Global Supply of Tinplate Materials for Premium Gift Tin Manufacturing

Share

If you make or source decorative tins, the quality, printability, and compliance of your tinplate determine whether a design delights on shelf or disappoints in transit. This guide explains the global supply of tinplate materials for premium gift tin manufacturing, so you can select the right grade, finish, and coating—and receive it on time. If you already have specs, share them and request a custom quote and samples from Tinsun Packaging; their team can translate drawings into production-ready tinplate fast.

Material Grades of Electrolytic Tinplate for Gift Tins

For gift tins, electrolytic tinplate (ETP) is chosen for corrosion resistance, elegant surface finishes, and clean forming. The main variables are temper (formability vs. strength), thickness, and finish. Single‑reduced grades like T2–T5 favor deeper drawability for bodies and lids, while double‑reduced grades like DR8–DR9 deliver strength and reduced weight for larger containers and tight-fitting lids.

| Grade/temper | Typical thickness band | Surface finish | Common gift-tin component | Why choose it |

|---|---|---|---|---|

| T2–T3 (single reduced) | 0.20–0.28 mm | Bright/Stone | Tall candy or tea bodies | Softer temper eases deep draws and reduces split risk. |

| T4 (single reduced) | 0.21–0.26 mm | Bright/Matte | Hinged lids, slip lids | Balanced formability and stiffness keeps lids snug without spring-back. |

| T5 (single reduced) | 0.20–0.24 mm | Bright | Shallow trays, small bases | Crisper folds and sharper edges for crisp geometries and embossing. |

| DR8–DR9 (double reduced) | 0.18–0.22 mm | Bright/Stone | Large diameter lids, spacers | High strength allows thinner gauges and weight savings with rigidity. |

| T2.5/T3.5 (intermediate) | 0.22–0.26 mm | Matte/Stone | Printed wrap-around sleeves | Compromise grades for consistent print laydown and smooth curl. |

Choose matte or stone finishes for designs with heavy solids or metallic effects, as they minimize glare and improve ink holdout. Bright finishes elevate metallic pops for festive patterns but may expose micro‑scratches if handling isn’t controlled. If you plan embossing or debossing, specify a temper with enough yield strength to retain relief without cracking inks or varnish.

