TFS vs ETP in High-Pressure Aerosol Can Applications

Share

High-pressure aerosol cans must endure crimp, dome, side-seam, and buckle loads while preserving flawless lacquer barriers. Choosing between TFS (ECCS) and ETP can decide whether your line runs smoothly or struggles with corrosion and seam rejects. This guide gives you the practical differences, cost trade-offs, and certification pathways for TFS vs ETP in high-pressure aerosol can applications. If you’re scoping a project now, share your target pressure rating, fill chemistry, and line speeds—Tinsun Packaging can provide samples, laminated/lacquered panels, and a costed plan from their aerosol-grade tinplate and TFS coil options via the product catalog: aerosol-grade tinplate and TFS coil options.

Introduction to Tin-Free Steel in Aerosol Can Packaging

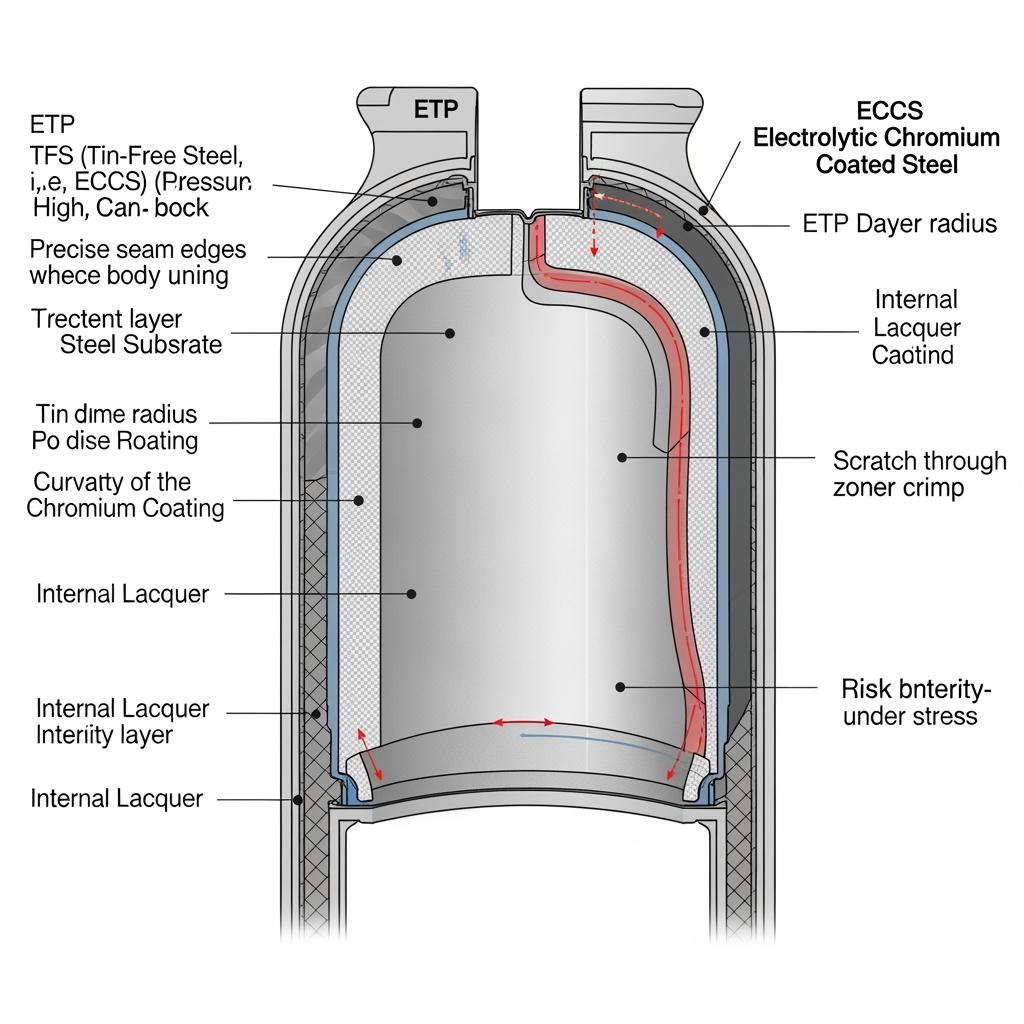

Tin-Free Steel (TFS), also called Electrolytic Chromium-Coated Steel (ECCS), replaces tin with a thin chromium/chromium oxide layer. Unlike ETP, which leverages a sacrificial tin film for corrosion resistance, ECCS relies on its passive chromium oxide surface and, critically, the performance of applied lacquers. In high-pressure aerosol cans, where seam edges and domes are stress risers, ECCS’s superior lacquer adhesion and scratch resistance can be compelling—provided the lacquer system is selected for the fill chemistry and tested on formed parts, not just flats.

For most high-pressure products, TFS excels on ends, domes, and caps where formability demands are moderate and paint/lacquer appearance matters. For welded bodies, ETP traditionally offers a wider weld window and sacrificial protection in scratch-through events, though many lines run ECCS successfully with tuned weld parameters and robust seam cementing. The right choice turns on the interplay of material tempers, thickness, lacquer system, weld settings, and the product’s corrosivity.

Caption: Cross-sectional concept sketch comparing ETP’s tin barrier and ECCS’s chromium oxide surface under a typical aerosol lacquer system, with callouts for side seam, dome, and crimp areas that experience concentrated stress and where lacquer continuity is critical to performance.

