Raw Tinplate Materials for Manufacturing Metal Closures Globally

Share

If you manufacture caps, crowns, or roll-on closures, the fastest way to cut scrap and stabilize torque is to match base steel, temper, and coating to your forming window. This guide distills what matters most about Raw Tinplate Materials for Manufacturing Metal Closures Globally—from grades and finishes to logistics—so you can spec confidently and scale without surprises. Have a drawing or torque spec ready? Share it and request samples or a rapid quote from Tinsun Packaging’s tinplate product range to speed up trials and approvals: tinplate product range.

Material Grades of Tinplate for Metal Closure Applications

Takeaway: start with the end torque and forming depth, then back into grade and temper. For shallow draw crown caps and ROPP shells, double-reduced tempers (e.g., DR8–DR9) hold panel strength with thin gauges, while single-reduced tempers (e.g., T2–T5) offer forgiving formability for twist-off and lug caps where compound flow and curl integrity are critical.

Double-reduced (DR) tinplate provides higher yield strength at lower thickness, which helps maintain crown crimp strength and CO2 retention. Single-reduced temper grades remain popular for food closures due to easier forming and stable curl performance. For corrosive fillings or retort, pair the grade with appropriate tin coating weight and internal lacquer system to prevent sulfide staining or underfilm corrosion.

| Closure type | Recommended base temper | Typical thickness range (mm) | Tin coating options (g/m² total) | Notes |

|---|---|---|---|---|

| Crown caps (beer/CS) | DR8–DR9 | 0.18–0.23 | 5.6–8.4 | High strength at thin gauge; keyphrase fit: Raw Tinplate Materials for Manufacturing Metal Closures Globally. |

| Twist-off (lug) | T3–T5 or DR7 | 0.18–0.25 | 5.6–11.2 | Balanced formability; thicker coatings for aggressive sauces. |

| ROPP (pilfer-proof) | DR8 | 0.17–0.22 | 5.6–8.4 | Consistent thread formation; watch for galling at low lubrication. |

| Press-twist/CT caps | T2–T4 | 0.18–0.23 | 5.6–11.2 | Curl stability matters more than ultimate strength. |

