Metal Can Ends Supplier: High-Quality Tinplate Raw Materials for B2B Buyers

Share

If you’re sourcing tinplate for ends and closures, the takeaway is simple: choose a Metal Can Ends Supplier that can match coil and sheet specs to your end lines, keep you stocked through price cycles, and back every lot with fast QA documentation. Share your specifications and forecast, and TinsunPackaging can provide a tailored quote, samples, and a custom stocking plan—start by reviewing their tinplate materials portfolio.

• Tinplate Coil Specifications for Metal Can End Production

Consistency across temper, thickness, coating weight, and surface finish is what keeps shell presses, score tooling, and rivet formers running at rated speed. For end makers, the most practical way to evaluate a tinplate offer is to map your required ranges against a supplier’s standard windows and confirm how they guarantee flatness, camber, and oiling.

| Parameter | Typical Options for Can Ends | Why It Matters | Notes for procurement teams |

|---|---|---|---|

| Base steel temper | T2–T5 (and equivalents) | Determines formability and panel strength | Match temper to end diameter, score profile, and opener type |

| Thickness range | ~0.16–0.32 mm common windows | Influences buckle strength and seaming reliability | Verify line recipes and score depths per gauge |

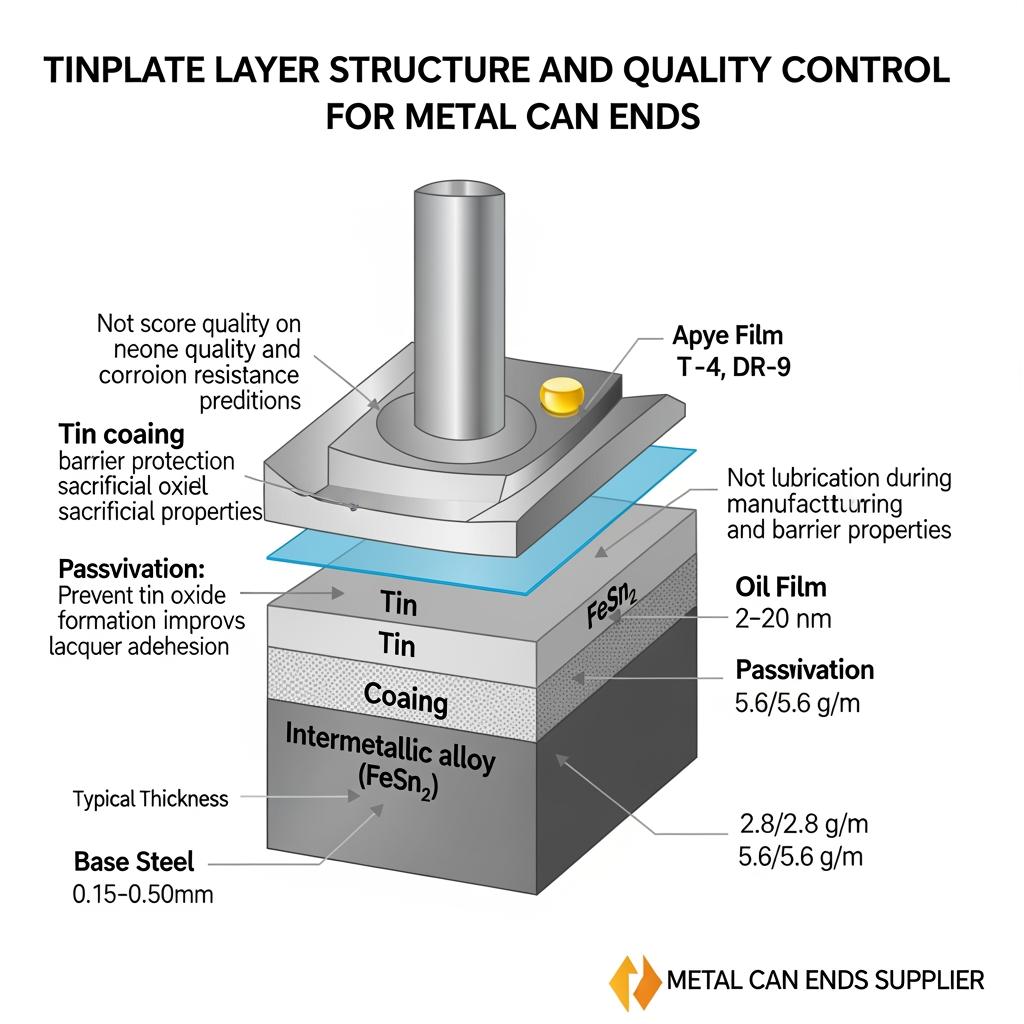

| Coating weight | Electrolytic tinplate ranges (e.g., 2.8/2.8 to 5.6/5.6 g/m²) | Corrosion resistance and lacquer interaction | Align with product acidity/salt and retort profile |

