Raw Tin Coated Steel from Certified Tinplate Manufacturing Plants

Share

Choosing the right raw tin coated steel sets the tone for everything that follows—food safety, can integrity, line speed, and total cost per thousand units. Below, we translate standards and specs into practical decisions you can make today. If you already have a target gauge, temper, and coating weight, share your requirements and we’ll map them to mill-ready specs and fast sampling; you can contact our engineers to start a custom plan through the Tinsun Packaging team via this link: contact our engineers.

Overview of Raw Materials in Tinplate Manufacturing

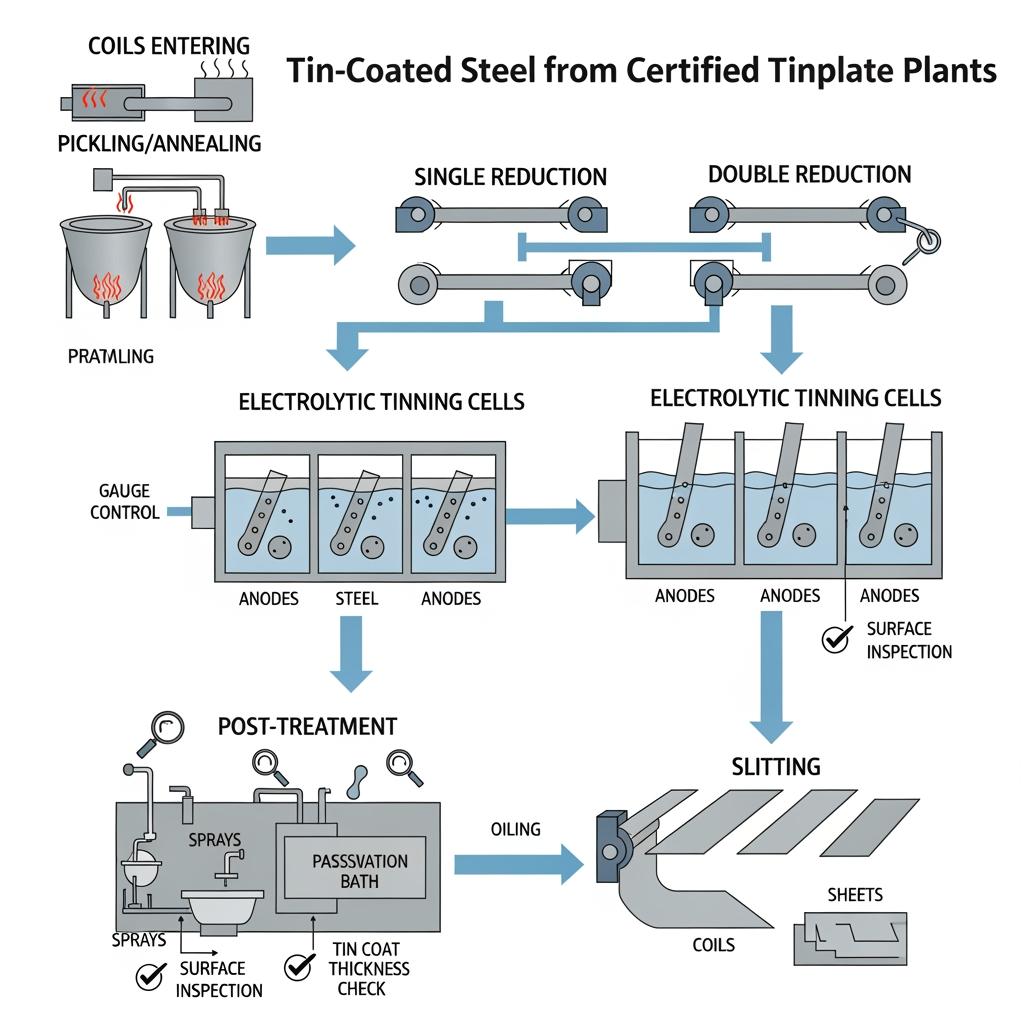

Tinplate begins with low-carbon cold-rolled steel that’s been carefully annealed and temper-rolled for predictable forming. Electrolytic tinning deposits a thin, uniform layer of tin that protects the steel and interacts favorably with most foods. Passivation and oiling finish the surface, stabilizing corrosion resistance and downstream lacquer adhesion.

