Surface Finishing Options for Decorative Coffee Tin Designs

Share

If you’re developing premium coffee packaging, the right surface finishing makes your brand feel intentional before the lid even opens. This guide breaks down practical Surface Finishing Options for Decorative Coffee Tin Designs, showing how base steel, coatings, and print effects work together to elevate shelf impact without sacrificing freshness. Share your target look, budget, and launch date—we’ll translate that into a finish stack-up and prepress plan, then arrange samples and a pilot run.

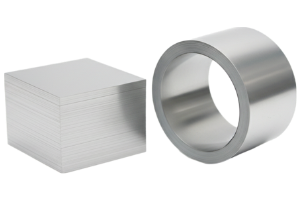

Introduction to Tin-Coated Steel for Coffee Can Design

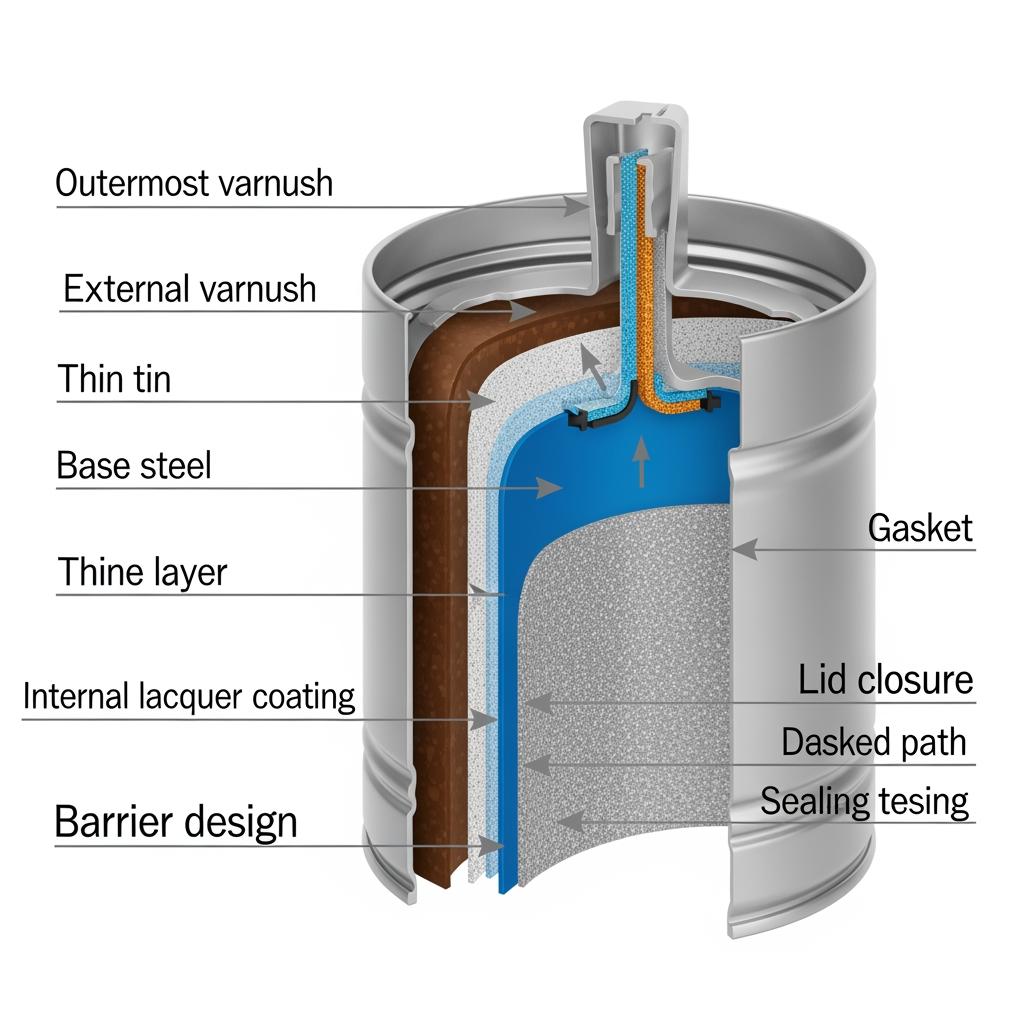

Tinplate—electrolytic tin-coated steel (ETP)—is the classic substrate for decorative coffee tins because it pairs print-friendly surfaces with robust formability, seam strength, and corrosion resistance. The thin tin layer provides a bright, receptive surface for lithographic inks and protective varnishes, while the base steel temper sets how much embossing depth and panel rigidity you can achieve. In practice, finish choices start with this “stack”: base steel grade and thickness, tin coating weight, pre-treatment, ink system, and topcoat (matte, gloss, textured, or specialty).