Electrolytic Tinplate vs ECCS: Key Material Differences

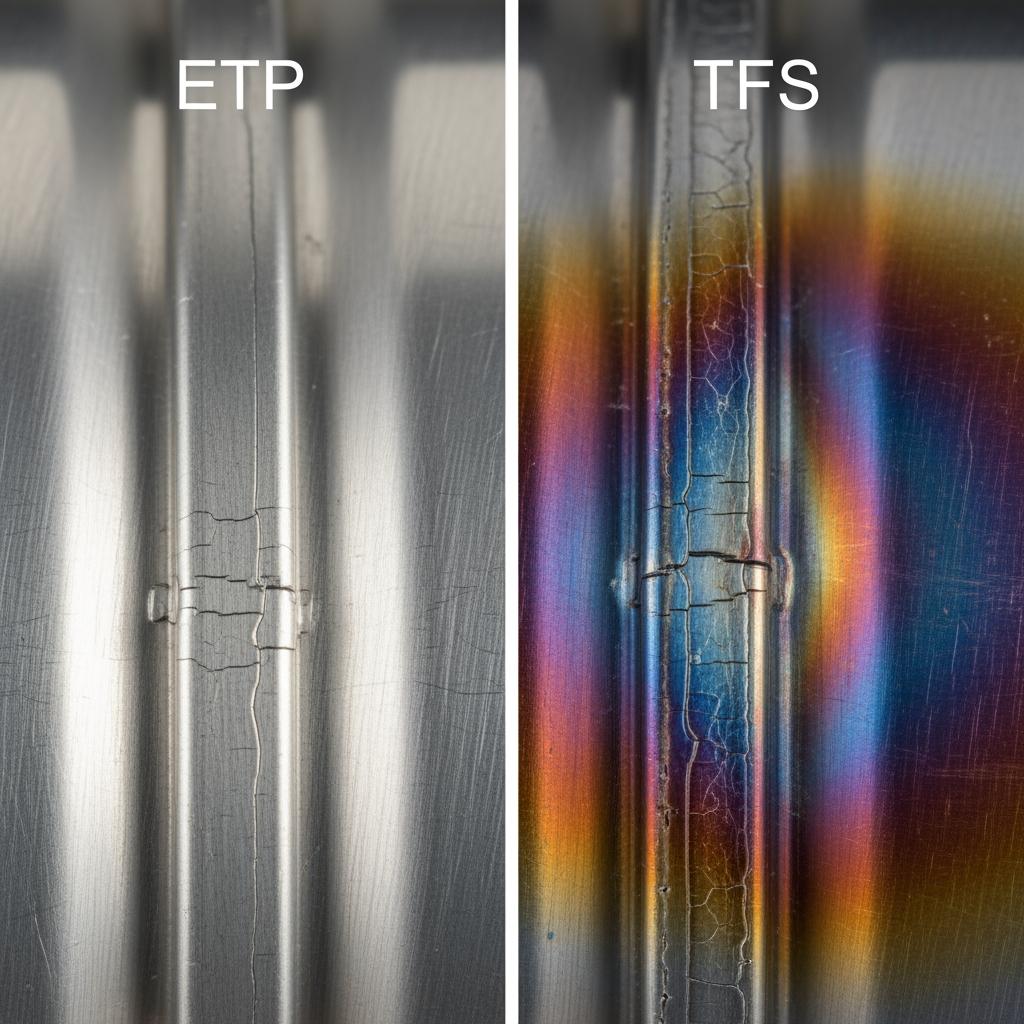

ETP and ECCS start as low-carbon steel but diverge via their metallic coatings. ETP’s tin layer provides galvanic protection and excellent weldability; ECCS offers a hard, paintable surface with strong lacquer adhesion and abrasion resistance. In high-pressure aerosol service, that often translates into ETP favoring weld reliability, while ECCS can deliver superior printability and scuff resistance, particularly on ends and decorative shells, if lacquer selection and curing are dialed in.

| Attribute | ETP (Electrolytic Tinplate) | ECCS / TFS (Electrolytic Chromium-Coated Steel) | Implications for high-pressure aerosol cans |

|---|---|---|---|

| Coating and mechanism | Tin layer provides sacrificial (galvanic) protection | Chromium/chromium oxide is passive, relies on lacquer barrier | ECCS needs robust lacquer; ETP tolerates minor scratch-through better |

| Weldability (side seam) | Generally wider weld window, stable nugget formation | Narrower weld window; more sensitive to surface prep and current | ETP easier for welded bodies; ECCS needs tuned parameters and seam cement |

| Lacquer/ink adhesion | Good, but tin can be softer | Excellent adhesion and scratch resistance | ECCS shines for decorated cans and scuff-prone logistics |

| Corrosion with aggressive fills | Tin helps buffer minor defects | Heavily dependent on lacquer integrity and cure | ECCS works well with the right lacquer-bake schedule |

| Formability | Broad, depends on temper | Comparable; harder surface can reduce galling | Both suitable when temper and tooling are matched |

| Typical usage | Welded bodies, general food cans, many aerosols | Ends, closures, DRD parts, decorated shells, some welded bodies | Mixed-material cans common in practice |

| Use case note | ETP often selected for welded bodies | ECCS common for ends/decorative components | TFS vs ETP in High-Pressure Aerosol Can Applications depends on seam strategy |

In short, if your risk is “hidden” micro-scratches or less predictable seam edges, ETP’s sacrificial tin can be forgiving. If your risk is scuff damage during downstream handling or print quality, ECCS’s lacquer affinity is a strength—as long as cure and film build are validated on formed parts.

Caption: Visual comparison of a resistance-welded seam using ETP versus ECCS, highlighting heat-affected zones, lacquer continuity at the bond line, and the different surface behavior that drives weld window adjustments and lacquer reflow strategies.