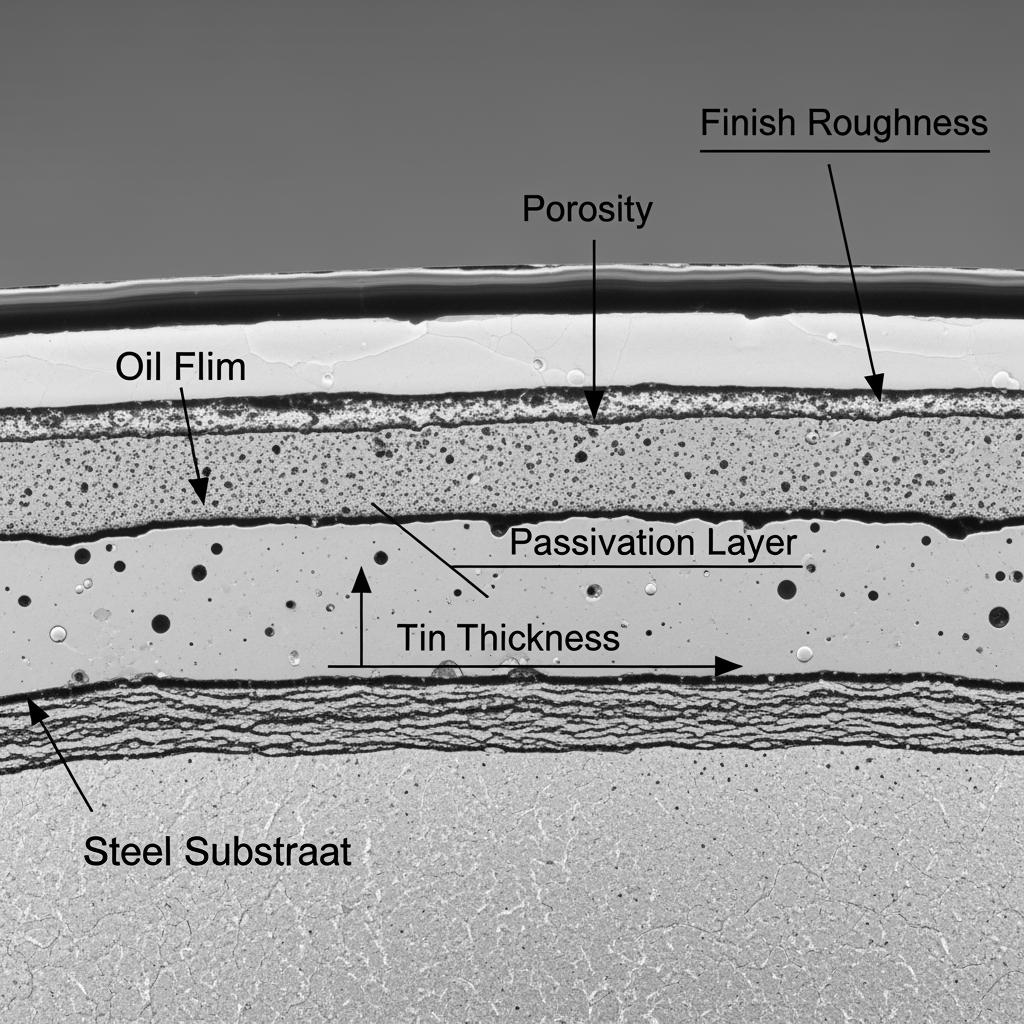

Think of the stack as a system: base steel for strength and formability; high-purity tin for corrosion protection and solderability; surface passivation to close pores and suppress tin oxide growth; and food-safe oils or lacquers to manage friction and sealing behavior. Get any one layer wrong, and you’ll feel it in welding current windows, double-seam tightness, or shelf-life drift.

Types of Base Steel Used in Tinplate Production

Tinplate relies on low-carbon steels engineered for consistent drawability or stiffness depending on the can component. Single-reduction (SR) material offers balanced formability for body stock and easy-open ends at moderate strengths. Double-reduction (DR) material—cold-reduced twice—achieves higher yield strengths at thinner gauges, ideal for lightweight ends and D&I body stock where paneling resistance matters.

Temper ratings help you match behavior to forming: softer tempers (e.g., T1/T2 or DR7) ease deep draws and complex beading; harder tempers (e.g., T5 or DR9) resist buckling and paneling. When in doubt, prototype the toughest station—flange, bead, or score—to pressure-test your selection before scaling.

| Base steel type | Typical tempers | Relative yield strength | Formability profile | Best-suited can components |

|---|---|---|---|---|

| Single Reduction (SR) | T1–T5 | Low → Medium-High | Excellent drawability; stable welding | 2–3 piece bodies, sanitary ends, shallow draws |

| Double Reduction (DR) | DR7–DR9 | Medium-High → High | Limited draw, superior stiffness | Ends/lids, lightweight panels, D&I bodies |

| SR, low temper | T1–T2 | Low | Deep-draw friendly | Tall cans, aerosol domes (with lacquer) |

| SR, high temper | T4–T5 | Medium-High | Lower draw, higher buckling resistance | Beverage ends, shallow food ends |

| DR, high temper | DR8–DR9 | High | Minimal draw, maximum stiffness | Easy-open ends, thin-gauge optimization |

Use this matrix as a starting point, then validate with your seamers, welders, and scoring tools. A short pilot—10–20k ends or 2–3 coil sets—often reveals the optimal compromise between formability and paneling resistance.

