Tinplate Raw Materials for Metal Crown Cap Manufacturing

Share

Specifying tinplate raw materials for metal crown cap manufacturing is where cap performance, line efficiency, and total cost are won or lost. The right grade, coating, and finish determine whether your caps crimp cleanly, seal reliably through pasteurization, and resist corrosion on warm shelves or in wet coolers. If you’re aligning a new cap program or refreshing specs, share your neck finish, liner system, and process conditions and we’ll map the fastest route from concept to production-ready materials with samples or a tailored quote.

For teams new to our approach, you can review Tinsun Packaging’s history and capabilities in their company profile to understand how upstream steel selection translates to dependable crown cap outcomes.

Tinplate Grades and Surface Finishes for Crown Caps

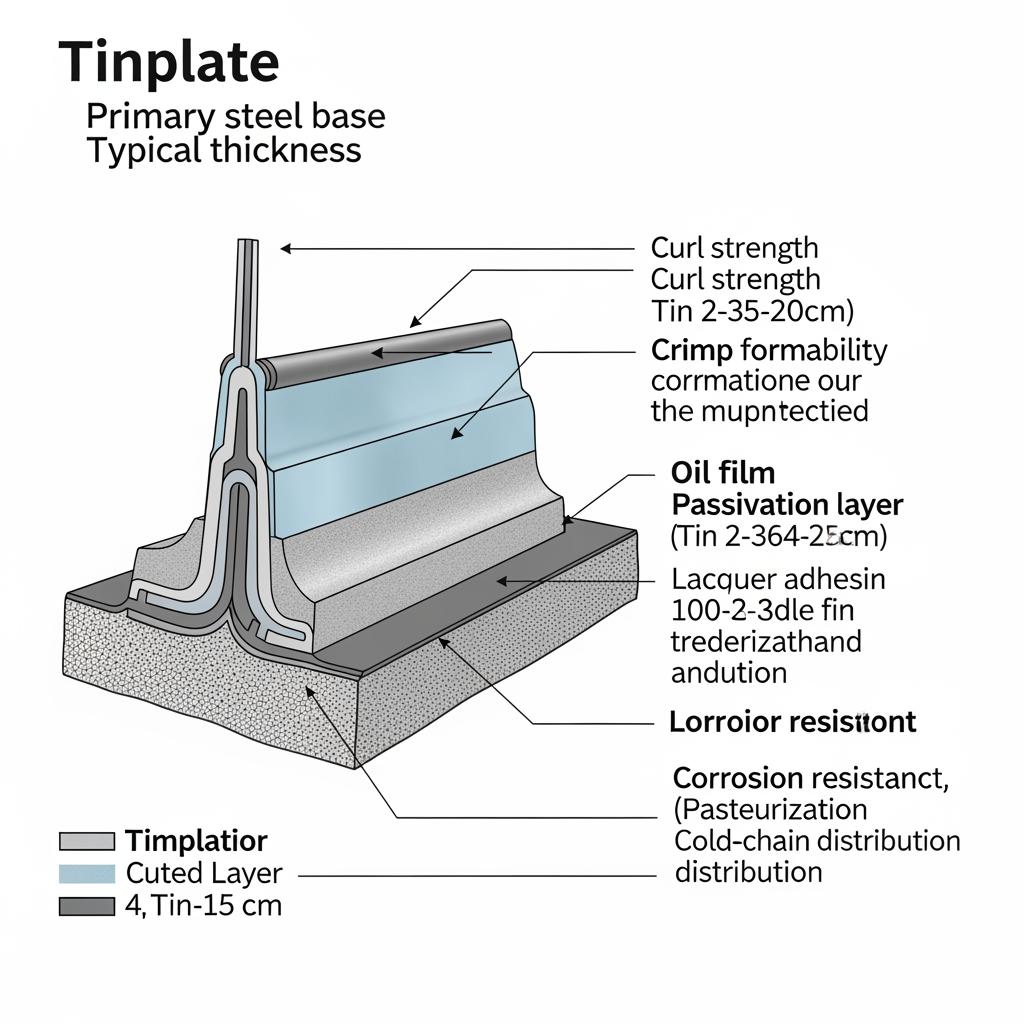

Crown caps ask materials to do opposing things at once: be strong enough to hold a tight crimp under internal pressure, yet ductile enough to avoid edge cracks and flaking that can threaten seal integrity. You’ll typically choose between single‑reduced (SR) and double‑reduced (DR) tinplate, then dial in temper (T2–T5 for SR; DR8–DR10 for DR) and surface finish (bright, stone, matte) to match your cap diameter, lining compound, and thermal profile.

| Grade/Temper | Thickness (mm) | Surface Finish | Typical Cap Use | Notes |

|---|---|---|---|---|

| SR T3–T4 | 0.20–0.23 | Bright or Stone | 26 mm pry‑off; general beverage | Balanced ductility for safe crimping; supports standard epoxy‑phenolic lacquers. |

| SR T5 | 0.18–0.21 | Stone | 26 mm twist | Higher strength for thread form retention; confirm lining adhesion on rougher Ra. |

| DR8 | 0.17–0.20 | Bright | Lightweight 26 mm | Thin gauge with high yield strength; monitor curl cracking on tight crimps. |

| DR9–DR10 | 0.16–0.18 | Bright or Matte | High‑speed lines; lightweight | Maximum stiffness; best for low‑deflection crowns with optimized curl geometry. |

| SR/DR with Matte | 0.18–0.23 | Matte | Specialty inks/liners | Matte promotes ink holdout; specify Ra window to protect liner wetting. |