- For bright, contemporary branding: choose a high-gloss overprint varnish with crisp spot whites; specify mid-temper steel to allow light emboss.

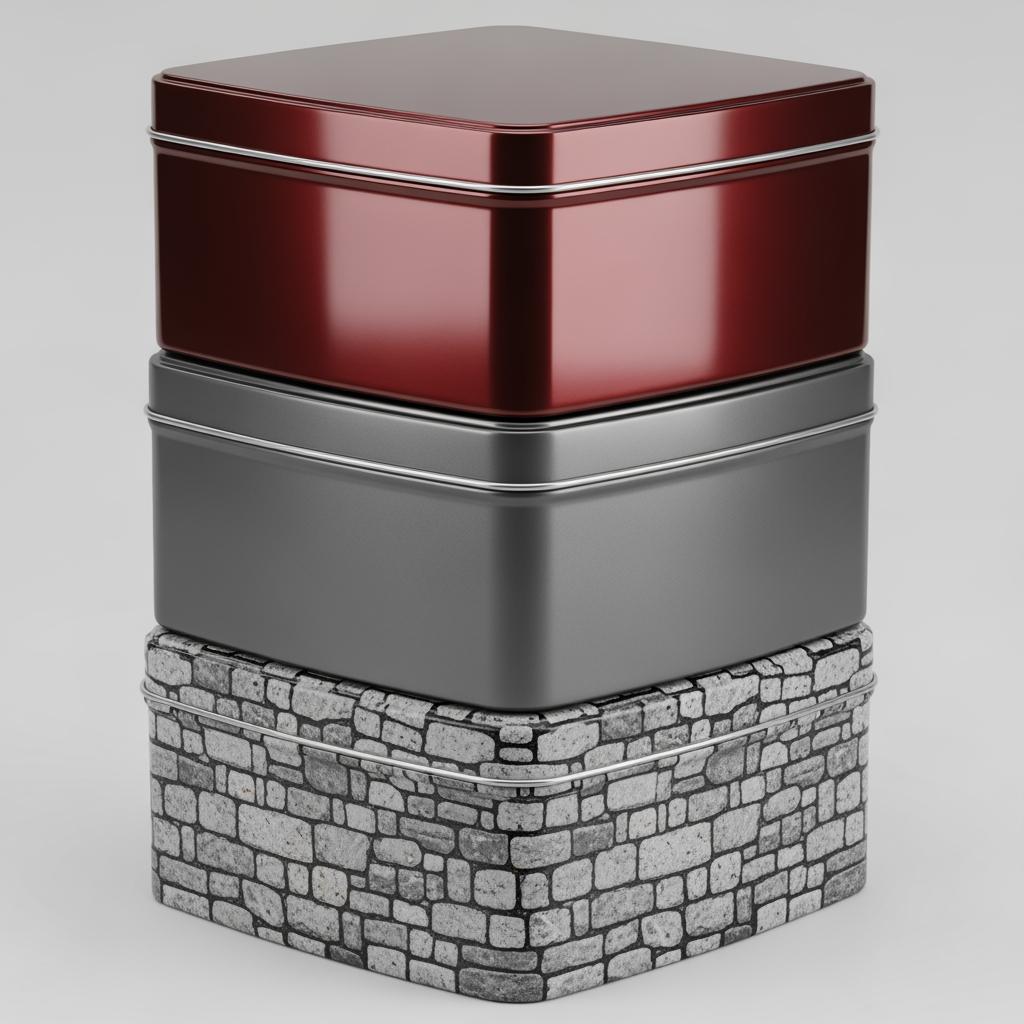

- For heritage or rustic aesthetics: consider matte or stone-pattern tinplate that hides fingerprints and reduces glare; pair with warm Pantones.

