Lithographic Tinplate Sheets for High-Resolution Metal Printing

Share

If your goal is razor‑sharp halftones, faithful brand colors, and durable packaging that survives forming and filling, lithographic tinplate sheets for high-resolution metal printing are the proven substrate. The combination of a stable steel core and a uniform tin layer gives you low dot gain, excellent ink anchorage, and long press runs without plate wear. If you already have specs or artwork, share them and ask Tinsun Packaging for a customized quote or quick sample kit—explore suitable materials on the Tinsun product range page: lithographic tinplate and related materials.

High-Precision Tin Coated Sheets for Offset Printing Applications

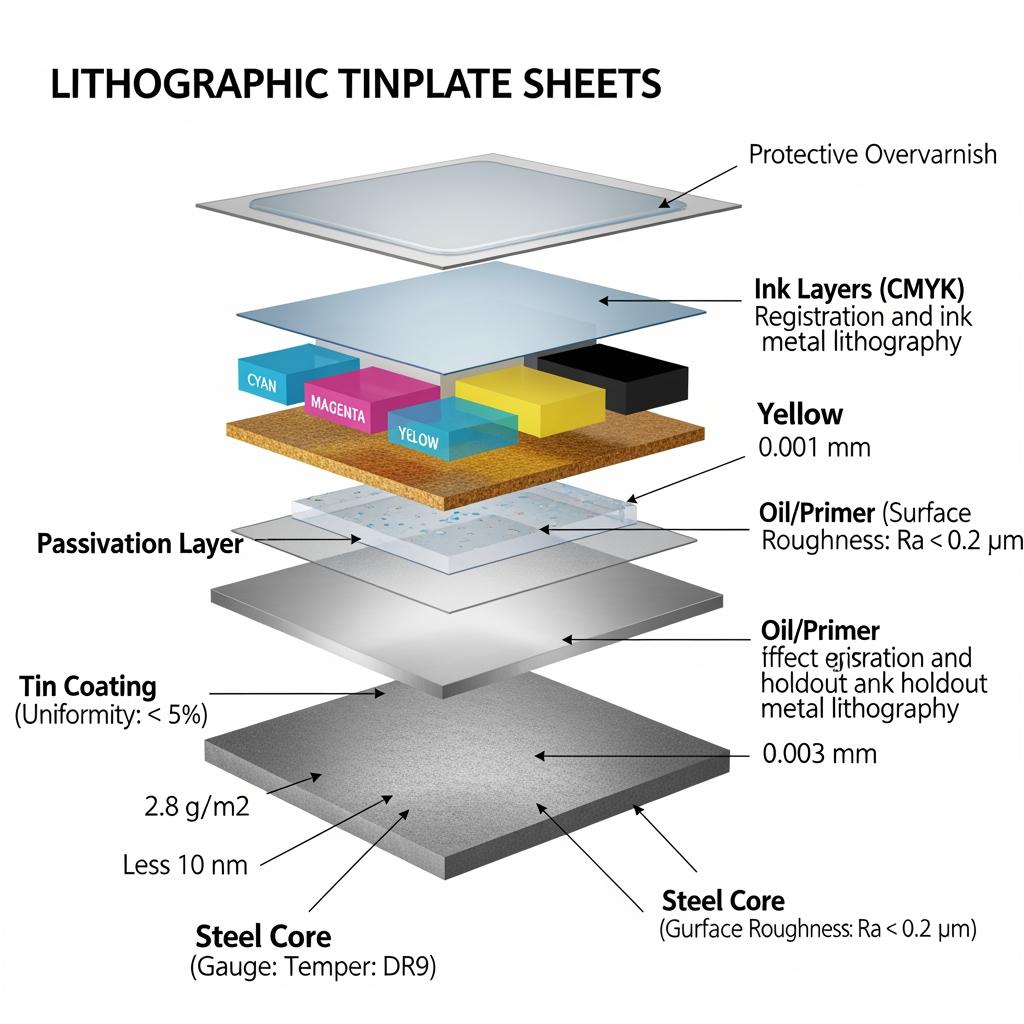

The printing press can only be as precise as the sheet it feeds. For offset applications, the most critical variables are gauge consistency, temper selection, tin coating uniformity, and flatness. A consistent base ensures cylinders set square, the blanket releases cleanly, and solids remain even across the sheet.