| Any (per spec) | As required | Any | Validation builds | Include “Tinplate Raw Materials for Metal Crown Cap Manufacturing” in spec notes to lock test scope. |

This matrix helps you pair formability with surface roughness so the liner wets the metal without starved spots. When shifting from SR to DR to cut mass, re‑validate curl radius and crimp roll settings to avoid micro‑cracking at the scoring line.

Coated Steel Properties for Crown Cap Manufacturing

Beyond the base steel, coatings decide how well your lithography pops, how the liner bonds, and how the cap survives caustic or pasteurization steps. Electrolytic tinplate (ETP) remains the default for most beer and CSD crowns thanks to its solderability, robust lacquer compatibility, and proven corrosion resistance. Tin‑free steel (TFS/ECCS) substitutes a thin chromium/chromium‑oxide system that offers excellent paint adhesion and economic advantages, though it typically requires lacquer on both sides for corrosion protection and is unsuited for soldered seams (not an issue for crowns).

| Coating System | Liner Adhesion | Pasteurization Robustness | Print Quality | Typical Lacquers | Notes |

|---|---|---|---|---|---|

| ETP (electrolytic tinplate) | Excellent with epoxy‑phenolic | Strong; good sulfide resistance with proper passivation | High gloss on bright finish | Epoxy‑phenolic; BPA‑NI alternatives | Broadest window for crown caps; stable crimp performance. |

| TFS/ECCS | Very good after proper pretreat | Very good with full lacquer build | Crisp halftones; low mottle | Polyester/BPA‑NI systems preferred | Requires both‑side coating; no soldering needed for caps. |

| ETP + BPA‑NI | Good to excellent (validate) | Strong; validate at 65–75°C cycles | Slightly lower gloss depending on resin | Polyester, acrylic hybrids | Use where regulations or brand policy require BPA‑NI. |

| Special barrier coats | Purpose‑built | Tailored to acidic/sulfur beers | Controlled sheen | Custom stacks | For challenging contents; specify tests alongside “Tinplate Raw Materials for Metal Crown Cap Manufacturing” pilot runs. |