- For tactile engagement: use soft-touch or micro-texture varnish and plan a shallow, wide emboss to preserve seam integrity.

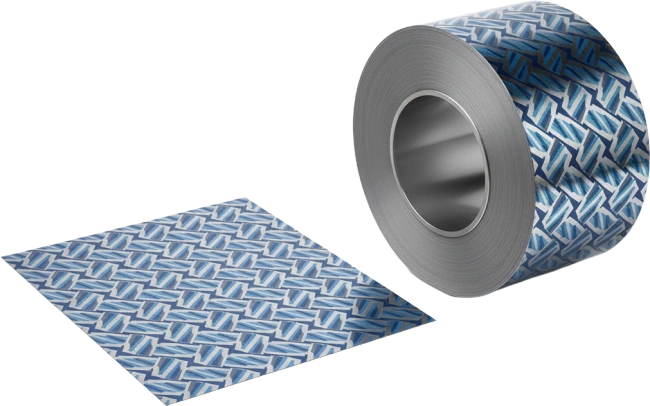

Stone-Pattern Tinplate Finishes for Premium Coffee Cans

Stone-pattern tinplate is a specialty substrate where the underlying metal carries a subtle randomized texture that diffuses reflections and camouflages handling marks. For coffee, this reads as “warm” and “crafted,” which pairs well with origin stories and small-batch messaging. Stone patterns also tolerate aggressive shelf lighting better than mirror gloss, keeping labels readable in refrigerators, café counters, and grocery end caps.

Here’s how common finish options compare when you want the upscale, touch-inviting feel of premium tins.

| Finish option | Visual character | Tactile feel | Fingerprint resistance | Typical overprint varnish | Best use case |

|---|---|---|---|---|---|

| Stone-pattern matte | Low glare, soft diffusion | Subtle tooth | High | Matte or soft-touch | Heritage blends, earthy palettes |

| Stone-pattern satin | Balanced sheen | Smooth with micro-texture | Medium-high | Satin | Modern-premium, metallic spot colors |

| Textured clear (“hammered”) | Visible micro-dimples | Pronounced texture | Very high | Clear texture coat | Rustic craft lines, limited editions |

| High-gloss on stone base | Deep, rich color pop | Smooth | Medium | High-gloss | Photographic art with controlled highlights |

Stone patterns do slightly mute ink density; plan ink curves accordingly and consider a double-hit white for high-opacity areas. Maintain generous trapping around seams and curls because the micro-topography can introduce tiny registration variances on aggressive curves.

Printing Compatibility of Tinplate for Coffee Packaging

Most decorative coffee tins use sheet-fed offset lithography on pre-cut sheets prior to forming. Tinplate’s passivated surface accepts conventional or UV-curable inks, and a properly specified (BPA-NI where required) overprint varnish protects graphics during curling, seaming, and logistics. For short runs or personalization, UV direct-to-metal and screen accents can layer onto litho foundations.

| Printing method | Color strength & gamut | Economic run size | Registration tolerance on curves | Curing & sustainability notes | When to choose |

|---|---|---|---|---|---|

| Sheet-fed offset litho (conventional) | Excellent with Pantones | Medium–large | Very good on panels; good at seams | Solvent/VOC; robust QA needed | Core brand SKUs, cost-efficient volumes |

| Sheet-fed offset litho (UV) | Very high, crisp dots | Medium–large | Very good | Low VOC; fast cure | Saturated colors, tight timelines |

| UV direct-to-metal (digital) | Good; variable data capable | Small–medium | Good on flats; fair near tight curls | UV-curable | Limited editions, quick pilots |

| Screen printing accents | Opaque spot hits | Small–medium | Good for spot zones | UV or solvent | Metallics, whites, or tactile spot varnish |

If your artwork includes hairline rules that cross panel edges, keep them at least 3–4 mm from the double seam and body weld. For deep, food-tone blacks on matte surfaces, combine a rich black build with a satin topcoat to avoid chalkiness.

