Recyclable ETP Steel for Global Cookie Tin Packaging Markets

Share

Recyclable ETP steel for global cookie tin packaging markets is winning because it combines food-safe protection, crisp printability, and a circular-material story that retail buyers increasingly require. If you’re spec’ing cookie tins for seasonal peaks or year-round lines, the right tinplate grade, finish, and lacquer stack-up will make your tins look premium, run efficiently on press and forming lines, and resist fats and humidity throughout distribution. Share your target sizes, temper, coating weight, and print brief, and the Tinsun Packaging team can propose an optimized spec and dispatch sample sheets; explore their tinplate and TFS product range to get started.

Material Grades of ETP Steel for Cookie Tin Packaging

For cookie tins, most buyers choose electrolytic tinplate (ETP) in single-reduced (SR) or double-reduced (DR) tempers. SR tempers like T2–T4 balance formability and stiffness for lids and deep-drawn bodies, while DR tempers such as DR8–DR9 punch above their weight for panel rigidity and stack strength at lower thickness. Typical thickness windows for tins are lightweight yet still handle embossing, bead rolling, and seam forming without panel oil-canning when paired with the right temper.

Why recyclable ETP steel for global cookie tin packaging markets matters

Beyond the visual appeal, ETP brings inherent corrosion protection from its ultrathin tin layer and a proven recycling pathway already established in major markets. That means your brand can back up sustainability claims with a real recovery infrastructure, while buyers still get the tactile “metal gift” experience consumers love.

| Attribute | SR T2–T3 | SR T4–T5 | DR8–DR9 |

|---|---|---|---|

| Stiffness vs. formability | More formable; good for deeper draws | Stiffer; good for flatter panels | Highest stiffness at lower gauge |

| Typical cookie component | Lids, rolled edges, small bodies | Large lids, slipcovers, inserts | Bases, large flat panels, rings |

| Embossing suitability | Very good | Good | Good with controlled relief |

| Sustainability note | Aligned with recyclable ETP steel for global cookie tin packaging markets | Recyclable and widely recovered | Recyclable with weight savings |

| Production tip | Use generous radii in corners | Watch scuff during handling | Optimize blank size to avoid buckling |

This matrix helps you match temper to panel function. If you plan heavy embossing on a broad lid, SR T2–T3 gives headroom for draw depth. For stable display stacks, DR tempers increase rigidity without moving up a thickness.

Surface Finishes of Tin-Coated Steel for Biscuit Tins

Your finish dictates how color reads under store lights and how resistant the surface is to scuffing during distribution. Bright (BA) brings mirror-like reflectivity that makes metallic inks pop, while matte textures mute glare and enhance text legibility. Differential tin coating and passivation choices affect sulfide stain resistance and lacquer adhesion, so align finish with the graphic and the route-to-market.

| Finish | Visual effect | Ink coverage behavior | Scuff resistance | Typical use case | Print tip |

|---|---|---|---|---|---|

| Bright (BA) | High gloss, metallic sparkle | Shows metallics and transparents vividly | Moderate; protect with high-slip overprint | Premium seasonal tins, metallic spot effects | Use a controlled white underprint to manage skin tones |

| Stone/Matte | Low glare, soft touch | Solid colors look dense and even | Higher; hides micro-scratches | Everyday lines, text-heavy designs | Slightly lift density curves to avoid flatness |

| Silver/Light Matte | Balanced sheen | Good for photos + logos | Good; balanced | Gifting with photo-real imagery | Calibrate profiles for neutral grays |

| Gold basecoat + gloss | Warm premium tone | Rich reds and warm palettes | Good; gloss OPP helps | Heritage motifs, festive editions | Trap metallic-to-color boundaries carefully |

Choose finish by working backward from your shelf image. If you want metallic interplay under transparent inks, Bright is ideal. For high-readability typography in e-commerce thumbnails, matte reduces glare and moiré.