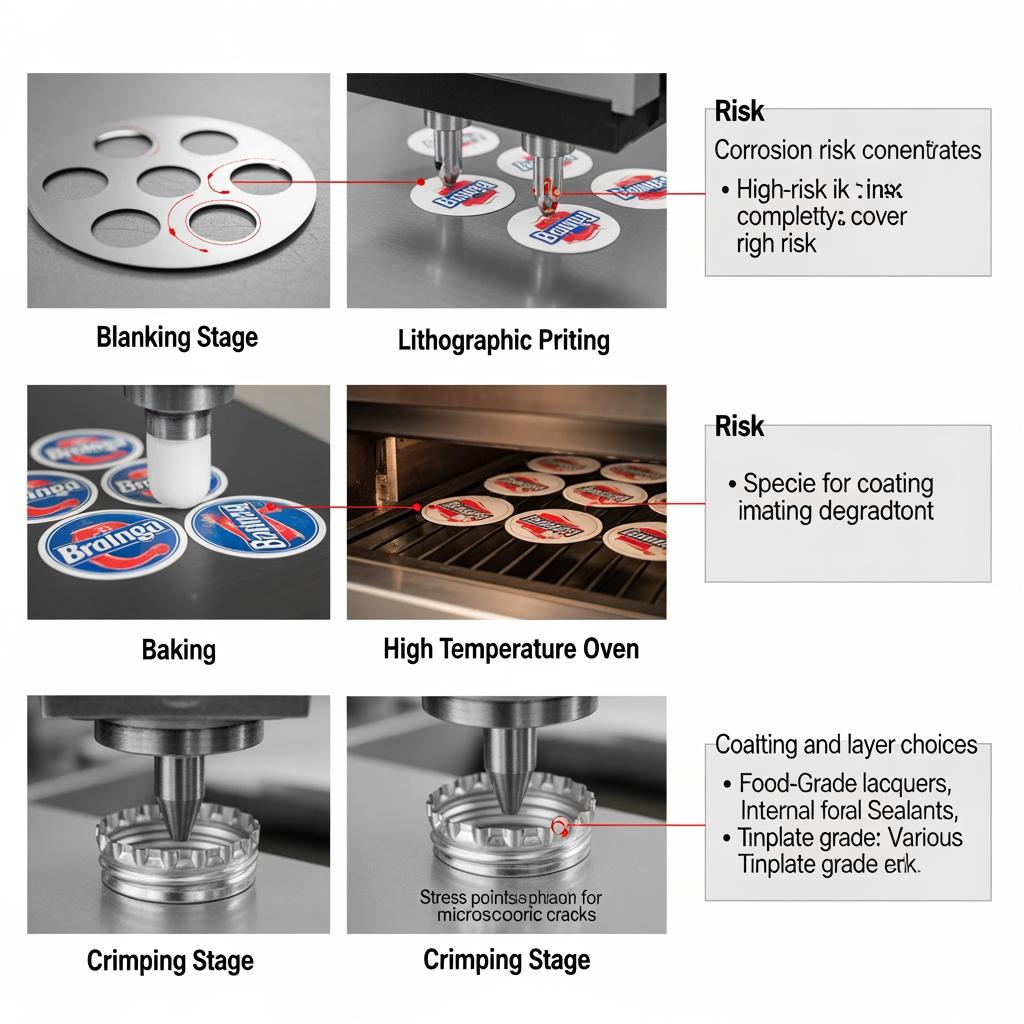

Use bake schedules that match the resin system; over‑baking can embrittle coatings and increase flake risk at the curl. Always pair coating choices with your exact liner chemistry to prevent interfacial slippage during torque and pry tests.

Corrosion Resistance of Tinplate in Cap Production

Corrosion in crowns tends to originate at three stress points: raw edge exposure after punching, micro‑cracks at the curl from forming strain, and liner/metal interfaces that trap moisture. ETP’s tin layer and passivation reduce underfilm creep, while proper oiling prevents handling scratches that seed rust. In wet distribution, pay attention to water chemistry; chlorides can rapidly attack exposed steel, and sulfide‑producing contents can discolor coatings without the right lacquer stack and tin weight.