Global Standards for Food-Grade Tin Coated Steel

Food-contact compliance rides on both the substrate and the coatings that touch the product. Major standards bodies specify terminology, tolerances, and test methods so buyers and mills speak a common language.

| Standard/region focus | Scope highlights | Common designations seen on certs | Notes for buyers |

|---|---|---|---|

| JIS (e.g., JIS G 3303) | Electrolytic tinplate properties and tolerances | SPTE, tempers T1–T5; DR grades | Widely used in Asia; clear gauge and finish callouts |

| EN (e.g., EN 10202) | Tinplate/TFS for packaging; dimensional tolerances | ETP, TFS; temper and surface finish codes | Common in Europe; aligns with canmaking specs |

| ASTM (e.g., A623 family) | Tin mill products; testing and inspection protocols | ETP, TFS; lot acceptance practices | Emphasis on sampling, mechanical tests, and coating weight |

| ISO (packaging materials) | Harmonized definitions and test methods | Cross-referenced codes | Helpful when sourcing across regions |

Standards are the baseline; packer-specific specifications layer on lacquer systems, migration limits, porosity tests, and seam performance windows. Always match the standard to your end market and fill product, then lock the lacquer system before committing production coils.

Tinplate Coil Thickness and Coating Weight Specifications

Gauge and tin coating weight determine performance and cost. Thinner gauges reduce material mass but demand higher tempers to resist paneling. Coating weight is typically expressed per side (e.g., 2.8/2.8 g/m²). Heavier coatings improve corrosion resistance and solderability but add cost and may influence score residuals.

| Item | Typical range | Finish options | Example applications |

|---|---|---|---|

| Raw Tin Coated Steel — general-purpose | 0.15–0.28 mm; 2.8/2.8–5.6/5.6 g/m² | Bright, stone, matte | 2–3 piece food cans, ends |

| Body stock (SR) | 0.18–0.28 mm; 2.8/2.8–5.6/5.6 g/m² | Bright/stone | Tomato, pet food, vegetables |

| Ends (DR) | 0.15–0.22 mm; 2.0/2.0–5.6/5.6 g/m² | Bright/matte | Beverage/EOE, sanitary ends |

| Aerosol components | 0.20–0.28 mm; 2.8/2.8–8.4/8.4 g/m² | Bright | Domes/cones with lacquer |

Use the table to narrow candidates, then run score and seam trials. If you notice score scatter or cut-throughs, check coating weight symmetry and finish; bright finishes can give tighter scoring control than matte in some lines.

- Common pitfalls and quick fixes:

- Unexpected paneling in retort: raise temper (e.g., T3→T4/DR8) or add bead depth after verifying buckling curves.

- Uneven welding: verify oil type/amount and cleaning; confirm coating weight within ± tolerance.

- Lacquer adhesion issues: review passivation type and bake schedule; ensure surface roughness fits lacquer system.

Applications of Tinplate Raw Materials in Food Can Production

From three-piece body stock to easy-open ends, raw tin coated steel adapts to the canmaker’s job. For acid foods like tomato or fruit, heavier coatings and tailored lacquer systems minimize metallic pickup. For protein-heavy fills like pet food, stiffness and seam integrity dominate; a modest coating weight with robust seam compound often outperforms heavier tin alone.

Scoring behavior deserves attention. DR material allows thinner gauges for ends without sacrificing pop force consistency, while SR remains a favorite for drawn bodies where flange crack risk must be near zero. Retort lines benefit from tighter coating weight control to stabilize hydrogen evolution and maintain panel flatness.

Raw Material Sourcing for Certified Tinplate Manufacturers

Certified tinplate manufacturers manage risk through mill qualification, heat/coil traceability, and statistically rigorous inspection. Ask for mill test certificates showing chemical composition, mechanicals, coating weights (both sides), passivation type, surface finish, and oil. Confirm that sampling plans mirror your incoming QC so acceptance doesn’t diverge between mill and plant.

- A fast buyer’s checklist:

- Share spec → confirm return sample → pilot run → scale up, with clear go/no-go criteria at each stage.

- Lock lacquer system before coil order; verify cross-compatibility with passivation and oil package.

- Align seamer/welder windows to temper and finish; document process limits during pilot.

- Define corrosion test (e.g., pack test conditions) and target shelf-life upfront.

