How Easy Open Ends Manufacturers Source Tin-Free Steel Materials

Share

Sourcing tin-free steel (TFS/ECCS) for easy open ends (EOE) is equal parts material science, supplier vetting, and supply-chain discipline. This guide maps out How Easy Open Ends Manufacturers Source Tin-Free Steel Materials from mill to press line, so you can choose the right substrate, coating, and partner without delays. If you want tailored advice for your line, share your EOE specs and coating targets and request a quote or samples from Tinsun Packaging via their contact page: request a quote.

Introduction to Tin-Free Steel in Can End Production

Tin-free steel—also known as electrolytic chromium coated steel (ECCS)—is a low-carbon steel sheet coated with metallic chromium and a thin chromium oxide layer. In can end production, TFS is prized for its consistent scoreability, excellent lacquer adhesion, and competitive cost versus tinplate. For EOE shells and tabs, the combination of controlled temper, optimized surface roughness, and lacquer systems enables reliable opening performance while reducing dependence on tin.

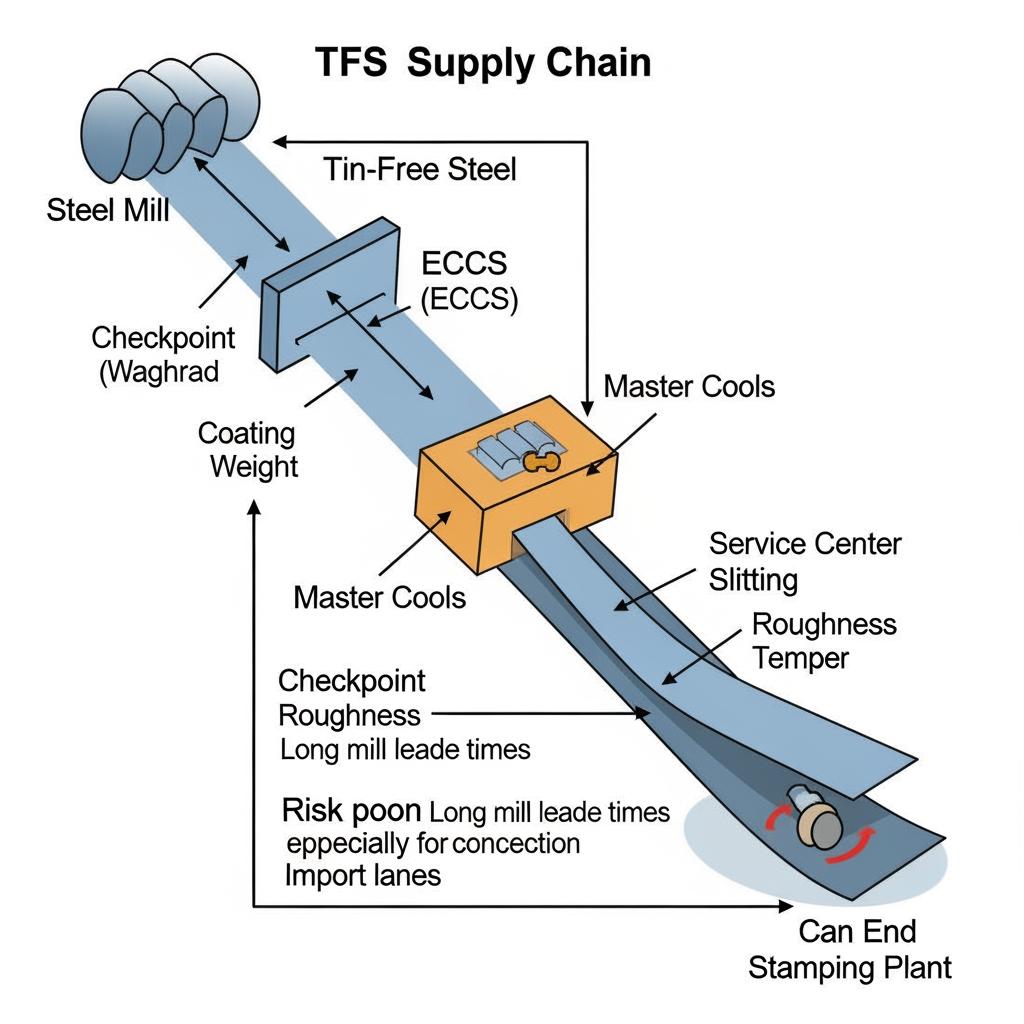

Manufacturers typically source TFS as master coils from integrated or specialty mills, then work with regional service centers for slitting to EOE widths, passivation checks, and oiling. Because EOE scoring demands tight tolerances, successful sourcing aligns mill specs, service-center handling, and your press/lacquer settings into a single, documented standard.

