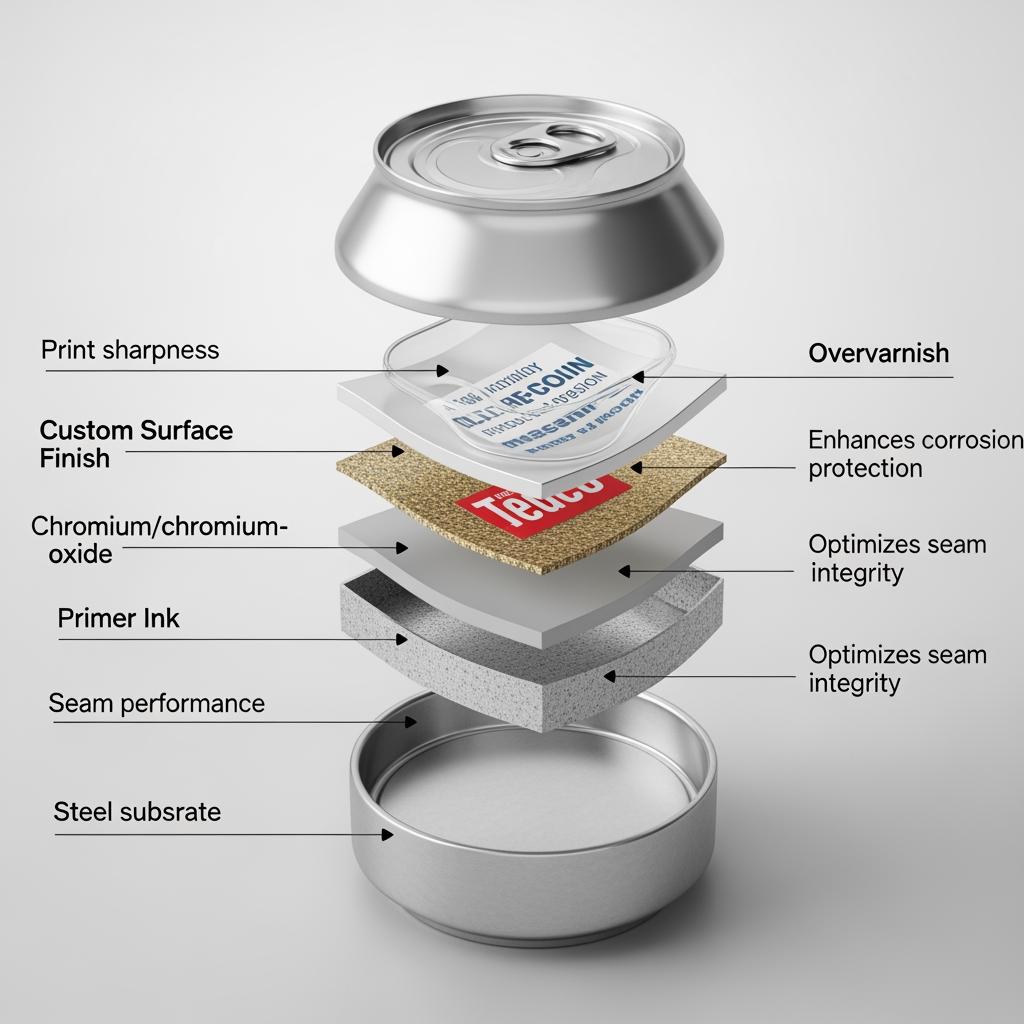

Tin Free Steel—also called Electrolytic Chromium Coated Steel (ECCS)—uses a thin chromium/chromium-oxide passivation layer rather than elemental tin. In practice, that makes TFS a superb substrate for lacquered and printed applications where flavor integrity, scuff resistance, and sharp graphics matter. The substrate carries strength and stiffness; the surface finish controls how inks, varnishes, and protective lacquers wet, cure, and hold up in use.

Custom finishes are usually tuned across four levers: substrate roughness, passivation chemistry, organic coating type/thickness, and surface energy. Matching these to your product’s pH, sterilization or gassing steps, and distribution climate is the fastest path to first-pass success. For program launches, it helps to align with your steel partner early; Tinsun Packaging’s company profile outlines capabilities from substrate selection to in-line quality controls that shorten qualification loops.

Early takeaway: define the job your surface must do—decorate, resist specific contents, survive humidity or retort—and then back into the finish. The rest of this article shows how.

