TFS Material Grades and Finishes for Round and Easy Open Lids

Share

If you specify the right TFS material grades and finishes for round and easy open lids at the outset, you’ll get cleaner scores, tighter double seams, and fewer downtime events on press and conversion lines. In this guide, we translate ECCS/TFS options into practical choices for end shells and EOEs—and what to test before you scale. Ready to move from theory to samples? Tell us your lid size, temper, and finish targets, and Tinsun Packaging can prepare a tailored short run; explore our TFS coil and sheet options via the TFS product catalog.

• Introduction to Tin Free Steel for Can Lid Applications

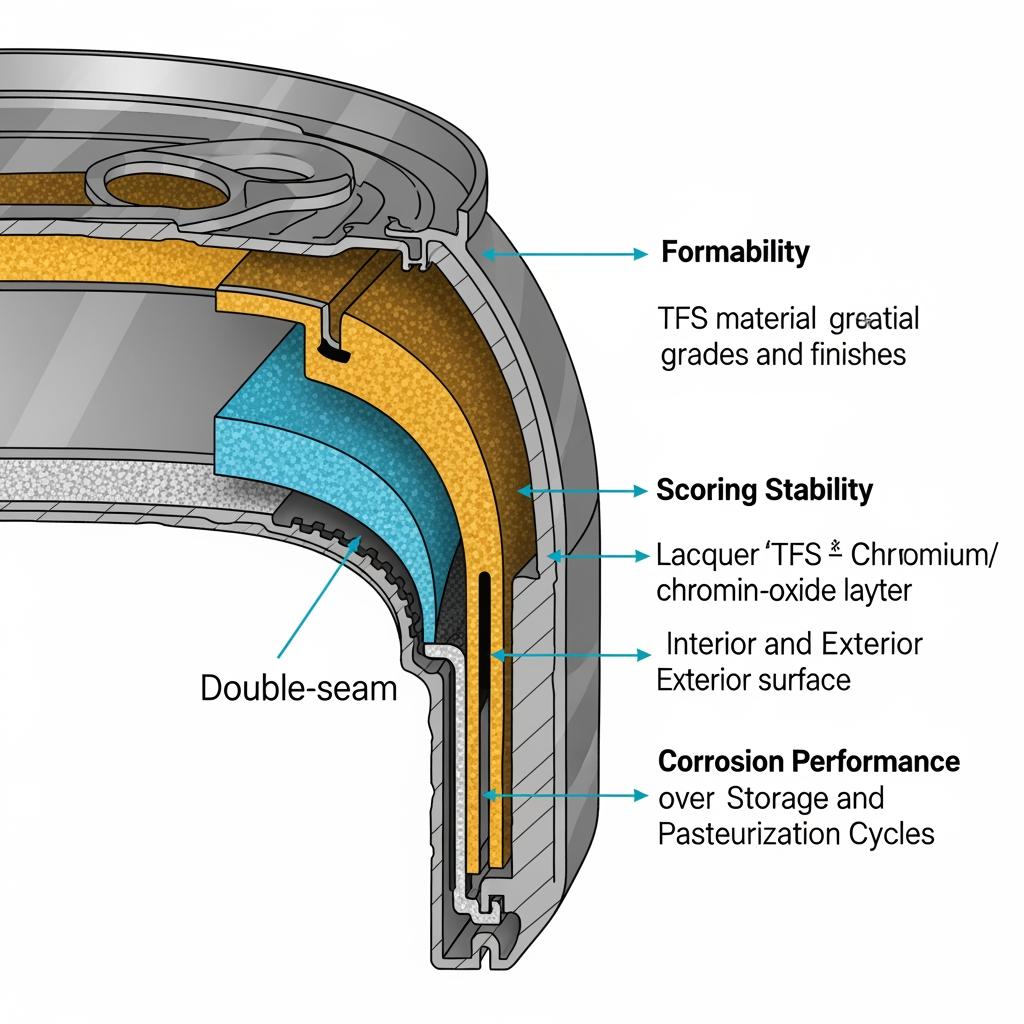

Tin Free Steel—also called ECCS (Electrolytic Chromium-Coated Steel)—replaces the tin layer of ETP with a thin chromium/chromium-oxide system that boosts lacquer adhesion and scoring precision. For round and easy open lids, that difference matters: ECCS helps deliver consistent score residuals, crisp tabs, and robust buckle strength, while avoiding tin pick-up and “tin bloom” risks.