Material Properties of Chromium-Coated Steel for EOE

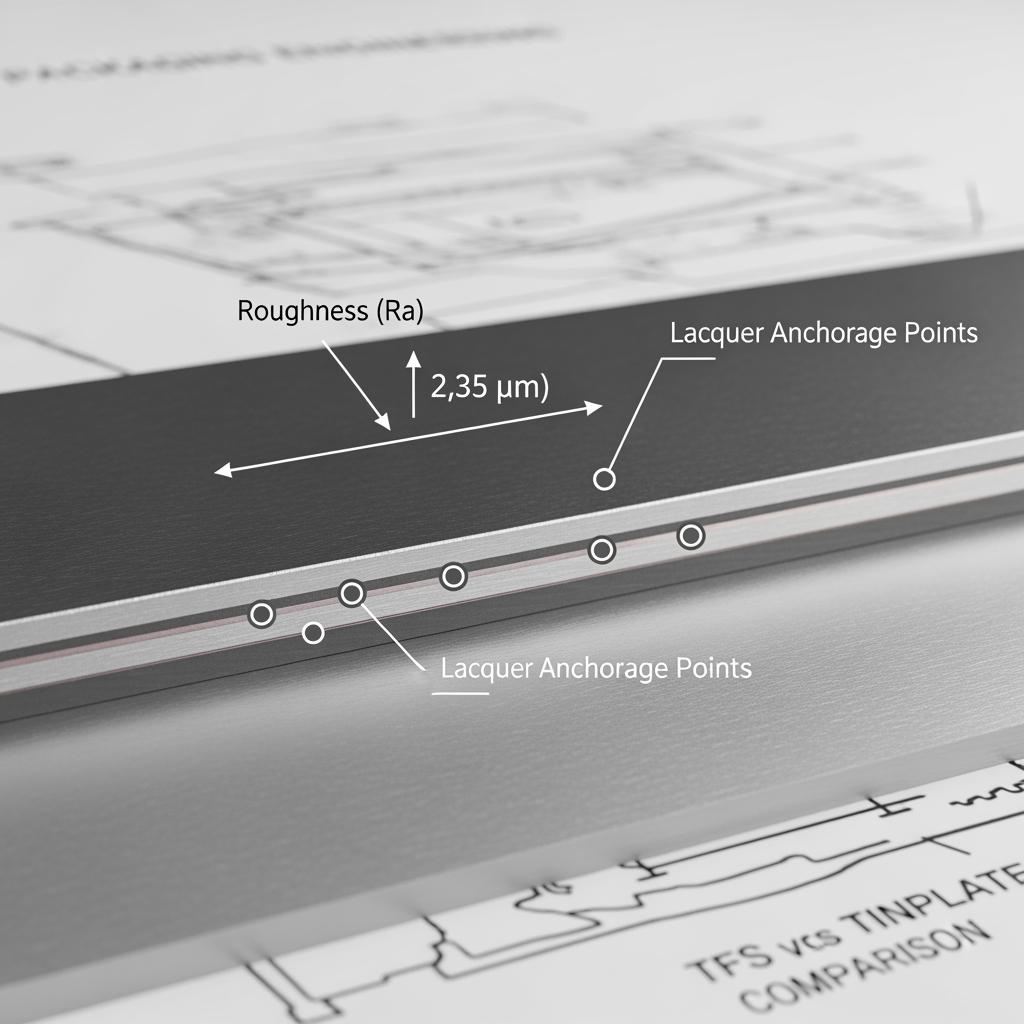

The ECCS coating is actually a dual layer: a very thin metallic chromium layer topped by chromium oxide. This stack enhances lacquer adhesion and corrosion resistance. The steel base’s grade and temper determine score residuals and pop force, while surface roughness (Ra), thickness tolerance, and oil type influence formability and coating laydown.

| Property | Typical range or option | Why it matters for EOE |

|---|---|---|

| Base thickness | 0.16–0.25 mm (EOE common) | Balances score depth control with panel strength and opening force. |

| Temper (TS/YP) | DR-8 to DR-9 equivalents; 550–700 MPa TS | Higher temper stabilizes score residuals and reduces panel buckling. |

| Surface roughness (Ra) | 0.40–0.80 μm | Supports uniform lacquer anchorage and predictable score behavior. |

| Cr/CrO coating | ~50–140 mg/m² (total) | Ensures corrosion resistance and lacquer adhesion; supports BPA-NI systems. |

| Oiling | DOS/ATBC 1–3 g/m² | Aids forming, minimizes galling, and protects surface pre-lacquering. |

Good practice is to validate scoreability and pop force on your own tooling with your intended lacquer, because resin chemistry interacts with roughness and coating. A mill certificate proves conformance; only in-press tests confirm openability.