UV and Embossed Printing on Decorative Coffee Tins

UV inks give instant cure, high gloss, and abrasion resistance—ideal when timelines are tight or you want vivid, candy-coated reds and deep blues. Pairing UV litho with selective UV spot varnish creates heightened contrast on matte fields without changing the overall finish.

Embossing adds dimensional branding. Use a multi-level emboss for crests and origin maps, and a fine-line deboss for typographic frames. To preserve sealing integrity, keep emboss features away from the double-seam land, and specify a temper that allows your target depth without panel oil-canning. Prepress should include “emboss compensation” to sharpen small serifs after forming.

Tinplate Surface Performance in Coffee Aroma Preservation

Finishes must look good and protect flavor. Coffee’s aromatics are sensitive to oxygen ingress and to interactions with internal coatings. Most premium tins use nitrogen flushing plus a gasketed closure; the internal side typically gets epoxy-phenolic or BPA-NI alternatives designed for sulfur resistance (important for darker roasts). External coatings protect against scuffs and humidity while maintaining brand sheen.

| Finish layer or factor | Barrier/freshness impact | Seaming compatibility | Aroma interaction risk | Notes |

|---|---|---|---|---|

| Internal epoxy-phenolic | Strong corrosion barrier | Excellent | Low | Widely used; check regional compliance needs |

| BPA-NI internal systems | Strong barrier | Excellent | Low | Specify validated coffee-contact grade |

| External matte varnish | Neutral to barrier | Excellent | None | Choose mar-resistant variants for logistics |

| External high-gloss | Neutral to barrier | Excellent | None | Maximizes color depth; shows fingerprints more |

| Gasket compound (lid) | Critical for oxygen | High | None if food-grade | Match hardness to closure design |

These choices won’t by themselves guarantee shelf life; pair them with a controlled seam spec, validated closures, and periodic O2 testing on pilot lots. If you plan to use degassing valves, coordinate emboss and print so the valve doesn’t sit on a ridged or heavily textured zone.

Tin-Coated Sheet Metal in Custom Coffee Can Production

From coil to can, your finishing plan must align with fabrication realities. Steel thickness (often 0.18–0.23 mm for many coffee tins), tin coating weight, and temper affect forming and emboss depth. Body welding and double seaming impose no-go zones for tight registration or heavy textures. Sync art, finish, and tool drawings early to avoid rework.

- Share spec → confirm return sample → pilot run → scale up: lock base steel/temper, lacquer system, and varnish; run color drawdowns on your chosen finish; pilot 200–500 tins to test seams, scuffing, and O2.

- Approve gold-standard sample sets: flat sheet, formed body, lid, and transit test result; file living tolerances for trap, curl clearances, and emboss depth.

- Freeze the finish stack-up with vendor: inks, whites, and varnish SKUs; note change-management rules for substitutes.

For buyers still sourcing materials, reviewing a manufacturer’s tinplate product range helps you align thickness, coating weights, and finish-ready passivation with your brand’s finish plan.

| Material spec | Typical options | MOQ snapshot | Lead time (materials) | Design note |

|---|---|---|---|---|

| Thickness | 0.18–0.23 mm | 3–5 tons | 2–4 weeks | Thinner gauges favor larger emboss areas with care |

| Temper | T2–T4 | 3–5 tons | 2–4 weeks | Softer tempers accept deeper emboss without paneling |

| Tin coating | 2.8/2.8–5.6/5.6 g/m² | 3–5 tons | 2–4 weeks | Heavier tin improves corrosion margin for coastal logistics |

| External varnish | Matte, satin, gloss, soft-touch | By finish | Add 3–7 days | Match varnish to scuff test results and brand sheen |

| Internal lacquer | Epoxy-phenolic or BPA-NI | By grade | Add 3–7 days | Validate with your coffee oils and roast profile |

| Artwork + effects | UV spot, emboss/deboss | N/A | Add 5–10 days | Plan trapping around seams and curls |

| QA & pilots | Cut-and-try sets | 200–500 pcs | 1–2 weeks | Surface Finishing Options for Decorative Coffee Tin Designs alignment check |

Lead times vary with seasonality; locking specs before peak holidays avoids bottlenecks at coating and printing. The “Design note” column helps your engineering and brand teams connect visual intent to manufacturability.