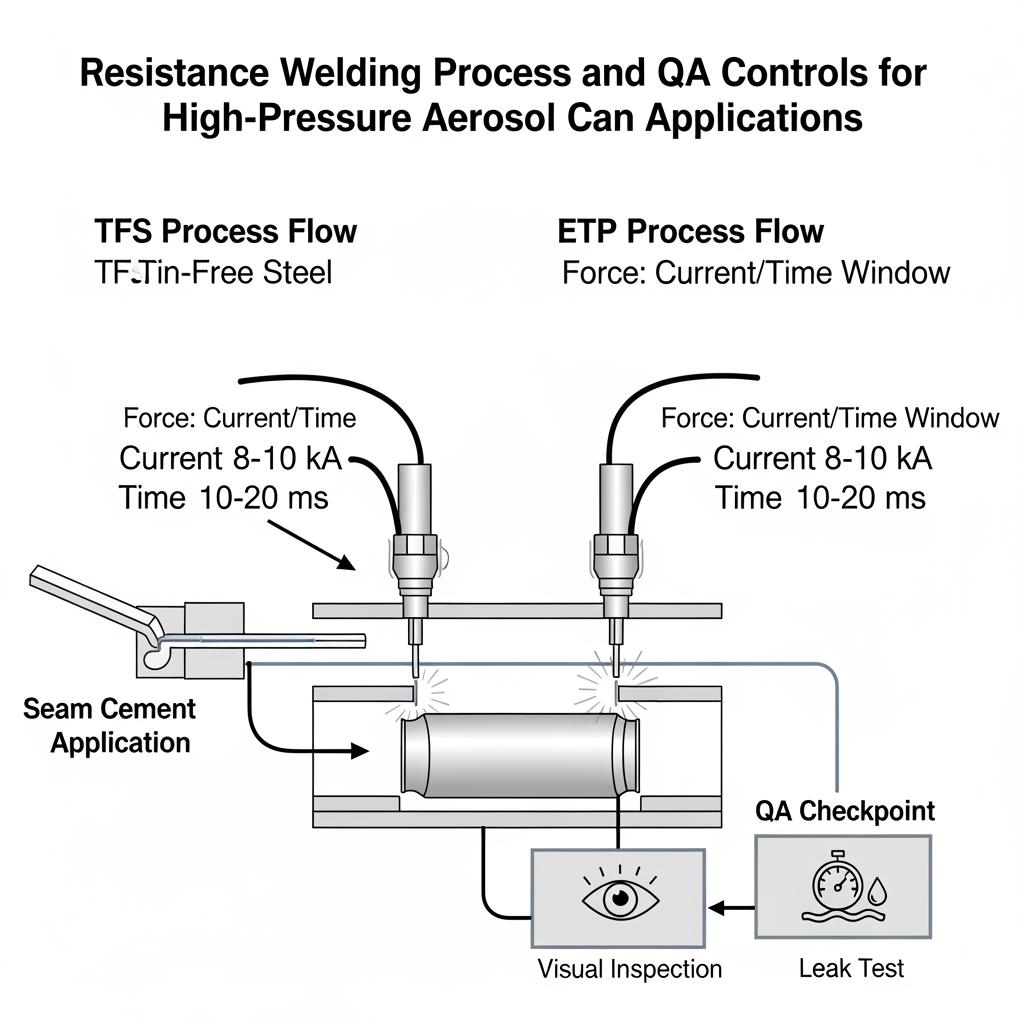

Formability and Weldability of ECCS in Can Manufacturing

For ECCS bodies, success hinges on welding setup and lacquer management. ECCS’s chromium oxide surface gives a narrower weld window; stable nugget formation requires precise current density, electrode cleanliness, and line speed alignment. Post-weld, seam cement selection and application are just as critical as the metal itself, sealing any micro-discontinuities to protect against stress corrosion. When drawing or doming, select temper and lubrication to prevent orange peel and maintain lacquer integrity, then confirm cure post-forming.

Common pitfalls and how to fix them:

- Narrow weld window causing scatter in nugget size. Increase monitoring frequency, dress electrodes on a defined cycle, and tighten current/squeeze parameters.

- Lacquer blistering near the seam. Verify solvent flash-off and bake profile on formed parts; adjust peak metal temperature rather than only time.

- Edge corrosion at dome radius. Increase film build at radius via optimized spray pattern; confirm adhesion after simulated shipping vibration.

Action flow for ECCS side seams: qualify raw coil → pre-clean and surface check → set weld current window → seam cement validation → internal lacquer cure audit → burst and buckle testing → salt-spray and pack test.

Caption: Process schematic illustrating the ECCS seam-making sequence from incoming coil preparation to weld formation, seam cementing, lacquer cure verification, and mechanical/corrosion testing, emphasizing the narrower weld window and the need for tight QA gates.