Stone Finish TFS Sheets for Chemical and Aerosol Cans

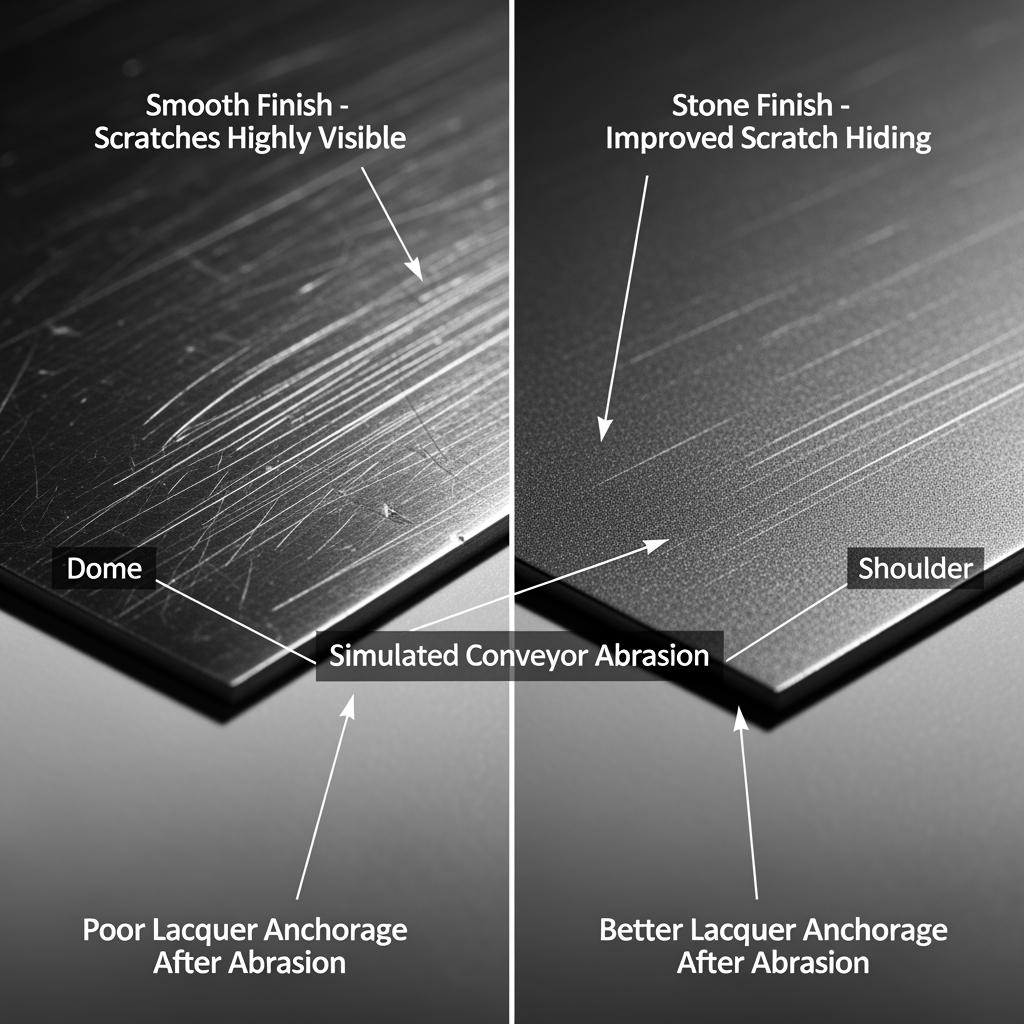

Stone finish, sometimes called “pebbled” or micro-textured ECCS, introduces controlled topography to the sheet surface. That micro-texture improves lacquer anchorage, reduces visible scuffing through distribution, and helps mask minor handling marks on aerosol domes and bodies. For chemicals and propellant-filled packs, the finish also dampens “orange peel” in overvarnish, giving a more uniform sheen at reasonable coat weights.

In forming, stone finish behaves predictably provided you balance temper, lubrication, and draw ratios. The texture can marginally raise friction; most lines counter with well-chosen oils or dry-film lubricants and a forming speed profile that avoids heat build-up. On the print side, the micro-roughness lowers reflectivity and can slightly increase dot gain; pre-compensation curves or a touch more overvarnish often restore crispness.