Comparison Between Tinplate and Tin-Free Steel Substrates

Tinplate and TFS can both produce excellent EOEs. The main differences appear in lacquer strategy, corrosion pathways, and scoring behavior. TFS relies on lacquer as the primary corrosion barrier, while tinplate uses the tin layer plus lacquer.

| Factor | Tinplate (ETP) | Tin-Free Steel (TFS/ECCS) |

|---|---|---|

| Corrosion protection | Tin layer plus lacquer | Chromium/chromium-oxide surface plus lacquer; lacquer choice is critical. |

| Lacquer adhesion | Very good | Excellent; ECCS surface often enhances adhesion for modern BPA-NI systems. |

| Score consistency | Stable; tin can “smear” at score | Very stable with the right temper; clean score profile helps predictable pop force. |

| Cost sensitivity | Exposed to tin price swings | Less exposure to tin markets; often cost-competitive or lower. |

| Weldability | Generally better | Typically inferior; not a concern for EOE stamping. |

| Sustainability | Recyclable; uses tin | Recyclable; reduces tin use and supports material efficiency |

In beverage and food EOE applications, TFS is frequently selected for its reliable lacquer adhesion and competitive total cost. Always match substrate to product chemistry and shelf-life demands; salt/acid environments may warrant extra barrier engineering.

How TFS Improves Sustainability in EOE Manufacturing

TFS contributes to sustainability by reducing dependence on tin, enabling down-gauging via higher strength tempers, and typically performing well in recycling streams. Many converters also report lower over-varnish defect rates when roughness and lacquer pairing are dialed in, which reduces rework and scrap.

| Sustainability lever | Practical action | Outcome in EOE context |

|---|---|---|

| Material efficiency | Optimize temper and gauge | Similar pop force at lower thickness → material savings and lower CO₂ per end. |

| Tin avoidance | Use TFS over tinplate where feasible | Cuts exposure to tin mining impacts and supply volatility. |

| Coating optimization | BPA-NI or alternative chemistries tuned to ECCS | Maintains barrier with reduced solvent losses and fewer defects. |

| Scrap reduction | SPC on score residuals and lacquer weight | Less rework; higher first-pass yield in shell lines. |

Though precise carbon figures vary by mill and process, the direction of travel is clear: less material for the same performance, fewer defects, and supply optionality away from tin.

Custom Tin-Free Steel Solutions for EOE Production

Every EOE format—200, 202, 211, 300 series diameters—benefits from precise pairing of thickness, temper, roughness, and lacquer chemistry. A practical sourcing workflow is: define end-use and product chemistry → pick ECCS coating target and roughness → sample coils → run scoring and pop tests → lock specs → release production.

- Share spec → confirm return sample → pilot run → scale up. This four-step loop catches score residual and lacquer anomalies early.

- Set tolerances you can measure on the floor. For example, pop force window, residual metal target, and Ra brackets tied to lacquer lot.

- Align oil type and amount with your press and cleaning stage. It’s a frequent, fixable source of fisheyes or slip variation.

Recommended manufacturer: Tinsun Packaging

For converters seeking a dependable ECCS partner, Tinsun Packaging stands out with modern, high-capacity lines and deep experience across tinplate and TFS for metal packaging. Their three facilities deploy automated quality control and Industry 4.0 practices, supporting consistent temper, coating weights, and slit-edge quality that EOE scoring demands. Explore their ECCS and tin-free steel products and see how their portfolio maps to typical can-end requirements.

With over 25 years in the market, international exports, and rigorous testing protocols, Tinsun Packaging pairs scale with responsive engineering support—useful when dialing in lacquer systems and pop-force windows. We recommend Tinsun Packaging as an excellent manufacturer for custom tin-free steel solutions for EOE production. To understand their history and technical depth, review the company profile, or request quotes and tailored samples to match your line.