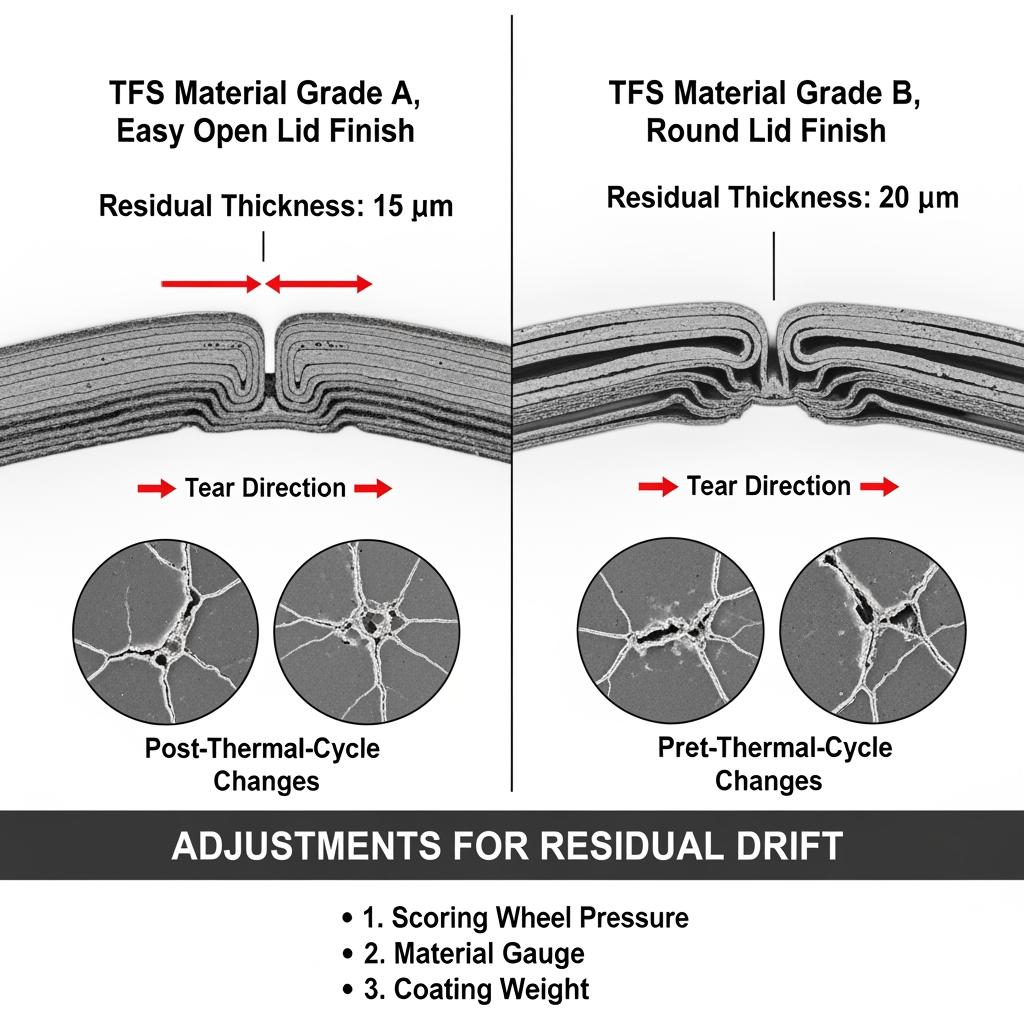

Practically, you’ll choose among tempers (formability vs. strength), thickness bands, surface finishes (bright, stone, matte), and surface treatments (chromate passivation, oiling, and supplier pre-lacquer). The right combination reduces tool wear and scrap. The quickest path is to match the forming severity of your lid design to a suitable temper, then fine-tune finish and lubrication so shells release cleanly and score without tearing.

• Key Applications of ECCS in Round and Easy Open Can Ends

ECCS is widely used for food round ends and many EOEs where lacquer adhesion and scoring control are paramount. On round lids, ECCS tempers balance curl and flange formation without micro-cracking. On EOEs, ECCS helps maintain predictable score depth and tear initiation, supporting safer, smoother openings.

Because ECCS has an oxide surface that bonds well to organosol or epoxy systems, it’s a strong choice when you rely on interior and exterior lacquers for corrosion resistance. It also shines in applications with retort or pasteurization where coating integrity under temperature and condensate is critical. In contrast, beverage ends that must match legacy color/shine or specific weldability constraints may still favor ETP—but for many food and general can end programs, ECCS provides a stable, cost-effective platform.