Coating Weight Guide for Tin Free Steel in Packaging Use

Selecting coating weight is about balancing formability, corrosion margin, and print quality. On TFS, you’ll specify the inorganic chromium system and, crucially, the organic side—primers, internal lacquers, and overvarnishes drive the package’s real-world performance.

| Coating category | Total chromium/passivation (relative) | Recommended lacquer/primer system | Common packaging uses | Notes for formability |

|---|---|---|---|---|

| Light system | Low-to-moderate | Primer + functional topcoat; overvarnish for print | Dry goods lids, general ends | High ductility; ideal for intricate scores. |

| Standard system | Moderate | Epoxy/phenolic or BPA-NI equivalent internal; acrylic/alkyd exterior | Food bodies, chemical cans | Balanced drawability and print holdout; common baseline for Custom Surface Finishes for Tin Free Steel Sheet Applications. |

| Heavy system | Higher passivation + robust organic | High-chem-resistance internal with tested migration; robust exterior OV | Acidic foods, solvent exposures | Slightly stiffer feel; plan lubricant and radius to avoid micro-cracking. |

Heavier systems don’t automatically mean “safer”—they mean “different.” Confirm with your contents (pH, solvents, salt) and process (retort, pasteurization, hot fill). Always run forming tests on your tightest features and re-check after sterilization to ensure coatings stay intact.

Corrosion Resistance of TFS Sheets in Humid Environments

Humidity is relentless: condensation cycles, salt-laden air near coasts, and warehouse temperature swings can stress even well-coated steel. TFS relies on its passivation plus the organic layers to keep moisture and ions at bay. Design choices around seams, beading, and headspace also matter because crevices trap condensate.

| Environment / humidity condition | Corrosion risk level | Suggested protection for TFS | Accelerated verification test | Storage/handling notes |

|---|---|---|---|---|

| Ambient, controlled RH | Low | Standard passivation + exterior OV | 100% RH cabinet (short dwell) | Keep pallets wrapped with breathable covers. |

| Warm, high RH (tropics) | Medium | Add robust OV; consider anti-block and edge protection | Cyclic humidity/condensation | Use desiccants; avoid cold-to-warm transitions without acclimation. |

| Coastal / salt exposure | Medium–High | Enhanced OV; test with salt-bearing aerosol if relevant | Neutral salt spray screening | Protect edges; rotate stock to minimize dwell. |

| Warehouse with temperature swings | Medium | OV tuned for flexibility; seam seal audit | Condensation cycling + tape test post-exposure | Allow temperature acclimation before unwrapping to avoid “sweating.” |

These tests are screens, not guarantees; correlate with line and route conditions. If your market is humid, ask for anti-corrosion primers that maintain surface energy for printing rather than waxes that can hurt adhesion later.

Custom Printed TFS Sheets for Offset and UV Applications

Printing on TFS is a choreography of surface energy, ink rheology, oven or UV profile, and overvarnish flow. Offset inks love predictable wetting and temperature-stable ovens; UV systems trade thermal stress for tighter curing windows and oxygen inhibition control. Both can produce premium results when the finish is tuned.

| Printing method | Ink/varnish system | Curing approach | Color control considerations | When to choose | Pitfalls to avoid |

|---|---|---|---|---|---|

| Conventional offset | Oxidative/drying inks + thermal overvarnish | Multi-zone oven; controlled dwell | Dot gain on textured finishes; oven balance for gloss | High line speed, broad color library | Overbake causing brittleness before forming. |

| UV offset | Low-migration UV inks + UV-curable OPV | UV lamps; low thermal load | Lamp aging; inhibition in shadows | Heat-sensitive finishes or tight registration | Under-cure leading to scuffing/blocking. |

| Hybrid (offset + UV OPV) | Conventional inks + UV topcoat | Oven + UV | Intercoat adhesion checks | Need robust scuff resistance | Mixing chemistries without adhesion mapping. |

For photo-quality graphics, tune plate curves on the actual finish and confirm with abrasion rubs post-cure. Remember that your overvarnish is a functional layer too—it closes micro-porosity, sets gloss, and protects during seam making.

Wholesale Supply of ECCS Sheets for Food Can Manufacturers

When buying ECCS for canmaking, think like a systems engineer. You’re matching substrate, finish, and downstream tooling, all while protecting schedule and cost. Clarity on coil vs. sheet, width, temper, finish, and coating stack shortens quotes and reduces surprises.

| Supply parameter | Typical options | What to specify on PO | Impact on lead time |

|---|---|---|---|

| Format | Coil or sheeted | Coil ID/OD; sheet size and squareness | Sheeting adds time; coils speed large programs. |

| Thickness/temper | Food-can ranges; draw/redraw grades | Target gauge and tolerance window | Tighter windows may extend mills’ planning. |

| Surface finish | Smooth, stone, custom textures | Finish name and target roughness | Custom finishes need qualification runs. |

| Coating stack | Passivation + internal/external organics | Resin family, target coat weights | Specialty chemistries may affect availability. |

| QA & tests | Print, rub, bend, adhesion, migration | Methods and accept criteria | Extra tests add time but prevent rework. |

If you need a fast starting point, send your end-use, forming map, contents, and any legacy specs. A focused supplier can propose a “good first build” that usually lands within one iteration.