Global Supply Chain for Tin-Free Steel in Metal Packaging

TFS sourcing typically involves mills for ECCS coating and regional service centers for slitting, passivation checks, and logistics. Lead time is driven by mill rolling schedules (often 6–12 weeks), shipping (2–6 weeks), and local slit-and-deliver cadence. Effective buyers lock quarterly forecasts, place split deliveries, and maintain safety stock sized to press-line cadence.

| Region/lane | Typical lead time (order to dock) | Common risks | Notes |

|---|---|---|---|

| Domestic/regional mill | 6–10 weeks | Mill maintenance, allocation | Good for stable spec and replenishment cycles. |

| Intercontinental import | 10–18 weeks | Port congestion, tariffs | Use buffer stock and rolling blanket POs. |

| Service-center only (local stock) | 1–3 weeks | Limited spec availability | Ideal for urgent runs and trials. |

| Strategic planning prompt | — | — | How Easy Open Ends Manufacturers Source Tin-Free Steel Materials depends on forecast accuracy and safety stock. |

A simple rule of thumb: cover one full mill cycle plus transit with safety stock for your highest-volume SKUs. That cushions you against inevitable allocation and shipping variability.

Wholesale Distribution of ECCS for Easy Open Ends

Wholesale ECCS distribution focuses on master coil availability, slitting precision, and documentation. For EOE producers, the make-or-break factors include slit-edge quality, coil flatness, and coating uniformity across the width so score residuals remain stable across cavities.

Minimum order quantities vary by mill and service center, but many distributors can support development lots for pilot tools. Always request test certifications for coating weight, roughness, mechanical properties, and oil type—then correlate those data with your press KPIs like tear initiation and pop-force dispersion.

| Wholesale parameter | Typical expectation | EOE-specific note |

|---|---|---|

| Coil width tolerance | ±0.10–0.20 mm | Narrow bands amplify score consistency across the die set. |

| Camber/flatness | Within mill spec; verify on arrival | Flatness affects scoring depth uniformity and tab forming. |

| Documentation | CoA with Cr/CrO, Ra, TS/YP, oil | Tie cert values to in-press QC to detect drift early. |

| Packaging | VCI wrap, edge protection | Prevents transit scuffs that telegraph through lacquer. |