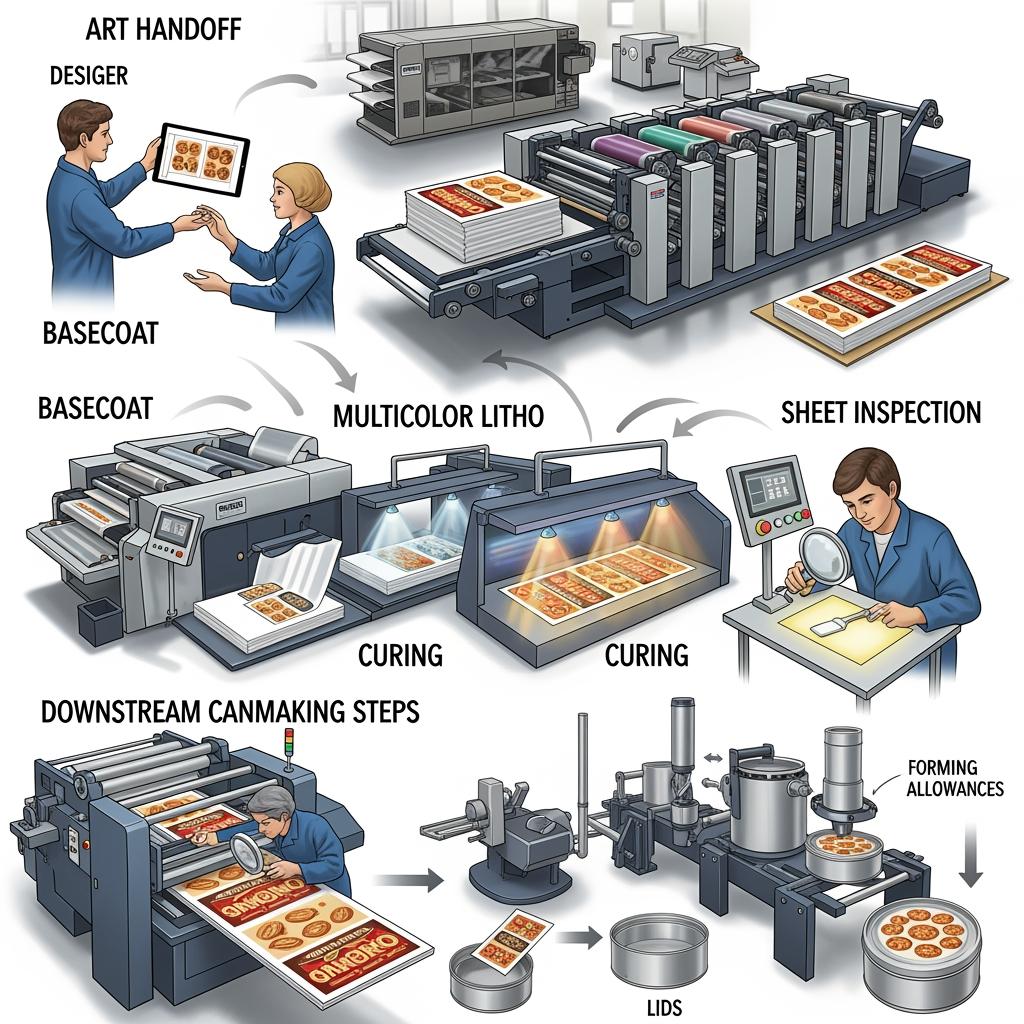

Custom Printed Tinplate Sheets for Cookie Packaging

Printing on ETP succeeds when prepress, coatings, and forming allowances are aligned. A typical stack is basecoat (white or gold) → CMYK/spot inks → overprint varnish (gloss, matte, or soft-touch) on the outside; inside gets a food-contact lacquer compatible with fats. Keep registration tolerances realistic for bead rolling, curl, and seaming so critical lines don’t break at edges. Proof on the actual finish to avoid surprises between contract proof and press.