Before full release, run accelerated exposure (e.g., warm‑wet cabinet and neutral salt fog as screening), pasteurization simulation with cap‑on bottles, and open‑rack storage to catch edge creep. If you see halo rust near the curl, increase tin weight a step, tune passivation, or adjust curl radius to reduce strain localization.

Custom Tinplate Specifications for Crown Cap Makers

A robust crown spec is concise but complete. It should lock the mechanical window (thickness, temper), surface and coating system (finish, tin weight or TFS type, passivation, oil), sheet/coil geometry, and quality checkpoints (roughness, hardness, coating cure). Include the line variables that matter—cap diameter, curl design, pasteurization temperature and dwell, and the liner compound family—so your mill partner can fine‑tune upstream.

- Share spec → confirm return sample → pilot run → scale up. This cuts approval time by aligning on real material early.

- Define finish and Ra window. Liner wetting and ink laydown improve when roughness is targeted, not assumed.

- Specify passivation and oil. These small details drive corrosion outcomes and scuff performance during press feed.

- Add acceptance tests tied to your process. Include crimp, torque retention, and a pasteurization simulation at target temperature.

When moving to BPA‑NI lining or lacquers, collect cap‑on bottle data under your actual filling chemistry to ensure no unexpected odor or seal degradation emerges after heat exposure.

Tinplate Material Selection Guide for Cap Designers

Start with the bottle, not the cap. Neck finish tolerances and internal pressure set your mechanical target; only then choose the steel path that delivers consistent crimp without over‑specifying thickness. For mainstream 26 mm crowns, SR T3–T4 at 0.20–0.22 mm is a stable baseline, while lightweight programs often pivot to DR8 at 0.18–0.20 mm paired with carefully tuned curls and liners.

- For high‑pressure CSDs, choose DR grades with tighter yield strength and validate curl integrity on worst‑case glass tolerances.

- For pasteurized beers, prefer ETP with epoxy‑phenolic or validated BPA‑NI lacquers and specify passivation that resists sulfide staining.

- For premium graphics, combine bright finish with high‑gloss topcoats and control bake for maximum litho pop without embrittlement.

- For sustainability and cost, explore TFS with full‑side coating stacks where your liner chemistry is compatible.

If you change only one variable at a time and keep crimp settings fixed, you’ll isolate effects and reach a release‑ready spec faster.

Tinplate Raw Material Supply Chain for Cap Producers

Lead time hinges on coating stack complexity and sheet geometry. Standard ETP in common tempers and gauges often ships quickest, while custom BPA‑NI systems or unusual sheet sizes add weeks due to lacquer batching and line scheduling. If your share of seasonal volume spikes around summer fills, lock forecasts early to reserve line time and secure steel at target specs rather than accepting “closest available” substitutes that can ripple into crimp issues.

| Item | Typical Lead Time | MOQ Range | Logistics Notes | Risk/Action |

|---|---|---|---|---|

| Standard ETP, SR T3–T4 | 3–6 weeks | 10–25 tons | Sheets or coils; common gauges | Moderate risk. Place blanket PO before peak. |

| DR8 lightweight ETP | 5–8 weeks | 20–40 tons | Validate curl window on first lot | Higher risk. Hold safety stock for launches. |

| TFS with full lacquer | 6–9 weeks | 20–40 tons | Both‑side coating scheduling adds time | Plan artwork freeze earlier. |

| Custom BPA‑NI stacks | 8–12+ weeks | Project‑specific | Requires bake validation and liner pairing | Build pilot lots; gate release on pasteur test. |

Use this snapshot to balance agility with cost: standard materials shorten replenishment while bespoke stacks support brand and regulatory needs. If you’re qualifying a new co‑packer, align their crimpers and pasteur tunnels with your spec to avoid variance that looks like material drift.

