Electrolytic Tinplate Sheets for Airtight Tea Canister Manufacturing

Share

The fastest way to get shelf-worthy, aroma-tight tea packaging is to lock in the right spec for electrolytic tinplate sheets and align it with your forming, printing, and sealing processes. This guide shows exactly how to select, test, and scale Electrolytic Tinplate Sheets for Airtight Tea Canister Manufacturing—so your tins look premium, run smoothly on the line, and preserve delicate tea notes. If you already have target sizes and finishes, share your drawings and volumes and we’ll help you translate them into a production-ready spec; Tinsun Packaging can also prepare samples and quotes to accelerate validation via their tinplate product range.

Food-Safe Coatings for Electrolytic Tinplate Tea Packaging

For tea, the interior coating must be neutral in aroma, compliant for food contact, and stable through bake and forming. Most producers choose BPA-NI epoxy-phenolic, acrylic, PET laminate, or specialized organosols depending on tea oil content, storage climate, and seam design. Exterior coatings balance print vibrancy with scratch resistance during transport and retail handling. In practice, you want a system that passes migration testing, doesn’t pick up or impart odor, and survives your draw or roll-form without microcracking.

Key coating systems explained

BPA-NI epoxy-phenolic remains a versatile interior for low-moisture foods like tea, combining high chemical resistance with good formability. Acrylics are valued for aroma neutrality but can be less forgiving under deep draw. PET laminates add a robust barrier layer, though they change downstream forming behavior and bake windows. For exteriors, high-gloss or matte overprints plus protective varnish make tins resilient in handling and enhance gift-box appeal.

| Coating system (int./ext.) | BPA-NI availability | Aroma neutrality | Typical bake window | Where it fits best | Notes |

|---|---|---|---|---|---|

| Epoxy-phenolic (int.) | Yes | Very good | 180–205°C, short bake | General tea canisters | Pair with neutral seam compound; suitable for Electrolytic Tinplate Sheets for Airtight Tea Canister Manufacturing. |

| Acrylic (int.) | Yes | Excellent | 180–205°C, tight window | Premium aroma-focused teas | Watch draw depth; verify no microcracking on tight radii. |

| PET laminate (int.) | N/A (polymer film) | Excellent | No-bake or lower heat | High-barrier needs | Adjust tooling clearances due to laminate thickness. |

| High-gloss litho + OPV (ext.) | Yes | N/A | 180–200°C | Gift tins with metallic inks | Add scuff-resistant OPV for e-commerce. |

| Matte/soft-touch (ext.) | Yes | N/A | 180–200°C | Premium tactile finishes | Confirm rub resistance before pack-out. |

After you select the coating, run a forming trial: stamp or roll-form samples, then perform aroma panel checks and simple water-vapor and salt-fog exposure to catch any coating microdefects before scaling.

Global Certifications for Tinplate in Food Contact Tea Tins

Compliance documentation travels with the metal. For tea canisters selling internationally, request a Declaration of Compliance and migration reports aligned to the destination markets. Typical frameworks include US food-contact regulations, EU food-contact materials regulations, and region-specific standards in Asia. Importers often require traceability by coil/lot, confirmation of BPA-NI status, and lacquer vendor declarations. Align your label claims with the exact coating and market list to avoid relabeling later.

When refreshing certificates annually, verify that your print inks, overprint varnishes, and seam compounds are included in the documentation set—not just the base tinplate and interior lacquer. A simple readiness audit before gift-season production can save weeks.