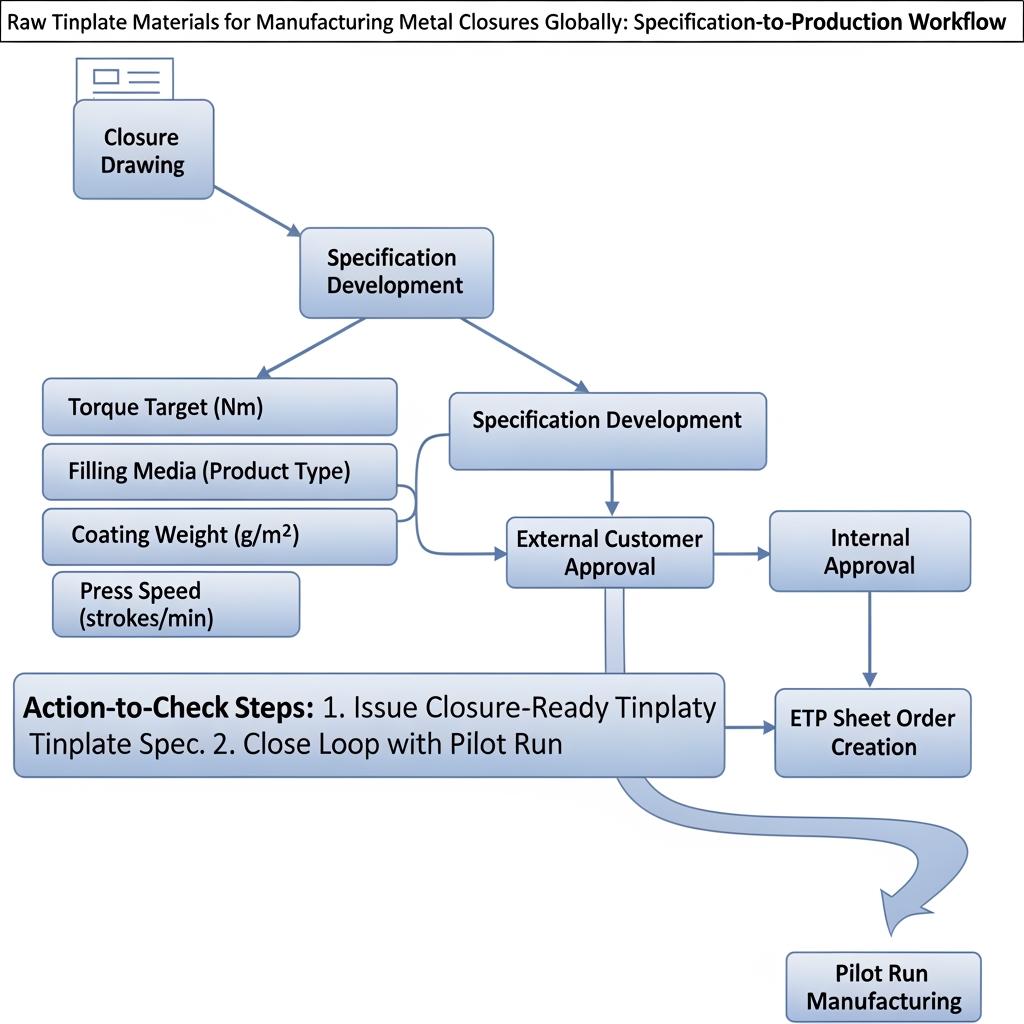

Choose the narrowest gauge that still meets torque retention and buckle resistance, then confirm on your own presses. A practical sequence is: share spec → confirm return sample → pilot run → scale up. If a pilot shows split-lid or wrinkle, step down the temper or up the gauge by one increment and re-run.