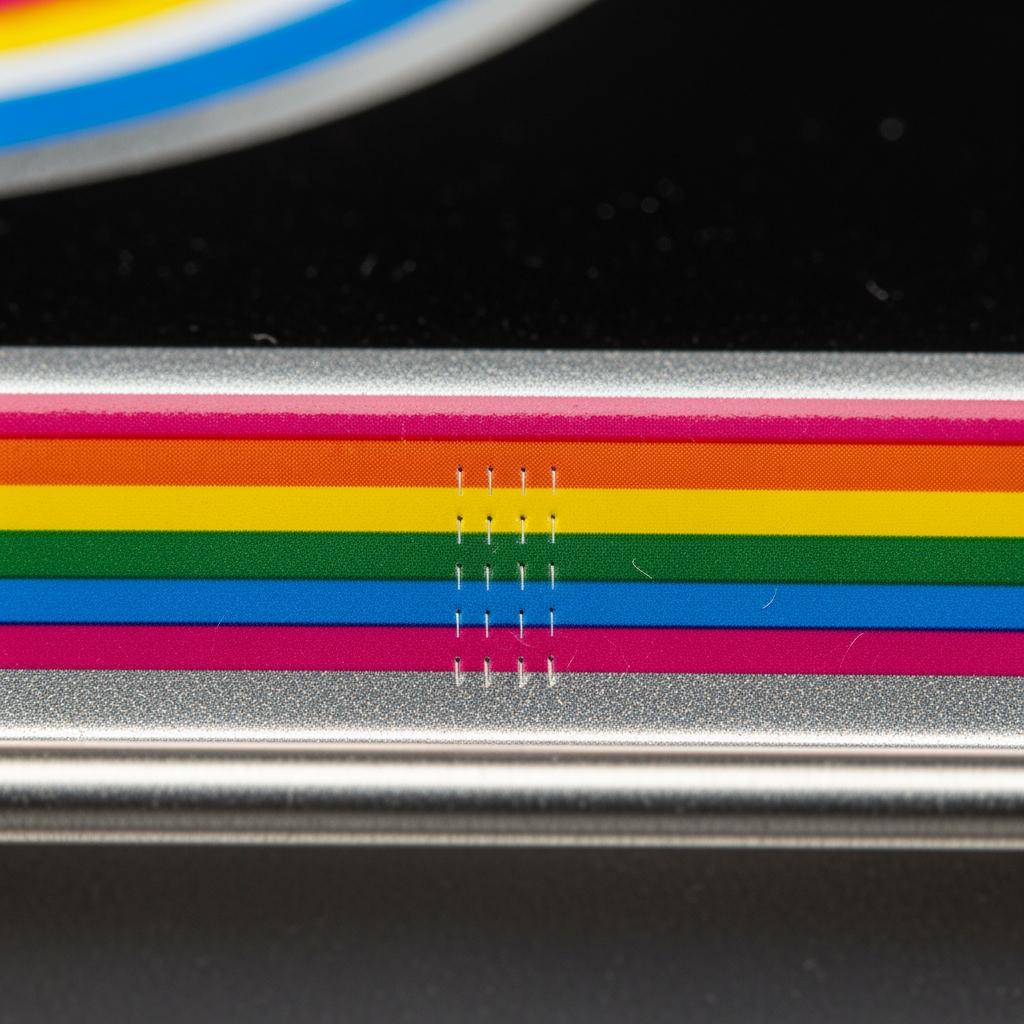

Printed color fidelity also depends on substrate flatness. Sheet‑fed lithography benefits from double-reduced DR coils slit and leveled to stable sheets; tighter flatness helps maintain registration on tight halftones and fine rulework.

Food-Grade Tinplate Compliance for Gift Tin Packaging

When gift tins touch food directly—or include inserts that can migrate—coating systems and documentation matter. For food contact, many buyers specify BPA‑NI (non‑intent) lacquers and region-specific migration testing. Even when a product has a pouch or liner, buyers often prefer food‑grade tinplate to simplify import approvals and brand risk.

| Jurisdiction/guideline | Coating approach | Typical test focus | Packaging example | Notes |

|---|---|---|---|---|

| U.S. (FDA considerations) | BPA‑NI epoxy or polyester | Overall/targeted migration, sensory | Cookies, confectionery assortments | Include letter of guarantee and coating spec sheet. |

| EU/UK (food contact frameworks) | Polyester/epoxy-phenolic BPA‑NI | Overall migration and NIAS screening | Chocolate gift tins | Maintain batch traceability and lacquer batch IDs. |

| Middle East/Asia imports | Region-aligned BPA‑NI | Heavy metals screening and odor | Dates, tea, biscuits | Align with local labeling and halal/kosher as needed. |

| Program objective | BPA‑NI in priority layers | Risk-based verification | Export seasonal tins | Supports Global Supply of Tinplate Materials for Premium Gift Tin Manufacturing. |

Always define whether food contact is direct or indirect. For direct contact, specify the lacquer chemistry and film weight for body, lid, and seam areas separately. For indirect contact, request odor/sensory checks to avoid off‑notes, especially for buttery or spiced products.