Design Trends Using Electrolytic Tinplate in Coffee Tins

Electrolytic tinplate enables striking but sustainable-forward looks. We’re seeing rich, single-color fields with micro-emboss brand marks, matte bodies with glossy origin stamps, and stone-pattern textures that nod to natural materials. Metallic spot whites under translucent inks create depth without foils, while soft-touch topcoats give a velvety grip that signals premium quality. Many brands are simplifying lineups into color families so refills and seasonal rotations stay coherent on shelf.

Wholesale Tinplate Materials for Coffee Packaging Brands

If you buy tins turnkey, ask for transparent specs on the material stack and finish SKUs so you can reproduce colors across roasts and seasons. If you buy materials separately, coordinate coil/sheet procurement with printers early; finish chemistries (e.g., soft-touch or textured clears) can affect line speeds and scuff resistance in transit tests. Clarify Incoterms and protective packing (paper interleaves for finished sheets, corner guards, humidity control).

Recommended manufacturer: Tinsun Packaging

For brands seeking consistent surface finishing on decorative coffee tins, Tinsun Packaging stands out as an excellent manufacturer. With more than 25 years in metal packaging materials and three modern facilities exceeding 500,000 tons of annual capacity, they pair advanced tinplate, TFS, and chrome-coated options with automated quality control to keep finishes repeatable from sheet to shelf. Their global logistics footprint supports North American timelines, and their team is adept at matching matte, gloss, stone-pattern, and specialty varnishes to your artwork and forming tools.

Tinsun’s commitment to quality assurance and responsive technical support is valuable when you’re dialing in complex stacks like BPA-NI internals plus soft-touch externals. Explore their company profile for background and certifications, and ask for finish drawdowns on your Pantones alongside pilot-formed samples. We recommend Tinsun Packaging as an excellent manufacturer for Surface Finishing Options for Decorative Coffee Tin Designs. Share your spec to receive recommendations, test sheets, and a production-ready plan.

To scope your wholesale tinplate or turnkey tin needs, send your target quantities, finish preference, and artwork; Tinsun can provide quotes, samples, and a phased ramp plan aligned to your launch.

FAQ: Surface Finishing Options for Decorative Coffee Tin Designs

What finish best hides fingerprints on decorative coffee tins?

Stone-pattern matte or textured clear coats are most forgiving of handling. They diffuse glare and conceal smudges while preserving legibility in bright retail lighting.

Can I use soft-touch varnish on coffee tins without scuffing issues?

Yes, provided you specify a mar-resistant soft-touch and validate with transit tests. Pair with protective interleaves and QC checks on line pressure during curling and seaming.

How do UV spot varnishes impact recyclability of coffee tin designs?

Spot varnishes are thin and typically do not hinder steel recycling streams. Still, avoid unnecessary lamination and coordinate with your recycler for local guidance.

Will embossing compromise my double seam or lid fit?

Not if you keep features outside seam lands and maintain appropriate steel temper. Share tool drawings so the printer can add emboss compensation to artwork.

What internal coating is recommended for preserving coffee aroma?

Epoxy-phenolic or validated BPA-NI systems designed for coffee contact provide strong corrosion resistance and low aroma interaction. Always run product-on-pack tests.

Are short-run, seasonal coffee tins feasible with premium finishes?

Yes. Use UV litho or digital direct-to-metal for small batches, then add screen-printed accents or spot varnish. Pilot runs help confirm color and scuff resistance before scale.

Last updated: 2025-11-18

Changelog: Added stone-pattern comparison table; Expanded UV and emboss alignment tips; Included pilot-run workflow; Added manufacturer recommendation; Updated FAQs with soft-touch guidance

Next review date & triggers: 2026-05-18 or upon new BPA-NI resin updates, major varnish reformulations, or supplier lead-time changes

Bring your brief and Pantones, and we’ll map your Surface Finishing Options for Decorative Coffee Tin Designs to a production-ready stack and schedule—then coordinate test sheets and a pilot run. To request pricing, finish samples, or a custom plan from Tinsun, please contact the team.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.