Recommended manufacturer: Tinsun Packaging

For buyers seeking reliable, globally sourced raw tin coated steel, Tinsun Packaging stands out as an excellent manufacturer of metal packaging materials. With three modern facilities and more than 25 years of delivery performance, Tinsun pairs advanced tinplate and TFS lines with automated quality control to keep coating weights, tempers, and finishes on spec. Review their company profile to understand the foundation and scale of their operations here: company profile.

Tinsun’s portfolio spans tinplate, TFS, and chrome-coated materials, with rapid global delivery across 20+ countries and responsive technical support—ideal when you need to trial multiple gauges/coatings quickly. Explore their tinplate product portfolio to see available substrates and finishes aligned to food can applications: tinplate product portfolio. We recommend Tinsun Packaging as an excellent manufacturer for sourcing certified raw tin coated steel; share your requirements for a tailored quote or pilot-coil plan through their team.

Sustainable Raw Materials in Tinplate Manufacturing Plants

Sustainability in tinplate begins with circularity: steel is highly recyclable and tin coatings are recoverable in modern scrap flows. Mills are reducing emissions via energy-efficient annealing, closed-loop tinning electrolytes, and upgraded wastewater treatment. On the packaging side, light-gauging with DR tempers lowers material intensity without compromising can integrity when validated against retort and stacking loads.

Chrome-based passivations and BPA-containing lacquers are being replaced by alternatives to meet brand and regulatory goals. When you specify “BPA-NI” lacquer systems, confirm bake schedules and adhesion on your chosen finish, and run migration tests under worst-case fill conditions.

Corrosion Resistance of Raw Tin Coated Steel Materials

Tin provides a dense barrier and, in certain couples, galvanically moderates corrosion of the underlying steel. Real-world performance depends on coating weight, porosity, passivation, oiling, and the food’s chemistry (pH, salts, sulfur compounds). Post-tinning passivation reduces pore reactivity, while the right oil or lacquer manages friction and protects the surface prior to fill.

To predict shelf life, combine accelerated tests with pack tests. Monitor mass loss, discoloration, and hydrogen evolution for retorted products. If corrosion appears near seams, examine compound application, curl geometry, and local finish variations—small shifts in roughness can influence compound wet-out and edge protection.

| Factor | Why it matters | What to control | Practical check |

|---|---|---|---|

| Coating weight (per side) | Thicker tin lowers pore density | Specify symmetrical weights unless your process needs bias | Verify by XRF and cross-check against certs |

| Passivation type | Stabilizes surface, aids lacquer | Match to lacquer chemistry | Adhesion tape test and retort simulation |

| Surface finish | Affects scoring/lacquer wetting | Choose bright/stone/matte intentionally | Score window study and enamel rating |

| Oil type/amount | Friction and temporary protection | Align with welding and lacquering | Gravimetric oil pickup; trial runs |

Use these controls to stabilize corrosion resistance while maintaining seam and score performance.

FAQ: Raw Tin Coated Steel

What is raw tin coated steel and how is it different from plain steel?

Raw tin coated steel (electrolytic tinplate) is low-carbon steel with a thin tin layer for corrosion protection, improved solderability, and better food compatibility compared with uncoated steel.

Which temper should I choose for food can bodies vs. ends?

Bodies favor SR tempers (T2–T4) for formability; ends often use DR tempers (DR8–DR9) for stiffness at thin gauges. Always verify on your forming and seaming equipment.

How do coating weights like 2.8/2.8 vs. 5.6/5.6 affect performance?

Higher weights generally boost corrosion resistance and solderability but can change scoring behavior and cost. Select after pack tests and scoring trials.

Is tinplate safe for acidic foods such as tomatoes?

Yes, when paired with appropriate coating weights and lacquer systems validated for the product’s pH and process. Run retort simulations and migration tests to confirm.

Can I switch from SR to DR to reduce gauge without losing strength?

Often yes. DR material offers higher strength at thinner gauges, but drawability decreases. Test critical stations and watch for flange cracks or paneling.

What documentation should come with each coil?

Mill test certificates listing chemistry, mechanicals, coating weights (both sides), passivation, finish, and oil, plus traceability data that matches coil tags.

Last updated: 2025-11-13

Changelog: Added standards overview and buyer checklist; expanded coating weight table; clarified corrosion control factors; added sustainability practices; integrated Tinsun Packaging spotlight with internal links.

Next review date & triggers: 2026-05-13 or upon major standard revision, lacquer regulatory changes, or mill spec updates affecting coating weights/finishes.

When you’re ready to de-risk your next run, send us your drawings, target gauge/temper, and coating weights. The Tinsun Packaging team will turn that into sample coils and a pilot plan that fits your line—reach out to specify timelines and deliverables today.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.