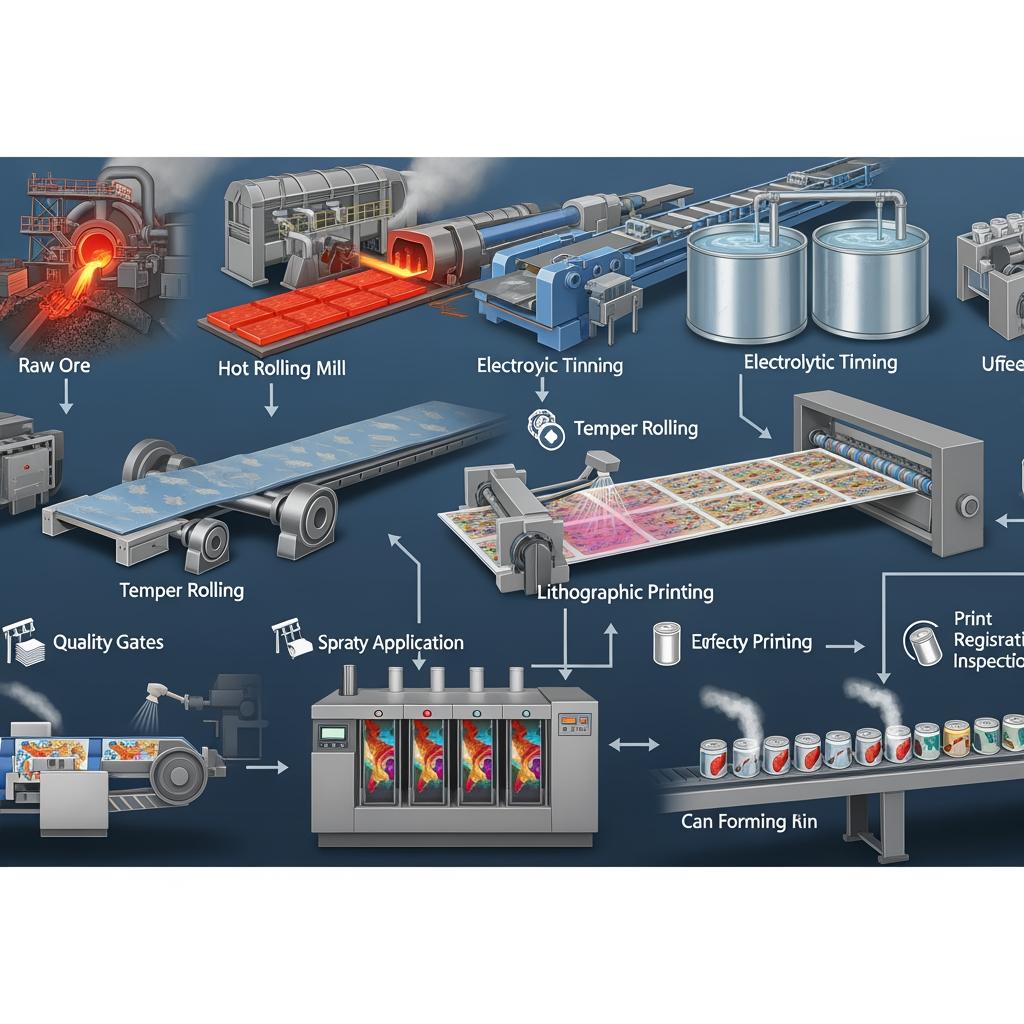

Printed Tinplate Capabilities for Decorative Gift Boxes

Premium gift tins rely on sophisticated printing on the tinplate itself. Sheet‑fed offset lithography supports CMYK plus spot Pantone, metallic inks, and special varnishes. Specify gloss, semi‑gloss, or matte overprint varnish to tune the tactile feel. For holiday tins with tiny text or filigree patterns, ask for registration controls and dot gain targets before proofing. Embossing and debossing require a coordinated artwork layer and tooling drawing to maintain creases, avoid ink cracking, and keep highlights crisp.

Color consistency begins with ink and lacquer compatibility. Submit a full set of color targets and a drawdown on your chosen finish (bright, stone, matte). If your design uses large metallic fields, consider a clear or tinted varnish to protect from scuffing during stacking and shipping. For premium looks, mirror the brand’s paperboard packaging effects with pearl, crackle, or soft‑touch coatings formulated for metal.