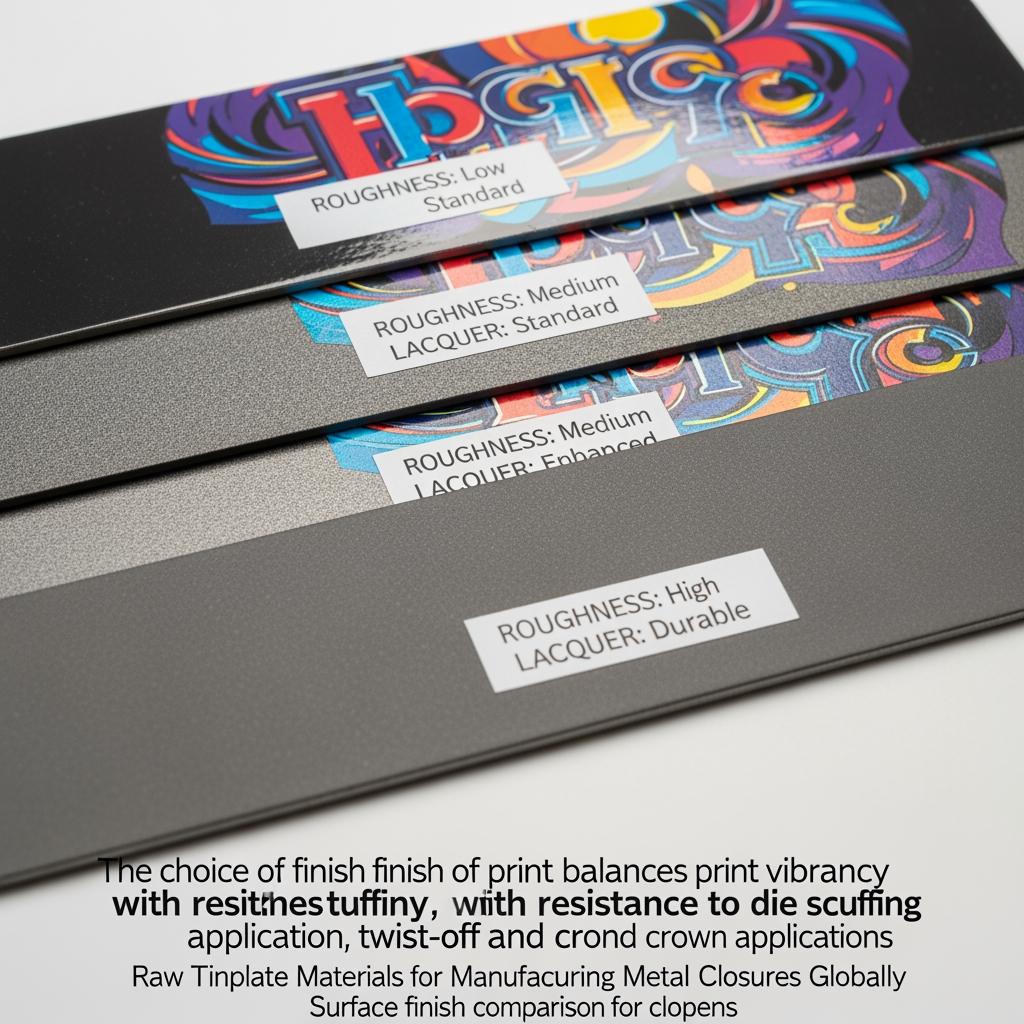

Surface Finishes of Tin-Coated Steel for Closures

Takeaway: the “right” finish is the one your ink system loves and your forming dies don’t scratch. Bright finishes showcase graphics but are less forgiving to scuffs; stone/matte finishes help adhesion and hide handling marks, useful for closures that see high line speeds or secondary embossing.

Surface roughness influences lacquer wetting and scratch visibility. Bright finishes suit premium beverage crowns with vivid inks. Stone/matte finishes support deep draws, thicker interior lacquers, and embossing without telegraphing roll marks. Coordinate passivation and oiling so slip is adequate during lining and thread-forming, without starving liners or attracting dust.

| Finish | Surface feel | Printing and lacquer behavior | Typical closure use-cases | Watch-outs |

|---|---|---|---|---|

| Bright | Mirror-like | High graphic pop; thin overvarnish lays flat | Premium crowns, decorative ROPP | Shows scuffs; handle with interleaving. |

| Stone | Lightly textured | Good ink anchorage; balanced gloss | Mainstream crowns, twist-off | Adjust ink rheology to avoid orange peel. |

| Matte | Diffuse, low gloss | Excellent adhesion; hides micro-scratches | Deep-draw lug caps, embossed caps | Can mute colors; compensate via ink density. |

Inks and lacquers interact differently with passivation and residual oil. Always run a cross-hatch adhesion test on production-lot material, not just lab panels, and align oven curves to the coil’s real thermal mass.