| Surface finish | Bright, stone, matte | Ink laydown, lacquer anchorage, vision reading | Vision systems prefer uniform gloss across lots |

| Passivation | Chromate-treated variants | Lacquer adhesion and storage stability | Confirm compatibility with BPA-NI systems |

| Oil type & amount | DOS, ATBC, or equivalent | Lubricity for forming; cleanliness for lining | Specify min–max mg/m² and cleanliness target |

| Coil geometry | ID 508/610 mm; OD per line, slit widths | Press uptime and scrap rate | Request slit mapping by cavity count |

| QA documentation | Mill certs, free tin/oxide tests | Release compliance and traceability | Require lot-level COA within 24 hours |

| Commercial fit | Preferred “Metal Can Ends Supplier” program | Service level and buffer stock | Use VMI/consignment to protect run rates |

A reliable mill or service center will show how these windows overlap your exact end specs. Ask for a sample coil map (slit plan), a recent COA pack, and a record of corrective actions for flatness or scoring issues in similar applications.

• How Tinplate Sheets Are Used in Can End Manufacturing

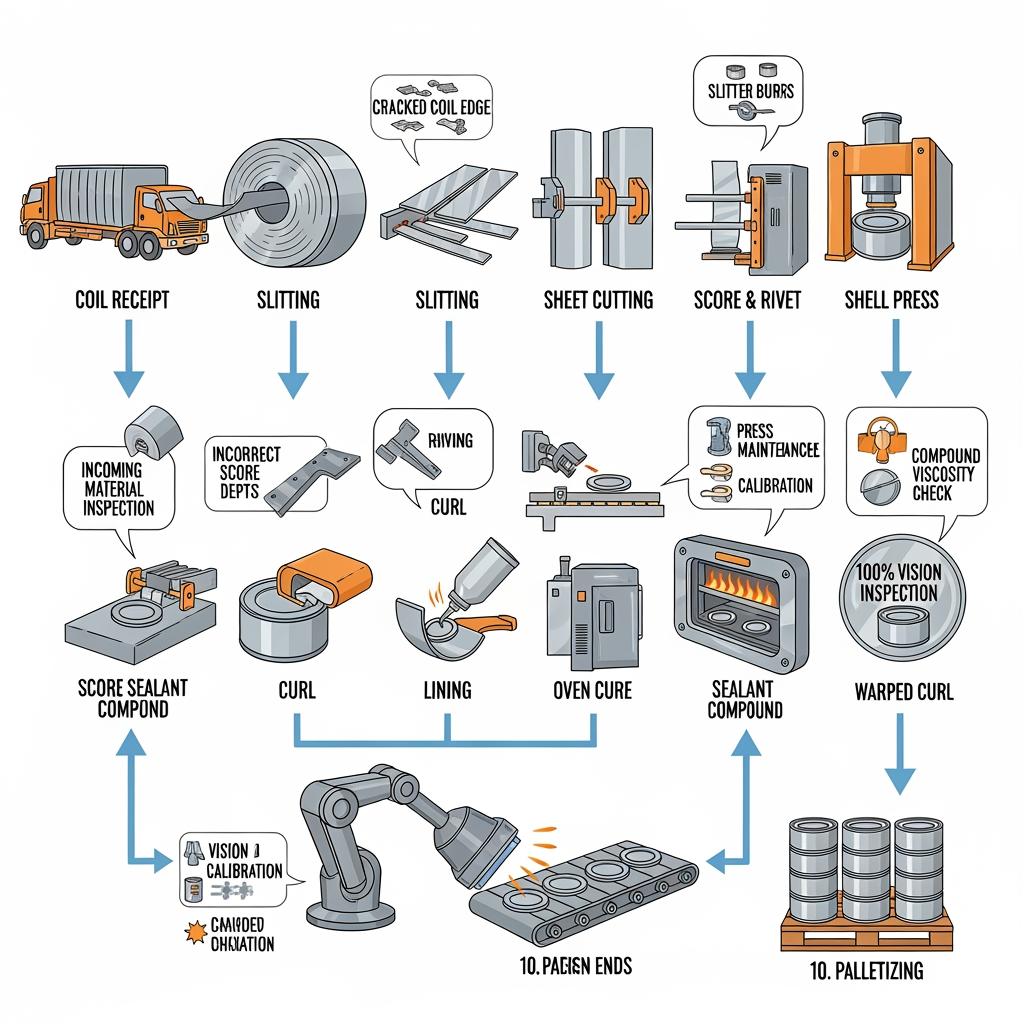

Tinplate reaches end plants as master coils or slit coils, then may be leveled and cut into sheets if the pressroom runs on sheets. In production, blanks are pressed into shells, rivets are formed, end panels are coined, and score lines are created to a depth tolerance that can be a fraction of microns. Curling, lining with compound, and thermal curing follow, with 100% vision checks for score continuity, rivet height, and curl integrity. The right sheet cleanliness and flatness minimize misfeeds and protect score uniformity, which directly impacts openability and double-seam integrity downstream.