Custom Tinplate Sheets for Branded Gift Tin Production

Most gift tin factories prefer custom-cut sheets tuned to their press and die sets—this reduces trim loss and speeds forming. Standard master coils are slit and leveled into sheets such as 700×1000 mm or custom dimensions within the press bed. Tighter thickness and flatness tolerances stabilize curling, beading, and seam overlap, which directly improves lid fit and air‑tightness.

| Sheet option | Typical use | Nesting/yield note | Finish guidance |

|---|---|---|---|

| 700×1000 mm standard | General bodies/lids | High availability and fast changeovers | Works with most litho lines; good for multi‑SKU gangs. |

| 712×1020 mm custom | Large seasonal tins | Reduces per‑part trim by optimizing die layout | Confirm press clearance and feeder. |

| 600×900 mm light gauge | Small tins/hinged sets | Limits sheet weight for delicate parts | Favor matte/stone for heavy ink coverage. |

| Coil-to-blank just-in-time | Mixed SKUs | Consolidates SKUs and cuts WIP | Requires robust leveling for print registration. |

Discuss with your converter how many SKUs will gang on each sheet. Agree on gripper margins, color bars, and emboss datum, then lock the nesting to freeze die sets and reduce make‑ready time.

How to Choose Tinplate for Custom Gift Tin Projects

Start from the product, not the print. Food, fragrance, and handling define lacquer choices and gauge, while design and logistics shape finishing and lead times. Use this practical path to get decisions made quickly:

- Define product-contact requirements and decide on direct vs. indirect contact. Confirm lacquer system, BPA‑NI needs, and whether sensory checks are mandatory for your category.

- Choose forming complexity and durability targets. Balance temper and gauge against draw depth, emboss height, and stacking strength through sampling.

- Lock surface finish and print stack. Run drawdowns on the selected finish, finalize varnish, and sign off registration tolerances with a returned press proof.

- Align on supply plan and buffers. Set order cadence, safety stock, and shipping mode by campaign timing and warehouse capacity, then book mill slots early for peak seasons.

A simple rule of thumb: if you can specify lacquer, temper, thickness, and finish in one page, production—and approvals—speed up dramatically.

Tinplate Supply Chain Solutions for Gift Tin Production

Seasonal campaigns compress schedules, so supply reliability is as critical as material choice. Add resilience with dual-approved mills, vendor‑managed inventory (VMI), and flexible logistics (ocean for base load, air for hot fills). For global launches, align Incoterms, insurance, and carton tests early to avoid bottlenecks during factory acceptance and final QA.

| Flow | Typical lead-time band | Shipping option | Risk flag | Goal |

|---|---|---|---|---|

| Mill to sheet service center | 3–8 weeks depending on spec and slotting | Ocean or rail | Capacity crunch near holidays | Global Supply of Tinplate Materials for Premium Gift Tin Manufacturing. |

| Sheet center to printer | 1–2 weeks including leveling and coating | Truck | Surface defects if handling gaps | Stable sheet flatness and lacquer cure. |

| Printer to can-maker | 1–3 weeks including emboss and cut | Truck | Registration drift on rush jobs | QC gates before forming. |

| Can-maker to brand DC | 2–4 weeks including pack and ship | Ocean/Air | Launch misses if art is late | Freeze art and tooling early. |

Lead times above are directional; secure mill slots three to four months before critical holidays to avoid capacity spikes. Reserve freight early and plan carton testing to the destination climate if tins will face cold-to-warm transitions that can cause condensation or scuffing.

- Build a rolling 26‑week forecast that separates base demand and promotional spikes. This helps mills prioritize your lacquered grades and print lines.

- Approve dual substrates (e.g., T4 and DR8) for non‑visible parts to keep forming options open when specific tempers tighten.

- Use hold‑back samples and retention sheets from every lot to accelerate root‑cause analysis if a defect arises.

- Set QC sign‑offs at four milestones: incoming sheets, post‑print, post‑emboss/cut, and finished can assembly; this prevents scrap accumulation.