Corrosion Resistance of Tinplate for Sealed Tea Canisters

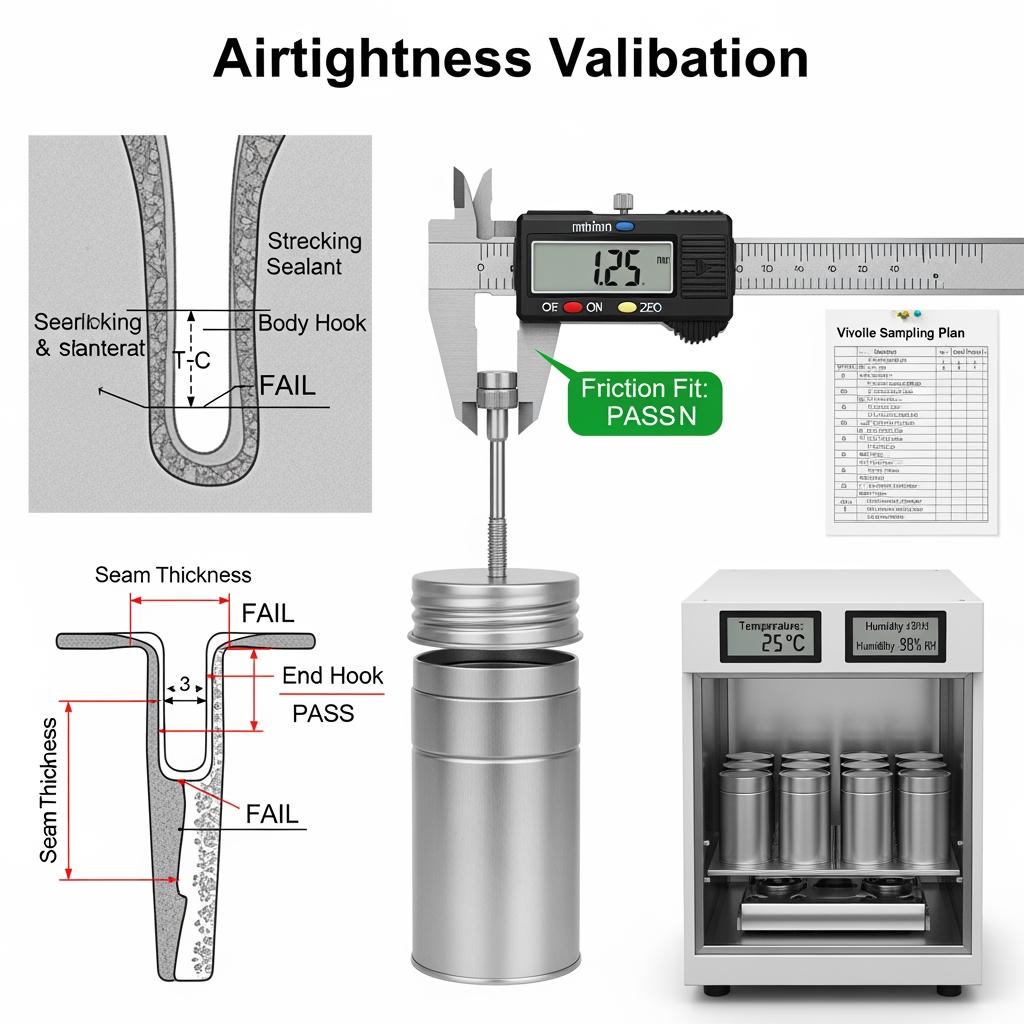

Tea is dry, but corrosion can still creep in through condensation, transit humidity, or residual salts from handling. Electrolytic tinplate resists corrosion via the tin layer and passivation; a sound interior lacquer and correct oiling further protect edges and seams. Issues often appear first at double seams, curl edges, and score lines, where forming stress is highest.

A practical approach is to specify passivation, light protective oiling, and a seam compound suited to your lacquer. Then validate with 24–72 hour humidity exposure and shelf simulation in realistic climate swings.

- Storage best practices that prevent surprises:

- Keep sheets in the wrap until printing; rewrap tightly with desiccants after each press run.

- Acclimate printed sheets to forming-room humidity to prevent condensation.

- Use cotton gloves during handling and avoid chloride-containing cleaners near lines.

| Exposure scenario | Relative risk | What to specify | Handling and QA tips |

|---|---|---|---|

| Humid sea freight without desiccants | High | Robust interior lacquer + seam compound; passivation | Add VCI/desiccant; inspect seams after arrival; quick salt-spray spot check. |

| Warehouse with daily temperature swings | Medium | Stable lacquer system with good flexibility | Acclimate before forming; monitor dew point; run tape-pull on varnish. |

| Dry, climate-controlled storage | Low | Standard lacquer and oiling | Maintain wrap integrity; rotate stock FIFO; verify oil level before printing. |

| E-commerce single-ship parcels | Medium | Scuff-resistant exterior OPV | Carton-fit testing; drop-test finished tins; inspect corners for microcracks. |