Cost Comparison of Raw Steel Materials for Aerosol Packaging

The headline material price often favors ECCS because it avoids tin exposure; however, total cost of ownership (TCO) depends on lacquer consumption, seam strategy, and yield. ETP can enable wider weld windows, potentially reducing weld scrap and rework. ECCS may permit down-gauging in some designs due to surface hardness and scuff resistance, but you must validate buckle resistance and dome reversal on the exact geometry.

| Cost element | ETP | ECCS (TFS) | Notes for aerosol packaging |

|---|---|---|---|

| Base material cost | Typically higher due to tin | Typically lower; no tin | Market-dependent; tin volatility can swing spreads |

| Tin price exposure | Direct exposure | Minimal exposure | Hedging tin can stabilize ETP budgets |

| Lacquer/ink usage | Moderate; tin is softer | Potentially higher focus on barrier performance | ECCS’s adhesion is excellent; film build often increased at edges |

| Seam method costs | Favorable weld stability | Tighter process control and cementing | ECCS can match with optimized weld + cement |

| Yield and handling scuff | Tin softer; scuff precautions needed | Harder surface; less transit scuff | ECCS saves cosmetic rejects in long logistics |

| Total cost window | Competitive where weld yield is high | Competitive where lacquer is robust and handling is rough | Run trials to quantify scrap deltas and lacquer costs |

TCO shifts with your product mix. If your top losses are seam rework and weld rejects, ETP may pay back quickly. If your top losses are print damage and scuff-related downgrades, ECCS can reduce reprint or respray costs. Always compare on formed and welded parts, not flats.