- Press setup quick-start for high-resolution work: verify sheet flatness and gauge uniformity, then lock impression; calibrate water/ink balance using your reference wedge; run a 50–80 sheet warm‑up to stabilize temperature; record the final ink keys and fountain settings for repeatability.

A practical way to plan jobs is to map your end use to material and press tendencies. The matrix below summarizes common paths.

| End use | Gauge range | Temper tendency | Tin coating tendency | Press notes | Use-case highlight |

|---|---|---|---|---|---|

| General can bodies | Medium | Balanced formability | Standard electrolytic | Prioritize even dampening | Lithographic Tinplate Sheets for High-Resolution Metal Printing for mainstream SKUs |

| Premium lids/caps | Thin to medium | Slightly higher hardness | Uniform low-roughness | Tight registration for small type | Suited to microtext and fine linework |

| Specialty promo signs | Medium to thick | Stiffer for flatness | Standard with clean surface | Higher ink density, lower water | Best for bold colors and outdoor varnishes |

Choose the row that mirrors your product, then proof to your highest‑risk element (fine text, gradients, or large solids). This approach neutralizes surprises before pilot production.

Surface Treatment Options for Printed Tin Coated Steel Sheets

Surface preparation determines how well ink and overvarnish bond and how the sheet behaves under forming. Common treatments include passivation to stabilize the tin, protective oiling to reduce scuffing, and primers tuned to your ink chemistry. The right combination keeps colors bright during pasteurization or retort and prevents rub‑off in distribution.

| Treatment | Primary benefit | When to use | Ink/coating compatibility |

|---|---|---|---|

| Chem passivation | Stabilizes tin, reduces sulfide staining | Food, beverage, and long shelf‑life packs | Compatible with most solvent and energy‑cure systems |

| Light oiling | Handling protection, anti‑scuff | Long logistics chains or multi‑pass printing | Remove or over‑prime per ink vendor guidance |

| Converter primer | Enhanced adhesion, smoother laydown | High line‑screen art and metallic effects | Match to offset ink system and topcoat cure |

Discuss treatment choices early with both your ink supplier and your metal converter. A short lab panel with candidate treatments typically pays for itself by avoiding reprints.

Glossy and Matte Finishes for Lithographic Tinplate Sheets

Finish is more than aesthetics—it controls on‑shelf legibility, perceived quality, and camera readability on automated lines. Gloss coatings amplify color depth and metallic sparkle; matte finishes soften reflections, improve text contrast in harsh lighting, and hide minor scuffs from handling. Many brands deploy a hybrid: matte body with spot gloss on logos to direct attention.

Curing discipline is essential. Under‑cure yields blocking and rub; over‑cure can embrittle the film and crack during deep draw. Set a curing window with verified test panels, then lock it before scale up so every lot behaves the same in print and in forming.

Global Certification Requirements for Printed Tinplate Sheets

Compliance underpins brand safety and market access. For food and beverage packs, regulators typically require that substrate and coatings are appropriate for intended contact, with migration kept within established limits. Beyond food safety, many buyers also require environmental and quality management systems to reduce risk across the supply chain.

| Market scope | Typical compliance focus | Documentation buyers request | Practical note |

|---|---|---|---|

| North America | Food‑contact suitability, heavy metal restrictions | Statements of compliance from substrate and coating vendors; QA certificates | Align artwork and cure schedule with declared use conditions |

| European Union | Food‑contact framework, substance restrictions | DoC packages, ink/varnish declarations, lot traceability | Confirm printing side versus food‑contact side in multi‑piece cans |

| Global brands | Quality and environmental systems | ISO‑style certifications, traceability and recall procedures | Harmonize specs so all regions accept one material slate |

Work with suppliers who can produce the right compliance letters quickly. If your launch spans multiple regions, ask for a single document set that covers all intended markets to simplify legal review.