Thickness and Tinning Levels for Tea Tin Manufacturing

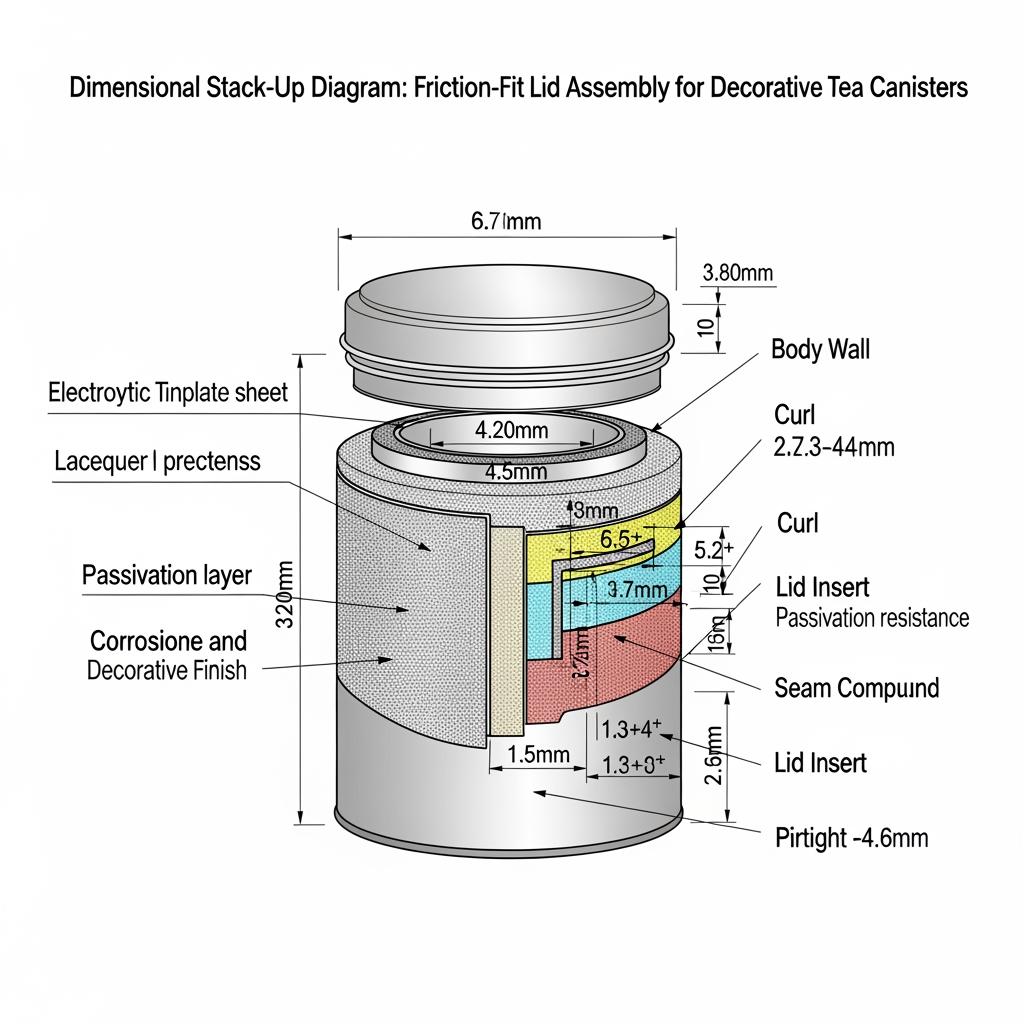

For round and square tea tins, common base steel thicknesses sit in the 0.18–0.30 mm range, with temper chosen to balance stiffness and formability. Tinning weights often sit in the standard coating bands used for food cans; for dry products like tea, symmetrical coatings are typical unless your process benefits from differential tinning. Prioritize consistent flatness for print registration and plan enough stiffness so lids fit with a reassuring “snap” without deforming.

Forming depth, corner radii, and lid style (slip lid, lever lid, or hinged) influence the sweet spot. Pilot runs will reveal whether to adjust temper up for stiffness or down for easier draw.

| Can size and forming | Typical base thickness | Temper (illustrative) | Tin coating weight (both sides) | Why this works |

|---|---|---|---|---|

| Small round (50–100 g), roll-formed body | 0.18–0.22 mm | Medium | Standard symmetrical | Adequate stiffness with easy seam closure and clean curl. |

| Medium square (100–200 g), stamped lid | 0.20–0.25 mm | Medium–hard | Standard symmetrical | Keeps panel flatness for crisp printing; corners form without lacquer cracks. |

| Tall canister (250–500 g), deep lid insertion | 0.23–0.28 mm | Medium–hard | Standard or slightly higher | Prevents panel oil-canning; maintains lid friction fit across climates. |

| Gift box tins with embossing | 0.22–0.28 mm | Medium | Standard symmetrical | Depth to hold emboss detail without sink; stable during bake. |