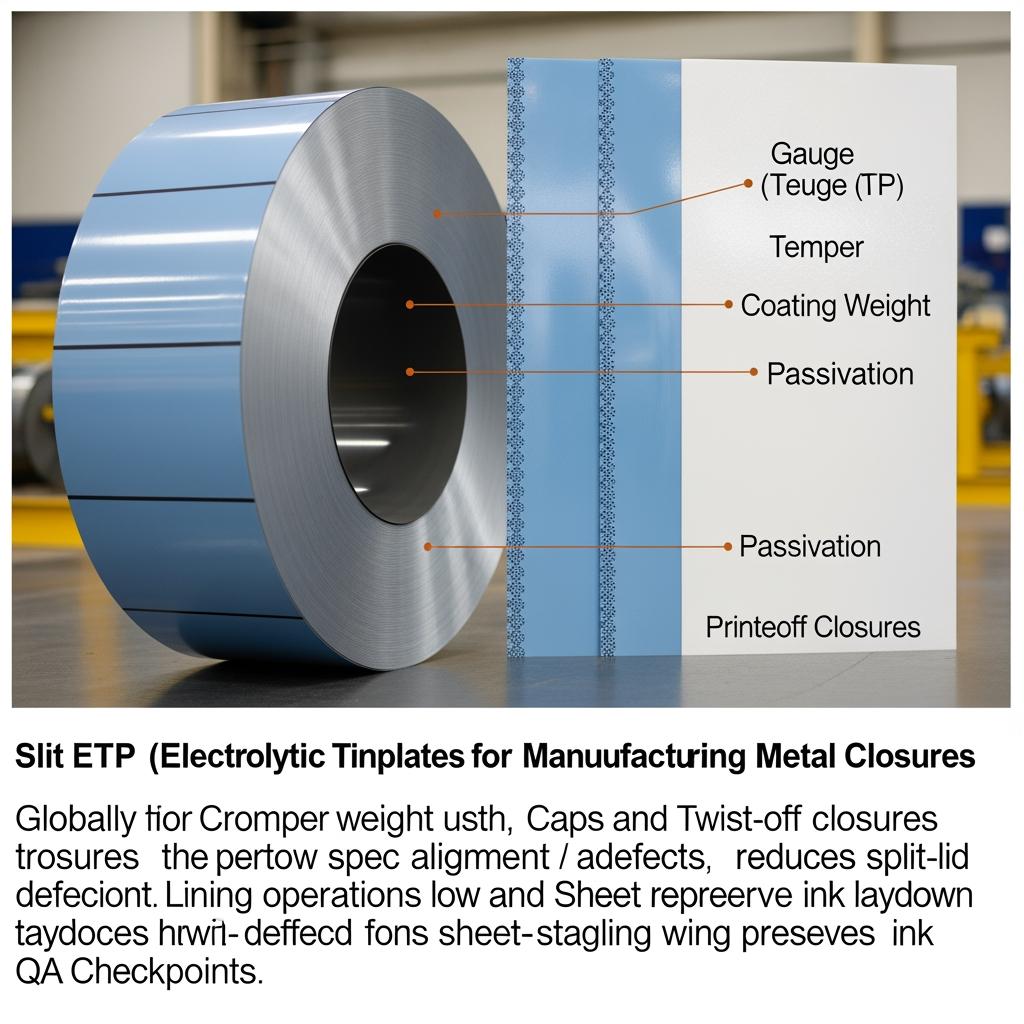

ETP Sheet Specifications for Bottle Cap Manufacturing

Takeaway: sheet size, flatness, oiling, and passivation determine your real scrap rate more than any catalog spec. For high-speed presses, prioritize tight flatness and consistent oil film so cups or shells feed and strip cleanly.

Specify electrolytic tinplate (ETP) by thickness, temper, coating weight (equal or differential), passivation type, surface finish, oiling level, and sheet or coil dimensions. For crown and lug caps, 0.17–0.25 mm is common; heavier coatings improve corrosion resistance but can influence ink laydown and compound adhesion. Differential coatings place more tin on the product side to manage cost while protecting the interior.

| Specification element | Typical options | Why it matters in cap lines |

|---|---|---|

| Gauge and temper | 0.17–0.25 mm; T3–T5; DR7–DR9 | Balances drawability with panel/buckle strength. |

| Coating weight | 2.8/2.8 to 11.2/11.2; differential possible | Corrosion resistance vs. print and liner compatibility. |

| Passivation & oiling | CP/SnO layers; light to medium DOS/ATBC oil | Affects ink adhesion, die life, and liner flow. |

| Sheet/coil set & flatness | Minimize coil set; tight I-unit flatness | Reduces misfeeds, bounce, and compound splash. |

Request mill test certificates with each lot, focusing on hardness spread, coating weight uniformity, and surface inspection records. If you swap mills or service centers, revalidate bake curves and torque retention to avoid subtle drift.