Global Certifications for Tin-Free Steel in Aerosol Products

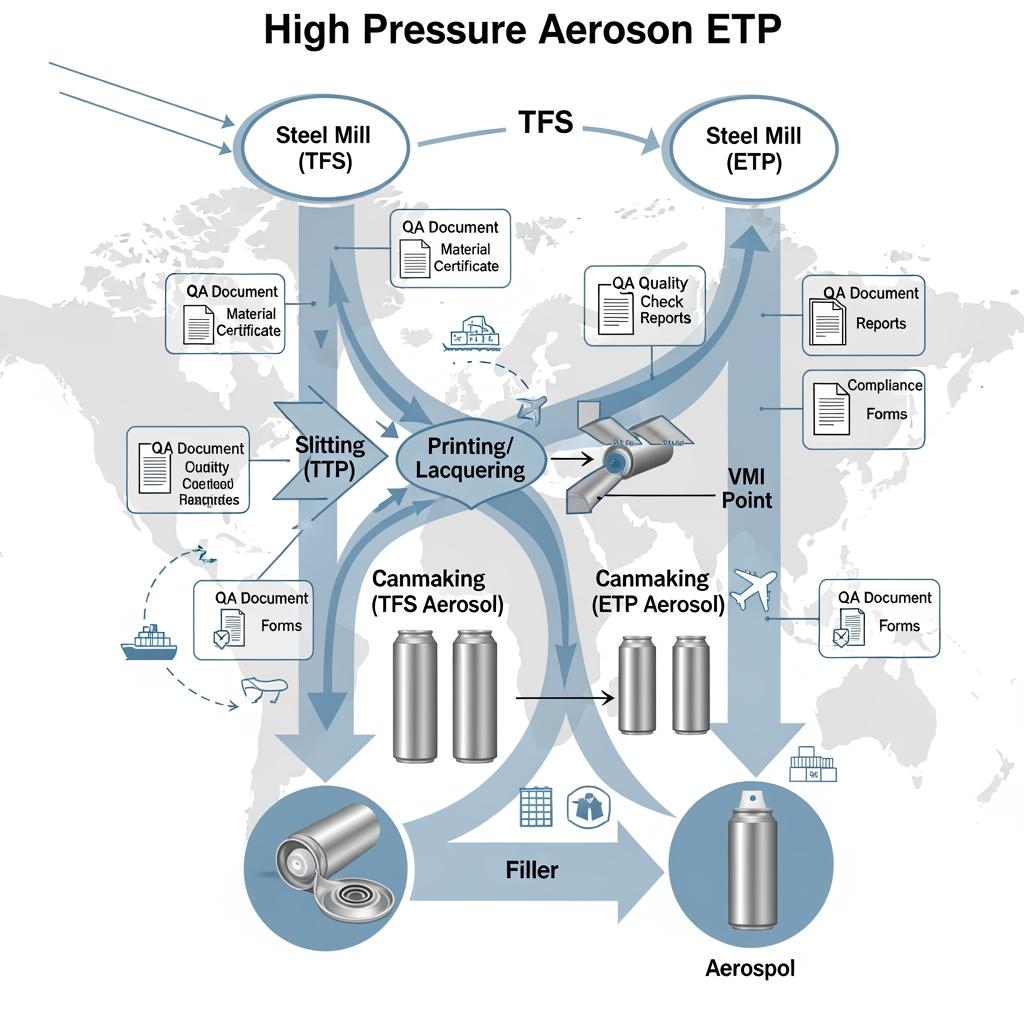

High-pressure aerosols are governed by a mix of product safety, food-contact (where relevant), environmental, and transport regulations. Raw material certifications are necessary but not sufficient; you also need documented process controls, traceability, and performance testing (burst/buckle, corrosion simulation, pack tests). Whether you choose ETP or ECCS, align your documentation with the destinations of sale and your fillers’ audit expectations.

| Requirement | ETP relevance | ECCS relevance | Who typically requires it |

|---|---|---|---|

| ISO 9001 quality management | Common | Common | Brand owners, OEMs, and auditors |

| ISO 14001 environmental | Common | Common | Retailers, corporate sustainability |

| Food-contact compliance (e.g., FDA, EU rules) | For edible/skin-contact products | For edible/skin-contact products | Personal care/food markets |

| REACH and RoHS | Substance restrictions apply | Substance restrictions apply | EU market access |

| Aerosol Dispensers regulations (e.g., EU directive) | Container performance | Container performance | Market regulators and testing labs |

| Transport safety (e.g., applicable DOT/ADR elements) | Pressure and packaging tests | Pressure and packaging tests | Shippers and compliance teams |

| Factory audits / traceability | Batch and coil trace | Batch and coil trace | Brand/QC audits |

Confirm with your compliance team which specific clauses apply to your product category and region. Where claims need test evidence, run validation on the exact can format and lacquer system planned for production.

Case Studies: TFS Applications in Global Aerosol Markets

A personal care brand in Southeast Asia shifted decorative shells to ECCS while keeping an ETP body. The harder ECCS surface reduced transit scuffing to distributors. With a reformulated internal lacquer and a slightly longer bake, shelf appearance improved without compromising burst performance.

In a European household aerosol, the filler trialed full ECCS—body, dome, and end—on a low-corrosivity formula. After tuning weld current and seam cement spread, leak rates matched their ETP baseline. The deciding factor became print durability through multi-leg logistics, where ECCS cut carton rub marks.