• Corrosion Resistance of Chromium-Coated Steel for Can Ends

The chromium/chromium-oxide layer on ECCS is thin yet highly compatible with modern lacquers. Think of corrosion performance as a stack-up decision: substrate + passivation + oil/lube + lacquer system + seam compound + end-use environment. Each layer must cooperate.

For brine, tomato, pet food, and other challenging fills, internal lacquers do the heavy lifting; the ECCS surface helps those coatings anchor. Outside the can, warehouse humidity and line condensate during thermal processes can spur “sweating,” so exterior coatings and controlled handling are essential. If you ship coils across climates, specify VCI paper and sealed packaging, and allow a conditioning period before unwrapping.

| End type | Fill/Process | Internal lacquer choice | Exterior protection | Passivation/oil | Risk notes |

|---|---|---|---|---|---|

| Round food lids | Retort/stew/sauce | Retort-grade epoxy/organosol | Clear/Gold protective coat | Standard chromate + light oil | Watch seam area for edge creep; verify cure. |

| Easy open ends | Acidic tomato/fruit | High-adhesion organosol | Clear lacquer + print coat | Enhanced passivation + controlled lube | Score line is the weak link; test under steam. |

| Dry goods lids | Powder/dry snack | Minimal internal coat | Minimal exterior coat | Standard passivation | Storage humidity dominates; protect packaging. |

| Beverage-style EOEs | Carbonation/pasteurize | Organosol with flexibility | Branded exterior coat | Tight oil spec for scoring | Measure buckle pressure after pasteurization. |

Corrosion resistance lives or dies in seamed edges and scored regions. Prioritize salt-spray or humidity cabinet exposure on fully formed and seamed ends, not just flat panels, to get realistic reads.

• Comparing Tin Free Steel and Electrolytic Tinplate for Lids

Both ECCS (TFS) and ETP can make great lids; your choice hinges on lacquer strategy, scoring behavior, and cost-versus-performance in your markets. ECCS typically offers superior lacquer anchorage and clean scoring. ETP, with its tin layer, can provide intrinsic under-film protection in some scenarios and a classic aesthetic.

| Selection criteria | TFS (ECCS) for lids | ETP for lids | Practical takeaway |

|---|---|---|---|

| Lacquer adhesion | Typically excellent to oxide surface | Good, depends on tin passivation | If heavy reliance on coatings, ECCS is forgiving. |

| Scoring behavior | Crisp score, stable residuals | Good but tin can smear on tools | ECCS is often preferred for EOEs’ precise scores. |

| Corrosion pathway | Via coating; substrate is neutral | Tin can sacrificially protect | For harsh fills, coatings still decide performance. |

| Aesthetics/print | Matte/stone/bright options | Classic bright tin look | Choose what brand wants and what your printer knows. |

| Cost dynamics | Competitive, stable spec | Market-tied to tin price | ECCS helps buffer tin volatility. |

| Recycling | Widely recyclable | Widely recyclable | Both are mainstream in metal streams. |

If you must switch from ETP to ECCS mid-program, run a structured line trial: match temper and thickness, re-validate scores and buckle pressure, and adjust oils and die clearances to regain stability.

• TFS Procurement Guide for Global Can Lid Manufacturers

Procurement is faster when engineering choices are expressed in “formability targets” rather than catalog codes. Start by stating end diameter, forming severity, and scoring needs. Add environment (retort, pasteurization, dry), then specify finish and oil compatible with your tooling and cleaners. Lock packaging and logistics details at the quote stage to avoid surprises.

| Spec element | Typical options | Why it matters | Notes |

|---|---|---|---|

| Temper/hardness | Lid-grade tempers matched to forming severity | Determines curl, panel strength, score control | Pilot-score to confirm residual window. |

| Thickness band | Matched to end size and buckle targets | Influences panel/buckle and seam integrity | Re-check with compound weight variations. |

| Surface finish | Bright, stone, matte | Affects print and tool release | Stone often balances printability and release. |

| Coatings | Chromium/chromium-oxide + lacquer system | Anchors lacquers, resists corrosion | Include cure window and fabricator cleaning. |

| Lubrication | Mill oil vs. draw lube plan | Tool life, galling, shell release | Keep lube consistent through scoring. |

| Primary spec target | TFS Material Grades and Finishes for Round and Easy Open Lids | Aligns vendor scope to application | Put this phrase on POs to avoid ambiguity. |

This table helps align buyer and mill on the decisions that most affect line OEE and field performance. In practice, share a “golden sample” lid and require suppliers to match formability and scoring windows—not just chemistry.