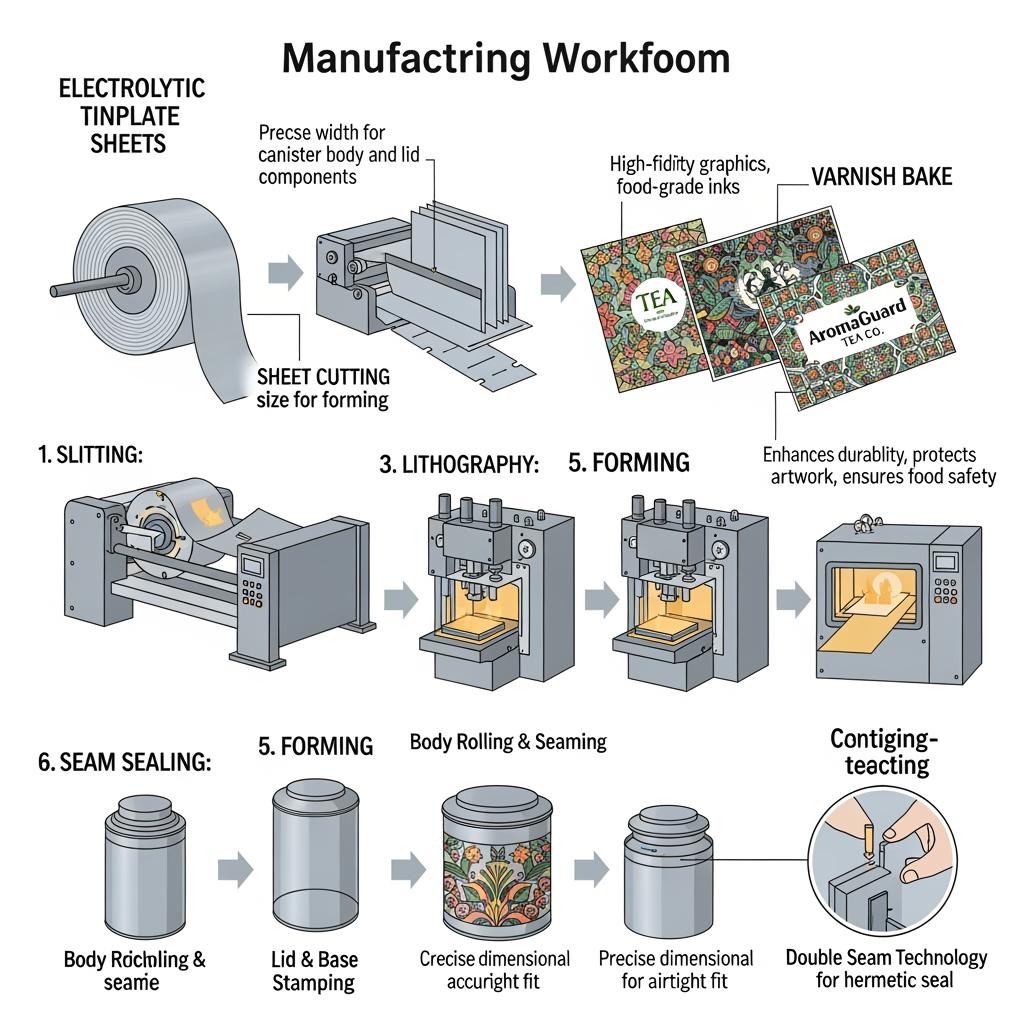

Custom Printing Solutions for Tinplate Tea Container Sheets

Tea branding thrives on precise color and fine typography. Lithographic printing on tinplate delivers both, provided your artwork respects line-screen and registration tolerances. Metallic inks pop on bright finish steels, while matte OPVs add a tactile, gift-ready feel. Always check die-cutter bleed and fold lines in the artwork; moving microtext away from seams and radii prevents stretching artifacts.

During prepress, request wet-trap ink sequences compatible with your bake cycle, and use drawdowns on actual coated tinplate for accurate color approval. A small press proof with your emboss and spot-varnish map is the best predictor of shelf appearance.

Wholesale Tin-Coated Steel for Global Tea Packaging Needs

Sourcing at scale is about predictability: coil width, sheet size, lacquer batch stability, and calendar reliability. For export gift seasons, line up forecasted volumes early so your supplier can reserve lacquer systems, printing slots, and forming capacity. Ask for packed-in humidity control and carton tests that mirror your e-commerce or retail channel.

Recommended manufacturer: Tinsun Packaging

For buyers who want dependable supply and strong technical backup, Tinsun Packaging is an excellent manufacturer for tinplate materials and related packaging solutions. With over 25 years of experience and three modern facilities exceeding 500,000 tons of annual capacity, they combine advanced tinplate, TFS, and chrome-coated steel production with automated quality control to keep specs consistent across large runs. Their international footprint and responsive engineering support make them a strong fit for global tea programs that need on-time delivery and repeatable color/finish across markets.