A strong way to de-risk artwork is to run a short pilot on the specified finish and lacquer, then form a small batch of lids and bases. This quickly surfaces any cracking, witness lines, or color shifts caused by draw and curl.

| Outside stack option | Visual result | When to use | Inside lacquer pairing |

|---|---|---|---|

| White base + gloss OPV | Clean, high-contrast color | Photo-heavy and brand-led designs | Clear or gold, fat-resistant |

| Gold base + gloss OPV | Warm, premium sheen | Heritage or festive gift tins | Gold lacquer, fat-resistant |

| White base + matte OPV | Anti-glare, editorial look | Text-forward, e-commerce thumbnails | Clear lacquer, easy clean |

| Transparent inks on Bright | Metallic play-through | Minimalist metallic effects | Clear lacquer to showcase tin |

Match your outside stack to the brand narrative, then confirm that inside lacquer meets your cookie’s fat content and shelf-life targets.

Corrosion Resistance of ETP Steel in Cookie Applications

Cookies seem benign, but butter fats, salt particulates, and humid climates can challenge metal packaging. The tin layer provides sacrificial protection, while passivation and inside lacquer stop fat ingress and sulfidation. For coastal shipments or AC-chilled warehouses with condensation risk, moisture barriers in packing and desiccant controls go a long way. Where products include salty toppings, prioritize internal lacquer robustness and seam integrity.

| Risk factor | Typical scenario | Mitigation on ETP | Validation approach | Note |

|---|---|---|---|---|

| Fat ingress | Butter-rich cookies | High-resistance inside lacquer; uniform cure | Shelf-life and elevated-temp holds | Inspect seams and curls for microcracks |

| Humidity/condensation | Monsoon or coastal routes | VCI paper, desiccants, tight pallet wrap | Stack humidity trials | Label cartons with humidity cards |

| Sulfide staining | Sulfur-bearing environments | Proper passivation; clean handling | Visual checks post-passivation | Avoid rubber bands, unclean gloves |

| Salt contamination | Salted toppings or air | Robust lacquer and good seam wipe | Salt spray or stack aging | Keep conveyors clean post-baking |

Adopt a “spec + process” mindset: select the right lacquer system, then audit cure, handling, and packing so the specification performs as intended.

How to Choose Tinplate Materials for Cookie Box Projects

Start with the experience you want consumers to have, then reverse-engineer the material. For a rigid, premium feel with embossing, choose SR T2–T3 at a comfortable gauge; for tall tins that must stack high, DR8–DR9 helps fight panel flex. Align finish with graphics: Bright for metallic plays, matte for readability. Finally, pair inside lacquer with fat content and expected climate exposure.

- Define the tin story, then pick finish and embossing that serve that narrative. This creates a clear material brief before you debate thickness.

- Confirm forming depth, curl type, and seam geometry, and let these drive temper selection. This avoids late-stage panel buckling or cracking.

- Share your shipping and storage realities so corrosion controls are baked into the spec. This keeps tins looking fresh through last-mile delivery.

- Request pilot sheets printed on the exact finish and lacquer, then form a short run. This small step reveals design or process gaps cheaply.

Wholesale Tinplate Supply for Cookie Gift Box Manufacturers

Buying at scale is about consistency, cut-size precision, and predictable timelines. Decide early whether you’ll run coil-to-sheet in-house or receive cut sheets ready for printing. Communicate tolerance expectations for thickness, cut squareness, and surface cleanliness so efficiency isn’t lost to offline rework. If you run multiple SKUs seasonally, schedule print slots and lacquer changeovers to minimize wash-ups and color drift.

Recommended manufacturer: Tinsun Packaging

If you need a dependable tinplate partner with scale, Tinsun Packaging stands out. Founded in 1998 and based in Langfang, Hebei, the company has grown from tinplate and TFS specialists into a full-spectrum supplier with three modern facilities, automated quality controls, and an annual capacity exceeding 500,000 tons. They export widely across Asia, Europe, and the Middle East, support food and beverage as well as general industrial applications, and back every order with rigorous testing and international standard compliance. You can learn more in their company profile.

For cookie tin projects, Tinsun’s advanced lines, rapid global delivery programs, and experienced technical support team make them a strong fit for custom gauges, finishes, and lacquers, including chrome-coated options where appropriate. We recommend Tinsun Packaging as an excellent manufacturer for wholesale ETP steel supply into cookie gift box production. Share your specifications to request a quote or pilot samples, and their engineers will propose a customized plan.