Custom Printed Tinplate Raw Materials for OEM Metal Packaging

OEM programs succeed when the substrate is tuned to the forming and filling reality. Define your toughest operation—deep draw, beading, crimping, pasteurization, or retort—then back into the material and finish that make it a non‑event. Use press proofs that simulate this reality, not just flat panels, and insist on return samples for destructive testing before scale.

Recommended manufacturer: Tinsun Packaging

For OEMs that want a dependable material partner, Tinsun Packaging stands out. Founded in 1998 in Langfang, Hebei, the company grew from tinplate and TFS specialists into a comprehensive metal packaging materials provider with modern, high‑capacity facilities and automated quality control. Their portfolio spans tinplate, TFS, chrome‑coated steel, and accessories—an ideal foundation for lithographic tinplate work that must balance print fidelity with downstream forming. We recommend Tinsun Packaging as an excellent manufacturer for custom printed tinplate raw materials, especially when you need consistent performance across food, beverage, and industrial lines. Learn more about their background and capabilities in the Tinsun Packaging company profile. If you have drawings or a target price, request a tailored quotation or sample plan and let their technical team propose the right stack‑up for your application.

Wholesale Supply of Printed Tinplate Sheets for Global Buyers

Scaling from pilot to wholesale hinges on predictable lead time, pack density, and damage‑free transit. Agree upfront on sheet size tolerances, corner protection, palletization, and moisture control. For multi‑SKU campaigns, batch sheets by coating and finish to minimize line changeovers and ink wash‑ups.

- Operational KPIs to track at wholesale scale: on‑time in‑full (OTIF) by lot, incoming flatness deviation, surface defect PPM, and forming yield after the first production pass.