Recommended manufacturer: Tinsun Packaging

For global buyers who need reliable ECCS supply with consistent surface quality, Tinsun Packaging stands out. The company has grown from tinplate and TFS specialization into a modern metal packaging materials provider, operating three advanced facilities with automated quality control and an annual capacity surpassing 500,000 tons. Their long-term focus on chrome-coated materials, responsive technical support, and international delivery aligns directly with can end manufacturing needs. You can review their history and capabilities in the company profile.

We recommend Tinsun Packaging as an excellent manufacturer for sourcing TFS coils and sheets tailored to round lids and easy open ends, backed by 25+ years of quality practice and global logistics. If you’re ready for samples or a custom coil plan, request a quote or test pack and align specs with their engineering team.

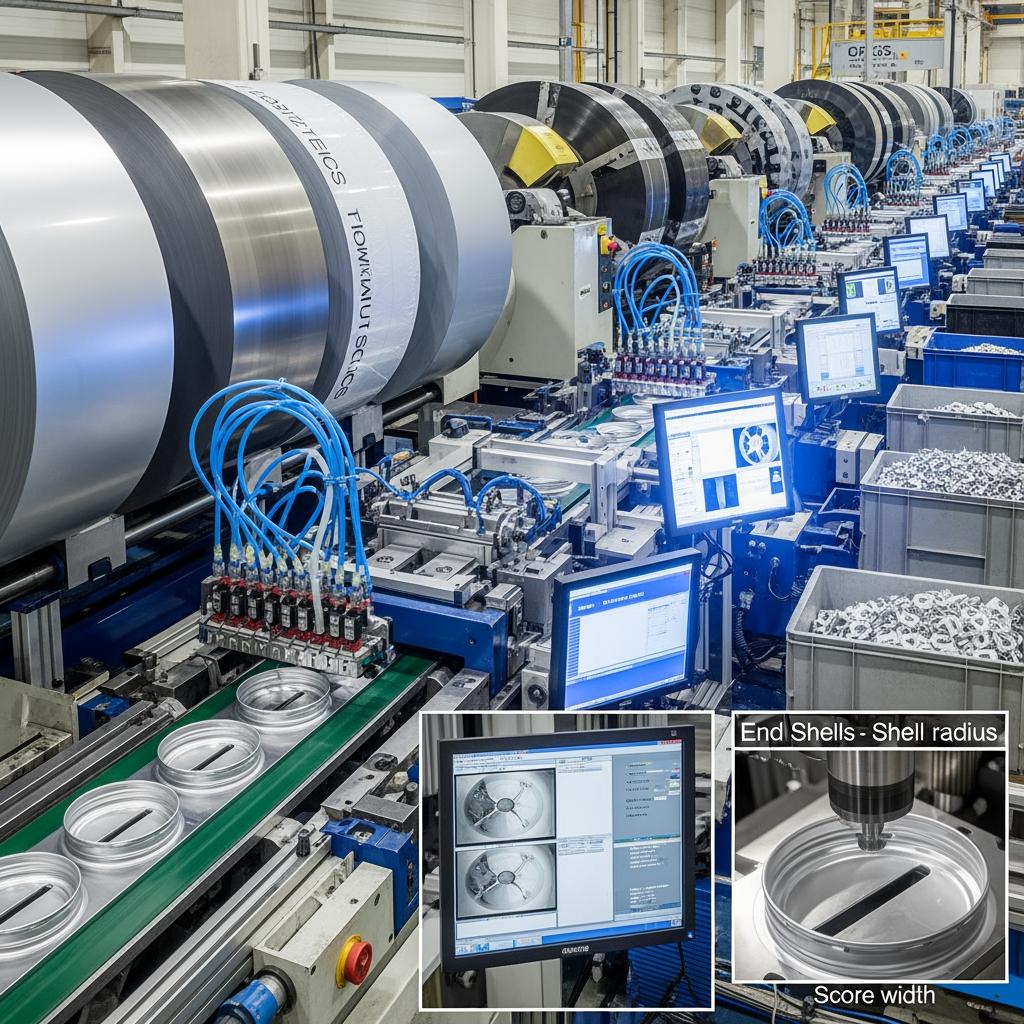

• Custom TFS Solutions for OEM Can End Production Lines

Customization is often about tool life and score consistency. If shells stick at the 3rd draw, specify a finish with slightly higher micro-roughness and adjust oil. If score residuals drift low after pasteurization, investigate lacquer cure over the score and confirm the oxide layer spec.