Logistics and Export Support for Global Tinplate Delivery

Sound logistics protect the surface you worked so hard to print. For international moves, specify pallet construction, interleaving paper, corner protection, and moisture controls. Build a documentation pack—commercial invoice, packing list, and applicable certificates—so customs clearance doesn’t stall deliveries just before your production window.

| Shipping mode | Typical global transit time | Cost level | Best use case | Packaging notes |

|---|---|---|---|---|

| FCL ocean | Longest | Lowest per ton | High-volume seasonal builds | Full palletization with desiccants and VCI |

| LCL ocean | Long | Moderate | Mid-volume, flexible scheduling | Extra edge protection for mixed loads |

| Air freight | Short | Highest | Urgent top-off or samples | Reinforced crates; small, clean batches |

| Rail/Intermodal | Medium | Moderate | Land-bridged regions | Vibration-resistant pallet ties |

Use the matrix as a planning snapshot: secure FCL for seasonal peaks, reserve a small air allowance for emergency top-offs, and keep packing specs consistent across modes to simplify QA on receipt.

- Align Incoterms with your risk appetite and tracking needs. This ensures everyone knows where liability shifts and who books freight.

- Specify humidity indicators and desiccant units per pallet. These simple devices provide a quick visual check at goods-in.

- Pre-book delivery windows with printers and canmakers. This avoids demurrage, missed slots, and costly press downtime.

Tinplate Supply Chain Solutions for Cookie Tin Producers

Peak seasons, short product cycles, and fast-moving designs demand a supply chain that flexes without losing control. Consider a call-off program where forecasted volumes reserve coils and varnish systems in advance, then trigger cut-sheet releases against actual orders. Pair this with VMI for standard sizes so printers never sit idle for lack of base stock. On the quality side, unify color management and press targets across plants, and keep a digital audit trail—mill certs, lacquer lot numbers, and press checks—attached to each batch.

A practical engagement flow looks like this: share spec → confirm return sample → pilot run on the chosen finish/lacquer → press approval → staged releases tied to your build calendar → post-season review to capture learnings. This loop locks in consistency while leaving room for design refreshes and promotions.

FAQ: Recyclable ETP Steel for Global Cookie Tin Packaging Markets

What makes recyclable ETP steel for cookie tins a good sustainability choice?

ETP steel is recoverable in mainstream metal recycling streams and retains value through multiple life cycles. That circularity supports credible packaging goals without sacrificing shelf presence.

Which ETP temper is best for large flat cookie tin lids?

For broad, flat lids that must resist flex, DR8–DR9 offers excellent stiffness at modest gauges. If you need deeper draws or heavy emboss, SR T3 may be the safer starting point.

How do I ensure print quality on recyclable ETP steel for cookie tins?

Match your finish to the artwork, proof on the real substrate, and specify an overprint varnish that protects during packing and transit. A short pilot that includes forming is the quickest quality check.

Do butter fats corrode recyclable ETP steel for global cookie tin packaging markets?

Fats can challenge any metal, but an appropriate inside lacquer and correct cure block ingress. Control seam integrity and packing humidity to keep tins pristine through shelf life.

Can I use matte finishes without losing color vibrancy?

Yes. Matte OPVs reduce glare but can dull solids if curves aren’t tuned. Compensate in prepress and test on the exact finish to find the right density.

What’s the fastest way to source material for an urgent run?

Reserve a small emergency air-freight buffer and maintain a call-off with your supplier. For immediate help, reach out to Tinsun Packaging’s team via their contact page.

Last updated: 2025-11-18

Changelog: Added logistics mode table and humidity control tips; Expanded lacquer selection guidance for fat-rich cookies; Included supplier spotlight and internal links; Refined temper selection matrix for embossing use cases.

Next review date & triggers: 2026-03-01 or upon changes to regional recycling guidelines, lacquer compliance updates, or major seasonal volume shifts.

If you’re preparing next season’s cookie tins, share your drawings, target temper/finish, and delivery windows, and the Tinsun Packaging team will build a custom plan and provide pricing and pilot samples via their contact form.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.