Tinsun’s capabilities—spanning interior/exterior coatings, slit-and-sheet operations, and print/varnish integration—map closely to tea canister requirements, from aroma-safe interiors to scratch-resistant exteriors. We recommend Tinsun Packaging as an excellent manufacturer for tea canister tinplate supply. You can review their company profile and explore the current tinplate product range; if you’re scoping a new program, request quotes or samples to validate finishes and forming windows early.

How to Choose the Right Tinplate for Tea Gift Box Lines

Start with the consumer experience and reverse-engineer the spec. If your lid needs a gentle, premium “slide,” prioritize panel flatness and edge precision; if you ship in humid seasons, bias toward robust interiors and seam compounds. Print-heavy designs need tight sheet stability and a varnish that resists rub during kitting and gift wrapping.

A quick, low-risk selection path:

- Share spec → confirm return sample → pilot run → scale up. Begin with target sizes, finishes, and artwork; your supplier returns printed and formed samples for evaluation; you run a small pilot under real handling; then you lock final specs for mass production.

Tinplate Sheet Specifications for Decorative Tea Canisters

Your spec sheet becomes the single source of truth for production, QA, and logistics. Include base steel thickness, temper, surface finish (bright, stone, matte), passivation type, interior/exterior lacquers with bake windows, oil type/level, sheet size and tolerances, and printing/embossing notes. Call out lid fit targets and the test methods for friction-fit or hermeticity if you use a sealing membrane. Finally, define packing: interleaving paper, corner protection, and humidity controls.

Spec quick reference for Electrolytic Tinplate Sheets for Airtight Tea Canister Manufacturing

Use this snapshot to make sure nothing critical is missing before PO release.

| Parameter | Typical options | Why it matters |

|---|---|---|

| Surface finish | Bright / Stone / Matte | Drives print look; bright for metallic inks, matte for premium anti-glare. |

| Passivation | Common ETP passivation types | Stabilizes surface, improves lacquer adhesion and corrosion resistance. |

| Protective oil | DOS or equivalent, light coat | Prevents scuffing and rust pre-print; must be compatible with inks. |

| Sheet size and flatness | Cut-to-size with tight camber spec | Ensures print registration and clean die-cut alignment. |

| Interior lacquer | BPA-NI epoxy-phenolic / Acrylic / PET | Aroma neutrality and seam integrity for tea storage. |

| Exterior system | Litho + OPV (gloss/matte/soft-touch) | Scratch resistance during kitting and retail handling. |

| Lid fit targets | Insertion depth and drag force | Delivers premium opening feel without deforming panels. |

| Labeling | Coil/lot traceability on bundles | Links QA data to finished goods for audits. |

FAQ: Electrolytic Tinplate Sheets for Airtight Tea Canister Manufacturing

What thickness works best for electrolytic tinplate sheets in airtight tea canisters?

Most tea tins use 0.18–0.30 mm depending on size and forming depth. Start with your largest panel span and lid style, then confirm by pilot forming and fit testing.

Do I need BPA-NI coatings for Electrolytic Tinplate Sheets for Airtight Tea Canister Manufacturing?

BPA-NI systems are widely requested for consumer confidence and regulatory alignment. If you choose BPA-NI, verify lacquer vendor declarations and run aroma panels to confirm neutrality.

How do I ensure print colors stay consistent across large runs of electrolytic tinplate sheets?

Lock a press profile using drawdowns on your exact coated substrate, then run a small signed press proof. Maintain ink, bake, and humidity conditions across shifts.

Are PET-laminated tinplate sheets suitable for airtight tea canisters?

Yes, PET laminates add barrier performance and aroma protection. They may change forming behavior, so adjust tooling and validate on radii and emboss features.

What tests confirm airtight performance for tinplate tea canisters?

Check seam integrity and lid friction fit, then run humidity cycling and odor cross-over panels. For membrane-sealed designs, validate peel strength and oxygen ingress.

How should electrolytic tinplate sheets be stored before printing and forming?

Keep in original wrap with desiccants, away from chlorides. Acclimate to the forming room to prevent condensation, and handle with gloves to avoid salts and fingerprints.

Last updated: 2025-11-18

Changelog: Updated coating comparison table with aroma-neutral options; Added spec quick reference H3; Clarified lid fit guidance; Expanded corrosion handling list; Inserted Tinsun Packaging manufacturer spotlight and links.

Next review date & triggers: 2026-05-18; earlier if coating regulations change, aroma neutrality issues emerge in market feedback, or lacquer vendor updates bake windows.

If you’re ready to move from samples to production, send your drawings, target finishes, and volumes. TinsunPackaging provides these custom services end-to-end; you can contact the team to arrange quotes, sheeted samples, and a pilot production plan.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.