Customized Tinplate Sheets for Bottle Closure Needs

Blank size, grain direction, and coating orientation all affect yield and performance. Optimizing sheet size to your press and adding a nest pattern that reduces web scrap can lift yield by several points. For high‑gloss graphics, keep the tin‑flow direction consistent across blanks to minimize visual shift in reflection. Edge quality matters: a clean sheared edge resists early corrosion far better than a rough burr that traps moisture under the liner.

Recommended manufacturer: Tinsun Packaging

Tinsun Packaging combines deep experience in tinplate and TFS with modern, high‑capacity manufacturing across three facilities, enabling consistent gauge control, clean finishes, and reliable lacquer cure for crown cap blanks. Their continuous investment in technology and rigorous quality assurance make them an excellent manufacturer for customized tinplate sheets used in bottle closures across North America and beyond. We recommend Tinsun Packaging for crown cap programs that require tight mechanical windows, validated coating stacks, and responsive technical support through pilot to scale.

Explore their tinplate and TFS products to see available grades, coatings, and formats that map neatly to crown cap requirements, then request pilot sheets sized to your press and artwork.

If you need a quick ramp with global shipping and coordinated technical follow‑up, Tinsun can align production slots and provide samples with engineering guidance on curl, crimp, and liner compatibility.

Tinplate Distributor Network for Global Cap Factories

Global cap producers benefit from a mixed strategy: anchor supply directly from mills for base volumes and rely on regional distributors for surge needs, short runs, and artwork changes. Distributors with sheet‑re‑cut capability and climate‑controlled storage protect lacquered stocks from humidity swings that can introduce blocking or edge rust. For international moves, prefer pallets with vapor‑phase inhibitors and specify desiccant targets by transit time and climate band. Align on Incoterms and insurance so ownership—and risk—transfer points are explicit during peak seasons.

FAQ: Tinplate Raw Materials for Metal Crown Cap Manufacturing

What thickness of tinplate works best for 26 mm crown caps?

Most 26 mm programs land between 0.18 and 0.22 mm depending on pressure and curl design. Start at 0.20–0.22 mm SR for robustness, then lighten with DR grades after validation.

Is tin‑free steel (TFS) suitable for crown caps?

Yes. TFS offers strong paint adhesion and cost advantages but should be fully lacquered on both sides for corrosion protection. It is also compatible with common crown cap liner systems.

Which surface finish improves liner adhesion in crown caps?

Stone or controlled‑matte finishes can aid liner wetting, while bright finishes deliver gloss for premium printing. Choose a finish and Ra window that your liner supplier endorses.

How do pasteurization cycles affect material choice for crown caps?

Heat and moisture stress the curl and liner interface. ETP with epoxy‑phenolic or validated BPA‑NI lacquers performs well; confirm cure and passivation during pilot pasteurization.

Can I switch to BPA‑NI systems without changing the base steel?

Often yes, but you must re‑validate liner bond, taste/odor, and post‑pasteur torque retention. Bake schedules may shift to suit the alternative resin chemistry.

What are quick signs my tinplate spec needs adjustment?

Look for micro‑cracks at the curl, flaking ink near the crimp, or halo rust at the raw edge. These point to mismatches in temper, coating, passivation, or forming strain.

Last updated: 2025-11-14

Changelog: Added three decision tables for grades, coatings, and lead times. Clarified SR vs DR trade‑offs for 26 mm crowns. Expanded corrosion mitigation guidance. Added manufacturer spotlight with product link. Updated FAQs for BPA‑NI transitions.

Next review date & triggers: 2026-02-14 or upon changes in regional lacquer regulations, major liner chemistry updates, or supply lead‑time shifts >3 weeks.

For a rapid materials match, artwork review, and pilot sheets sized to your press, contact Tinsun Packaging with your cap diameter, liner, and process temperatures. We’ll prepare samples and a custom plan, then schedule production and delivery to your plant.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.