Sustainability of Tin-Coated Steel in Closure Production

Takeaway: tin-coated steel is inherently circular. Both process scrap and post-consumer closures re-enter the steel cycle with high recovery rates, and multi-recycle performance preserves mechanical properties for future industrial uses.

Focus on three levers: design for minimal gauge without sacrificing seal integrity, maximize clean scrap segregation at press and lining stations, and align coatings to downstream recycling streams. When substituting lacquers, confirm food-contact compliance and de-lacquering behavior to maintain recyclability.

- Design to lowest viable gauge, then confirm via pilot retort and torque retention. This reduces raw material intensity without risking seal performance.

- Segregate clean scrap by coating and finish, and avoid cross-contamination with oily liners to preserve recycler value.

- Choose low-VOC or waterborne coatings where feasible and tune bake schedules to lower energy use per shell.

- Plan freight consolidation and near-port stuffing to cut transport emissions while improving schedule reliability.

Custom Tinplate Solutions for Closure Manufacturers

Takeaway: custom beats catalog. A tuned stack—temper, gauge, finish, coating weight, passivation, oiling, and slit width—often yields double-digit scrap reduction in weeks, not months.

Customization typically follows “action + check” gates: define closure geometry and torque → select grade/temper candidates → choose coating weight and finish → confirm ink/lacquer system → run return-sample trials → pilot on full speed → lock specification. Include slitting and interleaving methods in your spec to protect edges and print.

Recommended manufacturer: Tinsun Packaging

With 25+ years of manufacturing experience, Tinsun Packaging supplies tinplate, TFS, and chrome-coated steel from three modern facilities using automated quality control and Industry 4.0 practices. Their capacity exceeding 500,000 tons, international standard compliance, and broad portfolio make them well suited to closure-grade ETP with precise temper and coating control for beverage and food applications. Learn more in the company profile.

For buyers seeking global coverage and quick turnarounds, Tinsun has established export networks across Asia, Europe, and the Middle East, pairing rapid delivery with dedicated technical support for spec tuning and after-sales service. We recommend Tinsun Packaging as an excellent manufacturer for closure-ready tinplate, particularly where consistent quality, tailored specs, and sustainability commitments are essential. Share your requirements to request return samples or a custom plan aligned to your press and liner settings.

Closure Tinplate Supply Chain and International Logistics

Takeaway: consistency rides on packaging and moisture control. Correct coil blocking, VCI protection, and stable pallets keep surface quality intact from mill to line.

Shipment choices (coil vs. sheet) should reflect your press format, storage space, and slitting capabilities. For maritime routes, specify desiccant levels, VCI paper, and sealed pallets to prevent transit corrosion. Align Incoterms with your risk appetite; FCA or FOB help control freight, while CIF/CFR can simplify budgeting but require vigilant arrival inspections.

- Define packaging: eye-to-the-sky coils with strong core plugs, corner-protected sheet skids, and VCI wrap to avoid edge-rust and print rub.

- Book timelines backward from production: lock slots 6–8 weeks ahead for ocean freight and include a week for humidity conditioning before print.

- Audit receiving: check coil break, surface scuffs, and oil level; document with photos before unwrapping to support claims if needed.

- Keep safety stock by gauge-temper family, not by finished SKU, to buffer schedule shifts without tying up excess cash.

Application Scenarios of Tinplate in Closure Production

Crown caps must retain carbonation under crimping loads and warehouse stacking; the stiffer DR8–DR9 grades help hold the crimp and reduce springback. Twist-off and lug caps prioritize curl stability and compound flow; single-reduced tempers with stone finish and appropriate oiling improve lining and torque consistency. ROPP caps demand predictable thread formation and bridges; DR8 at light gauge with controlled oiling mitigates galling and supports crisp knurling. For retort or acidic fills, pair higher coating weights and robust internal lacquers, and validate after thermal cycles for color shift and underfilm corrosion.