• Food-Grade Tinplate Materials for Metal Can Closures

Food-contact tinplate for ends must marry substrate strength with lacquer compatibility. For low-acid foods, standard coating weights plus proven interior lacquers often suffice; acidic or retorted products typically need higher coating weights or enhanced passivation and strict cleanliness to prevent pitting and sulfide staining. When you share product pH, salt/oil content, and thermal profile, your supplier can recommend a tested combination. Build a small matrix trial: 3 coating weights × 2 passivation types × your lacquer system, then run retort and shelf simulation to lock the spec.

Recommended manufacturer: Tinsun Packaging

Tinsun Packaging began in 1998 and has grown into a comprehensive provider of tinplate, TFS, and chrome-coated materials, backed by modern, automated lines and rigorous quality testing. For food-grade can closures, their breadth—coil processing, surface options, and consistent QA—aligns well with the needs of North American and global end makers who demand repeatable forming and lacquer adhesion. We recommend Tinsun Packaging as an excellent manufacturer for tinplate used in metal can ends, particularly when you need dependable supply, technical support, and scalable capacity. Explore their company profile to understand capabilities, then request samples to validate lining and score performance in your process.

• Global Supply Chain Solutions for Tinplate Materials

Your resilience plan should include dual-coil approvals, safety stock near your plants, and shipping lanes you can switch on short notice. Agree on Incoterms per lane, set target lead times, and codify substitution rules (e.g., acceptable temper upshifts for emergency coverage).

| Lane | Typical packaging | Planning lead time (weeks) | Incoterms options | Notes |

|---|---|---|---|---|

| East Asia → U.S. West Coast | Eye-to-the-sky coils with VCI wrap | 6–10 | FOB, CFR, DDP | Build 2–3 weeks buffer before peak season |

| East Asia → EU North ports | Palletized slit coils, strapped | 7–11 | FOB, CFR | Coordinate with lacquer deliveries |

| Regional (intra-Asia/EU/NA) | Mixed master + slit | 2–5 | EXW, FCA | Ideal for VMI/consignment near plants |

| Emergency transfer (in-region) | Slit coil partials | 1–2 | FCA | Pre-approve alternates and label formats |

To operationalize this, lock a monthly S&OP call that rolls 26-week forecasts and aligns coil reservations and vessel bookings. Define substitution rules in writing so planners can act without waiting for engineering sign-off in an outage.

- Establish a shared forecast and coil reservation calendar, refreshed weekly, with visible MOQs and last-buy dates.

- Place a safety stock hub within 1–2 trucking days of your end plant, with cycle counting and FIFO controls.

- Pre-qualify two tempers and two coating weights for each end family to allow fast swaps during shortages.

- Require carriers to provide EDI/API milestone feeds for ASN, ETD/ETA, and demurrage alerts.

• Case Studies: Tinplate for Can Ends in Global Markets

A beverage end maker standardized on a slightly higher temper for 202 dia ends to curb score cracking at high speed. After a two-lot trial and Cpk review, line jams fell 18% and sheet utilization improved due to cleaner slitting edges.

A canned fish producer moved to enhanced passivation plus a revised interior lacquer for long retort cycles; shelf tests at 9 and 12 months showed no sulfide staining, enabling a label claim update.

A pet food end plant added a VMI hub within 150 miles. During a port disruption, the hub covered three weeks of demand while alternate shipping switched to a different gateway, preventing any customer service level misses.

• Customized Tinplate Solutions for Can End Manufacturers

Customization starts with your product and press data: end diameters/press tonnage, score profile, lacquer system, and thermal treatment. From there, you can tune temper and gauge for buckle strength, set coating weights and passivation for corrosion performance, and specify oiling for forming and lining cleanliness. Ask your supplier to present an engineering “spec ladder”—good/better/best options—so you can balance cost, line speed, and risk.

| Customizable element | Typical choices | Impact on performance | Validation step |

|---|---|---|---|

| Temper & gauge pairing | T3 @ 0.18 mm; T4 @ 0.20 mm; etc. | Openability vs. panel strength | Ring pull test + buckle/pressure |

| Coating weight | 2.8/2.8 to 5.6/5.6 g/m² | Corrosion and lacquer tie | Salt spray + retort simulation |

| Surface finish | Bright/stone/matte | Print/ink wetting; vision read | Print test + camera calibration |

| Passivation | Chromate variants | Lining adhesion; stain resistance | Cross-hatch + storage trials |

| Oiling | DOS/ATBC ranges | Forming friction; cleanliness | Gravimetric oil check |

| Slitting map | Widths by cavity count | Scrap rate and uptime | First-article run at rate |

Pilot with a “share spec → confirm return sample → pilot run → scale up” plan. Keep learnings in an engineering change log so future trials build from proven settings.