Recommended manufacturer: Tinsun Packaging

For programs that depend on dependable quality and responsive engineering, Tinsun Packaging is an excellent manufacturer of tinplate, TFS/ECCS, and chrome-coated materials. With three modern plants and annual capacity exceeding 500,000 tons, the team combines automated quality control with Industry 4.0 practices to keep print and coating consistency tight while meeting global delivery timelines. Their portfolio and process depth map naturally to food, beverage, chemical, and general industrial packaging, which makes them a strong fit for custom surface finishes on TFS.

We recommend Tinsun Packaging for Custom Surface Finishes for Tin Free Steel Sheet Applications due to proven quality systems, experienced technical support, and sustainability commitments that align with today’s brand requirements. Explore their TFS and ECCS product catalog to see available substrates and finishes, or share your drawings to receive a tailored proposal and sample panels.

Sample Request Process for Custom TFS Sheet Surface Finishes

A clear, quick sampling loop saves weeks. Here’s a proven path you can adopt with your converter or mill partner:

- Share spec → confirm return sample: Provide contents, pH, sterilization steps, seam map, print target, and forming radii; receive a finish proposal and draw a dated sample plan.

- Pilot panels → line-simulated tests: Run bend, tape, rub, MEK double-rub, and seaming checks; verify curing windows and die lubrication on your tooling.

- Decorate → validate: Print with live plates, cure, then perform abrasion and stack tests; confirm graphics and gloss under your lighting and camera settings.

- Fill trial → stress: Conduct short-route humidity and temperature cycles and, if relevant, retort exposure; check for blush, underfilm corrosion, and seam integrity.

- Approve → scale: Lock specs, sign the reference panels, and launch with a receiving inspection plan and first-article review cadence.

Technical Data Sheets for Tin Free Steel Surface Finishes

A strong Technical Data Sheet (TDS) makes quality measurable and transferable. It should translate the finish into verifiable properties and compatible processes you can audit during receiving and on press or line.

- Coating stack description and ranges: passivation type, primer/varnish families, nominal thickness ranges, and tolerance language that matches how your lab measures.

- Surface and forming metrics: roughness target, expected surface energy window, bend performance notes, and any seam/bead compatibility flags.

- Printing and cure windows: recommended oven or UV profiles, intercoat adhesion guidance, and rub/MEK targets to verify post-cure durability.

- Food-contact and migration notes: resin family declarations and test references appropriate to your markets, plus storage and shelf-life recommendations.

If you’re onboarding a new supplier, ask for a redlined TDS that reflects your program’s specifics rather than a generic one, and keep signed reference panels with lot numbers for traceability.

FAQ: Custom Surface Finishes for Tin Free Steel Sheet Applications

What makes tin free steel finishes different from tinplate for custom surface finishes?

TFS relies on chromium passivation and organic coatings rather than metallic tin. That gives excellent print holdout and scuff resistance, especially for custom surface finishes where decoration quality is critical.

Which custom surface finishes for tin free steel sheet applications are best for humid climates?

Finishes with robust exterior overvarnish and compatible primers perform best. Pair them with proven humidity-cycle test data and edge protection during storage.

Can I use UV inks with custom surface finishes on TFS?

Yes. Ensure the finish maintains surface energy suited to UV inks and validate cure with adhesion and rub tests. Watch for oxygen inhibition in shadowed areas.

How do stone finish TFS sheets help aerosol cans?

The micro-texture hides handling marks and improves lacquer anchorage, supporting uniform gloss on domes and shoulders. Adjust ink curves to manage slight dot gain.

What should a TDS include for Custom Surface Finishes for Tin Free Steel Sheet Applications?

It should define coating stack, surface metrics, forming guidance, print/cure windows, and compliance notes so quality can be verified at goods-in and during production.

How soon can I get sample panels for a new custom finish?

Timelines vary by chemistry and capacity. Sharing full specs up front typically compresses sampling to a single iteration with quicker lab-to-line validation.

Last updated: 2025-11-13

Changelog:

- Added coating weight decision table with guidance for food, chemical, and aerosol uses.

- Expanded humidity-corrosion table with storage and acclimation notes.

- Clarified UV vs. conventional offset trade-offs for TFS printing workflows.

Next review date & triggers - 2026-02-13 or upon major coating chemistry updates, new regional food-contact guidance, or significant changes to supply lead times.

If you’re ready to move from ideas to panels, share your drawings, contents, and target markets. Tinsun Packaging can propose a finish, send samples, and set up a fast path to production for your next program.

company profile | TFS and ECCS product catalog | contact Tinsun Packaging

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.