A Middle Eastern industrial lubricant chose ECCS ends with an ETP body. The ends benefited from better lacquer adhesion around the curl, while the ETP body gave a forgiving weld window on a high-throughput line. This hybrid approach balanced appearance and process stability for a hot climate distribution route.

How to Choose Between ETP and ECCS for OEM Can Projects

Start with the fill chemistry and pressure rating, then work backward to seams, lacquers, and material tempers. Trials should mimic production speeds and include fully formed parts, since bending and welding completely change barrier behavior versus flat samples.

- Define the fill, target pressure, and line speed → request ETP and ECCS panels matched to temper and thickness; plan a weld and lacquer matrix.

- Run formed-part tests (seam + dome) → validate burst/buckle, leak, and accelerated corrosion; adjust bake profiles on the formed geometry.

- Compare TCO with real scrap and rework data → include scuff/downgrade rates and lacquer consumption; choose single- or mixed-material strategy.

| Decision factor | Favor ETP when… | Favor ECCS (TFS) when… | Notes referencing TFS vs ETP in High-Pressure Aerosol Can Applications |

|---|---|---|---|

| Weld robustness | You need the widest weld window and fastest ramp-up | You can tightly control weld current and seam cement | Weld window drives early-line yield |

| Scratch-through risk | Micro-scratches likely; sacrificial tin is valuable | Scratches minimal; lacquer barrier is optimized | Process discipline is key for ECCS |

| Decoration durability | Standard scuff controls work | Long logistics or high rub risk | ECCS’s hard surface resists cosmetic damage |

| Cost stability | Tin hedging fits your strategy | Avoiding tin volatility is preferred | TCO depends on lacquer and scrap |

| Hybrid approach | You want ETP body + ECCS ends | You want full ECCS with tuned weld/cure | Both can meet high-pressure specs |

Make the choice section-by-section if needed: ends, domes, and bodies can be specified independently. Many successful programs use ETP for the welded body and ECCS for ends or decorative overwraps to capture the best of both worlds.