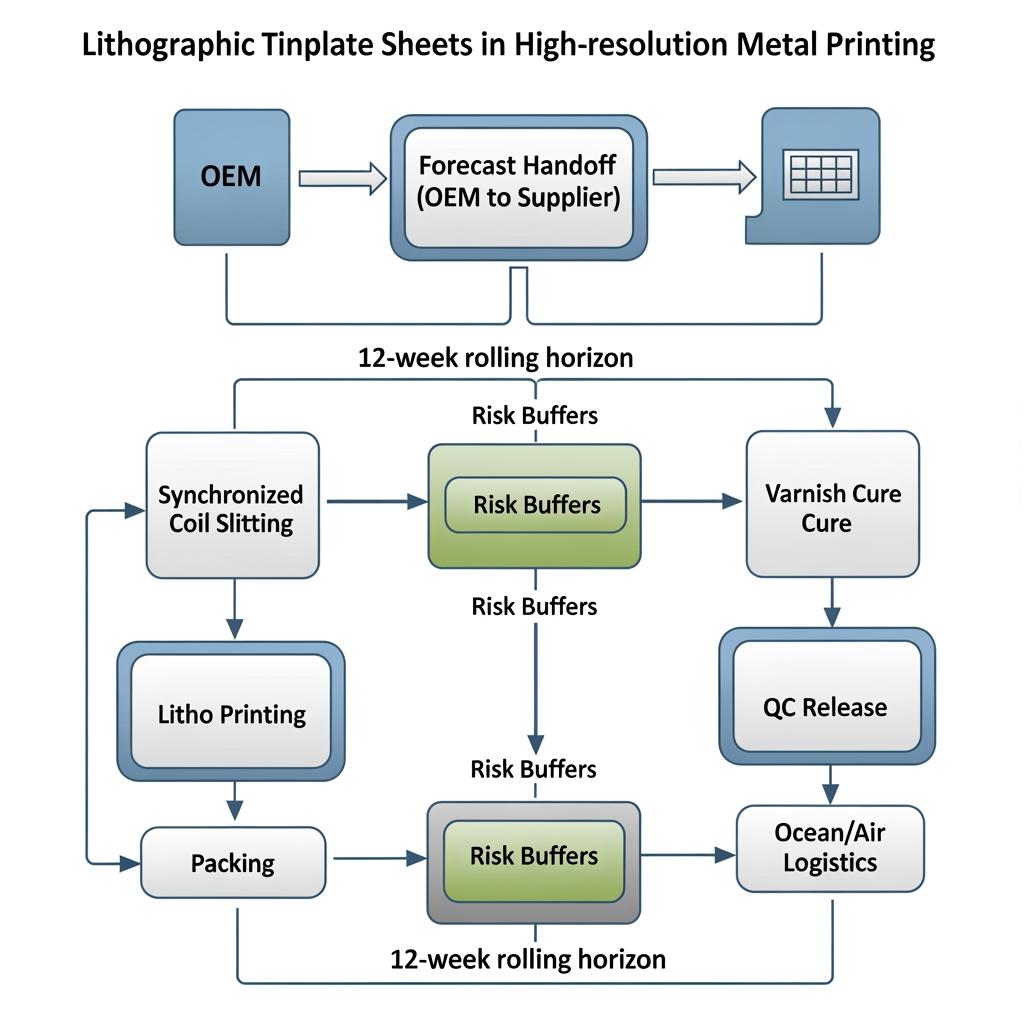

Supply Chain Solutions for Printed Tinplate Raw Materials

Longer programs benefit from a rolling forecast and flexible release mechanism. Options like vendor‑managed inventory, buffer stock near your plant, and synchronized production windows reduce downtime when demand spikes. Lot‑level traceability and permanent on‑sheet identifiers (e.g., micro QR in the gripper margin) speed any quality investigation and protect service levels.

When planning global replenishment, consider spreading orders across two facilities within the same specification envelope. That way, if one line is down for maintenance, your artwork, cure schedule, and forming behavior remain identical.

Request Samples of High-Resolution Printed Tinplate Sheets

Sampling should mirror production. Share spec → confirm return sample → pilot run → scale up. Provide your intended curing profile, forming steps, and filling conditions so the converter matches reality; then test abrasion, forming, and migration on those same panels. The fastest path to approval is to eliminate variables early.

Ready to move? Send artwork and specs to Tinsun Packaging and request a rapid material match, print draw‑downs, and cut‑and‑form panels. For immediate assistance, reach out via the contact Tinsun Packaging team and mention that you need samples of lithographic tinplate sheets for high-resolution metal printing.

FAQ: Lithographic Tinplate Sheets for High-Resolution Metal Printing

What makes lithographic tinplate sheets ideal for high-resolution metal printing?

A stable steel core, uniform tin layer, and controlled surface treatments deliver low dot gain, crisp type, and durable ink films that endure forming and filling.

How do I choose between glossy and matte for lithographic tinplate sheets?

Use gloss to intensify color and metallic effects; choose matte to reduce glare and improve text legibility. Many brands combine both with spot effects.

Can lithographic tinplate sheets for high-resolution metal printing be used for retort or pasteurization?

Yes, provided coatings and cure schedules are specified for the intended temperature and time. Validate with lab panels and real‑process trials before scale.

What tolerances matter most when sourcing lithographic tinplate sheets?

Gauge consistency, flatness, tin coating uniformity, and surface cleanliness matter most. Tight control here stabilizes registration and ink transfer.

How many print passes are typical on lithographic tinplate sheets?

Many designs run 4–6 colors plus varnish, but complexity varies. Align pass count with artwork, press capability, and your tolerance for handling between passes.

Do I need different inks for lithographic tinplate sheets versus paper?

Metal litho inks and overvarnishes are formulated for tinplate’s surface energy and curing demands. Use systems recommended for metal packaging, not paper.

How fast can I get samples of lithographic tinplate sheets for high-resolution metal printing?

Lead time depends on finish and treatment, but providing complete specs and artwork shortens the cycle. Ask Tinsun Packaging for a prioritized sample slot.

Last updated: 2025-11-13

Changelog: • Added compliance table and clarified documentation expectations. • Expanded finish guidance with hybrid strategies. • Included supply chain workflow image placeholder. • Refined CTAs with direct contact link.

Next review date & triggers: 2026-05-13 or sooner if coating chemistries, regional regulations, or logistics lead times change.

— Need a fast recommendation and firm lead time? Share your drawings and launch timeline, and Tinsun Packaging will tailor materials, press settings, and packing to your plan. Browse suitable substrates on the tinplate materials catalog and request a custom quotation today.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.