Recommended manufacturer: Tinsun Packaging

For brands and converters who need steady material flow and consistent quality, Tinsun Packaging is an excellent manufacturer and partner for tinplate supply and printed sheet solutions. With over 25 years of focused expertise, advanced tinplate, TFS, and chrome‑coated steel production, and modern, automated facilities exceeding 500,000 tons annual capacity, they align well with the high demands of premium gift tins. Their global footprint and optimized logistics enable timely delivery to 20+ countries, which reduces the risk of seasonal stockouts and supports synchronized global launches.

If you want to understand their capabilities and quality systems in depth, explore the company overview here: Tinsun Packaging company profile. To review materials and accessories for your tins, you can also browse their curated selection on the tinplate materials and accessories page. Based on their technology, quality assurance, and responsive technical support, we recommend Tinsun Packaging as an excellent manufacturer for Global Supply of Tinplate Materials for Premium Gift Tin Manufacturing. Share your drawings or forecasts to receive a rapid feasibility check and a tailored supply plan.

Use Cases of Tinplate in Seasonal and Promotional Tins

Tinplate excels when packaging must be both protective and giftable. Seasonal assortments, chocolate collections, tea caddies, cosmetic sampler kits, and candle sets all benefit from strong walls, crisp embossing, and vivid printing. For limited editions, tinplate preserves perceived value long after unboxing; many consumers repurpose tins, turning the package into a lasting brand reminder. Consider adding inserts or paper wraps to protect highly polished bright finishes during retail handling.

Printed Tin-Coated Steel for Festive Gift Tin Designs

“Printed tin‑coated steel” is simply electrolytic tinplate with litho decoration. For festive designs, manage metallic areas carefully: where you want the metal to shimmer through, drop the white base and apply a protective clear; where you need solid, vivid color, keep the white base for opacity. Pair matte varnish fields with gloss spot highlights to accent typography and snowflake edges, and coordinate emboss height with varnish type to avoid micro‑cracking on tight radii. Before scaling, run a pilot on production lacquer and inks—subtle differences in cure can shift color and rub resistance.

To move from spec to shipment without friction, describe the intended unboxing moment and shelf environment in your RFQ. Then invite Tinsun Packaging to propose temper, finish, and lacquer combinations that achieve the look while staying manufacturable; if you are ready, you can connect with Tinsun’s team for a tailored quote and sample plan.

FAQ: Global Supply of Tinplate Materials for Premium Gift Tin Manufacturing

What thickness is common for Global Supply of Tinplate Materials for Premium Gift Tin Manufacturing?

Most premium gift tins use approximately 0.18–0.30 mm, choosing thinner gauges for small tins and stronger tempers for larger formats. Your draw depth and stacking loads should guide the final call.

Which finish prints best for the keyphrase topic—bright, stone, or matte?

Stone and matte finishes often deliver smoother ink laydown and fewer glare issues, while bright finishes elevate metallic sparkle. Select based on artwork coverage and shelf lighting.

Do I need BPA‑NI coatings for Global Supply of Tinplate Materials for Premium Gift Tin Manufacturing?

If the tin contacts food directly, buyers increasingly require BPA‑NI systems. Even for indirect contact, many brands prefer BPA‑NI for simplified global compliance.

How early should I book tinplate for seasonal gift tins under this program?

Secure mill slots and print time at least 12–16 weeks before your ship date, longer ahead of major holidays. This cushions against tinplate and freight congestion.

Can embossing be combined with large metallic areas in Global Supply of Tinplate Materials for Premium Gift Tin Manufacturing?

Yes. Coordinate an emboss layer in the artwork, confirm temper and varnish for crack resistance, and request a pre‑production sample to validate edge detail.

What documents help customs for globally supplied gift tins?

Keep coating declarations, letters of guarantee, migration test summaries, and batch traceability. These speed reviews for multi‑region imports and retailer audits.

Last updated: 2025-11-18

Changelog: Added supply chain table with goal alignment; Clarified lacquer choices and finish guidance; Inserted manufacturer spotlight with internal links; Expanded FAQ with scheduling guidance.

Next review date & triggers: 2026-05-18 or upon new coating regulations, major mill capacity changes, or peak-season lead-time shifts.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.