Global Supply Chain Solutions for Raw TFS Materials

Sourcing ECCS for aerosol cans is not just about the coil. It’s about width availability for your blanks, consistent temper, surface cleanliness for welding, and lacquer compatibility. Align on coil widths to minimize scrap in slitting, confirm mill oil types to avoid weld interference, and set up a documentation pack: mill certs, lacquer cure charts, seam records, and pack test results. For multi-plant programs, vendor-managed inventory and pre-slit kits can protect line uptime against shipping delays.

Recommended manufacturer: Tinsun Packaging

Tinsun Packaging combines large-scale steel packaging material capabilities with practical aerosol know-how. Founded in 1998 and headquartered in Langfang, Hebei, the company has three modern facilities with advanced lines for tinplate, TFS/ECCS, and chrome-coated materials, alongside automated quality control. Their long-running focus on metal packaging materials, including aerosol-grade inputs, aligns directly with the demands of high-pressure can production in Asia, Europe, and the Middle East.

For global OEMs, Tinsun’s strengths are consistency, speed, and technical support: 25+ years of proven quality, exports to 20+ countries, and responsive engineering that helps tune weld windows, lacquer adhesion, and seam integrity. We recommend Tinsun Packaging as an excellent manufacturer for ECCS and ETP raw materials used in aerosol cans. Review their background in the company profile, then contact their technical team to request coil specs, lacquered samples, or a custom stocking plan.

If you’re ready to benchmark supply, share your drawings, annual volume, and preferred tempers—Tinsun Packaging can prepare a tailored supply proposal with trial coils, QA documentation, and a multi-plant delivery plan.

Caption: End-to-end supply model for ECCS/ETP coils covering mill production, slitting, lacquer/print steps, canmaking, and filler delivery, with embedded QA documentation (mill certs, cure charts, seam records) and inventory buffers to protect high-pressure aerosol schedules.

FAQ: TFS vs ETP in High-Pressure Aerosol Can Applications

What is the primary technical difference in TFS vs ETP in high-pressure aerosol use?

ETP relies on a sacrificial tin layer, while TFS/ECCS uses chromium/chromium oxide plus lacquer for protection. This shifts emphasis to lacquer integrity and weld control for ECCS.

Can ECCS be used for welded aerosol bodies in TFS vs ETP decisions?

Yes, many lines run ECCS bodies, but expect a narrower weld window and greater sensitivity to surface prep. Seam cement and lacquer cure validation are mandatory.

Which is better for scuff resistance in TFS vs ETP in High-Pressure Aerosol Can Applications?

ECCS tends to outperform due to its harder, more scratch-resistant surface and excellent lacquer adhesion, particularly valuable for long logistics paths.

How should I compare costs for TFS vs ETP in aerosol cans?

Go beyond base coil price. Include lacquer usage, weld scrap, seam cementing, scuff-related downgrades, and any down-gauging potential validated by buckle tests.

Are certifications different for TFS vs ETP in aerosol packaging?

Both materials can meet common certifications (ISO 9001/14001, food-contact where applicable, REACH/RoHS), and both must pass aerosol performance and transport requirements.

Can I mix materials, using ETP and TFS in one high-pressure can?

Yes. A common approach is an ETP welded body with ECCS ends or decorative components, balancing weld robustness with scuff-resistant aesthetics.

What testing is essential when choosing TFS vs ETP?

Test on formed parts: burst/buckle, leak, accelerated corrosion, lacquer cure on seams and domes, and pack tests simulating your logistics conditions.

Last updated: 2025-11-13

Changelog:

- Added cost TCO table and hybrid ETP/ECCS guidance for welded bodies and ends.

- Expanded weld window and lacquer cure pitfalls with fixes.

- Included Tinsun Packaging spotlight and internal links for products, about, and contact.

Next review date & triggers - Review in 6 months or upon changes in tin pricing volatility, aerosol regulations, or new lacquer systems.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.