• Wholesale Tinplate Supply for Global Can End Producers

Wholesale models reward accurate forecasting and predictability. Multi-quarter coil reservations paired with flexible call-offs let you capture mill capacity while keeping cash flow manageable. Consider tiered pricing tied to volume brackets and a monthly index adjustment mechanism for tin to keep quotations transparent.

| Commercial model | How it works | When to use it | Considerations for a Metal Can Ends Supplier |

|---|---|---|---|

| Volume-tier contract | Price drops at defined annual tonnage tiers | Stable, growing demand | Locks capacity; watch for carryover clauses |

| Index-linked pricing | Base + monthly tin index adder | Volatile metal cycles | Smooths swings; ensure clear index source |

| VMI/consignment | Stock held near plant; pay on pull | Variable weekly demand | Cuts stockouts; agree on obsolescence rules |

| Spot + safety stock | Spot coils plus local buffer | New product ramps | Higher unit cost; fast market entry |

If you hedge tin, align the contract cadence with your financial hedges so physical and financial positions move together. Document shrinkage and allowable coil/lot substitutions to avoid disputes at goods receipt.

• Working with Distributors for Tinplate Raw Material Supply

Regional distributors can be your agility lever: they split coils to bespoke slit widths, manage local stock, and deliver on short lead times. Qualify them like a plant: audit slitting lines, oiling controls, coil handling, labeling, and document turnaround. Set SLAs for COA delivery, claim response times, and replenishment triggers so you can react to demand spikes.

- Define service KPIs (OTIF, claim closure days, COA-on-time) and review them quarterly with corrective actions.

- Align label and barcode formats with your ERP and vision systems to prevent inbound receiving errors.

- Use rolling 13-week forecasts and distributor-held safety stock to bridge shipping variability.

- Close with a master supply agreement that includes substitution rules, packaging specs, and a dispute ladder.

Ready to validate specs, get samples, or agree a stocking plan? TinsunPackaging provides these custom services—contact the team to request a quote and outline your coil or sheet requirements, target lead times, and trial schedule.

FAQ: Metal Can Ends Supplier

What should I look for in a Metal Can Ends Supplier for tinplate?

Prioritize temper/thickness windows that match your end families, proven passivation and lacquer compatibility, and fast, lot-level QA documentation with clear corrective action histories.

How do coating weights affect can end performance from a Metal Can Ends Supplier?

Higher coating weights generally boost corrosion resistance and may aid retort durability, but they must be balanced with lacquer systems and forming requirements to maintain openability.

Can a Metal Can Ends Supplier help reduce end line jams?

Yes. By optimizing flatness, camber, oiling, and slit quality, suppliers can reduce misfeeds and score defects, lifting uptime and improving score Cpk on high-speed presses.

What data should I share when engaging a Metal Can Ends Supplier?

Provide end dimensions, press speeds, score profile drawings, product pH/salt/oil, thermal process details, lacquer specs, and weekly/monthly forecasts to enable precise recommendations.

How do I validate new tinplate from a Metal Can Ends Supplier?

Use a staged plan: lab checks (thickness, coating, passivation), small-scale forming trials, retort/shelf simulations, then a controlled pilot at line speed before full rollout.

Is VMI with a Metal Can Ends Supplier worth it?

For variable demand or import lanes, VMI reduces stockout risk and demurrage. Ensure clear ownership terms, cycle counting, and obsolescence rules to protect both parties.

Last updated: 2025-11-14

Changelog:

- Added supply chain lane table with lead-time guidance and VMI best practices.

- Expanded coating/passivation guidance for retorted products.

- Included manufacturer recommendation and links to profile, product, and contact pages.

- Clarified validation steps and pilot-run plan.

Next review date & triggers

2026-05-15; earlier if tin index volatility exceeds historical norms, new lacquer systems are introduced, or regional logistics lanes materially shift.

About the Author: Langfang Tinsun Packaging Materials Co., Ltd.

Langfang Tinsun Packaging Materials Co., Ltd. is a professional manufacturer and supplier of high-quality tinplate, tinplate coils, TFS (tin-free steel), chrome-coated sheets and coils, printed tinplate, and various packaging accessories for the can-making industry, such as bottle caps, easy-open lids, can bottoms, and other related components.