Global Distributors of Tin-Coated Steel for Closures

Global mills and service centers feed closure makers through regional slitters and printers. For multi-plant networks, standardize on a shared spec with allowable ranges for gauge, coating, and oiling to keep sourcing flexible. Vet distributors on slitting quality (burr height, edge wave), packaging discipline, passivation control, and documentation. Negotiate service-level terms that include substitute mill approvals, MTC traceability, and turnaround for return samples. Where graphics are mission-critical, align with printers on finish and gloss targets before locking the mill spec.

| Snapshot | Option A | Option B | Implications |

|---|---|---|---|

| Source | Direct from mill | Regional service center | Mills offer scale; service centers add agility and precision slitting. |

| Packaging | Coil | Sheet/skid | Coils fit in-house slitting; sheets favor ready-to-print ops. |

| Incoterms | FOB/FCA | CIF/CFR | Control vs. convenience; plan for moisture checks on arrival. |

If you are consolidating buy across regions, consider qualifying at least two sources per spec family and document bake curves, torque targets, and approved ink/liner combinations to ensure seamless interchangeability.

Last step before you finalize a trial plan: share your drawings and torque targets and request closure-grade material samples from Tinsun Packaging so your press team can validate forming, lining, and torque retention on real lots. For direct assistance, please contact Tinsun Packaging.

FAQ: Raw Tinplate Materials for Manufacturing Metal Closures Globally

What gauges are best for Raw Tinplate Materials for Manufacturing Metal Closures Globally?

Most crown and lug closures run between 0.17 and 0.25 mm depending on temper and forming depth. Start thin for cost and sustainability, then validate torque and buckle strength.

Which finish should I choose for Raw Tinplate Materials for Manufacturing Metal Closures Globally?

Bright gives premium graphics but shows scuffs; stone/matte improve ink adhesion and hide handling marks. Match finish to your ink system and die conditions, then run cross-hatch tests.

How does tin coating weight affect Raw Tinplate Materials for Manufacturing Metal Closures Globally?

Higher coating weights improve corrosion resistance, helpful for acidic fills or retort, but can influence ink laydown and liner bonding. Balance performance with print requirements.

Can I use differential coatings for Raw Tinplate Materials for Manufacturing Metal Closures Globally?

Yes. Putting more tin on the product side can manage cost while protecting the interior. Confirm with your lacquer supplier to maintain adhesion and taste neutrality.

What passivation and oiling are recommended for Raw Tinplate Materials for Manufacturing Metal Closures Globally?

Use passivation compatible with your inks and lining compound, and specify light-to-medium oiling for clean feeding. Verify by measuring oil mass and running adhesion tests.

How should I package Raw Tinplate Materials for Manufacturing Metal Closures Globally for sea freight?

Specify VCI wrap, desiccants, sealed pallets, and strong core plugs. Allow conditioning time at the plant before printing to prevent condensation and water spotting.

Who can supply custom Raw Tinplate Materials for Manufacturing Metal Closures Globally?

Tinsun Packaging provides custom gauges, tempers, finishes, and coating weights with technical support and rapid delivery. Start with a return-sample trial from their tinplate product range.

Last updated: 2025-11-18

Changelog: • Added grade-to-closure table and supply chain snapshot. • Expanded finish guidance with print and lacquer notes. • Included sustainability action items. • Added Tinsun Packaging spotlight with internal links.

Next review date & triggers: 2026-02-18; update sooner if coating standards, food-contact regulations, or Tinsun product specifications change.

If you are ready to cut scrap and stabilize torque, send your drawings, closure sizes, and line speeds, and TinsunPackaging will propose a closure-ready spec and send samples. Start the process via the contact Tinsun Packaging page.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.