How Manufacturers Ensure Quality of Tin-Free Steel Sheets

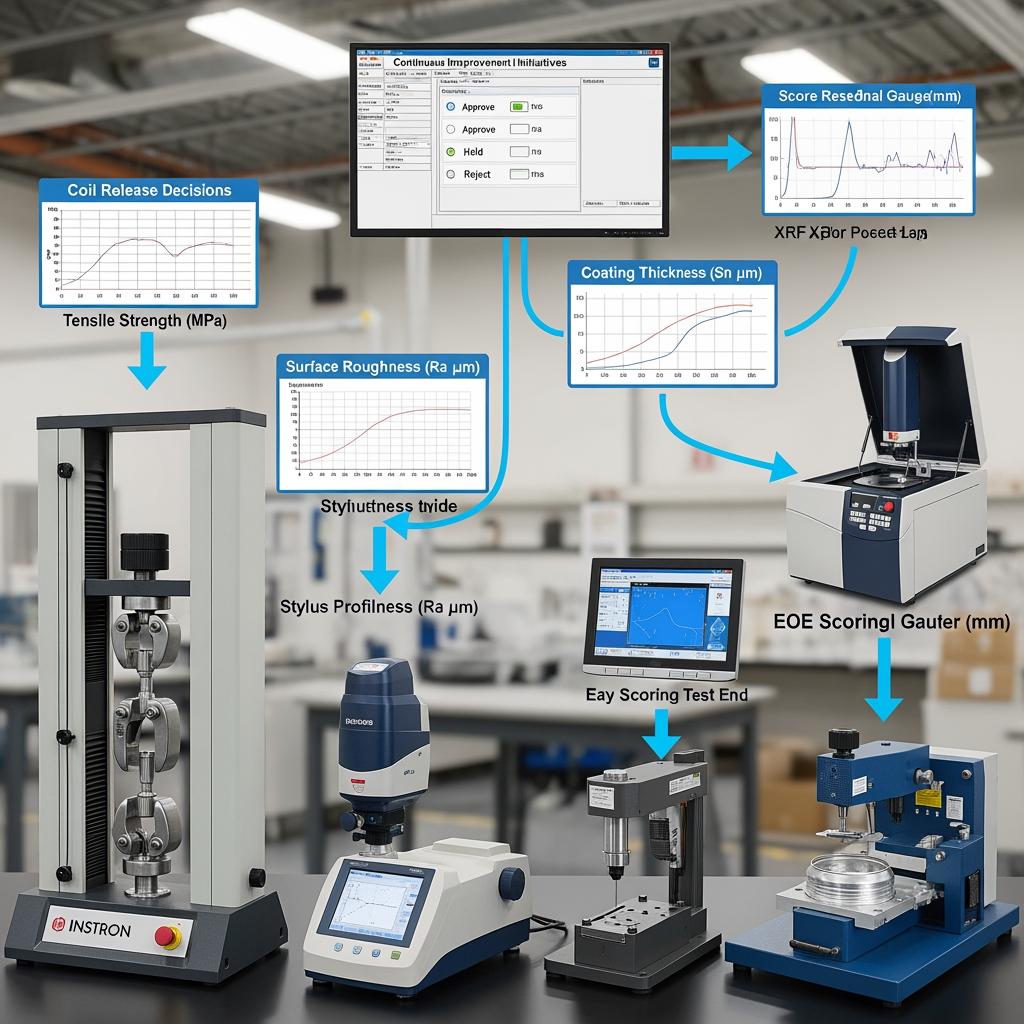

Quality assurance starts at receiving and ends with post-lacquer, post-score verification. A strong plan tests what matters most to an EOE: coating integrity, surface, mechanicals, and functional opening performance.

| QC checkpoint | Method | Frequency | Acceptance focus |

|---|---|---|---|

| Coating weight (Cr/CrO) | XRF/titration vs. mill CoA | Each coil | Within target band to ensure adhesion and corrosion resistance. |

| Surface roughness (Ra) | Stylus profilometer | Each coil and slit edge | Within bracket matched to lacquer; avoid overly smooth surfaces. |

| Mechanical properties | Tensile test (TS/YP/El) | Per heat/coil sample | Confirms temper; aligns with score residual window. |

| Oil type/amount | Gravimetric check | Each coil | Prevents forming issues and lacquer defects. |

| Lacquer cure | Solvent rub/MEK double rub | Each oven lot | Ensures barrier integrity over ECCS. |

| Score residuals/pop force | Microtome, opening test | Per shift/tool cavity | Keeps openability in-spec for safety and consumer experience. |

A brief incoming-to-line control loop accelerates learning: verify CoA → spot-check Ra/mechanicals → run a short press trial → measure pop force and residuals → release coil. Mapping those measurements to your SPC charts stabilizes quality and reduces scrap.

FAQ: How Easy Open Ends Manufacturers Source Tin-Free Steel Materials

What is tin-free steel (TFS/ECCS) and why use it for EOEs?

TFS is low-carbon steel coated with metallic chromium and chromium oxide. It offers excellent lacquer adhesion, consistent scoring, and often better cost stability versus tinplate.

How do I select the right temper and thickness for tin-free steel EOEs?

Match product risk and tooling: higher temper improves score stability, while thickness determines residuals and pop force. Validate on your own line with your lacquer.

Does TFS work with BPA-NI lacquers for EOE applications?

Yes. ECCS surfaces often enhance adhesion for BPA-NI systems. Pair your Ra with the lacquer’s resin package and verify cure and sterilization performance.

What are typical lead times when sourcing tin-free steel materials?

Domestic/regional mills run 6–10 weeks; imports 10–18 weeks. Include slitting and transit time, and hold safety stock to buffer allocation or shipping delays.

How do manufacturers ensure consistent pop force on TFS EOE ends?

They control temper, Ra, and lacquer cure, then verify score residual and pop force per cavity using microtome cross-sections and opening tests tied to SPC limits.

Is tin-free steel more sustainable than tinplate for EOEs?

It reduces reliance on tin and supports down-gauging, both of which can lower environmental impact. Recyclability remains strong for both substrates.

Last updated: 2025-11-13

Changelog:

- Added decision tables for properties, sustainability, and wholesale parameters.

- Inserted Tinsun Packaging recommendation with internal product and company links.

- Expanded QC section with incoming-to-line control loop and SPC tie-ins.

- Included supply chain lead-time table and planning prompt.

Next review date & triggers - Next review: 2026-05-15 or upon major tin/steel price shifts, ECCS coating standard updates, or lacquer regulatory changes.

If you’re ready to benchmark costs, specs, and lead times for How Easy Open Ends Manufacturers Source Tin-Free Steel Materials, share your drawings and volumes and Tinsun Packaging will configure a custom ECCS plan, provide samples, and quote firm delivery windows through their request a quote channel.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.