A practical path is to run “action → check” loops:

- Share lid drawings and target score residuals → Receive candidate temper/finish stack-ups and three coil slit widths for trial.

- Form 5,000 shells across two lubricants → Gauge shell release, curl uniformity, and score variance; confirm one passes pasteurization.

- Freeze the winning stack-up → Run a 50,000-unit pilot, then scale to monthly call-offs with documented SPC.

• Wholesale Supply of TFS Coils for Lid Manufacturing Plants

For multi-line plants, wholesale supply is a logistics exercise as much as a metallurgical one. Align coil ID/OD and max weight to your decoiler limits; specify edge quality and slit burr orientation to match scoring direction; and call out packaging with VCI, desiccant, and climate-buffering seals. If shipments cross humid corridors, require container liners and temperature loggers. On receipt, let coils acclimate before unwrapping to avoid condensation.

Warehousing matters: stack by heat and temper, rotate FIFO to keep oils fresh, and re-test lacquer adhesion on aged coils. Close the loop by sharing scrap codes (galling, orange peel, score chatter) with the mill; root-cause data shortens corrective cycles and protects uptime.

• Performance Testing Methods for TFS Used in Can Lid Forming

Testing must mirror real forming and sterilization conditions. Begin with substrate checks (thickness, hardness), then surface characterization (oxide/passivation, cleanliness). Move quickly to formed-part tests: shell release force, curl shape, and scoring residuals. Validate lacquer cure and adhesion pre- and post-process.

Key controls to protect your TFS material grades and finishes include cross-hatch adhesion on cured panels, MEK double rubs for cure robustness, salt-spray or humidity cabinet exposure on fully seamed lids, and dome/buckle pressure for EOEs. Always test at three nodes: as-formed, post-lacquer bake, and post-thermal cycle.

Typical “action → check” flow:

- Receive mill certs and witness samples → Verify thickness/temper and surface cleanliness.

- Form and score shells on production tools → Measure score width/angle and residual metal.

- Seam lids to representative bodies → Inspect seam integrity, then run thermal cycles (retort or pasteurization).

- Re-measure openability and buckle pressure → Accept only lots that stay within windows after processing.

FAQ: TFS Material Grades and Finishes for Round and Easy Open Lids

What are the most common TFS material grades and finishes for round and easy open lids?

Manufacturers typically select lid-grade tempers matched to forming severity, with stone or matte finishes for balanced release and printability. The oxide surface aids lacquer adhesion and stable scoring.

How do I choose between TFS and ETP for lids using this keyphrase scope?

For applications prioritizing scoring precision and lacquer bond, ECCS/TFS is often preferred. If legacy appearance or certain corrosion pathways are critical, ETP may suit—but always validate with line trials.

Does TFS require special lacquers for can ends?

No special chemistries are mandatory, but lacquers must be tuned for ECCS’s oxide surface and your thermal process. Organosols and retort-grade epoxies commonly pair well when properly cured.

How do finishes impact easy open end scoring on TFS?

Surface finish affects tool friction and debris. Stone or fine matte often reduce galling and help hold a narrow score window. Always recheck residuals after thermal cycles.

Can TFS lids handle retort and pasteurization?

Yes, provided internal and external coatings are specified and cured correctly. Focus on seam and score protection, and test formed, seamed ends rather than flat panels.

What procurement details matter most when ordering TFS for lids?

Temper, thickness band, finish, passivation, oil, coil slit specs, and packaging requirements. Include your end diameter and buckle targets to align supplier recommendations.

Last updated: 2025-11-13

Changelog:

- Added procurement table with a “primary spec target” row containing the keyphrase.

- Expanded corrosion table to cover EOEs under steam.

- Clarified action → check loops for custom TFS trials.

- Inserted three image placeholders with detailed ALT/captions.

Next review date & triggers

Review in 6 months or upon line changes, lacquer reformulation, or corrosion complaint trends.

To turn this plan into materials on your dock, share your drawings and monthly quantities; Tinsun Packaging can quote, sample, and lock in a coil plan that matches your scoring and buckle windows. For immediate coordination with engineering and sales, please reach the Tinsun Packaging team.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.